Beruflich Dokumente

Kultur Dokumente

EvolutionofACI562Code Part9 PDF

Hochgeladen von

Oscar FernándezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EvolutionofACI562Code Part9 PDF

Hochgeladen von

Oscar FernándezCopyright:

Verfügbare Formate

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/316686313

Evolution of ACI 562 Code—Part 9 Interface

bond provisions in ACI 562-16

Article in Concrete International · November 2016

CITATIONS READS

0 50

2 authors, including:

Khaled Nahlawi

American Concrete Institute

4 PUBLICATIONS 30 CITATIONS

SEE PROFILE

All content following this page was uploaded by Khaled Nahlawi on 05 May 2017.

The user has requested enhancement of the downloaded file.

Evolution of ACI 562

Code—Part 9

Interface bond provisions in ACI 562-16

by Khaled Nahlawi and Jay H. Paul

A

lthough ACI can trace its concrete design standard The second version of the code was published in June

back to 1910,1 more than a century elapsed before 2016.3 The most significant changes to ACI 562 include:

the organization issued its first concrete repair code, •• Revisions to Chapters 1 and 4 to include specific criteria

ACI 562-13.2 The repair code, unlike other ACI standards, is requirements for assessment and design of repair and

primarily a performance-based document. It was developed rehabilitation for varying levels of damage, deterioration,

to provide licensed design professionals (LDPs) with the or faulty construction;

minimum requirements for assessing and repairing or •• Revisions to allow the repair code to be used with the

rehabilitating existing structural concrete buildings, members, International Existing Building Code or as a stand-alone

systems, and, where applicable, nonbuilding structures. Prior code (Appendix A); and

to the development of the code, an LDP might set repair and •• Revisions to the interface bond provisions in Chapter 7.

rehabilitation requirements arbitrarily or based on the culture To assist engineers in applying the new code, ACI and the

or past experiences of the LDP’s firm. The new standard International Concrete Repair Institute (ICRI) have collaborated

should result in improved consistency and overall performance and produced a guide for its use (refer to Reference 4). This

in the industry and thus further protect lives and property. article discusses the updated interface bond provisions, provides

excerpts from the new guide, and includes an example to

Existing Concrete Structures—Learning illustrate the application and significance of these new provisions.

Lessons and Advancing Solutions

ACI Committee 562, Evaluation, Repair, and Guide to the ACI 562 Code

Rehabilitation of Concrete Buildings, strives to advance The primary purpose of the new guide is to help LDPs gain

the practice of engineering and improve the repair and more knowledge and skill in interpreting and properly using

rehabilitation of existing concrete structures. ACI ACI 562-16. Although specifically developed for LDPs, the

Subcommittee 562-E, Education, is dedicated to helping guide was also designed to provide insights into the use and

engineers, building officials, contractors, owners, benefits of ACI 562 for contractors, material manufacturers,

inspectors, and others by conveying information in more building owners, and building officials. To achieve these

detail than is possible solely through the ACI 562 Code goals, the guide is separated into two main components:

and Commentary. To this end, and in the hope of chapter guides and project examples. The chapter guides

improving these documents, members of ACI 562 are explain the proper use of ACI 562, and the project examples

providing a series of articles under the main theme, illustrate the process of carrying out a concrete building

“Existing Concrete Structures—Learning Lessons and evaluation, repair, rehabilitation, or strengthening project

Advancing Solutions.” from inception through completion.

Through this series, the committee members explain the The chapter guides follow the general organization of

rationale behind some of the changes in the ACI 562-16 ACI 562; section numbers in Chapters 1 to 11 and Appendix A of

Code as well as share example problems, ideas, concepts, the guide correspond to the provision numbers in ACI 562. The

and the thoughts discussed in ACI Committee 562 chapter guides include background and explanation of the various

meetings. It is also anticipated the series will help the Code provisions with particular insight into how the chapters

committee address questions from the engineering and and sections of ACI 562 are applied to a repair project. Where

construction sectors, solicit answers to problems, and applicable, flowcharts are provided to help users navigate the

review areas of needed research. various provisions of the Code. References to project examples

are provided where needed to illustrate how specific

52 NOVEMBER 2016 | Ci | www.concreteinternational.com

“Guide to the Code for Assessment, According to ACI 562-16, Section 7.4.2, for bonded

Repair, and Rehabilitation of interfaces with vu values of less than 30 psi (0.2 MPa), only

Existing Structures” is available at qualitative bond-integrity testing is required. For bonded

the ACI Store at www.concrete.org interfaces with vu of more than 60 psi (0.4 MPa) (per Section

7.4.4), or a repaired section that is subjected to a sustained

provisions within each chapter of tension force, reinforcement must be provided between the

ACI 562 are incorporated into the substrate and overlay.

design process. In some instances, The guide to ACI 562-16 includes an expanded discussion

additional limited-scope examples of this topic along with two examples to illustrate the application

are included to better illustrate and significance of these new provisions.

a point that is not covered by The following is such an example, taken from Chapter 7

the project examples. of the guide, addressing the approach and requirements to

To give readers a preview of the guide, some aspects determine bond strength of an overlay to an elevated slab in a

relative to Chapter 7 of ACI 562 are discussed herein. parking structure.

Section 7.4—Interface bond Example 7.2—Determining Bond Strength of

Section 7.4 was revised to emphasize the importance of Overlay to an Elevated Slab

proper bonding between the substrate and overlay.5 Bond Background

strength is influenced by the strength of the substrate concrete, A nine-story parking structure located in the Midwest of

strength of the repair material, quality of the substrate concrete the United States was constructed of 8 in. (200 mm) thick

surface preparation, construction procedures, characteristics of lightweight concrete flat slabs in 1971. The owner contracted

repair materials, and time-dependent factors such as shrinkage with an engineering firm to evaluate the structure and design

of concrete and variations in repair material properties with repairs. From the outset, the owner made it clear that

time. Section 7.4.3C of the Code commentary stresses the inspection and repair activities should have minimal impact

importance of substrate preparation and various methods used on operation of the structure (the revenue stream could not

to test for bond integrity. Various methods to prepare concrete be interrupted).

surfaces are discussed in ICRI 310.2R-20136 and ACI 546R- The design concrete compressive strength was 3750 psi

147 to achieve the desired performance of concrete repairs. (25 MPa) and the reinforcing steel was specified to be in

The Code commentary also references ICRI 210.3R-2013,8 accordance with ASTM A615 Grade 60 (yield strength of

which discusses bond strength in repairs and suggests 60,000 psi [400 MPa]).10 The top surfaces of the decks were

minimum values depending on application criticality. sounded and visually inspected and were found to be badly

The LDP should determine the factored interface shear deteriorated. The LDP estimated that the extent of deterioration

and tension stresses across the bonded interfaces between the on the top side ranged between 30 to 70%. Delamination and

repair materials and existing substrates. Then, the LDP should cracking was also evident on the bottom surfaces of the decks,

verify that the calculated horizontal shear strength is at least but the deterioration was much less extensive than that on

equal to the required bond strength or tensile strength of the the top surfaces.

concrete substrate, such that Cores extracted from several areas of the deck were tested

for strength and chloride content. Tests revealed that the concrete

vu ≤ φvni (ACI 562-16, Eq. (7.4.1.1)) compressive strength matched the design concrete compressive

strength and that chloride was present, with excessive concen

Here, vu is the calculated bond demand shear stress based on tration levels near the top. Insufficient cover over the reinforce

mechanics, f is the reduction factor obtained from ACI 562-16, ment was detected at various locations throughout the garage.

Section 5.3.2, and vni is the measured bond stress determined using

a valid test method such as ASTM C1583/C1583M.9 The overlay Procedure

should be tested for proper bonding as required by ACI 562-16, The LDP determined that the repair would consist of the

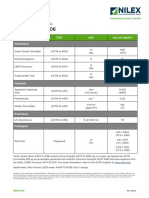

Sections 7.4.2 through 7.4.4, and as presented in Table 1. removal of 3-1/2 in. (90 mm) of the top of the deck slabs and

Table 1:

Testing requirements based on interface bond stress demand vu (Table 7.4.5 from Reference 4)

vu Section No. (ACI 562-16) Testing requirements

Less than 30 psi (0.2 MPa) 7.4.2 Bond-integrity testing

Between 30 and 60 psi (0.2 and 0.4 MPa) 7.4.3 Quantitative bond strength testing

Greater than 60 psi (0.4 MPa) 7.4.4 Quantitative bond strength testing

Completely resisted by interface reinforcement 7.4.5 Quantitative bond strength testing not required

www.concreteinternational.com | Ci | NOVEMBER 2016 53

replacement with a bonded lightweight concrete overlay. There A total of six tests were performed (Table 2). The test results

are several methods for concrete removal, including shotblasting, exceeded 100 psi (0.69 MPa), a minimum value stated in

hydrodemolition, cutting, impact milling, pre-splitting, and ACI 562-16, Section 7.4.2C, and ICRI 210.3, and the

abrading. Irrespective of the method used, it must be effective, difference between maximum and minimum test results was

safe, and economical, and it should produce minimum damage 47 psi or 30%.

to the concrete substrates left in place (free of microcracks). The Once the LDP was satisfied with the test results and the

contractor and the LDP evaluated the different methods and it process was confirmed, the contractor proceeded with the

was decided to use hydrodemolition because it: implementation of the repair work starting with removal of

•• Results in a rough, irregular surface profile that provides the upper surface of the slab (Fig. 2).

an excellent bond for all types of repair materials, creating The LDP requested extensive testing of the repair work

a monolithic repair; throughout the duration of the project. The testing for the

•• Minimizes or eliminates surface microcracking; overlay concrete was similar to the testing for new cast-in-

•• Exposes aggregates without fractures or damage and thus place concrete. Pulloff testing in accordance with ASTM

ensures they will interlock with the overlay; C1583/C1583M was performed to confirm the adequacy of

•• Selectively removes lower strength and deteriorated the bond of the overlay to the substrate concrete. The results

concrete (delamination); of the pulloff tests are presented in Table 3.

•• Minimizes vibration in the surrounding structure; and The test results varied between 32 psi and 190 psi (0.22 MPa

•• Preserves and cleans reinforcing bars for reuse and and 1.31 MPa). The difference of 158 psi (1.09 MPa) or 83%

minimizes the need for sandblasting. indicates large scatter and is unacceptable. The LDP ordered

Robotic equipment was used for this job to ensure uniform petrographic examination of some of the samples. The test

removal of concrete. But prior to the start of the production results revealed that the contractor did not remove all debris

work, a mockup was installed and extensively tested to ensure and loose material from the substrate surface area, thus creating

the success of the recommended procedure. a weak bond between the substrate and overlay (Fig. 3).

The testing of the mockup slab included: Corrective actions were implemented to improve the bond

•• Tensile bond tests of the overlay concrete to the substrate strength:

by pulloff (Fig. 1); and •• The contractor improved the methods used to clean the

•• Petrographic examinations of cores. surface of the substrate and to remove residue resulting

Fig. 1: Pulloff test on an overlay concrete (Fig. 7.2a from Reference 4)7 Fig. 2: Removal of 3-1/2 in. of slab by hydrodemolition (Fig. 7.2b from

Reference 4)

Table 2:

Test results of the pulloff test of the mockup area (after Table 7.2a in Reference 4)

Test parameters

Test number Test location Bond force, lb (kN) Bond strength, psi (MPa) Separation location

A1 900 (4.0) 126 (0.87) Substrate concrete

Level P8 floor slab

A2 790 (3.5) 110 (0.76) Surface of the substrate concrete

mockup area A

A3 790 (3.5) 110 (0.76) Surface of the substrate concrete

B1 1125 (5.0) 157 (1.08) Substrate concrete

B2 Level P8 floor slab 1000 (4.5) 142 (0.98) Surface of the substrate concrete

mockup area B

50% substrate concrete

B3 1000 (4.5) 142 (0.98)

50% surface of the substrate concrete

54 NOVEMBER 2016 | Ci | www.concreteinternational.com

from hydrodemolition; and least 100 psi (0.69 MPa), with the exception of one test result.

••Inspectors examined the substrate surface more closely to The LDP ordered another set of petrographic evaluations

determine suitability to receive the bonded overlay. of some of the samples. The examinations indicated that the

The pulloff testing after the corrective measures indicated overlay was well consolidated and there was good bond at the

more consistent results (Table 4). Tensile bond values were at contact surface with the substrate (Fig. 4).

Table 3:

Results of pulloff tests of the partially completed work (after Table 7.2b in Reference 4)

Test Date of Test parameters

number Test area and location placement Bond force, lb (kN) Bond strength, psi (MPa) Separation location

Level P9 on column line 2

BT-1 6-29-06 560 (2.5) 79 (0.54) Substrate concrete

between column lines G and H

Level P9 on column line 2

BT-2 6-29-06 670 (3.0) 96 (0.66) Substrate concrete

between column lines K and L

75% interface between

Level P9 west of column line 2

BT-3 7-08-06 225 (1.0) 32 (0.22) substrate concrete and overlay,

between column lines N and P

25% within substrate concrete

Level P9 between column lines

BT-4 7-14-06 1350 (6.0) 190 (1.31) Epoxy adhesive

8 and 9 and J and K

Level P9 between column lines

BT-5 7-14-06 1350 (6.0) 190 (1.31) Substrate concrete

8 and 9 and F and G

Fig. 3: Petrographic examination of the interface between the new Fig. 4: Petrographic examination of the interface between the

overlay and the existing concrete slab (Fig. 7.2c in Reference 4) concrete substrate and the overlay (Fig. 7.2d in Reference 4)

Table 4:

Results of pulloff tests after the remedial actions (Table 7.2c from Reference 4)

Test parameters

Test Date of concrete Bond force, Bond strength, Separation

number Test area and location placement lb (kN) psi (MPa) location

BT-16 Level P9, NWC Not provided 1240 (5.5) 174 (1.2) Interface zone

BT-17 Level P9, SWC Not provided 560 (2.5) 79 (0.54) Substrate concrete

BT-17A Level P9, SWC, 9 ft N of core BT-17 Not provided 790 (3.5) 100 (0.69) Interface zone

BT-17B Level P9D, West, 3 ft N of core BT-17 Not provided 790 (3.5) 100 (0.69) Interface zone

BT-18 Level P8D, West Not provided 1450 (6.5) 206 (1.42) Interface zone

BT-19 Level P8D, West, column 2 between N and P Not provided 1350 (6.0) 190 (1.31) Interface zone

Note: 1 ft = 0.3 m

www.concreteinternational.com | Ci | NOVEMBER 2016 55

Conclusions Repair Materials,” Concrete International, V. 38, No. 9, Sept. 2016,

To ensure any project is successful, the construction pp. 56-60.

phase of the work should be performed with high-quality 6. ICRI Surface Preparation Committee, “Selecting and Specifying

workmanship and materials that satisfy the intent of the Concrete Surface Preparation for Sealers, Coatings, and Polymer

construction documents. The described project (Example 7.2) Overlays (ICRI Technical Guideline No. 310.2R-2013),” International

was in large part successful because the owner, contractor, Concrete Repair Institute, Rosemont, IL, 2013, 54 pp.

and engineers worked together. While this repair was very 7. ACI Committee 546, “Guide to Concrete Repair (ACI 546R-14),”

challenging because it was necessary to keep the garage open American Concrete Institute, Farmington Hills, MI, 2014, 70 pp.

with a maximum number of spaces while the repairs were 8. ICRI Evaluation Committee, “Guide for Using In-Situ Tensile

made, the project was completed on time and within budget. Pull-Off Tests to Evaluate Bond of Concrete Surface Materials (ICRI

Technical Guideline No. 210.3R-2013),” International Concrete Repair

Maintenance program Institute, St. Paul, MN, 2013, 20 pp.

Repair work may fail prematurely if a well-established 9. ASTM C1583/C1583M-13, “Standard Test Method for Tensile

maintenance program is not implemented. Therefore, Strength of Concrete Surfaces and the Bond Strength or Tensile Strength

ACI 562-16, Chapter 1, General Requirements, and Chapter 8, of Concrete Repair and Overlay Materials by Direct Tension (Pull-Off

Durability, require that the LDP provides the owner with a Method),” ASTM International, West Conshohocken, PA, 2013, 5 pp.

maintenance program for the individual repairs. Properly 10. ASTM A615, “Specification for Deformed Billet-Steel Bars for

executed and monitored, a maintenance program will extend Concrete Reinforcement,” ASTM International, West Conshohocken,

the life span of repair work and minimize the total cost of PA, 1968.

ownership. The maintenance program for the example parking 11. Nam Shui, K., and Stanish, K., “Extending the Service Life of

structure could be divided into three categories11: Parking Structures,” Concrete International, V. 30, No. 4, Apr. 2008,

•• Routine maintenance—this includes repairing leaking joint pp. 43-49.

sealant, clearing plugged drain lines, repairing small areas

of spalled or delaminated concrete, replacing expansion joint Selected for reader interest by the editors.

seals, and washing down the parking decks twice a year.

Keeping the structure clear of deicing salts and other debris

can significantly improve the life span of the repair work; Khaled Nahlawi is a Senior Engineer

•• Preventive maintenance—this includes reapplication of at ACI. He has extensive experience in

surface sealers, traffic membranes, joint sealants, and design of new structures as well as design

expansion joints. Preventive maintenance usually does not and management of retrofit and repair

entail the major disruptions associated with structural projects. He was the project engineer on

repairs; and the first U.S. application of post-tensioning

•• Replacement—this includes replacement of structural and strengthening to an unreinforced

operational items at the end of their service lives. Lighting, masonry structure after the Loma Prieta

elevator equipment, plumbing fixtures, and parking access Earthquake. He serves as the Secretary

and control equipment must be maintained to ensure that on the ACI TAC Repair and Rehabilitation Committee. He received

customers are safe and keep coming back. his BS in civil engineering from Damascus University, Damascus,

Syria; his MS in construction engineering and management;

References and his PhD in structural engineering from the University of

1. “Standard Building Regulations for the Use of Reinforced Michigan, Ann Arbor, MI.

Concrete,” Standard No. 4, National Association of Cement Users (ACI),

Jay H. Paul, FACI, is Senior Principal at

V. 6, 1910, 13 pp.

Klein and Hoffman, Inc., Chicago, IL. He

2. ACI Committee 562, “Code Requirements for Evaluation, Repair,

has more than 40 years of experience

and Rehabilitation of Concrete Buildings (ACI 562-13) and Commentary,”

in the evaluation, design, and repair of

American Concrete Institute, Farmington Hills, MI, 2013, 59 pp.

environmental structures, parking facilities,

3. ACI Committee 562, “Code Requirements for Assessment, Repair,

building façades, roofs, and foundations.

and Rehabilitation of Existing Concrete Structures (ACI 562-16) and

He is the Secretary of ACI Committee 563,

Commentary,” American Concrete Institute, Farmington Hills, MI, 2016,

Specifications for Repair of Structural

86 pp. Concrete in Buildings. He serves on the

4. “Guide to the Code for Assessment, Repair, and Rehabilitation of ACI TAC Repair and Rehabilitation Committee and ACI Committees

Existing Concrete Structures—A Companion to ACI 562-16 Repair Code 364, Rehabilitation; 546, Repair of Concrete; and 562, Evaluation,

(MNL-2 [16]),” American Concrete Institute, Farmington Hills, MI, Repair, and Rehabilitation of Concrete Buildings. He received his

2016, 175 pp. BS and MS in architectural engineering from the University of

5. Brewe, J.E.; Tumialan, J.G.; and Kelly, P.L., “Evolution of Illinois at Urbana-Champaign, Urbana, IL.

ACI 562 Code—Part 7, Interface Bond between Existing Concrete and

56 NOVEMBER 2016 | Ci | www.concreteinternational.com

View publication stats

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- ASCE Guidelines For Evaluation and Repair of Residential FoundationsDokument20 SeitenASCE Guidelines For Evaluation and Repair of Residential Foundationsgeowoz100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Drillef Shaft Manual FHWA NHI 10 016Dokument973 SeitenDrillef Shaft Manual FHWA NHI 10 016nicthegreek100% (3)

- FHWA Micropile Design and Construction (2005 Version) PDFDokument456 SeitenFHWA Micropile Design and Construction (2005 Version) PDFKai Ho100% (2)

- Spreader Beam CalculationDokument2 SeitenSpreader Beam Calculationhombre.muerto595977% (13)

- Bolt Torque & Bolt Tap TestDokument20 SeitenBolt Torque & Bolt Tap Testbudymood100% (3)

- Aci-318-08 Español PDFDokument520 SeitenAci-318-08 Español PDFSaul Pacompia Vilca100% (17)

- 235 1863 Cs Basics Assessment Existing Structures CB PDFDokument113 Seiten235 1863 Cs Basics Assessment Existing Structures CB PDFscegts100% (2)

- Códigos y Estándares 364 PDFDokument97 SeitenCódigos y Estándares 364 PDFOscar FernándezNoch keine Bewertungen

- 235 1863 Cs Basics Assessment Existing Structures CB PDFDokument113 Seiten235 1863 Cs Basics Assessment Existing Structures CB PDFscegts100% (2)

- 235 1863 Cs Basics Assessment Existing Structures CB PDFDokument113 Seiten235 1863 Cs Basics Assessment Existing Structures CB PDFscegts100% (2)

- Aci 437R - 03Dokument28 SeitenAci 437R - 03Mai KawayapanikNoch keine Bewertungen

- 437r - 91 ACI 437R-91 Strength Evaluation Ofexisting Concrete Buildings PDFDokument24 Seiten437r - 91 ACI 437R-91 Strength Evaluation Ofexisting Concrete Buildings PDFSoe SoeNoch keine Bewertungen

- Corrosion Damged Concrete.1 PDFDokument45 SeitenCorrosion Damged Concrete.1 PDFOscar FernándezNoch keine Bewertungen

- Code Requirements For Evaluation, Repair, and Rehabilitation of Concrete Buildings (ACI 562M-13) and CommentaryDokument8 SeitenCode Requirements For Evaluation, Repair, and Rehabilitation of Concrete Buildings (ACI 562M-13) and CommentaryOscar FernándezNoch keine Bewertungen

- Code Requirements For Evaluation, Repair, and Rehabilitation of Concrete Buildings (ACI 562M-13) and CommentaryDokument8 SeitenCode Requirements For Evaluation, Repair, and Rehabilitation of Concrete Buildings (ACI 562M-13) and CommentaryOscar FernándezNoch keine Bewertungen

- Concrete Repair CodeDokument2 SeitenConcrete Repair Codeemonwre0% (1)

- Evaluación de Fiabilidad de Las Pruebas de Carga para Edificios de HormigónDokument162 SeitenEvaluación de Fiabilidad de Las Pruebas de Carga para Edificios de HormigónOscar FernándezNoch keine Bewertungen

- Icc Iebc 2012Dokument324 SeitenIcc Iebc 2012Oscar FernándezNoch keine Bewertungen

- Ibc 2006Dokument63 SeitenIbc 2006adnan100% (1)

- Gec8 PDFDokument293 SeitenGec8 PDFAddrien DanielNoch keine Bewertungen

- Verification and Implementation of Strut-And-Tie Model inDokument281 SeitenVerification and Implementation of Strut-And-Tie Model inrpatel5509Noch keine Bewertungen

- Rajat Report On Folding TableDokument21 SeitenRajat Report On Folding TableRajat Thakur0% (1)

- Steel Pipes C1 C2Dokument1 SeiteSteel Pipes C1 C2arya asusNoch keine Bewertungen

- UTP CementDokument56 SeitenUTP CementbrayanNoch keine Bewertungen

- Dowel Bar Size and Spacing For Rigid Pavements PDFDokument8 SeitenDowel Bar Size and Spacing For Rigid Pavements PDFTim Lin100% (1)

- Presentation For JBF-TP MGMT Meeting-Rev1 020216Dokument17 SeitenPresentation For JBF-TP MGMT Meeting-Rev1 020216SajeshKumarNoch keine Bewertungen

- Computational Contact Mechanics YastrebovDokument308 SeitenComputational Contact Mechanics YastrebovJoe SatchNoch keine Bewertungen

- "Mytol" Lubricants - Equiv Alent ChartDokument65 Seiten"Mytol" Lubricants - Equiv Alent Chartmsharaths80% (5)

- Technical SpecificationsDokument30 SeitenTechnical SpecificationsFerdinand Descalzo100% (1)

- Lapp Pro261425enDokument5 SeitenLapp Pro261425engogugangNoch keine Bewertungen

- Report On Green Concrete: Central Tool Room and Training CentreDokument14 SeitenReport On Green Concrete: Central Tool Room and Training CentreRithik singhNoch keine Bewertungen

- BTS Road 5.4 - 6.00 KMPDokument21 SeitenBTS Road 5.4 - 6.00 KMPrajibchattarajNoch keine Bewertungen

- Fujitsu Klima Uredjaj Zidni Inverter Awyz14lbc Aoyz14lbc Service ManualDokument18 SeitenFujitsu Klima Uredjaj Zidni Inverter Awyz14lbc Aoyz14lbc Service ManualDino wowowNoch keine Bewertungen

- Determination of Depth of Frost Penetration by The Method Specified in UDokument2 SeitenDetermination of Depth of Frost Penetration by The Method Specified in UMadhava Reddy NNoch keine Bewertungen

- 06 - 3D Embankment ConsolidationDokument28 Seiten06 - 3D Embankment ConsolidationRaynaldo JodistiroNoch keine Bewertungen

- Plastic Laser Welding Design Guidelines PDFDokument14 SeitenPlastic Laser Welding Design Guidelines PDFAbhishek MohiteNoch keine Bewertungen

- Steady Flows in Pressurised NetworksDokument63 SeitenSteady Flows in Pressurised NetworksAyele ErmiyasNoch keine Bewertungen

- Tarifa Repagas 2015 PDFDokument284 SeitenTarifa Repagas 2015 PDFAntonio Alvarez DominguezNoch keine Bewertungen

- Career Objective:: Ricky Solis SibalDokument4 SeitenCareer Objective:: Ricky Solis Sibalroselyn sibalNoch keine Bewertungen

- 05a - HORIZONTAL BRACEDokument10 Seiten05a - HORIZONTAL BRACEShyamontika Choudhury ChakrabartiNoch keine Bewertungen

- Mjejane Game Reserve BOQ PDFDokument8 SeitenMjejane Game Reserve BOQ PDFSijabuliso NdlovuNoch keine Bewertungen

- EL NR Blend PU Foam PRIMDokument9 SeitenEL NR Blend PU Foam PRIMGlasst Innovacion 2019Noch keine Bewertungen

- Peltier Cooling ModuleDokument43 SeitenPeltier Cooling ModuleVenkatesh MohanNoch keine Bewertungen

- Lecture 4. Pipes Materials and LoadsDokument13 SeitenLecture 4. Pipes Materials and LoadsjsmnjasminesNoch keine Bewertungen

- Specs Woven 2006 - Updated 102018Dokument1 SeiteSpecs Woven 2006 - Updated 102018tranoNoch keine Bewertungen

- Rubber Pad FormingDokument15 SeitenRubber Pad FormingAdula Rajasekhar67% (3)

- Chromium-Nickel-Molybdenum-Iron (UNS N08366 and UNS N08367) Plate, Sheet, and StripDokument6 SeitenChromium-Nickel-Molybdenum-Iron (UNS N08366 and UNS N08367) Plate, Sheet, and StripGreg YeeNoch keine Bewertungen

- Melting Stainless Steel Using An Induction FurnaceDokument5 SeitenMelting Stainless Steel Using An Induction FurnaceErman DurmazNoch keine Bewertungen

- Very Important XPS - Thermal Insulation BoardsDokument10 SeitenVery Important XPS - Thermal Insulation BoardsPravin MundeNoch keine Bewertungen