Beruflich Dokumente

Kultur Dokumente

Piping Query

Hochgeladen von

zakaria masud sonyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Piping Query

Hochgeladen von

zakaria masud sonyCopyright:

Verfügbare Formate

Piping Query 14.10.

18

1. Minimum height and arrangement for ground and other floors piping.

2. Vessel and heat exchanger position on the structure and their (slot/hole)

connection with beams.

3. Minimum safe distance between ISBL, product and raw material storage area.

4. Loading/un-loading piping for product storage and raw material storage area.

5. Types of valves, instrument, safety equipment used in raw material

storage/product storage area.

6. Different valves position & instrument air connection with valves in piping.

7. Suction and discharge piping of pump and pump position.

8. Drain line and vent line in chemical plant and usually used treatment process.

9. Vessel to vessel safe distance and provision for maintenance.

10. Which type elbow (SR/LR) used in process unit?

11. Which type flanges used for different criterion and tee connection?

12. Sock-olet, weld-olet used or avoid.

13. Flex hose use and piping support arrangements.

14. On-off valves/PSV position in piping (minimum distance).

15. Branch connection for different points.

16. If possible, information about field isometric drawing, time duration and cost.

17. Reserve space for actuator valve.

18. Control valve size, capacity and space occupied (FV/FT).

19. Weld point and required test done in commissioning.

Das könnte Ihnen auch gefallen

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsVon EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Guidelines For Basic Engineering (Incl. Design Calculations)Dokument55 SeitenGuidelines For Basic Engineering (Incl. Design Calculations)Djamel Ait MohamedNoch keine Bewertungen

- Basics On Piping LayoutDokument11 SeitenBasics On Piping Layoutpuru55980Noch keine Bewertungen

- Basics On Piping LayoutDokument11 SeitenBasics On Piping Layoutpuru55980100% (1)

- Considerations For Development of Plant Layout: A Brief PresentationDokument9 SeitenConsiderations For Development of Plant Layout: A Brief PresentationShyam Prasad K SNoch keine Bewertungen

- Saddle-Fusion-Mcelroy Guidelines For PE Pipe Butt Fusion WeldingDokument13 SeitenSaddle-Fusion-Mcelroy Guidelines For PE Pipe Butt Fusion WeldingAnand KPNoch keine Bewertungen

- INSPECTION SHEET FOR EX DDokument2 SeitenINSPECTION SHEET FOR EX DAlinaIordache100% (1)

- Checklist For SiteDokument4 SeitenChecklist For Sitemuk3128Noch keine Bewertungen

- BASIC ENGINEERING (Incl Design Calculations)Dokument55 SeitenBASIC ENGINEERING (Incl Design Calculations)Nilesh Gohel100% (1)

- Work Method Statement For Afam III Flow Meter InstallationDokument2 SeitenWork Method Statement For Afam III Flow Meter InstallationISAACNoch keine Bewertungen

- Piping Interview QuestionDokument10 SeitenPiping Interview Questiondharmendra_kanthariaNoch keine Bewertungen

- P&ID Guidelines For Pumps Heat ExchangersDokument1 SeiteP&ID Guidelines For Pumps Heat ExchangersVraja KisoriNoch keine Bewertungen

- 001 (Method Statement For Installation and Inspection of Firefighting System) (K)Dokument5 Seiten001 (Method Statement For Installation and Inspection of Firefighting System) (K)Wahid HusainNoch keine Bewertungen

- OISD Check List - 1Dokument5 SeitenOISD Check List - 1Pinjala AnoopNoch keine Bewertungen

- Safety IN LPG Storage, Bottling & TransportationDokument28 SeitenSafety IN LPG Storage, Bottling & TransportationkavehNoch keine Bewertungen

- OHT Semi Gantry CraneDokument1 SeiteOHT Semi Gantry Cranesai KRISHNANoch keine Bewertungen

- Process Design Safety ChecklistDokument8 SeitenProcess Design Safety ChecklistAditya DubeyNoch keine Bewertungen

- Water Control Gates TrainingDokument132 SeitenWater Control Gates TrainingsaishankarlNoch keine Bewertungen

- 3.plotplan and Equipment LayoutDokument12 Seiten3.plotplan and Equipment LayoutAmarKumarNoch keine Bewertungen

- SOP FOR FWD MOORING STATIONS B108 20 Sept 2020Dokument2 SeitenSOP FOR FWD MOORING STATIONS B108 20 Sept 2020capmanirajNoch keine Bewertungen

- Heat Load CalculationDokument5 SeitenHeat Load Calculationsantosh IndulkarNoch keine Bewertungen

- 15915s01 Fume Hoods LC-PPDDokument8 Seiten15915s01 Fume Hoods LC-PPDKhyle Laurenz DuroNoch keine Bewertungen

- Interplant Standard - Steel IndustryDokument10 SeitenInterplant Standard - Steel IndustryVishal Singh PatelNoch keine Bewertungen

- Govt. Polytechnic: AmadalavalasaDokument58 SeitenGovt. Polytechnic: AmadalavalasaPraveen SingupurapuNoch keine Bewertungen

- 0905.1.0 - Instrument Installation RequirementsDokument12 Seiten0905.1.0 - Instrument Installation RequirementsSaoloan NaiborhuNoch keine Bewertungen

- Air and Water Cooled Liquid Chillers: Maintenance and Operating ManualDokument20 SeitenAir and Water Cooled Liquid Chillers: Maintenance and Operating ManualRick LynchNoch keine Bewertungen

- Electrical Wiring Methods and Check ListDokument3 SeitenElectrical Wiring Methods and Check Listssb100% (1)

- Plant Layout Design Rules PDFDokument8 SeitenPlant Layout Design Rules PDFKarthikeyan Moorthy100% (1)

- Att 04, GTR-I&CDokument8 SeitenAtt 04, GTR-I&CSiriepathi SeetharamanNoch keine Bewertungen

- Aramco Q&aDokument5 SeitenAramco Q&aEzhil Arasan100% (2)

- 1 - Checklist For PSC Inspections - CompleteDokument19 Seiten1 - Checklist For PSC Inspections - CompleteEmiliano Berriel AlcaldeNoch keine Bewertungen

- 1Dokument1 Seite1DILSHAD AHEMADNoch keine Bewertungen

- Construction Method of Statement: Submitted By: Mega Air EnterprisesDokument12 SeitenConstruction Method of Statement: Submitted By: Mega Air Enterprisesallen bernabeNoch keine Bewertungen

- Feild Inspection of Shell and Tube Heat ExchangersDokument4 SeitenFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNoch keine Bewertungen

- Specs For Pipeline LayingDokument38 SeitenSpecs For Pipeline LayingRanjan Kumar100% (2)

- Location of Equipment and ServicesDokument1 SeiteLocation of Equipment and ServicesmatzoyekNoch keine Bewertungen

- Sprinkler MethodDokument6 SeitenSprinkler Methodakram husseinNoch keine Bewertungen

- Temporary Building and Porta Cabin Safety Inspection ChecklistDokument3 SeitenTemporary Building and Porta Cabin Safety Inspection ChecklistHabib ur rahman0% (1)

- Plant Layout Design Rules Piping Layout Rules PDFDokument11 SeitenPlant Layout Design Rules Piping Layout Rules PDFLeandro colussiNoch keine Bewertungen

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDokument81 SeitenC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (2)

- 30% Model Review ChecklistDokument3 Seiten30% Model Review Checklistmithoon_021068100% (2)

- PLANT LAYOUT and ISOMETRICDokument51 SeitenPLANT LAYOUT and ISOMETRICMudhita Putri100% (2)

- A Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesDokument20 SeitenA Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesHilal Al KhuzaimiNoch keine Bewertungen

- General Guiidelines For Precommissioning and Commissioning A Chemical Process PlantDokument2 SeitenGeneral Guiidelines For Precommissioning and Commissioning A Chemical Process Plantankur2061100% (1)

- EIL Scope of WorkDokument11 SeitenEIL Scope of WorkManjunath VenkateshNoch keine Bewertungen

- Plant 1Dokument6 SeitenPlant 1Janardhana PaiNoch keine Bewertungen

- LEEA-059-5 Documentation and Marking - Part 5 Lifting Accessories, Slings PDFDokument13 SeitenLEEA-059-5 Documentation and Marking - Part 5 Lifting Accessories, Slings PDFJason RobertsNoch keine Bewertungen

- UPP Piping Install-Small PDFDokument12 SeitenUPP Piping Install-Small PDFsk lukoNoch keine Bewertungen

- JSA For Hydro Test Activites (Generic)Dokument4 SeitenJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- Cable Tray InstallationDokument7 SeitenCable Tray Installationareef007Noch keine Bewertungen

- Various Considerations in Equipment Layout in The Equipment and Plot PlanDokument12 SeitenVarious Considerations in Equipment Layout in The Equipment and Plot PlanThiruvengadam100% (1)

- Replacement of Bad Pipe and Gate Valve Methd StatmDokument10 SeitenReplacement of Bad Pipe and Gate Valve Methd StatmOdejobi OloladeNoch keine Bewertungen

- Vendor Drawing Review A Review of Valve DrawingsDokument3 SeitenVendor Drawing Review A Review of Valve Drawingsthuyenquyen_vt100% (1)

- Commissioning Checkpoints O&M/AU/01: SR - No Civil RemarksDokument3 SeitenCommissioning Checkpoints O&M/AU/01: SR - No Civil RemarksDevend HarinkhedeNoch keine Bewertungen

- Furnace ATT by R K JainDokument9 SeitenFurnace ATT by R K JainRajeevAgrawal67% (3)

- General Notes On PRDSDokument6 SeitenGeneral Notes On PRDSmkbeast60Noch keine Bewertungen

- Method of Statement of Installation of TubingDokument24 SeitenMethod of Statement of Installation of TubingAhmed KhamisNoch keine Bewertungen

- Sample Pre-Startup Safety Review ChecklistDokument4 SeitenSample Pre-Startup Safety Review ChecklistPrem Shanker Rawat100% (4)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Resume: Anisur Rahman 351, Zahurul Haque Hall University of Dhaka Cell: 01730977999 Career ObjectiveDokument3 SeitenResume: Anisur Rahman 351, Zahurul Haque Hall University of Dhaka Cell: 01730977999 Career Objectivezakaria masud sonyNoch keine Bewertungen

- KSB VALVE With HS CodeDokument2 SeitenKSB VALVE With HS Codezakaria masud sonyNoch keine Bewertungen

- Md. Imroz Kabir: Career ObjectivesDokument2 SeitenMd. Imroz Kabir: Career Objectiveszakaria masud sonyNoch keine Bewertungen

- Boiler Act-2022Dokument20 SeitenBoiler Act-2022zakaria masud sonyNoch keine Bewertungen

- Stud Move OrderDokument1 SeiteStud Move Orderzakaria masud sonyNoch keine Bewertungen

- BOM of InsulationDokument6 SeitenBOM of Insulationzakaria masud sonyNoch keine Bewertungen

- Introduction To Computational Fluid Dynamics: Basics of CFD Numerical Model in CFD Steps in A CFD SimulationDokument53 SeitenIntroduction To Computational Fluid Dynamics: Basics of CFD Numerical Model in CFD Steps in A CFD Simulationzakaria masud sonyNoch keine Bewertungen

- Curriculum Vitae of Md. Mahabubur RahmanDokument2 SeitenCurriculum Vitae of Md. Mahabubur Rahmanzakaria masud sonyNoch keine Bewertungen

- Marks Distribution (Section I: 50 1 50, Section II: 10 1 10, Section III: 10 4 40)Dokument11 SeitenMarks Distribution (Section I: 50 1 50, Section II: 10 1 10, Section III: 10 4 40)zakaria masud sonyNoch keine Bewertungen

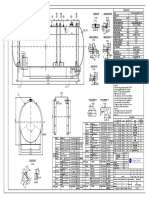

- (GA 1) V 1001 EO Storage VesselDokument1 Seite(GA 1) V 1001 EO Storage Vesselzakaria masud sonyNoch keine Bewertungen

- Bid Table For Stud Nut BoltDokument1 SeiteBid Table For Stud Nut Boltzakaria masud sonyNoch keine Bewertungen

- Fluid Mechanics and Machinery Hydraulic TurbinesDokument17 SeitenFluid Mechanics and Machinery Hydraulic Turbineszakaria masud sonyNoch keine Bewertungen

- West Zone Power Distribution Company LTD.: Ongoing ProjectsDokument5 SeitenWest Zone Power Distribution Company LTD.: Ongoing Projectszakaria masud sonyNoch keine Bewertungen

- Flex Hose: 9. HTTPS://WWW - Metline-Pipefittings - In/stainless-Steel-Flexible-Hose-Braided-Pipes-CorrugatedDokument5 SeitenFlex Hose: 9. HTTPS://WWW - Metline-Pipefittings - In/stainless-Steel-Flexible-Hose-Braided-Pipes-Corrugatedzakaria masud sonyNoch keine Bewertungen

- Bcs and BankDokument3 SeitenBcs and Bankzakaria masud sonyNoch keine Bewertungen

- Company IntroductionDokument58 SeitenCompany Introductionzakaria masud sonyNoch keine Bewertungen

- Short Cut Math by Arifur Rahman PDFDokument180 SeitenShort Cut Math by Arifur Rahman PDFzakaria masud sonyNoch keine Bewertungen

- Types of ChillerDokument13 SeitenTypes of Chillerzakaria masud sonyNoch keine Bewertungen

- Company IntroductionDokument58 SeitenCompany Introductionzakaria masud sonyNoch keine Bewertungen

- Full ThesisDokument156 SeitenFull Thesiszakaria masud sonyNoch keine Bewertungen

- Full Isbl CapDokument6 SeitenFull Isbl Capzakaria masud sonyNoch keine Bewertungen

- Quotaion of FittingsDokument5 SeitenQuotaion of Fittingszakaria masud sonyNoch keine Bewertungen

- Supplier Link 14.10.18Dokument1 SeiteSupplier Link 14.10.18zakaria masud sonyNoch keine Bewertungen

- Cap, BW, Asme B16.9, Astm A403-Wp 304/304L-SDokument7 SeitenCap, BW, Asme B16.9, Astm A403-Wp 304/304L-Szakaria masud sonyNoch keine Bewertungen

- 3D Parts-180408-10-58-42Dokument12 Seiten3D Parts-180408-10-58-42zakaria masud sonyNoch keine Bewertungen