Beruflich Dokumente

Kultur Dokumente

Performance Characteristics Comparison of CNG Port and CNG Direct Injection in Spark Ignition Engine

Hochgeladen von

ivanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Performance Characteristics Comparison of CNG Port and CNG Direct Injection in Spark Ignition Engine

Hochgeladen von

ivanCopyright:

Verfügbare Formate

Performance Characteristics Comparison of CNG Port and CNG

Direct Injection in Spark Ignition Engine

1. Introduction

The reason the study because CNG is one of the best alternative fuel due to its

cleanest burning characteristics and high octane rating. In this study researchers

purpose to compare the various performance parameters of both CNG-PI and

CNG-DI system. The performance of bi-fuel engine with port injection system is

poor in terms of lower brake power and less volumetric efficiency. This researcher

idea of injecting a CNG directly in the cylinder like a diesel injection due to its

better volumetric efficiency and higher thermal efficiency. It means the researcher

did some changes to the petrol engine to CNG engine.

2. System and Experimental Procedure

This research uses experimental methods. The four cylinder spark Ignition

engine was modified into a CNG direct injection engine. Research procedures,

researchers first perform modifications to the cylinder head. Next special injector

rail is mounted near the throtle body. The major difficulty in this research work

was to get correct value of air pressure at the end of compression stroke. The

major difference in the operation of CNG-PI and CNG-DI system is that, in the

CNG-PI system, 2-3 bar pressure is sufficient for a single gas injector to inject

CNG fuel in the air induction system (throttle body). It is mixed with the air and

then the CNG-air mixture is flowing towards the intake system to enter in the

cylinder during suction stroke by opening the inlet valve. In the CNG-DI system,

only air is inducted during the suction stroke and the CNG is injected in the

cylinder directly at the end of compression stroke with injection pressure of 20-25

bar. The engine was run alternately with CNG-PI and CNG-DI system keeping the

operating parameters constant and the observations were recorded

3. Results and Discussions

Engine was run from 1000 rpm to 3000 rpm with each incremental speed of

300 rpm. The constant load of 2 kw was applied to the engine during the

observations. The CNG-DI system produces 8 to 9% higher brake power than

CNG-PI system.

The result of brake spesific fuel consumption for cng-di system is higher than

cng-pi system initially upto 1500 rpm due to less conversion of chemical energy

into mechanical energy related to volumetric efficiency. After 1600 rpm speed,

the bsfc decreases for cng-di system due to increase in volumetric efficiency with

increase in speed. Overall, the average bsfc of cng-di system is 11 to 12% lower

than that of cng-pi system in the speed range from 1600 to 3000 rpm

The result of brake thermal efficiency for cng-di system is lower than cng-pi

system initially upto 1300 rpm speed. Then, it started increasing from 1600 rpm

due to more conversion of chemical energy into mechanical work. However, the

brake thermal efficiency of cng-di system is about 10 to 11% higher than that of

cng-pi system over the speed range from 1600 to 3000 rpm.

4. Conclusion

1. The gasoline engine can be converted CNG-DI system by making

modification in the cylinder head and by installing other components

for CNG injection.

2. The CNG-DI system showed 8-9 % higher brake power than the CNG-

PI system over the given speed range.

3. The average BSFC is approximately 7 to 8% lower in case of CNG-DI

system than the CNG-PI system due to higher volumetric efficiency of

CNG-DI system.

4. The brake thermal efficiency is 6 to 7 % higher for the CNG-DI system

than the CNG-PI system due to more scope of conversion of heat

energy into mechanical work

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 39ED3050CT - RT49S - AP Service ManualDokument31 Seiten39ED3050CT - RT49S - AP Service Manualبوند بوند100% (1)

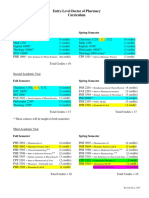

- Pharmd CurriculumDokument18 SeitenPharmd Curriculum5377773Noch keine Bewertungen

- Orofacial Complex: Form and FunctionDokument34 SeitenOrofacial Complex: Form and FunctionAyushi Goel100% (1)

- THRGGDokument10 SeitenTHRGGBob AustinNoch keine Bewertungen

- Ignition SystemDokument46 SeitenIgnition SystemivanNoch keine Bewertungen

- Automated System For Air Pollution Detection and Control of Speed in VehiclesDokument8 SeitenAutomated System For Air Pollution Detection and Control of Speed in VehiclesivanNoch keine Bewertungen

- A Genetic Fuzzy Controller For Vehicle Auomatic Steering ControlDokument15 SeitenA Genetic Fuzzy Controller For Vehicle Auomatic Steering ControlivanNoch keine Bewertungen

- Donaldson Fuel FiltrationDokument42 SeitenDonaldson Fuel FiltrationIongornistu100% (1)

- Drive ShaftDokument34 SeitenDrive ShaftivanNoch keine Bewertungen

- 40 - Engine Coolant Temperature Sensor - InspectionDokument1 Seite40 - Engine Coolant Temperature Sensor - InspectionivanNoch keine Bewertungen

- Filtration Handbook: Liquids: Theodore H. Melzer Maik W. JornitzDokument12 SeitenFiltration Handbook: Liquids: Theodore H. Melzer Maik W. JornitzivanNoch keine Bewertungen

- 26-12 JanoskoDokument9 Seiten26-12 JanoskoivanNoch keine Bewertungen

- Brake 03Dokument0 SeitenBrake 03Pushpendra Singh RathoreNoch keine Bewertungen

- 40 - Engine Coolant Temperature Sensor - InspectionDokument1 Seite40 - Engine Coolant Temperature Sensor - InspectionivanNoch keine Bewertungen

- Basic HydraulicDokument106 SeitenBasic HydraulicKuthubuddin ArellaNoch keine Bewertungen

- 3319 8554 1 PBDokument8 Seiten3319 8554 1 PBivanNoch keine Bewertungen

- Water in Fuel SensorDokument11 SeitenWater in Fuel Sensornachof1Noch keine Bewertungen

- EG BensinDokument39 SeitenEG BensinivanNoch keine Bewertungen

- Class 12 - Maths - MatricesDokument87 SeitenClass 12 - Maths - MatricesAishwarya MishraNoch keine Bewertungen

- Tran-Effects of Assisted JumpingDokument5 SeitenTran-Effects of Assisted JumpingyoungjessNoch keine Bewertungen

- 9701 w09 QP 21Dokument12 Seiten9701 w09 QP 21Hubbak KhanNoch keine Bewertungen

- Government of West Bengal:: Tata Motors LTD: Abc 1 1 1 1 NA 0 NA 0Dokument1 SeiteGovernment of West Bengal:: Tata Motors LTD: Abc 1 1 1 1 NA 0 NA 0md taj khanNoch keine Bewertungen

- The Wild T1 TheodoliteDokument61 SeitenThe Wild T1 TheodoliteCJLara100% (1)

- GLP BmsDokument18 SeitenGLP BmsDr.Subhashish TripathyNoch keine Bewertungen

- (Eng) Zx890lch 5a Ks En316Dokument13 Seiten(Eng) Zx890lch 5a Ks En316MC TAK LEENoch keine Bewertungen

- Physics 101Dokument21 SeitenPhysics 101Kuna KunavathiNoch keine Bewertungen

- Poems Prescribed For 2012-2014 English B CSEC ExamsDokument24 SeitenPoems Prescribed For 2012-2014 English B CSEC ExamsJorge Martinez Sr.100% (2)

- Science Involved in Floating Paper Clip Science Experiment GuidelinesDokument4 SeitenScience Involved in Floating Paper Clip Science Experiment GuidelinesSHIELA RUBIONoch keine Bewertungen

- Abnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorDokument21 SeitenAbnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorGopala KrishnanNoch keine Bewertungen

- PAG7.1 Student The Effects of Antibiotics On Microbial Growth - v0.3Dokument3 SeitenPAG7.1 Student The Effects of Antibiotics On Microbial Growth - v0.3Habib UddinNoch keine Bewertungen

- CE Review GEOMETRY 2Dokument6 SeitenCE Review GEOMETRY 2Paul Gerard AguilarNoch keine Bewertungen

- Relationsh Between EM and Young S ModuliDokument7 SeitenRelationsh Between EM and Young S ModuliDwight AndersonNoch keine Bewertungen

- Guidelines For The Management of Brain InjuryDokument26 SeitenGuidelines For The Management of Brain InjuryfathaNoch keine Bewertungen

- Rido, Rudini - Paediatric ECGDokument51 SeitenRido, Rudini - Paediatric ECGFikriYTNoch keine Bewertungen

- Psychology 114: Chapters 3 & 4Dokument18 SeitenPsychology 114: Chapters 3 & 4Grace AndersonNoch keine Bewertungen

- Food Biotechnology in Ethical PerspectiveDokument340 SeitenFood Biotechnology in Ethical Perspectivemojtaba2500100% (2)

- Astm 2017-F2059Dokument5 SeitenAstm 2017-F2059laythNoch keine Bewertungen

- Intro Slow Keyofg: Em7 G5 A7Sus4 G C/G D/F# AmDokument2 SeitenIntro Slow Keyofg: Em7 G5 A7Sus4 G C/G D/F# Ammlefev100% (1)

- L2 Biostatistics ProbabilityDokument84 SeitenL2 Biostatistics ProbabilityAaron CiudadNoch keine Bewertungen

- Efficient Rice Based Cropping SystemDokument24 SeitenEfficient Rice Based Cropping Systemsenthilnathan100% (1)

- Bolt Action Italian Painting GuideDokument7 SeitenBolt Action Italian Painting GuideTirmcdhol100% (2)

- DS Ltch00601daa0 R05Dokument4 SeitenDS Ltch00601daa0 R05rajareddy235Noch keine Bewertungen

- VTA28-G5: Fuel OptimizedDokument3 SeitenVTA28-G5: Fuel OptimizedIslam HemdanNoch keine Bewertungen

- Active Faults in MalaysiaDokument52 SeitenActive Faults in MalaysiaHazim HaNoch keine Bewertungen

- Milviz F-15e Poh V 2Dokument499 SeitenMilviz F-15e Poh V 2Jose Ramon Martinez GutierrezNoch keine Bewertungen