Beruflich Dokumente

Kultur Dokumente

Transfer Tower

Hochgeladen von

Alif Rahmat FebriantoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Transfer Tower

Hochgeladen von

Alif Rahmat FebriantoCopyright:

Verfügbare Formate

PAGE

1 OF 3

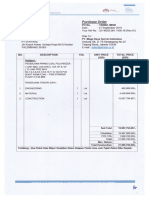

ITP FOR TRANSFER TOWER

DOC. NO. : I-T-3122-QAQC-005

ORIGINATED BY REVIEWED BY APPROVED BY DISTRIBUTION

- SDCC : Original

- All Div. : Copy

- All Dept. : Copy

- Client : Copy

Irvan Meliala A. Rusdi H. Saito

QAQC Coordinator Site Manager QAQC Manager SCED

ISSUED EFFECTIVE

REV. NO. BRIEF OF REVISION

DATE DATE

0 17-Mar-10 17-Mar-10

1 26-Mar-10 26-Mar-10 Revised from BVI

PMR-001-Form 01

ITP NO. : I-T-3122-QAQC-001

WI for FIELD INSPECTION AND TEST PLAN (F-ITP) Rev. No. : 1

LEGENDS, ABBREVIATIONS, REMARKS OF ITP Date : 17-Mar-10

PROJECT NAME : Tanjung Jati "B" Coal Fired Power Station Unit 3&4 (2x660 MW)

OWNER : PT. Central Java Power

CLIENT : SCJO-Erection Division (SCED)

TJE JOB NO. : T-3122

DESCRIPTION :

I LEGEND INSPECTION / SURVEILLANCE CODES

NOTIFICATION = Inspection Request in writing and require a minimum of 24 hours notice of impending inspection / test.

H - HOLD POINT = As notification point, however work may not proceed beyond this point without acceptance or formal waiver from Inspection

Authority ( Client / Owner )

W - WITNESS = Witness of inspection by Client / Owner and Sub-Contractor may proceed if Client / Owner not appearance at the pointed time.

Witness point shall be given by Notification

SW - SPOT WITNESS = Witness of inspection by Client / Owner and to be done at spot or random ( random sample )

R - REVIEW = Review of verifying certificate / Review a document to ensure compliance with specification/Review of inspection report or proc.

A - APPROVAL = Approval documentation ( Procedure, Work instruction, Inspection report, etc. ) or Control document required to be approved

IR = Issued report or documents required (i.e Inspection Report, Mill Certificate, Fabrication Completed Certificate, Etc.)

Note;

1. Inspection and test items covered by this list and applicable requisition and specifications are TJE's general requirements. If any conflict arise

between this list and individual requisition and specifications, the requirements in individual requisition and specification shall govern.

2. The legend used throughout this list shall have the meaning denoted and can be changed to suit with Client or Owner Comments.

II ABBREVIATIONS

AWS = AMERICAN WELDING SOCIETY NCR = NON CONFORMANCE REPORT RT = RADIOGRAPHY TEST

ASTM = AMERICAN SOCIETY TESTING OF MATERIAL RFI = REQUEST FOR INFORMATION UT = ULTRASONIC TEST

DIN = DEUTCHES INSTITUT FUR NORMUNG MDR = MANUFACTURER'S DATA REPORT PT = PENETRANT TEST

WPS = WELD PROCEDURE SPECIFICATION NDT = NON DESTRUCTIVE TESTING MT = MAGNETIC PART. TEST

PQR = PROCEDURE QUALIFICATION RECORD PWHT = POST WELD HEAT TREATMENT

WQTR = WELDER QUALIFICATION TEST RECORD Proc. = PROCEDURE

N/A = NOT APPLICABLE

III REMARKS

1) Ref. Approval Section of Document.

a : Where there is a Subcontractor element, the Subcontractor involved will sign the approval of the activity.

b : Where there is no Subcontractor element, TJE will sign approval of activity and present to the Client.

2) Inspection and Test Plan (ITP) Status

It is to be understood that the Inspection and Test Plan forms an integeral part of the control/verification documentation.

However, where no other documents are required or exit " The Inspection and Test Plan " only will be understood to be

the control/verification document.

Page 5 of 15

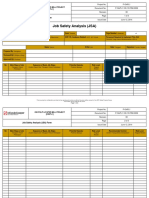

PT.TRUBA JAYA ENGINEERING ITP NO. : I-T-3122-QAQC-005

Rev. No. : 1

FIELD INSPECTION & TEST PLAN (F-ITP)

Date : 26-Mar-10

PROJECT NAME : CFSPP 2x660 MW-TJB U#3, #4 Central Java

OWNER : PT. Central Java Power

CLIENT : Sumitomo Corporation Erection Division (SCED)

TJE JOB NO. : T-3122

DESCRIPTION : TRANSFER TOWER INSTALLATION

INSPECTION ACTIVITIES

REFERENCE

ITEM ACTIVITIES DOCUMENTS/ACCEPTANCE VERIFYING DOCUMENT Owner's Rep /

TJE SCED BVI

CRITERIA Engineer

1.0 DOCUMENT REVIEW

1.1 Review all technical specifications, drawing, procedures & work instructions Approved General

1.2 All tech. spec., procedures, work instruction shall be clarified, TJE Management System R R/A W R/A

Instruction, Technical

Manual M-01, Standard

understood and implemented accordingly Specification &

Operating Procedure, Contract

1.3 Finalise deviation, generate new procedure and work instruction Procedures, drawings,

Agreement, Standard & Code

if required etc.

2.0 ERECTION

2.1 Material Receiving Inspection Material Receiving

2.1.1 Verification document; packing list, mill certificates, etc. if required Inspect. Report , OSD W&R SW & R SW & R SW & R

Material Receiving Procedure

2.1.2 Visual (corrosion, damage, bent, etc) & Dimensional check as required (Over, Shortage,

Note : Raise NCR of any Non Comformance Damage) report, NCR

2.2 Foundation Check

2.2.1 Verify civil setting points / datum Installation Procedure of Transfer Tower - R R R R

2.2.2 Chek center line, elevation, anchor bolt location (A-TT-M-TP6-3522) Inspection Report (F1-10) W&R W&R SW & R SW & R

2.3 Initial Preparation (Before Column Installation)

2.3.1 Check hole diameter of column and leveling of packers /shim plate at Installation Procedure of Transfer

Inspection Report (F2-2) W&R W&R SW & R SW & R

each column location Tower (A-TT-M-TP6-3522)

2.3.2 Welding (if any)

- Welding Procedure Specification (WPS/PQR) WPS/PQR W&R SW & R SW & R SW & R

ASME Sec.IX

- Welder Performance Qualification Test (WPQT) WPQTR W&R SW & R SW & R SW & R

2.4 Erection

2.4.1 Check structure for line, level and dimensional as required Installation Procedure of Transfer Inspection Report (F2-2) W&R SW & R SW & R SW & R

2.4.2 Welding fit-up (if any) Tower (A-TT-M-TP6-3522) - SW - - -

2.4.3 Visual inspection (Before, during,after welding) (if any) AWS D1.1 Inspection Report (F1-3) W&R SW & R SW & R SW & R

2.4.4 Check of plumbness / verticality Installation Procedure of Transfer Inspection Report (F2-1) W&R SW & R SW & R SW & R

2.4.5 Bolt Tightening Check (Bolt Pre-tension verification check) Tower (A-TT-M-TP6-3522) Inspection Report (F2-4) W&R SW & R SW & R SW & R

3.0 FINAL INSPECTION

3.1. Check completion installation all accessories and parts of Eqp as per drawing Installation Procedure of

3.2 Make sure that all inspection check list or Quality control Transfer Tower (A-TT-M-TP6- Punch List H H W&R W&R

activities has been meet with client's specification and requirements 3522)

4.0 DOCUMENTATION

All documents dossier required as per contract shall be collected and submitted

to Client and copy for file All Quality Document as

Contract, Tech. Spec., Proc.

4.1. All Inspection as per this ITP has been done & the inspection per Contract (Inspection R

R R R

Reports, RFI, NCR, MDR,

report has already been generated and signed Installation Procedure of Punch List, NDT Report,

Transfer Tower (A-TT-M-TP6- As built Drawings, Etc.)

3522)

Page 6 of 15

PT.TRUBA JAYA ENGINEERING ITP NO. :I-T-3122-QAQC-005

Rev. No. : 1

FIELD INSPECTION & TEST PLAN (F-ITP)

Date : 26-Mar-10

PROJECT NAME : CFSPP 2x660 MW-TJB U#3, #4 Central Java

OWNER : PT. Central Java Power

CLIENT : Sumitomo Corporation Erection Division (SCED)

TJE JOB NO. : T-3122

DESCRIPTION : TRANSFER TOWER INSTALLATION

INSPECTION ACTIVITIES

REFERENCE All Quality Document as

ITEM ACTIVITIES DOCUMENTS/ACCEPTANCE per ContractDOCUMENT

VERIFYING (Inspection Owner's Rep /

TJE SCED BVI

CRITERIA Reports, RFI, NCR, MDR, Engineer

Installation Procedure of Punch List, NDT Report,

4.2 All NCR or any deviation of contract already closed and documented Transfer Tower (A-TT-M-TP6- As built Drawings, Etc.)

4.3 All drawing changes already updated in mark up drawing 3522)

Page 7 of 15

PT.TRUBA JAYA ENGINEERING ITP NO. : I-T-3122-QAQC-005

Rev. No. : 1

FIELD INSPECTION & TEST PLAN (F-ITP)

Date : 26-Mar-10

PROJECT NAME : CFSPP 2x660 MW-TJB U#3, #4 Central Java

OWNER : PT. Central Java Power

CLIENT : Sumitomo Corporation Erection Division (SCED)

TJE JOB NO. : T-3122

DESCRIPTION : TRANSFER TOWER INSTALLATION

INSPECTION ACTIVITIES

REFERENCE

ITEM ACTIVITIES DOCUMENTS/ACCEPTANCE VERIFYING DOCUMENT Owner's Rep /

TJE SCED BVI

CRITERIA Engineer

1.0 DOCUMENT REVIEW

1.1 Review all technical specifications, drawing, procedures & work instructions

Approved General

1.2 All tech. spec., procedures, work instruction shall be clarified, TJE Management System R R/A W R/A

Instruction, Technical

Manual M-01, Standard

understood and implemented accordingly Specification &

Operating Procedure, Contract

Procedures, drawings,

1.3 Finalise deviation, generate new procedure and work instruction Agreement, Standard & Code

etc.

if required

2.0 ERECTION

2.1 Material Receiving Inspection

Material Receiving

2.1.1 Verification document; packing list, mill certificates, etc. if required Inspect. Report , OSD W&R SW & R SW & R SW & R

Material Receiving Procedure

2.1.2 Visual (corrosion, damage, bent, etc) & Dimensional check as required (Over, Shortage,

Damage) report, NCR

Note : Raise NCR of any Non Comformance

2.2 Foundation Check

2.2.1 Verify civil setting points / datum - R R R R

Installation Procedure of Transfer Tower

2.2.2 Chek center line, elevation, anchor bolt location (A-TT-M-TP6-3522) Inspection Report (F1-10) W&R W&R SW & R SW & R

2.3 Initial Preparation (Before Column Installation)

2.3.1 Check hole diameter of column and leveling of packers /shim plate at Installation Procedure of Transfer

Tower (A-TT-M-TP6-3522)

Inspection Report (F2-2) W&R W&R SW & R SW & R

each column location

2.3.2 Welding (if any)

- Welding Procedure Specification (WPS/PQR) WPS/PQR W&R SW & R SW & R SW & R

ASME Sec.IX

- Welder Performance Qualification Test (WPQT) WPQTR W&R SW & R SW & R SW & R

2.4 Erection

2.4.1 Check structure for line, level and dimensional as required Installation Procedure of Transfer Inspection Report (F2-2) W&R SW & R SW & R SW & R

Tower (A-TT-M-TP6-3522) SW - - -

2.4.2 Welding fit-up (if any) -

2.4.3 Visual inspection (Before, during,after welding) (if any) AWS D1.1 Inspection Report (F1-3) W&R SW & R SW & R SW & R

2.4.4 Check of plumbness / verticality Installation Procedure of Transfer Inspection Report (F2-1) W&R SW & R SW & R SW & R

Tower (A-TT-M-TP6-3522) W&R SW & R SW & R SW & R

2.4.5 Bolt Tightening Check (Bolt Pre-tension verification check) Inspection Report (F2-4)

3.0 FINAL INSPECTION

3.1. Check completion installation all accessories and parts of Eqp as per drawing Installation Procedure of

3.2 Make sure that all inspection check list or Quality control Transfer Tower (A-TT-M-TP6- Punch List H H W&R W&R

3522)

activities has been meet with client's specification and requirements

4.0 DOCUMENTATION

All documents dossier required as per contract shall be collected and submitted

to Client and copy for file Contract, Tech. Spec., Proc.

All Quality Document as

4.1. All Inspection as per this ITP has been done & the inspection per Contract (Inspection R R R R

Reports, RFI, NCR, MDR,

report has already been generated and signed Installation Procedure of Punch List, NDT Report,

4.2 All NCR or any deviation of contract already closed and documented Transfer Tower (A-TT-M-TP6- As built Drawings, Etc.)

3522)

4.3 All drawing changes already updated in mark up drawing

F2-6

FIELD INSPECTION REPORT

Tanjung Jati "B" Coal-Fired 2x660 MW SCED

DIMENSIONAL INSPECTION REPORT (DIR)

OWNER : PT. CENTRAL JAVA POWER REPORT NO. :

CLIENT : SUMITOMO CORPORATION ERECTION DIVISION DATE :

SUBJECT : REF. DWG NO.:

AREA : PSS NO. :

SKETCH

Notes.

Prepared & Inspected by, Witnessed / Approved by, Witnessed / Approved by, Reviewed / Approved by,

PT. Truba Jaya Engineering SCED BVI Owner's / Engineer

F1-3

FIELD INSPECTION REPORT

Tanjung Jati "B" Coal-Fired 2x660 MW SCED

WELDING INSPECTION REPORT (WIR)

OWNER : PT. CENTRAL JAVA POWER REPORT NO. :

CLIENT : SUMITOMO CORPORATION ERECTION DIVISION DATE :

SUBJECT : REF. DWG NO. :

AREA : PSS NO. :

Applicable Code :

Welder Result

Line No Joint No Process Thickness Diameter Remarks

Stamp Accepted Rejected

Notes.

Prepared & Inspected by, Witnessed / Approved by, Witnessed / Approved by, Reviewed / Approved by,

PT. Truba Jaya Engineering SCED BVI Owner's / Engineer

F1-10

FIELD INSPECTION REPORT

PLTU 2 BANTEN (2 x 300MW) SCED

FOUNDATION INSPECTION REPORT (FIR)

OWNER : PT. CENTRAL JAVA POWER REPORT NO. : R-EQU-FIR-

CLIENT : SUMITOMO CORPORATION ERECTION DIVISION DATE :

SUBJECT : REF. DWG NO. :

AREA : PSS NO. :

SKETCH

Notes.

Prepared & Inspected by, Witnessed / Approved by, Witnessed / Approved by, Reviewed / Approved by,

PT. Truba Jaya Engineering SCED BVI Owner's / Engineer

F2-2

FIELD INSPECTION REPORT

Tanjung Jati "B" Coal-Fired 2x660 MW SCED

ELEVATION INSPECTION REPORT (EIR)

OWNER : PT. CENTRAL JAVA POWER REPORT NO. :

CLIENT : SUMITOMO CORPORATION ERECTION DIVISION DATE :

SUBJECT : REF. DWG NO. :

AREA : PSS NO. :

E L E V A T I O N (mm)

NO. POSITION RESULT

Design Actual Dev. N

1 0

2 0 1 2 3

3 0

8 4

4 0

5

7 6 5

6

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Notes.

Prepared & Inspected by, Witnessed / Approved by, Witnessed / Approved by, Reviewed / Approved by,

PT. Truba Jaya Engineering SCED BVI Owner's / Engineer

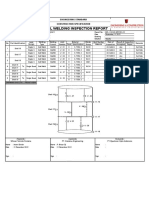

F2-1

FIELD INSPECTION REPORT

Tanjung Jati "B" Coal-Fired 2x660 MW SCED

COLUMN - VERTICALITY INSPECTION REPORT (VER)

OWNER : PT. CENTRAL JAVA POWER REPORT NO. : R-EQU-CVR-

CLIENT : SUMITOMO CORPORATION ERECTION DIVISION DATE : 17-Jun-10

SUBJECT : Column Structur REF. DWG NO. : F5585-T0502-01 rev.3

AREA : TRANSFER TOWER T-102 PSS NO. : 322

DEVIATION (mm) deviation

NO. POSITION Vertical Degree Center Line RESULT

North South West East e1 e2

1

2

3

4

5

Tier 1

6

7

8

9

10

11

12

North

West East

South

Notes.

Prepared & Inspected by, Witnessed / Approved by, Witnessed / Approved by, Reviewed / Approved by,

PT. Truba Jaya Engineering SCED BVI Owner's / Engineer

F2-4

FIELD INSPECTION REPORT

Tanjung Jati "B" Coal-Fired 2x660 MW SCED

BOLT TIGHTENING REPORT (BTR)

OWNER : PT. CENTRAL JAVA POWER REPORT NO. :

CLIENT : SUMITOMO CORPORATION ERECTION DIVISION DATE :

SUBJECT : REF. DWG NO.:

AREA : PSS NO. :

Inspection Result :

VALUE (NM)

NO STRUCTURAL PART NAME SPEC SIZE METHOD RESULT

PLAN ACT

Sketch :

Notes.

Prepared & Inspected by, Witnessed / Approved by, Witnessed / Approved by, Reviewed / Approved by,

PT. Truba Jaya Engineering SCED TOSHIBA Owner's / Engineer

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Ffisj .,,, N (Rones' : L (O-Date: PT - Vertii (Al N0-FkentenDokument2 SeitenFfisj .,,, N (Rones' : L (O-Date: PT - Vertii (Al N0-FkentenAlif Rahmat FebriantoNoch keine Bewertungen

- Product Data Sheet: Circuit Breaker Easypact Ezc100H - TMD - 20 A - 3 Poles 3DDokument6 SeitenProduct Data Sheet: Circuit Breaker Easypact Ezc100H - TMD - 20 A - 3 Poles 3DAlif Rahmat FebriantoNoch keine Bewertungen

- F5 05 GD FFO Building Hydrant Systems DRAFT PDFDokument18 SeitenF5 05 GD FFO Building Hydrant Systems DRAFT PDFAlif Rahmat FebriantoNoch keine Bewertungen

- QE-038 FF III-2019 R1 Tyco GentecDokument1 SeiteQE-038 FF III-2019 R1 Tyco GentecAlif Rahmat FebriantoNoch keine Bewertungen

- Penawaran Q 544 FF VII 2017Dokument1 SeitePenawaran Q 544 FF VII 2017Alif Rahmat FebriantoNoch keine Bewertungen

- 02.situasi Plaza & Bangku Gate 1.compressedDokument1 Seite02.situasi Plaza & Bangku Gate 1.compressedAlif Rahmat FebriantoNoch keine Bewertungen

- Penawaran Q 442 FF VI 2017 R1Dokument2 SeitenPenawaran Q 442 FF VI 2017 R1Alif Rahmat FebriantoNoch keine Bewertungen

- Storage Tank Shell Banding Quality Control and Inspection Report FormDokument1 SeiteStorage Tank Shell Banding Quality Control and Inspection Report FormAlif Rahmat FebriantoNoch keine Bewertungen

- P OkiPL1 100 15 FRM 0009 Job Safety Analysis (JSA)Dokument3 SeitenP OkiPL1 100 15 FRM 0009 Job Safety Analysis (JSA)Alif Rahmat FebriantoNoch keine Bewertungen

- Hardness Test Quality Control and Inspection Report FormDokument17 SeitenHardness Test Quality Control and Inspection Report FormAlif Rahmat Febrianto0% (1)

- Visual Inspection ReportDokument17 SeitenVisual Inspection ReportAlif Rahmat Febrianto0% (1)

- Img 0001Dokument1 SeiteImg 0001Alif Rahmat FebriantoNoch keine Bewertungen

- RP32-3 Inspection & Testing of in Service Civil & Mechanical Plant Management PrincipalDokument7 SeitenRP32-3 Inspection & Testing of in Service Civil & Mechanical Plant Management PrincipalAlif Rahmat FebriantoNoch keine Bewertungen

- Progress Piping GCC CaCo3Dokument66 SeitenProgress Piping GCC CaCo3Alif Rahmat FebriantoNoch keine Bewertungen

- W QC A 009 Rev1 Written PracticeDokument17 SeitenW QC A 009 Rev1 Written PracticeAlif Rahmat FebriantoNoch keine Bewertungen

- Chart Title: Pt. Gemilang Cipta Wawasan Schedule ProjectDokument10 SeitenChart Title: Pt. Gemilang Cipta Wawasan Schedule ProjectAlif Rahmat FebriantoNoch keine Bewertungen

- W QC A 004 Rev1, WQT ProcedureDokument15 SeitenW QC A 004 Rev1, WQT ProcedureAlif Rahmat FebriantoNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ISO 9001:2015 Questions Answered: Suppliers CertificationDokument3 SeitenISO 9001:2015 Questions Answered: Suppliers CertificationCentauri Business Group Inc.100% (1)

- Crankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsDokument6 SeitenCrankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsKukuh SeptiantoNoch keine Bewertungen

- Materials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilDokument5 SeitenMaterials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilBart MaxNoch keine Bewertungen

- Rigaku Progeny Spec Sheet LTR 3.14Dokument2 SeitenRigaku Progeny Spec Sheet LTR 3.14DATA24Noch keine Bewertungen

- A Sample of Wet Soil Has A Volume of 0Dokument8 SeitenA Sample of Wet Soil Has A Volume of 0eph0% (1)

- Justine J. Beroy: Career ObjectivesDokument5 SeitenJustine J. Beroy: Career ObjectivesJustine BeroyNoch keine Bewertungen

- Skytrain Avia Services: Emergency Procedures ManualDokument32 SeitenSkytrain Avia Services: Emergency Procedures ManualEndro RastadiNoch keine Bewertungen

- 500-600 Forklifts & Buckmaster: Parts CatalogDokument281 Seiten500-600 Forklifts & Buckmaster: Parts CatalogRoberto Mariano100% (2)

- WEISER Locks and HardwareDokument24 SeitenWEISER Locks and HardwareMaritime Door & WindowNoch keine Bewertungen

- Honeywell P7640B1032 Differential Pressure Sensors PDFDokument2 SeitenHoneywell P7640B1032 Differential Pressure Sensors PDFMarcello PorrinoNoch keine Bewertungen

- Jacky Smith Resume Project ManagerDokument1 SeiteJacky Smith Resume Project ManagerGrey GrayNoch keine Bewertungen

- Doing Hot Work On Gas ShipDokument5 SeitenDoing Hot Work On Gas ShipAnonymous icnhaNsFNoch keine Bewertungen

- Prospects For Alkaline Zero Gap Water Electrolysers For Hydrogen ProductionDokument16 SeitenProspects For Alkaline Zero Gap Water Electrolysers For Hydrogen Productionkhan47pkNoch keine Bewertungen

- Bio-Sensors and Bio-Devices: Spring 2020Dokument22 SeitenBio-Sensors and Bio-Devices: Spring 2020barristertoto99 chanNoch keine Bewertungen

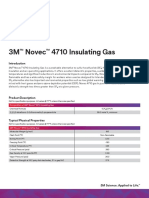

- SF6 Novec 4710Dokument4 SeitenSF6 Novec 4710Fidya Eka PrahestiNoch keine Bewertungen

- WDU 2.5 enDokument14 SeitenWDU 2.5 enAhmadBintangNegoroNoch keine Bewertungen

- Web 2.0: Dynamic Web PagesDokument12 SeitenWeb 2.0: Dynamic Web PagesAra PantaleonNoch keine Bewertungen

- VB Script ReferenceDokument27 SeitenVB Script ReferenceRajkumarNoch keine Bewertungen

- Noise and Vibration During CosntructionDokument12 SeitenNoise and Vibration During Cosntructionpierre3101Noch keine Bewertungen

- Shifting Meterials: Ground Floor ReceptionDokument3 SeitenShifting Meterials: Ground Floor Receptionvishwas pandithNoch keine Bewertungen

- Air-Bag: (1) Connector InformationDokument34 SeitenAir-Bag: (1) Connector InformationbakriramziNoch keine Bewertungen

- Comparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelDokument12 SeitenComparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelWaqqas ChaudhryNoch keine Bewertungen

- Distributed PowerDokument3 SeitenDistributed PowertibvalNoch keine Bewertungen

- BPSK SimulinkDokument13 SeitenBPSK SimulinkpootommyNoch keine Bewertungen

- Standardization of Naoh 1Dokument3 SeitenStandardization of Naoh 1api-309208977Noch keine Bewertungen

- Problems PDFDokument9 SeitenProblems PDFEduarGelvezNoch keine Bewertungen

- User'S Manual: Capstone MicroturbineDokument56 SeitenUser'S Manual: Capstone MicroturbinemassimocalviNoch keine Bewertungen

- Service Manual: PhilipsDokument39 SeitenService Manual: PhilipsRogerio E. SantoNoch keine Bewertungen

- How To Measure MTFDokument64 SeitenHow To Measure MTFamtcorporationNoch keine Bewertungen

- 701.ssvseat 1.04Dokument2 Seiten701.ssvseat 1.04Cosmin MuscaluNoch keine Bewertungen