Beruflich Dokumente

Kultur Dokumente

Silencer 1

Hochgeladen von

77614300 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

7 Ansichten7 Seitensilincer-1 for desx

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldensilincer-1 for desx

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

7 Ansichten7 SeitenSilencer 1

Hochgeladen von

7761430silincer-1 for desx

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

SSRG International Journal of Mechanical Engineering (SSRG - IJME) – Volume 4 Issue 6 June 2017

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 24 Design and Comparison of Mufflers

Having Different Arrangements for Diesel Engine Yash K. Kakadiya1 , Prof. B.S. Patel2 , Prof. J.P.

Hadiya3 1 Student, M.Tech - Machine Design, B.V.M. Engineering College, Vallabh Vidyanagar,

Anand, India 2Associated Professor, Mech. Department, B.V.M. Engineering College, Vallabh

Vidyanagar, Anand, India 3Assistant Professor, Mech. Department, B.V.M. Engineering College,

Vallabh Vidyanagar, Anand, India Abstract IC engines are wide area of applications like automobile

applications, marine applications, power generation, agricultural applications, light aircrafts etc. But

major issues by using IC engine are to cause the air pollutions and noise pollutions. A noise pollution

from the IC engine in a now a days is inherent issue. This noise can be reduced sufficiently by means

of a well designed muffler. Muffler is the device used in an IC engine to control a noise within a limit

and reduce a noise pollution. In this research work, six different arrangements of mufflers are

designed and compared noise level for all mufflers. From comparison it is found that the dual

exhaust type mufflers gets better reduction in noise compare to the single centre exhaust type and

single side exhaust type mufflers. This dual exhaust type muffler provides reduction in noise by

29.56 db in case study of 5 HP diesel engine. Keywords — IC Engine, Noise Pollution, Exhaust

Mufflers, Dual Exhaust Muffler. I. INTRODUCTION An internal combustion engine is a one type of

heat engine in which combustion takes place in a close cylinder; by combustion of fuel it produces a

power. IC engines converts the chemical energy of fuel by means of combustion of fuel in a

combustion chamber with help of air to the heat energy and then heat energy convert to the

mechanical work or energy by means of piston, connecting rod and crank shaft. IC engines are wide

area of applications like automobile applications, marine applications, power generation, agricultural

applications, earthmoving applications, locomotive engines, mining equipments, generators, light

aircrafts etc [17]. There are mainly two types (Petrol & Diesel) of IC engine mostly used in a most of

all applications[17] . Main disadvantages of IC engines are described as: Low efficiency (around 30-

40%) for producing power[17], High heat loss in IC engines, Vibration problem due to reciprocating

parts in a IC engine, There is major pollution caused by the IC engine (1) Air pollution (2) Noise

pollution. This research work mainly concern to reduce a noise pollution of IC engine. Noise is

defined as „an undesirable sound‟ or „an unwanted sound‟. Sound is the pressure wave developed

from the pulses of alternating high pressure and low pressure of air. In the IC engine, pressure wave

generated when the exhaust valve is opens & closes repeatedly. Therefore high pressure of exhaust

gases converted to low pressure that generates the pressure pulses, which produces a sound wave.

Sound wave flows to exhaust pipe along exhaust gases. These pressure pulses that a noise produces

from the engine. Without muffler gasoline engine produce exhaust noise in the range from 85 to 100

dB while an unmuffled diesel engine emits exhaust noise in the range from 100 to 125 dB [2] .

Human ears can sense the sound of frequency range 20 Hz to 20 kHz. While the ear can sustain a

noise up to 80-100 db, above 100 db noise creates pain and discomfort to human and also causes

the loss of hearing[2] . There is a need of designing the proper element to reduce a noise from the IC

engine and it is known as the muffler or silencer [12], [13]. Therefore in this research paper muffler

design procedure is described briefly. Muffler design is the trial & error type design. Therefore

muffler can be design by comparison of different arrangements. This research gives the detail design

of mufflers different arrangements and their noise level comparisons. Muffler is defined as a

mechanical device used to deplete the noise generated by an internal combustion engine. A muffler

not only reduces noise, but also diminishes vibrations. It was invented by “MILTON” and “REEVES” in

1896. There are main two types of muffler mostly used in an IC engine application: (1) Absorptive

muffler (2) Reflective or Reactive muffler [2]. Many times combination of both mufflers is also used

and it is known as combined muffler. This muffler having a very high capabilities to attenuate the

more noise compare to the absorptive and reactive mufflers. Many other types of mufflers are also

available in applications like, Baffles plate type, Resonance type, Wave cancellation type, Chambered

type, Active noise cancellation type muffler etc[2]. But all are worked as same principle for either an

absorptive type mufflers or reactive type mufflers. SSRG International Journal of Mechanical

Engineering (SSRG - IJME) – Volume 4 Issue 6 June 2017 ISSN: 2348 – 8360

www.internationaljournalssrg.org Page 25 II. MUFFLER DESIGN Mufflers are important equipment of

engine system and used in exhaust system to minimize noise caused by combustion process. Basic

requirements of muffler design are Quiet and interchangeable, Good Performance, Compact Design

& Light weight, Simple in maintenance and a Specific requirement of muffler design are Reduce the

noise in given application, Replaceable, Doesn‟t increase back pressure, Easy Manufacturing &

mounting, Cost of muffler etc.[6][4] There are mainly five design criteria considered for muffler

design. The acoustic criterion related to the noise reduction. The geometrical criterion, related to

the muffler shape and considerable volume for space availability. The mechanical criterion, related

to the material selection for the muffler design. The aerodynamic criterion, related to the pressure

drop calculation for engine exhaust gas at a given temperature and pressure. The economical

criterion, related to the cost factor for making a muffler. [10] For muffler design parameters should

be considered like; Size of muffler (Length and Diameter), Diameter of Inlet and outlet pipe,

Perforated Holes on the pipe, Number of reactive chambers, Length of absorptive chamber, Number

of inlets and outlet pipes, Required insertion loss, Cost of muffler etc[10] . Muffler can design by the

following steps; main design includes length and diameter of muffler and length of inner chambers

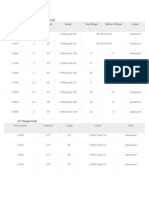

of muffler. A. Design of Muffler Length and Muffler Diameter Table 1: ASHRAE Standard Grades for

Muffler Design[2],[14] There are different standard mufflers grades provided by ASHRAE (American

society of heating, refrigerating and air-conditioning engineers) technical committee 2.6 for the

designing of mufflers for engines [14]. They provide four different grades (as shown in Table 1) for

design a muffler diameter and muffler length with require insertion loss. By these muffler grades,

muffler length and muffler diameter can design for optimum reduction in a noise level. Insertion

Loss (I.L.):- A muffler performance and muffler noise reduction capability is generally defined in

terms of insertion loss. It is defined as the difference between level of sound without and with

muffler attached. Here select critical grade for design the length and diameter of muffler by

considering insertion loss, space condition and cost parameters. Also from literature survey found

that the critical grade is best suitable grade for the designing of diesel engine mufflers. So critical

grade having [14] , I.L. = 25 to 35 dBA; Body Dia. of Muffler (Dm) / Exhaust Pipe Dia.(de) = 3; Length

of Muffler (Lm) / Exhaust Pipe Dia. (de) = 8- 10. Therefore; Dm= 3 x de = 3 x 40 = 120 mm (here de =

40 mm) & Lm= 8 x de to 10 x de = 8 x 40 to 10 x 40 = 320 mm to 400 mm B. Muffler Inner Reactive

Chamber Design For inner chambers design, it is requires to measure frequency at which peak noise

will be noted from the engine exhaust. Muffler inside reactive chamber length design by using

destructive phenomenon of sound wave and this was done by sound level meter attached with

frequency filter to get the value of frequencies at highest engine exhaust noise from which it can

found the length of inner reactive chamber. Here Bruel & Kjaer type 2235 Figure 1: Sound Level

Meter precision sound level meter used (Fig. 1) for measurement of noise from engine exhaust and

Bruel & Kjaer type 1625 frequency filter (Fig. 1) used to measurement of frequency range at peak

noise from engine [7] . From this experiment, it is found the reading of frequencies range at different

noise as shown in table 2. From this, graph of frequency v/s noise (fig.2) can plot and found the

three frequencies at which peak noises are recorded. From that length of muffler‟s Grades /

Parameters Industr -ial (or) Commrcial Residential Critical Super Critical Insertion Loss(DBA) 15 - 25

20 - 30 25 - 35 35 - 45 Body Dia. Of Muffler / Exhaust pipe Dia. 2 - 2.5 2 - 2.5 3 3 Length Of Muffler /

Exhaust pipe Dia. 5 - 6.5 6 - 10 8 - 10 10 - 16 SSRG International Journal of Mechanical Engineering

(SSRG - IJME) – Volume 4 Issue 6 June 2017 ISSN: 2348 – 8360 www.internationaljournalssrg.org

Page 26 reactive chamber will be calculated. From experiment found that the highest peak noise

occurs at middle range of frequencies, so select three frequency 500 Hz, 800 Hz & 1000 Hz (as shown

in fig. 2) at which peak noise from engine exhaust is noted. Muffler inside reactive chamber length

can design by using destructive phenomenon of sound wave. Destructive phenomenon says that the

destruction of sound wave occurs (maximum reduction of noise) when length of chamber is one

fourth of the wavelength [1], [3], [5], [7] . Table 2: Experimental Reading of Frequencies at Different

Noise Level Noise Frequency in Hz Noise level in DB 20 65.3 31.5 73 40 80 50 70.8 80 81 100 82.5 200

95 250 97.1 315 94 500 98 600 95 800 104 1000 97.9 1500 95.2 2500 83.7 3150 86.5 4000 74.4 5000

72.2 6300 65 8000 67.9 10000 65.2 12500 64.2 16000 62.7 20000 62.3 Figure 2: Noise V/S Frequency

Graph Mathematically; maximum noise reduction occurs when chamber length is, L = n x λ/4 ............

(1) The relation between the frequency and wavelength is given by; C = f x λ ............ (2) At STP speed

of sound is C = 332.4 m/s. Consider the three peak noise frequency 500Hz, 800Hz and 1000Hz for

designing (from experiment), So, from equation (2), • Wavelength for 500 Hz frequency is given by,

λ1 = C/f1 = 330/500 = 0.660 m = 660 mm Similarly, wavelength for frequencies 800 Hz and 1000 Hz;

λ2 = C/f2 = 330/800 = 0.4125 m = 412.5 mm, λ3 = C/f3 = 330/1000 = 0.33 m = 330 mm. Consider

above three calculated wavelength of sound wave, From equation (1), • Length of chamber for

wavelength λ1; L1 = λ1/4 = 660/4 = 165 mm Similarly for wavelengths λ2, λ3; L2 = λ2/4 = 103.125 ≅

103 mm, L3 = λ3/4 = 82.41 ≅ 82 mm • So, Length of reactive chamber is; Lmr1 = L1 + L2 = 268 mm

(for 2 reactive chamber) Lmr2 = L1 + L2 + L3 = 350 mm (for 3 reactive chamber) C. Design of Inner

pipes in Muffler It has been considered that the flow path diameter does not reduce at any point. If

flow path diameter reduces then there is possibility to produce a backpressure on the exhaust gases

and reduces the engine efficiency. So it improves the proper flow of the exhaust gases to the outlet

of the muffler and improves efficiency of engine [1], [3], [7], [9] . Therefore mathematically

described as, Ae = A1 + A2 π de 2 /4 = πd1 2 /4 + πd2 2 /4 402 = d1 2 + d2 2 2 d1 2 = 402 (Take, d1 =

d2 = muffler inner pipe diameter) d1 = √800 d1 = d2 = 28.28 mm ≅ 28 mm D. Design of Inlet and

Outlet Pipes Diameter From the literature survey found out that the diameter of inlet and outlet

pipes are taken same as the diameter of engine exhaust pipe and length of inlet and outlet pipes are

decide as per the engine space requirements. Therefore, Din = Dout = 40 mm E. Design of Absorptive

Part of Muffler Length of absorptive part of muffler is finding out by subtracting the muffler‟s

reactive part length from the total length of muffler. Therefore length of absorptive muffler is given

by, Lma1 = Lm - L1 - L2 = 400 – 268 = 132mm (for 3 chamber) 98 104 97.9 0 20 40 60 80 100 120

Noise in DB Frequency in Hz Noise V/S Frequency SSRG International Journal of Mechanical

Engineering (SSRG - IJME) – Volume 4 Issue 6 June 2017 ISSN: 2348 – 8360

www.internationaljournalssrg.org Page 27 Lma2 = Lm - L1 - L2 - L3 = 400 – 350 = 50mm (for 4

chamber) Here, three arrangement of muffler have a length of Lma1 and other three arrangement of

muffler have a length of Lma2. III.MUFFLER’S DIFFERENT ARRANGEMENTS Design inputs arrived

from theory of acoustics used to muffler design [5], [6], [7] , • Extended inlet and outlet in the

muffler will be minimum 55 to 75 mm for better attenuation results. • From benchmark and theory

three expansions chamber good for noise target for reactive muffler. • Noise reduction increases

with increase in a perforation hole sizes. • Inlet and outlet are introduced 180 deg reversal to

increase the acoustic performance. • Combined muffler gives better reduction in noise compare to

single reactive or absorptive muffler. By considering the above acoustics phenomenon and literature

review muffler can design by different arrangements. Muffler can design by different arrangements

like single exhaust, dual or twin exhaust, centre inlet – centre outlet, side inlet – side outlet,

changing the numbers of chambers, changing length of absorptive part of muffler, changing the

diameter of perforation holes etc. In this work different six arrangements of mufflers are designed.

All mufflers are combined type mufflers i.e. reactive and absorptive type muffler. Following six

alternative arrangements are manufactured and compared noise level from engine exhaust for all. 1.

Muffler with 3-chamber, single exhaust 2. Muffler with 3-chamber, single exhaust at side inlet and

side outlet 3. Muffler with 3-chamber, dual exhaust 4. Muffler with 4-chamber, single exhaust 5.

Muffler with 4-chamber, single exhaust at side inlet and side outlet 6. Muffler with 4-chamber, dual

exhaust Figure 3: Creo 2.0 - Drawings of all Different Muffler Arrangements In first three

arrangement of muffler having a total three chamber, in which two chambers are SSRG International

Journal of Mechanical Engineering (SSRG - IJME) – Volume 4 Issue 6 June 2017 ISSN: 2348 – 8360

www.internationaljournalssrg.org Page 28 reactive chamber and one is absorptive chamber.

Reactive chamber reduces a noise of lower frequencies 500 Hz and 800 Hz respectively while

absorptive chamber reduces a noise of higher frequencies above 1000Hz. In last three arrangement

of muffler having a total four chamber, in which three chambers are reactive chamber and one is

absorptive chamber. Reactive chamber reduces a noise of lower frequencies 500 Hz, 800 Hz and

1000 Hz respectively while absorptive chamber reduces a noise of higher frequencies above 1000Hz.

In this three arrangement length of absorptive part of muffler is reduced (132 mm to 50 mm)

compare to first three arrangements. Here different three type of exhaust system in muffler‟s

arrangement are taken; like single centre outlet exhaust, single side outlet exhaust and dual exhaust.

Figure - 3 shows the Creo Parametric 2.0 drawings (2-D) of all six type of arrangement. These all

arrangement of mufflers are manufacture and tested experimentally to measurement of noise level

for each muffler and select best muffler for given case study of 5 HP cooper diesel engine.

IV.MANUFACTURING OF MUFFLER Muffler must be sustaining high temperature and it has also high

corrosiveness. So muffler material must have high boiling point and high corrosion resistance.

Therefore generally material of all type of mufflers taken as mild steel or stainless steel, also mild

steel coated with aluminium that increases the corrosion resistivity of material. From literature

review and manual of muffler making companies found that the materials used for exhaust piping

and reactive mufflers mainly of ferrous alloys; Aluminium alloys are sometimes used as a coating on

ferrous alloys to impart additional corrosion resistance. (Exhaust products guide, Donaldson

Filtration Solution) [8], [14], [15], [4] . Generally muffler made from Sheet Steel; the aluminized mild

carbon steel and stainless steel (with or without coating of aluminium). Absorptive mufflers contain

sound-absorbing material such as fibreglass or wire wool [8]. This type of material absorbed the

pressure energy in form of the sound wave and this pressure energy converted into the heat energy

due to the friction in material therefore it results the reduction of noise level. Absorptive material

performance depends on their sound absorptive co-coefficient. Figure 4: Manufactured all Six

Arrangement of Muffler Mufflers manufacturing processes contains mainly cutting operations,

bending and press rolling operations, grinding operations, drilling operations, punching operations

and welding operation. First of all cutting operation will carry out on the mild steel sheet as per the

required dimensions of muffler then sheet will bended and pass out the press rolling process to give

the round shape of muffler. After that inner pipes and inlet – outlet pipes are welded on muffler

body as per the calculated design dimensions. Figure 5: Punching(Marking) at Inlet Pipes of Muffler

Figure - 4 show the all six manufactured mufflers with different arrangements. As shown in Figure –

5 punching operation carry out on inlet pipes with number one to six to easily identification of the

different arrangement of mufflers with their design drawings. Now these all mufflers are to be

tested experimentally on engine to identify best muffler which reduce more noise and noise level

comparison of all arrangement of mufflers are measured. V. EXPERIMENT AND RESULT This

experiment performs for measurement of noise level from engine exhaust without muffler and with

all arrangement mufflers. These experiments are useful to measurement of insertion loss of muffler.

Noise measurement was done with the sound level meter as per the ANSI technique of noise

measurement to get the optimum result of noise level. Figure 6: Experimental Setup for

Measurement of Noise Level from Engine Experimental setup for noise measurement is shown in

figure 5. As per the ANSI standard the microphone of sound level meter must be placed SSRG

International Journal of Mechanical Engineering (SSRG - IJME) – Volume 4 Issue 6 June 2017 ISSN:

2348 – 8360 www.internationaljournalssrg.org Page 29 behind the exhaust pipe at a distance of 50 ±

20 cm from the reference point of the exhaust pipe and at the same height as the reference point ±2

cm. Sound level meter place on an imaginary line at a 45° angle ±20° angle with respect to the

longitudinal axis of the exhaust pipe of the engine (figure - 5)[11], [16] . Table 3: Noise Level from

Engine - without Muffler & with all Six Mufflers at Different Loads Different Loads(kg) Noise Level in

DB (decibel) from Different Loading Conditions No Muffler With all Six Arrangements of Muffler 1 2 3

4 5 6 0 kg 109.5 82.3 83.3 81 79 81.4 77.1 2.26 kg (5 lb) 111.6 86.2 87.7 84.5 81.6 84.5 81.1 4.53 kg

(10 lb) 115.5 94.5 94.8 90.3 90.4 91.5 87.8 6.80 kg (15 lb) 118.1 97.1 98.9 94.6 92.3 93.1 90.1 9.07 kg

(20 lb) 121.9 99.4 101 97.2 95.1 95.9 92.7 Table 4: Insertion Loss of all Six Arrangement of Mufflers

Table 5: Average Insertion Loss of all Arrangements of Muffler Table 3 and Table 4 show the noise

level and Insertion Loss at different loads without muffler and with all six mufflers from engine

exhaust respectively. Now insertion loss calculated for each muffler, high insertion loss value

indicates the good muffler. Insertion loss calculated by following equation; I.L. (DB) = Noise level

before muffler attached – Noise level after muffler attached Below table 5 shows the average

Insertion loss for all loads. From this experiment it is found that the lowest noise level recorded for

muffler arrangement number six, which have four chambers and dual exhaust. Now figure number –

6 show the graph of the insertion loss comparison of all six arrangements of mufflers. Figure – 7

shows the graph (line chart) of insertion loss for all mufflers at different loads; from this found that

lowest I.L. noted for 2nd arrangement of muffler denoted as a Muffler 2 and highest I.L. noted for

6th arrangement of muffler denoted as a Muffler 6. Figure 7: Graph of Insertion Loss for all Mufflers

at Different Loads Different Loads(kg) I.L. in DB(Decibel) for all Muffler Arrangement at Different

Loading Condition 1 2 3 4 5 6 0 27. 2 26. 2 28. 5 30. 5 28. 1 32. 4 2.26 kg (5 lb) 25. 4 23. 9 27. 1 30 27.

1 30. 5 4.53 kg (10 lb) 21 20. 7 25. 2 25. 1 24 27. 7 6.80 kg (15 lb) 21 19. 2 23. 5 25. 8 25 28 9.07 kg

(20 lb) 22. 5 21. 1 24. 7 26. 8 26 29. 2 Muffler Different Arrangements Average I.L. in DB (Noise

Reduction) 1 23.42 2 22.22 3 25.80 4 27.64 5 26.04 6 29.56 SSRG International Journal of Mechanical

Engineering (SSRG - IJME) – Volume 4 Issue 6 June 2017 ISSN: 2348 – 8360

www.internationaljournalssrg.org Page 30 Muffler arrangement 4th and muffler arrangement 1 st

has a second highest I.L. (denoted as Muffler 4) & second lowest I.L. (denoted as Muffler 1)

respectively. Muffler arrangement 3rd and 5th has equal I.L. for 5 lb load; 3rd arrangement has more

I.L. than 5th arrangement for load 0 lb & 10 lb; and 3rd arrangement has lower I.L. than 5th

arrangement for 15 lb & 20 lb load. But average I.L. of 5th arrangement is more than 3rd

arrangement. Above experiment result shows that the high insertion loss found in a 6th muffler

arrangement. After that insertion loss are reduces in order of 4th, 5th , 3 rd, 1st, 2nd arrangement of

muffler. We observed that insertion loss higher in four chamber muffler compared to three chamber

muffler, dual exhaust muffler reduced high level of noise compared to single exhaust muffler, single

centre exhaust type muffler having high insertion loss compared to single side exhaust type muffler.

Therefore result shows that if numbers of chambers are increases in muffler then it gives high

reduction in noise and double exhaust muffler gives high I.L. compare to the single exhaust muffler

and single side outlet exhaust type mufflers having a lowest noise reduction. VI.CONCLUSIONS From

this research it is conclude that the muffler design is the trial and error type design; there will be

many possible muffler design solutions for a particular situation. Muffler can be design by the

different arrangements like single exhaust, dual or twin exhaust, centre inlet – centre outlet, side

inlet – side outlet, changing the numbers of chambers, changing length of absorptive part of muffler,

changing the diameter of perforation holes etc. The muffler can be designed by various methods to

achieve good performance. Combined muffler gives better reduction in noise compare to the single

reactive muffler or absorptive muffler. From the experimental comparison it is found the highest

noise reduction (29.56 db) noted for 6th arrangement of muffler which have 4 – chamber and dual

exhaust so that it is conclude that the high number of chamber and dual exhaust type muffler

reduces more noise compare to less number of chamber and single exhaust type muffler because it

has low resistance to exhaust the gases to atmosphere (due to the dual outlet – more outlet passage

area). Side single exhaust type muffler having lowest noise reduction (26.04 db - 5 th muffler &

22.22 db – 2 nd muffler) because travelling and resistance of exhaust gases are more in this type of

mufflers. Centre single exhaust type muffler‟s noise reduction (27.64 db - 4 th muffler & 23.42 db –

1 st muffler) is in middle range of dual exhaust & side single exhaust type mufflers. Noise reduction

in three chamber type mufflers is low compare to the four chamber type mufflers, therefore if

number of chamber increases in muffler it gives better reduction in noise. VII. NOMENCLATURE •

B.P. = Brake Power of Engine (HP) • DB or DBA = Unit of Noise Level – Decibel • I.L. = Insertion

Loss(db) • Dm = Diameter of Muffler Chamber (m) • Lm = Total length of Muffler (m) • de = Diameter

of Exhaust Pipe(m) • C = Sound Velocity of air • f = Frequency of Sound Wave (Hz) • λ = Wavelength

of the Sound (m) • L1 = Length of First Chamber of Muffler (m) • L2 = Length of Second Chamber of

Muffler (m) • L3 = Length of Third Chamber of Muffler (m) • Lmr = Length of Reactive Chamber of

Muffler (m) • d1 = Diameter of Inner Pipe 1(m) • d2 = Diameter of Inner Pipe 2(m) • N = Maximum

Engine Speed (rpm) • Din = Diameter of Muffler Inlet Pipe (m) • Dout = Diameter of Muffler Outlet

Pipe (m) • Lma = Length of Absorptive Chamber of Muffler (m) REFERENCES [1] Vinod Sherekar - PG

Scholar, P.R. Dhamangaonkar – “Design Principles for an Automotive Muffler”, - Mech. Engg.,

College of Engineering Pune, Maharashtra, India International Journal of Applied Engineering

Research, ISSN 0973-4562 Volume 9, Number 4 (2014). [2] Rajendra Kumar Kaushik, Prakash Kumar

Sen, Gopal Sahu, ”A review on a noise reduction system in IC engine”, Mechanical Engineering,

Kirodimal Institute of Technology, Raigarh, IJESRT(INTERNATIONAL JOURNAL OF ENGINEERING

SCIENCES & RESEARCH & TECHNOLOGY), October-2015, ISSN – 2277-9655. [3] Potente & Daniel,

“General design principles for an automotive muffler”, Day Design pty ltd, Acoustic Consultant,

Sydney, Australia, NOVEMBER-2005, [4] J.Kingston Barnabas, R.Ayyappan, M.R.Devaraj – “Design

and fabrication of exhaust silencer for construction equipment”, Anjalai Ammal Mahaligam

Engineering College, Kovilvenni – 614 403, Aksheyaa College of Engineering College, Pulidivakkam.-

603 304, “National Conference on Emerging Trends In Mechanical Engineering -2013.[14] [5] Shital

Shah – Defiance Technologies Ltd, Chennai; Saisankaranarayana K, Kalyankumar S. Hatti - Ashok

Leyland Technical Centre; Prof. D.G.Thombare - Rajarambapu Inst. Of Tech. Rajaramnagar, - “A

practical approach towards muffler design, development and prototype validation” - SAE

International Journal of Engines, September 2010 [6] M. Rahman, T. Sharmin, A F M E. Hassan, and

M. Al Nur, - “Design and construction of a muffler for engine exhaust noise reduction”, Department

of Mechanical Engineering, Bangladesh University of Engineering and Technology, Dhaka,

International Conference on Mechanical Engineering - 2005(ICME-2005) [7] S. Biswas –

“Combination muffler is more effective than reactive muffler even in small size”, Tata Motors Ltd,

Jamshedpur, Jharkhand - 831010, India, - International Conference paper – 2010 [8] Naresh M Kori –

“Performance Analysis Diesel Engine Silencer Design”, M.E. (Thermal Engineering), Department of

Mechanical Engineering, L. J. Institute of Engineering and Technology, Ahmadabad, May 2014, ISSN -

2250-1991[13] [9] Shubham Pal, Tejpreet Singh Golan, Vinod Kumar, Virag Jain, Nilesh Ramdas, O. P.

Sharma – “Design of muffler and effective resonator length for 3 cylinder SI engine”, IOSR SSRG

International Journal of Mechanical Engineering (SSRG - IJME) – Volume 4 Issue 6 June 2017 ISSN:

2348 – 8360 www.internationaljournalssrg.org Page 31 Journal of Mechanical and Civil Engineering

(IOSR-JMCE) eISSN: 2278-1684,p-ISSN: 2320-334X, Volume 11, Issue 3 Ver. VII (May- Jun. 2014), PP

85-91 [10] M. Rajasekhar Reddy & K. Madhava Reddy – “Design and optimization of exhaust muffler

in automobiles”, international journal of automobile engineering research and development (ijaerd),

issn 2277-4785 vol.2, issue 2 sep 2012. [11] Handbook of Acoustical – Measurement and Noise

Control by Cyril M. Harris, McGraw hill Publications [12] Vibration & Noise By Keval Pujara [13]

Engineering Noise Control By david a. Bies & colin h. Third Edition [14] Exhaust Silencers guide by

silex [15] Exhaust-Product-Guide by DONALDSON FILTRATION SOLUTION [16] Measurement of

exhaust pipe sound pressure levels of stationary motorcycles, Prepared by B. Lévesque, Department

of Mechanical Engineering, University Laval [17]

https://en.wikipedia.org/wiki/Internal_combustion_engine/Ap plications

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- How To Calculate Markup PercentageDokument4 SeitenHow To Calculate Markup Percentage7761430Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Mod 4 Revision Guide 1 Reaction Kinetics AQA A2 ChemistryDokument5 SeitenMod 4 Revision Guide 1 Reaction Kinetics AQA A2 Chemistryviyas07Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Basics of Pipe Stress Analysis-PartDokument5 SeitenBasics of Pipe Stress Analysis-Part7761430Noch keine Bewertungen

- Pre Calculus MIdTermsDokument5 SeitenPre Calculus MIdTermsLamette Austria Ayong0% (1)

- Form in MusicDokument8 SeitenForm in MusicAndri KurniawanNoch keine Bewertungen

- Step by Step Methods For WRC 107 (WRC 537) and WRC 297 CDokument13 SeitenStep by Step Methods For WRC 107 (WRC 537) and WRC 297 C7761430Noch keine Bewertungen

- DLT Strand Jack Systems - 2.0 - 600 PDFDokument24 SeitenDLT Strand Jack Systems - 2.0 - 600 PDFganda liftindoNoch keine Bewertungen

- 3 Perform Industry CalculationsDokument90 Seiten3 Perform Industry CalculationsRobinson ConcordiaNoch keine Bewertungen

- Hungarian NotationDokument6 SeitenHungarian NotationmelpaniNoch keine Bewertungen

- Estimating QuotientsDokument7 SeitenEstimating Quotientssheila mae neri100% (1)

- Extreme Fiber Elongation CalculationsDokument1 SeiteExtreme Fiber Elongation Calculations7761430Noch keine Bewertungen

- 6061 - T6 Aluminum Association I-BeamDokument1 Seite6061 - T6 Aluminum Association I-Beam7761430Noch keine Bewertungen

- API 6A Gate Valves-RefDokument3 SeitenAPI 6A Gate Valves-Ref7761430Noch keine Bewertungen

- Navigating in Catalog Manager: Connect To A DatabaseDokument3 SeitenNavigating in Catalog Manager: Connect To A Database7761430Noch keine Bewertungen

- UG-25 RefDokument1 SeiteUG-25 Ref7761430Noch keine Bewertungen

- Design Problems of Anchoring of Aboveground Steel Tanks: Lyubomir ZdravkovDokument1 SeiteDesign Problems of Anchoring of Aboveground Steel Tanks: Lyubomir Zdravkov7761430Noch keine Bewertungen

- Galvanized Anchor Bolts - Light PolesDokument1 SeiteGalvanized Anchor Bolts - Light Poles7761430Noch keine Bewertungen

- PTS1Dokument1 SeitePTS17761430Noch keine Bewertungen

- Anchor Rods (Thread Each End) : Part Number Diameter Length Grade Top Thread Bottom Thread FinishDokument2 SeitenAnchor Rods (Thread Each End) : Part Number Diameter Length Grade Top Thread Bottom Thread Finish7761430Noch keine Bewertungen

- Wm1 - Bolt Load Calculation: (Channel Flange)Dokument5 SeitenWm1 - Bolt Load Calculation: (Channel Flange)7761430Noch keine Bewertungen

- 3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of ComponentsDokument1 Seite3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of Components7761430Noch keine Bewertungen

- Error/Warning Messages For WRC107 Analysis 1 Warning - The Ratio Ro/Rm, 0.6313, Must Be 0.0571 and 0.571Dokument1 SeiteError/Warning Messages For WRC107 Analysis 1 Warning - The Ratio Ro/Rm, 0.6313, Must Be 0.0571 and 0.5717761430Noch keine Bewertungen

- TPG Mobile Terms and Conditions: 1. The AgreementDokument5 SeitenTPG Mobile Terms and Conditions: 1. The Agreement7761430Noch keine Bewertungen

- 13 Heat Exchanger TubesheetsDokument1 Seite13 Heat Exchanger Tubesheets7761430Noch keine Bewertungen

- More Details About My Computer: Print This Page Component Details Subscore Base Score Determined by Lowest SubscoreDokument1 SeiteMore Details About My Computer: Print This Page Component Details Subscore Base Score Determined by Lowest Subscore7761430Noch keine Bewertungen

- Proverb English Translation: LeavesDokument2 SeitenProverb English Translation: Leaves7761430Noch keine Bewertungen

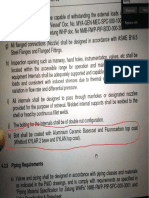

- Bolt Coating RequirementDokument1 SeiteBolt Coating Requirement7761430Noch keine Bewertungen

- Photo Luminescence of Surfaces and InterfacesDokument25 SeitenPhoto Luminescence of Surfaces and InterfacesNick KellerNoch keine Bewertungen

- W.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)Dokument371 SeitenW.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)El equipo de Genesis ProjectNoch keine Bewertungen

- Configuration A: Unloaded BJT Transistor AmplifiersDokument3 SeitenConfiguration A: Unloaded BJT Transistor AmplifiersdasdNoch keine Bewertungen

- Yang Learning Face Age CVPR 2018 PaperDokument9 SeitenYang Learning Face Age CVPR 2018 Paperandr234ibateraNoch keine Bewertungen

- DLP Mathematics 6 q1 w6Dokument5 SeitenDLP Mathematics 6 q1 w6Kathlyn PerezNoch keine Bewertungen

- WhiteLED1 8Dokument12 SeitenWhiteLED1 8Smyle KatariaNoch keine Bewertungen

- Computational Neuroscience CW1 (Bristol)Dokument3 SeitenComputational Neuroscience CW1 (Bristol)libannfNoch keine Bewertungen

- Sample Papers ScienceDokument199 SeitenSample Papers SciencerkkanodiaNoch keine Bewertungen

- List of Knapsack Problems: 2 Multiple ConstraintsDokument3 SeitenList of Knapsack Problems: 2 Multiple ConstraintssaiNoch keine Bewertungen

- en Product OverviewDokument81 Seitenen Product OverviewShakeel AhmedNoch keine Bewertungen

- 23AE23 DS enDokument4 Seiten23AE23 DS enBhageerathi SahuNoch keine Bewertungen

- Reaktor 5 Core Manual EnglishDokument210 SeitenReaktor 5 Core Manual EnglishmonistoNoch keine Bewertungen

- Improving of Transient Stability of Power Systems Using UPFCDokument6 SeitenImproving of Transient Stability of Power Systems Using UPFCTana AzeezNoch keine Bewertungen

- HST TrainingDokument11 SeitenHST TrainingRamesh BabuNoch keine Bewertungen

- Triosonate in F (TWV 42-F7)Dokument17 SeitenTriosonate in F (TWV 42-F7)EDMILSON BRUNO DO NASCIMENTONoch keine Bewertungen

- Best Approach: Compound AngleDokument8 SeitenBest Approach: Compound AngleAbhiyanshu KumarNoch keine Bewertungen

- Ee-502 Unit - IDokument2 SeitenEe-502 Unit - IVARAPRASADNoch keine Bewertungen

- CISCO Router Software - Configuration PDFDokument408 SeitenCISCO Router Software - Configuration PDFasalihovicNoch keine Bewertungen

- Technical Description: T610 Radio On The Tranceiver Board: ContentsDokument16 SeitenTechnical Description: T610 Radio On The Tranceiver Board: ContentsHeru AndikaNoch keine Bewertungen

- MTH 108Dokument10 SeitenMTH 108GetlozzAwabaNoch keine Bewertungen

- FlopX NT5.1 Patch V1aDokument5 SeitenFlopX NT5.1 Patch V1aAmilcar AndradeNoch keine Bewertungen

- Assignment 1Dokument3 SeitenAssignment 1Carolyn WangNoch keine Bewertungen

- Air Conditioner: Owner'S ManualDokument80 SeitenAir Conditioner: Owner'S Manualfred MaxNoch keine Bewertungen