Beruflich Dokumente

Kultur Dokumente

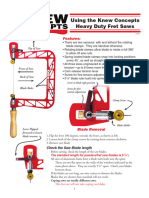

Razor Edge Guide Instructions

Hochgeladen von

Rafael DueñasOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Razor Edge Guide Instructions

Hochgeladen von

Rafael DueñasCopyright:

Verfügbare Formate

TRUE HOLLOW GRIND WEDGE GRIND CHISEL GRIND BLUNT GRIND

FIGURE 1 FIGURE 2 FIGURE 3 FIGURE 4

Razor Edge Guide and Cub Guide Anatomy

1/2” 1/2” 1/2” 1/2”

CLAMP

FEET

GUIDE BAR

Obtaining a burr the full length ofTRUE

the HOLLOW

blade isGRIND

critical toWEDGE GRIND CHISEL GRIND BLUNT GRIND

CLAMPING

SCREW CLAMP

achieving a sharp edge. To begin, place the

FIGURE 1

rubber pad FIGURE 2 FIGURE 3 FIGURE 4

FEET

under the hone. Using the coarse hone and with the knife BLADE FIGURE 6A FIGURE 6B

mounted securely in the clamp, begin grinding in a

circular or back and forth motion from handle to tip. Keep

the guide in contact with the hone at all times as this

FIGURE 6 THICKNESS

ADJUSTMENT

CORRECT INCORRECT

SHARPENING INSTRUCTIONS

provides a constant and consistent angle. Obtaining a NOTICE: It is important that these instructions are carefully studied and followed to achieve the best results.

burr may happen quickly or take up to 5 minutes or more

Razor Edge Guide and Cub Guide Anatomy

depending on the relief of the knife edge. When the burr

is obtained on the first side, flip the knife over

CLAMPand repeat

KNIFE BLADE GENERAL INFORMATION

FEET

the process on the second side. Make sure the GUIDE burrBARis Before going into the actual sharpening, it is most important to understand the edge, or relief of the knife we are going to sharpen.

BURR TURNED

felt from handle to tip. To grind tip area simply raise knife

CLAMPING

UP BY HONE A good relief will sharpen very quickly and can achieve a very high-quality edge. A knife with a poor relief will be very difficult to

SCREW HONE

handle keeping the guide bar in contact with hone at all CLAMP sharpen and have a poor edge as inHONE

COARSE figure 4. Unfortunately,

COARSE many

HONE quality knives SHADED

are manufactured with poor relief. The edges on

AREA: EDGE FACE

FEET

times. (Figure 9) these knives can be tapered back easily to a wedge grind (Fig. 2) by using the coarse hone. Remember, your knife is only as good as

BLADE FIGURE 6A FIGURE 6B its relief. B

FIGURE 6 THICKNESS FIGURE 7 FIGURE 8 C

ADJUSTMENT

CORRECT INCORRECT A

FINAL HONING FIGURE 9

After obtaining a burr on the second side it is now time to 1. The true hollow grind will produce the ultimate in an edge.

FIGURE 5

(Fig 1)

FIGURE 5A FIGURE A

put on the edge using the fine hone. Starting at the far end 2. The wedge grind will produce a very satisfactory edge. The thinner it is tapered back,

of the hone, place the guide bar on the hone BEFORE the the more desirable the edge will be.(Fig 2)

edge touches the hone. If the edge contacts the hone 3. The chisel grind should be tapered back to a wedge grind, or hollow ground. (Fig.3)

before the guide the edge can be ruined.KNIFE

Starting

BLADE nearest

4. The blunt grind should also be tapered or hollow ground. (Fig. 4)

the handle, draw the blade across the hone finishing at

BURR TURNED

the tip. Flip the knife over and repeat with alternating

UP BY HONE

HONE

strokes always going INTO the cutting edge as shown in

Figure 10 until the edge feels smooth (10 or more stokes

on each side). VERY IMPORTANT to make sure the guide

FIGURE 7 FIGURE 8 FIGURE 11

bar always contacts the hone before the blade does. 1/2” 1/2” 1/2” 1/2”

DOUBLE EDGING - The Ultimate Sharpness FIGURE 10 TRUE HOLLOW GRIND WEDGE GRIND CHISEL GRIND BLUNT GRIND

After final honing the knife will be very sharp, but can be FIGURE 1 FIGURE 2 FIGURE 3 FIGURE 4

greatly improved with the following simple steps. Loosen

and move the Guide down towards the cutting edge about

1/16” and out towards the tip of the blade approximately

1/16”. (Fig10) Using ONLY the fine stone alternate strokes

with very light pressure – 10 on each side. WHAT WE ARE TRYING TO DO

FIGURE 11 Razor Edge

Before we go any further let’s understand what we Guide

are working andtowardCub Guide The

accomplishing. Anatomy

goal is to ultimately prepare the edge

If you have followed the procedure, you have for the sharpening process for achieving a very sharp edge. It is important to understand figures1 – 5A are highly magnified and

a true Razor Edge. Caution! Handle your CLAMP

exaggerated drawings of the cutting edge.

FEET A knife edge resembling the Blunt Grind, (Fig 4) must be thinned out to resemble the

knife with care. GUIDE BAR

wedge grind (Fig 2) Note how this has been done in Fig. 5A. Lines AB and AC are the flat sides we have ground down with the coarse

CLAMPING

FIGURE 10 hone to obtain a better relief. They are called “edgeSCREW

faces,” (Fig. A) and CLAMP

are easy to see under a good light. If during the sharpening

Note: The best edges will be obtained using dry stones. process the edge face appears to be any wider than sewing thread youFEET can improve your edge by removing the Razor Edge guide

Always use the rubber pad provided with the hone to and tapering back the relief on your knife, as indicated

BLADE by the dotted FIGURE

lines 6A

on Fig. 5A. FIGURE 6B

prevent slippage. FIGURE 6 THICKNESS

ADJUSTMENT

CORRECT INCORRECT

COARSE HONE COARSE HONE SHADED AREA: EDGE FACE

B

KNIFE BLADE C

A

BURR TURNED

FIGURE 5 UP BY HONE FIGURE 5A FIGURE A

HONE

3 0 3 N 1 7 T H A V E E , E LY, M N 5 5 7 3 1 | 800-541-1458 | www.razoredgesystems.com

FIGURE 7 FIGURE 8

COARSE HONE

COARSE HONE COARSE HONE

COARSE HONE SHADED AREA:

SHADED

EDGE

AREA:

FACEEDGE FACE

B B

C C

A A

FIGURE 5 FIGURE 5 FIGURE 5AFIGURE 5A FIGURE A FIGURE A

Tapering the relief is not necessary for all blades and can be skipped if desired; however, you may not end up with the Mounting the Cub Guide will vary per knife due to varying blade sizes. What is most important is, 1) The clamp feet are

sharpest edge and the actual sharpening process may take longer. Tapering the knife relief is accomplished by parallel to the blade edge, 2) One inch or more of the blade tip protrudes beyond the guide bar and, 3) As much of the

following these easy steps: blade as possible is protruding from the clamp feet (up to approximately ¾”). Cub Guide is mounted with the long end of

the guide bar toward the knife tip (Exam 1a), but can be mounted the opposite direction for very short blades so that the

1. Lay the knife flat against the hone then raise the spine (back of the knife) off the hone tip of the knife can still be sharpened. (Exam 1b)

2. Grind the full length of the edge in a circular or back and forth motion to remove the unnecessary metal and thin the

1/2”

cutting edge to the desired thickness. 1/2”

Repeat this

1/2”process

1/2”on the1/2”

opposite

1/2”side of the

1/2”knife.1/2”

When finished the edge

should now be ready for the sharpening process.

COARSE HONE

COARSE HONE COARSE HONE

COARSE HONE SHADED AREA:

SHADED

EDGEAREA:

FACE EDGE FAC

TRUE HOLLOW

TRUEGRIND

HOLLOW GRIND

WEDGE GRIND

WEDGE GRIND

CHISEL GRIND

CHISEL GRIND

BLUNT GRIND

BLUNT GRIND

B B

FIGURE 1 FIGURE 1 FIGURE 2 FIGURE 2 FIGURE 3 FIGURE 3 FIGURE 4 FIGURE 4 C C

A A

EXAMPLE 1a EXAMPLE 1b FIGURE 5 FIGURE 5 FIGURE 5A EXAMPLE

FIGURE2 5A FIGURE A FIGURE A

RAZOR EDGE GUIDE AND CORRECT GUIDE

CUB GUIDE ANATOMY ADJUSTMENT

RazorRazor

Edge Edge

GuideGuide

and Cub

and Guide

Cub Guide

Anatomy

Anatomy Razor Edge Guide (Blades over 3 ½”)

CLAMP CLAMP

For sharpening long, thin blades such as filet knives, 1) Mount the guide in approximately the center of the knife or

FEET FEET

GUIDE BAR GUIDE BAR

approximately 2” from the tip with clamp feet parallel to the cutting edge, 2) Clamp enough of the blade to get a firm hold.

CLAMPING CLAMPING

(Example 3) Rule of thumb for most other blades over 3 ½” is 1) The guide should be mounted approximately 1 ½” from

SCREW SCREW CLAMP

FEET

CLAMP

FEET

the tip with the guide feet parallel to the knife edge and 2) Approximately ½” - ¾” of the knife should be protruding from

the clamp feet. This distance may be more depending on the depth of the blade.

BLADE BLADE FIGURE 6AFIGURE 6A FIGURE 6BFIGURE 6B 1/2” 1/2” 1/2” 1/2” 1/2” 1/2” 1/2” 1/2”

FIGURE 6 FIGURE 6 THICKNESS THICKNESS

ADJUSTMENTADJUSTMENT

CORRECT CORRECT INCORRECT

INCORRECT

The two blade thickness adjustment screws are designed to TRUE HOLLOW

TRUE

GRIND

HOLLOW GRIND

WEDGE GRIND

WEDGE GRIND

CHISEL GRIND

CHISEL GRIND

BLUNT GRIND

BLUNT GRIND

adjust to the thickness and taper of a knife blade. The clamp

feet should lie flat on the blade (Figure 6A), rather than contact FIGURE 1 FIGURE 1 FIGURE 2 FIGURE 2FIGURE 3 FIGURE 3 FIGURE 4 FIGURE 4

in one spot (Figure 6B). If the mounted blade resembles 6B

screw in the small allen screws until the clamp lays flat against

the blade.

KNIFE BLADEKNIFE BLADE EXAMPLE 3 EXAMPLE 4 EXAMPLE 5

BURR TURNEDBURR TURNED

UP BY HONE UP BY HONE

HONE HONE

Razor Razor

Edge Guide

Edge Guide

and Cub

andGuide

Cub Guide

Anatomy

Anatomy

Chef Knives

FIGURE 7 FIGURE 7 FIGURE 8 FIGURE 8 CLAMP CLAMP

MOUNTING THE GUIDE Extra-large blades, such as the chef knife, will not followFEET

the typical

FEET

GUIDE BAR GUIDE BAR

There are two methods for clamping a knife. First method is the table mount method. Lay the knife guide on a surface, slide sharpening pattern due to the blade depth. The 10” chef knife, as an

CLAMPING CLAMPING

the knife into the clamping position per instructions for your size knife blade, and tighten it down using the largest allen example, is best sharpened in two sections but can be done withoutSCREW SCREW CLAMP CLAMP

FEET FEET

wrench. The second method is by holding the clamp in the hand, positioning the knife into the correct clamping position moving the guide if using 8” hones. The guide will need to be mounted

and tightening it down. Even tough there are many types and sizes of knives if you follow the mounting instructions as approximately 2” from the tip and the guide feet approximately ¾”BLADE

from BLADE FIGURE 6A FIGURE 6A FIGURE 6B FIGURE 6B

FIGURE 6 FIGURE 6 THICKNESS THICKNESS

closely as you can for the example that most resembles your blade you will have great results. the cutting edge. ADJUSTMENT ADJUSTMENT

EXAMPLE 6

CORRECT CORRECT INCORRECTINCORREC

TABLE MOUNT METHOD HAND MOUNTING METHOD (3 PICTS)

OBTAINING THE BURR

FIGURE 11FIGURE 11 KNIFE BLADE KNIFE BLADE

Burr definition: A protruding, ragged edge created by

the coarse hone and rolled upward and away from the BURR TURNEDBURR TURNED

UP BY HONE UP BY HONE

side of the knife edge that is in contact with the hone HONE HONE

(fig_7). The burr is created with the coarse hone and

FIGURE 10FIGURE 10 may be too small to see but can be felt using your finger

nail or finger (fig 8). FIGURE 7 FIGURE 7 FIGURE 8 FIGURE 8

COARSE HONE

COARSE HONE COARSE HONE

COARSE HONE SHADED AREA:

SHADED

EDGE

AREA:

FACEEDGE FACE

B B

C C

A A

FIGURE 5 FIGURE 5 FIGURE 5AFIGURE 5A FIGURE A FIGURE A

Tapering the relief is not necessary for all blades and can be skipped if desired; however, you may not end up with the Mounting the Cub Guide will vary per knife due to varying blade sizes. What is most important is, 1) The clamp feet are

sharpest edge and the actual sharpening process may take longer. Tapering the knife relief is accomplished by parallel to the blade edge, 2) One inch or more of the blade tip protrudes beyond the guide bar and, 3) As much of the

following these easy steps: blade as possible is protruding from the clamp feet (up to approximately ¾”). Cub Guide is mounted with the long end of

the guide bar toward the knife tip (Exam 1a), but can be mounted the opposite direction for very short blades so that the

1. Lay the knife flat against the hone then raise the spine (back of the knife) off the hone tip of the knife can still be sharpened. (Exam 1b)

2. Grind the full length of the edge in a circular or back and forth motion to remove the unnecessary metal and thin the

1/2”

cutting edge to the desired thickness. 1/2”

Repeat this

1/2”process

1/2”on the1/2”

opposite

1/2”side of the

1/2”knife.1/2”

When finished the edge

should now be ready for the sharpening process.

COARSE HONE

COARSE HONE COARSE HONE

COARSE HONE SHADED AREA:

SHADED

EDGEAREA:

FACE EDGE FAC

TRUE HOLLOW

TRUEGRIND

HOLLOW GRIND

WEDGE GRIND

WEDGE GRIND

CHISEL GRIND

CHISEL GRIND

BLUNT GRIND

BLUNT GRIND

B B

FIGURE 1 FIGURE 1 FIGURE 2 FIGURE 2 FIGURE 3 FIGURE 3 FIGURE 4 FIGURE 4 C C

A A

EXAMPLE 1a EXAMPLE 1b FIGURE 5 FIGURE 5 FIGURE 5A EXAMPLE

FIGURE2 5A FIGURE A FIGURE A

RAZOR EDGE GUIDE AND CORRECT GUIDE

CUB GUIDE ANATOMY ADJUSTMENT

RazorRazor

Edge Edge

GuideGuide

and Cub

and Guide

Cub Guide

Anatomy

Anatomy Razor Edge Guide (Blades over 3 ½”)

CLAMP CLAMP

For sharpening long, thin blades such as filet knives, 1) Mount the guide in approximately the center of the knife or

FEET FEET

GUIDE BAR GUIDE BAR

approximately 2” from the tip with clamp feet parallel to the cutting edge, 2) Clamp enough of the blade to get a firm hold.

CLAMPING CLAMPING

(Example 3) Rule of thumb for most other blades over 3 ½” is 1) The guide should be mounted approximately 1 ½” from

SCREW SCREW CLAMP

FEET

CLAMP

FEET

the tip with the guide feet parallel to the knife edge and 2) Approximately ½” - ¾” of the knife should be protruding from

the clamp feet. This distance may be more depending on the depth of the blade.

BLADE BLADE FIGURE 6AFIGURE 6A FIGURE 6BFIGURE 6B 1/2” 1/2” 1/2” 1/2” 1/2” 1/2” 1/2” 1/2”

FIGURE 6 FIGURE 6 THICKNESS THICKNESS

ADJUSTMENTADJUSTMENT

CORRECT CORRECT INCORRECT

INCORRECT

The two blade thickness adjustment screws are designed to TRUE HOLLOW

TRUE

GRIND

HOLLOW GRIND

WEDGE GRIND

WEDGE GRIND

CHISEL GRIND

CHISEL GRIND

BLUNT GRIND

BLUNT GRIND

adjust to the thickness and taper of a knife blade. The clamp

feet should lie flat on the blade (Figure 6A), rather than contact FIGURE 1 FIGURE 1 FIGURE 2 FIGURE 2FIGURE 3 FIGURE 3 FIGURE 4 FIGURE 4

in one spot (Figure 6B). If the mounted blade resembles 6B

screw in the small allen screws until the clamp lays flat against

the blade.

KNIFE BLADEKNIFE BLADE EXAMPLE 3 EXAMPLE 4 EXAMPLE 5

BURR TURNEDBURR TURNED

UP BY HONE UP BY HONE

HONE HONE

Razor Razor

Edge Guide

Edge Guide

and Cub

andGuide

Cub Guide

Anatomy

Anatomy

Chef Knives

FIGURE 7 FIGURE 7 FIGURE 8 FIGURE 8 CLAMP CLAMP

MOUNTING THE GUIDE Extra-large blades, such as the chef knife, will not followFEET

the typical

FEET

GUIDE BAR GUIDE BAR

There are two methods for clamping a knife. First method is the table mount method. Lay the knife guide on a surface, slide sharpening pattern due to the blade depth. The 10” chef knife, as an

CLAMPING CLAMPING

the knife into the clamping position per instructions for your size knife blade, and tighten it down using the largest allen example, is best sharpened in two sections but can be done withoutSCREW SCREW CLAMP CLAMP

FEET FEET

wrench. The second method is by holding the clamp in the hand, positioning the knife into the correct clamping position moving the guide if using 8” hones. The guide will need to be mounted

and tightening it down. Even tough there are many types and sizes of knives if you follow the mounting instructions as approximately 2” from the tip and the guide feet approximately ¾”BLADE

from BLADE FIGURE 6A FIGURE 6A FIGURE 6B FIGURE 6B

FIGURE 6 FIGURE 6 THICKNESS THICKNESS

closely as you can for the example that most resembles your blade you will have great results. the cutting edge. ADJUSTMENT ADJUSTMENT

EXAMPLE 6

CORRECT CORRECT INCORRECTINCORREC

TABLE MOUNT METHOD HAND MOUNTING METHOD (3 PICTS)

OBTAINING THE BURR

FIGURE 11FIGURE 11 KNIFE BLADE KNIFE BLADE

Burr definition: A protruding, ragged edge created by

the coarse hone and rolled upward and away from the BURR TURNEDBURR TURNED

UP BY HONE UP BY HONE

side of the knife edge that is in contact with the hone HONE HONE

(fig_7). The burr is created with the coarse hone and

FIGURE 10FIGURE 10 may be too small to see but can be felt using your finger

nail or finger (fig 8). FIGURE 7 FIGURE 7 FIGURE 8 FIGURE 8

TRUE HOLLOW GRIND WEDGE GRIND CHISEL GRIND BLUNT GRIND

FIGURE 1 FIGURE 2 FIGURE 3 FIGURE 4

Razor Edge Guide and Cub Guide Anatomy

1/2” 1/2” 1/2” 1/2”

CLAMP

FEET

GUIDE BAR

Obtaining a burr the full length ofTRUE

the HOLLOW

blade isGRIND

critical toWEDGE GRIND CHISEL GRIND BLUNT GRIND

CLAMPING

SCREW CLAMP

achieving a sharp edge. To begin, place the

FIGURE 1

rubber pad FIGURE 2 FIGURE 3 FIGURE 4

FEET

under the hone. Using the coarse hone and with the knife BLADE FIGURE 6A FIGURE 6B

mounted securely in the clamp, begin grinding in a

circular or back and forth motion from handle to tip. Keep

the guide in contact with the hone at all times as this

FIGURE 6 THICKNESS

ADJUSTMENT

CORRECT INCORRECT

SHARPENING INSTRUCTIONS

provides a constant and consistent angle. Obtaining a NOTICE: It is important that these instructions are carefully studied and followed to achieve the best results.

burr may happen quickly or take up to 5 minutes or more

Razor Edge Guide and Cub Guide Anatomy

depending on the relief of the knife edge. When the burr

is obtained on the first side, flip the knife over

CLAMPand repeat

KNIFE BLADE GENERAL INFORMATION

FEET

the process on the second side. Make sure the GUIDE burrBARis Before going into the actual sharpening, it is most important to understand the edge, or relief of the knife we are going to sharpen.

BURR TURNED

felt from handle to tip. To grind tip area simply raise knife

CLAMPING

UP BY HONE A good relief will sharpen very quickly and can achieve a very high-quality edge. A knife with a poor relief will be very difficult to

SCREW HONE

handle keeping the guide bar in contact with hone at all CLAMP sharpen and have a poor edge as inHONE

COARSE figure 4. Unfortunately,

COARSE many

HONE quality knives SHADED

are manufactured with poor relief. The edges on

AREA: EDGE FACE

FEET

times. (Figure 9) these knives can be tapered back easily to a wedge grind (Fig. 2) by using the coarse hone. Remember, your knife is only as good as

BLADE FIGURE 6A FIGURE 6B its relief. B

FIGURE 6 THICKNESS FIGURE 7 FIGURE 8 C

ADJUSTMENT

CORRECT INCORRECT A

FINAL HONING FIGURE 9

After obtaining a burr on the second side it is now time to 1. The true hollow grind will produce the ultimate in an edge.

FIGURE 5

(Fig 1)

FIGURE 5A FIGURE A

put on the edge using the fine hone. Starting at the far end 2. The wedge grind will produce a very satisfactory edge. The thinner it is tapered back,

of the hone, place the guide bar on the hone BEFORE the the more desirable the edge will be.(Fig 2)

edge touches the hone. If the edge contacts the hone 3. The chisel grind should be tapered back to a wedge grind, or hollow ground. (Fig.3)

before the guide the edge can be ruined.KNIFE

Starting

BLADE nearest

4. The blunt grind should also be tapered or hollow ground. (Fig. 4)

the handle, draw the blade across the hone finishing at

BURR TURNED

the tip. Flip the knife over and repeat with alternating

UP BY HONE

HONE

strokes always going INTO the cutting edge as shown in

Figure 10 until the edge feels smooth (10 or more stokes

on each side). VERY IMPORTANT to make sure the guide

FIGURE 7 FIGURE 8 FIGURE 11

bar always contacts the hone before the blade does. 1/2” 1/2” 1/2” 1/2”

DOUBLE EDGING - The Ultimate Sharpness FIGURE 10 TRUE HOLLOW GRIND WEDGE GRIND CHISEL GRIND BLUNT GRIND

After final honing the knife will be very sharp, but can be FIGURE 1 FIGURE 2 FIGURE 3 FIGURE 4

greatly improved with the following simple steps. Loosen

and move the Guide down towards the cutting edge about

1/16” and out towards the tip of the blade approximately

1/16”. (Fig10) Using ONLY the fine stone alternate strokes

with very light pressure – 10 on each side. WHAT WE ARE TRYING TO DO

FIGURE 11 Razor Edge

Before we go any further let’s understand what we Guide

are working andtowardCub Guide The

accomplishing. Anatomy

goal is to ultimately prepare the edge

If you have followed the procedure, you have for the sharpening process for achieving a very sharp edge. It is important to understand figures1 – 5A are highly magnified and

a true Razor Edge. Caution! Handle your CLAMP

exaggerated drawings of the cutting edge.

FEET A knife edge resembling the Blunt Grind, (Fig 4) must be thinned out to resemble the

knife with care. GUIDE BAR

wedge grind (Fig 2) Note how this has been done in Fig. 5A. Lines AB and AC are the flat sides we have ground down with the coarse

CLAMPING

FIGURE 10 hone to obtain a better relief. They are called “edgeSCREW

faces,” (Fig. A) and CLAMP

are easy to see under a good light. If during the sharpening

Note: The best edges will be obtained using dry stones. process the edge face appears to be any wider than sewing thread youFEET can improve your edge by removing the Razor Edge guide

Always use the rubber pad provided with the hone to and tapering back the relief on your knife, as indicated

BLADE by the dotted FIGURE

lines 6A

on Fig. 5A. FIGURE 6B

prevent slippage. FIGURE 6 THICKNESS

ADJUSTMENT

CORRECT INCORRECT

COARSE HONE COARSE HONE SHADED AREA: EDGE FACE

B

KNIFE BLADE C

A

BURR TURNED

FIGURE 5 UP BY HONE FIGURE 5A FIGURE A

HONE

3 0 3 N 1 7 T H A V E E , E LY, M N 5 5 7 3 1 | 800-541-1458 | www.razoredgesystems.com

FIGURE 7 FIGURE 8

Das könnte Ihnen auch gefallen

- 121E Gear Cutting by Hobbing (20070930)Dokument51 Seiten121E Gear Cutting by Hobbing (20070930)Jaskaran SinghNoch keine Bewertungen

- Cortar CirculosDokument7 SeitenCortar CirculosarenasrubenNoch keine Bewertungen

- Johnny Rabb - The Official Freehand Technique PDFDokument6 SeitenJohnny Rabb - The Official Freehand Technique PDFBruno Quispe TiconaNoch keine Bewertungen

- Headspace and TimingDokument3 SeitenHeadspace and Timingblazerman3100% (1)

- Fluoride - Wide Range of Serious Health Problems"Dokument29 SeitenFluoride - Wide Range of Serious Health Problems"zataullah100% (2)

- Band Saw Circle Jig: ©2019 Cruz Bay Publishing, Inc. An Active Interest Media CompanyDokument2 SeitenBand Saw Circle Jig: ©2019 Cruz Bay Publishing, Inc. An Active Interest Media Companykostas1977100% (1)

- TL 02006 Z Q Head ManualDokument9 SeitenTL 02006 Z Q Head ManualMagno AguiarNoch keine Bewertungen

- Nyambe African Adventures An Introduction To African AdventuresDokument5 SeitenNyambe African Adventures An Introduction To African AdventuresKaren LeongNoch keine Bewertungen

- Autodesk Nastran In-CAD PDFDokument43 SeitenAutodesk Nastran In-CAD PDFFernando0% (1)

- Stochastic ProcessesDokument264 SeitenStochastic Processesmanosmill100% (1)

- Dfs-230 Assault GliderDokument1 SeiteDfs-230 Assault GliderCARMEN JUANA CRUZ CONDEMAITANoch keine Bewertungen

- Em FlexicokingDokument8 SeitenEm FlexicokingHenry Saenz0% (1)

- Application of Contemporary Fibers in Apparel - LyocellDokument5 SeitenApplication of Contemporary Fibers in Apparel - LyocellVasant Kothari100% (1)

- TAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1Dokument69 SeitenTAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1matheus santosNoch keine Bewertungen

- Pieza de Mano NSK PANA AIRDokument12 SeitenPieza de Mano NSK PANA AIRAna Teresa Manjarres MonteroNoch keine Bewertungen

- SB20 Tuning 2022Dokument3 SeitenSB20 Tuning 2022storm vanleeuwen100% (1)

- API Method of Statement Brochure - EN 1Dokument4 SeitenAPI Method of Statement Brochure - EN 1htc homeNoch keine Bewertungen

- Tourch 2017Dokument4 SeitenTourch 2017MigueNoch keine Bewertungen

- Mill Vise: InstructionsDokument1 SeiteMill Vise: InstructionsJF LuisNoch keine Bewertungen

- Hipshot Bassxtender enDokument2 SeitenHipshot Bassxtender enwoufscribdNoch keine Bewertungen

- MK - II Honing Guide: U.S. Pat. No. 7,553,216Dokument12 SeitenMK - II Honing Guide: U.S. Pat. No. 7,553,216Michele MariNoch keine Bewertungen

- Laminated Paper Plane Saber InnstructionsDokument1 SeiteLaminated Paper Plane Saber InnstructionsMugenNoch keine Bewertungen

- Singer 337 Sewing Machine Instruction ManualDokument38 SeitenSinger 337 Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- Assembling A Can SealerDokument12 SeitenAssembling A Can SealerPlantain frankyNoch keine Bewertungen

- Cosplay Specialty Cut GuideDokument6 SeitenCosplay Specialty Cut GuidevinyvalchinoNoch keine Bewertungen

- ManualDokument3 SeitenManualyoad974Noch keine Bewertungen

- M951D Series: M95Heid and M95Edid Destaticizer CartridgesDokument8 SeitenM951D Series: M95Heid and M95Edid Destaticizer CartridgesjuanfranzNoch keine Bewertungen

- Samick Sage/ Galaxy Sage Recurve BowDokument4 SeitenSamick Sage/ Galaxy Sage Recurve BowMartin SwartNoch keine Bewertungen

- Tension Watch Tw200 Instruction Manual: Position Gauge RingDokument1 SeiteTension Watch Tw200 Instruction Manual: Position Gauge RingCARLOS JAVIER PANTOJA MEDINANoch keine Bewertungen

- Common Baler Problems and Their Remedies: Possible Cause RemedyDokument1 SeiteCommon Baler Problems and Their Remedies: Possible Cause RemedyVarga Szabi100% (1)

- CNT 0011419 02Dokument3 SeitenCNT 0011419 02Sladjana KomacNoch keine Bewertungen

- CNT 0011419 02Dokument3 SeitenCNT 0011419 02Sladjana KomacNoch keine Bewertungen

- Snare Bed ManualDokument8 SeitenSnare Bed ManualorgqaualiaNoch keine Bewertungen

- 71 HBH DR EULSDokument2 Seiten71 HBH DR EULSsadaf KNoch keine Bewertungen

- Veritas Bench PlanesDokument8 SeitenVeritas Bench PlaneskeirgalNoch keine Bewertungen

- Calibration and Fault Finding and Fault Finding For Lal20X & Lal24X Dumpy Levels Dumpy LevelsDokument15 SeitenCalibration and Fault Finding and Fault Finding For Lal20X & Lal24X Dumpy Levels Dumpy LevelsStephenNoch keine Bewertungen

- Hanau Springbow Quick Reference Guide 10081Dokument12 SeitenHanau Springbow Quick Reference Guide 10081Kallingal NoufalNoch keine Bewertungen

- Web - Knife and Tool SharpenerDokument18 SeitenWeb - Knife and Tool SharpenerhoanguyentqNoch keine Bewertungen

- White Rotary 41/43 Sewing Machine Instruction ManualDokument16 SeitenWhite Rotary 41/43 Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- TL02007 ZQ-Hook Timing GuideDokument5 SeitenTL02007 ZQ-Hook Timing GuideAhmed KamelNoch keine Bewertungen

- Me-4045 4052Dokument30 SeitenMe-4045 4052AndreiNoch keine Bewertungen

- Baby Lock Grace BL40A Quick Reference Sewing Machine Instruction ManualDokument20 SeitenBaby Lock Grace BL40A Quick Reference Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- Econo CutterDokument1 SeiteEcono CutterdubiouslineageNoch keine Bewertungen

- Crosman 1077 Series Manual EN ES-minDokument2 SeitenCrosman 1077 Series Manual EN ES-minPiluni MehakNoch keine Bewertungen

- Assembly Instructions: Arh TigerDokument12 SeitenAssembly Instructions: Arh TigerHewertonMenezesNoch keine Bewertungen

- Regrinding Mfe En-GlDokument7 SeitenRegrinding Mfe En-GlGanga Dhar100% (1)

- Burgundy Tote With Drop in Lining - Part-IIDokument2 SeitenBurgundy Tote With Drop in Lining - Part-IISaraTustraNoch keine Bewertungen

- MFM Manual Flange FacerDokument1 SeiteMFM Manual Flange FacerProveedora de servicios y suministros PSSNoch keine Bewertungen

- Problems Encountered in Tissue ProcessingDokument3 SeitenProblems Encountered in Tissue ProcessingGlennford AcobaNoch keine Bewertungen

- Singer 457U15, U125, U135, U140 Operator's GuideDokument8 SeitenSinger 457U15, U125, U135, U140 Operator's GuideYEMC YEMC100% (1)

- Perfect Tenon: Routing ADokument2 SeitenPerfect Tenon: Routing ATdm AvoNoch keine Bewertungen

- Seiko TE TF-6, - 6B Instruction ManualDokument4 SeitenSeiko TE TF-6, - 6B Instruction ManualFabio BautistaNoch keine Bewertungen

- MK4 Saw Instructions-WebDokument4 SeitenMK4 Saw Instructions-WebCristian RamosNoch keine Bewertungen

- HookshrpDokument1 SeiteHookshrpOussama HayekNoch keine Bewertungen

- Fita Coaching Barebow PDFDokument12 SeitenFita Coaching Barebow PDFDwight Anthony YuNoch keine Bewertungen

- Sewing 03-Button Sewing-Accurate With Groz-Beckert NeedlesDokument4 SeitenSewing 03-Button Sewing-Accurate With Groz-Beckert NeedlesAkhil TripathiNoch keine Bewertungen

- Toxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuideDokument13 SeitenToxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuidePak Cik FauzyNoch keine Bewertungen

- Bender MB 105Dokument14 SeitenBender MB 105EdSoloNoch keine Bewertungen

- Oboe Common Problems and RemediesDokument2 SeitenOboe Common Problems and RemediesJacob AguadoNoch keine Bewertungen

- 68979Dokument8 Seiten68979nicole guestNoch keine Bewertungen

- CurvedfoldingDokument9 SeitenCurvedfoldingRafael RamosNoch keine Bewertungen

- Brother Chunky Gauge RIBBERSDokument1 SeiteBrother Chunky Gauge RIBBERSVictorNoch keine Bewertungen

- Veritas Side Clamping Honing Guide C 01 eDokument1 SeiteVeritas Side Clamping Honing Guide C 01 ev16902761Noch keine Bewertungen

- Veritas MK II Narrow Blade Honing Guide C 01 eDokument11 SeitenVeritas MK II Narrow Blade Honing Guide C 01 eduesenNoch keine Bewertungen

- Remedy MidTier Guide 7-5Dokument170 SeitenRemedy MidTier Guide 7-5martin_wiedmeyerNoch keine Bewertungen

- Saif Powertec Limited Project "Standard Operating Process" As-Is DocumentDokument7 SeitenSaif Powertec Limited Project "Standard Operating Process" As-Is DocumentAbhishekChowdhuryNoch keine Bewertungen

- Windows System Shortcut CommandsDokument2 SeitenWindows System Shortcut CommandsVenkatesh YerraNoch keine Bewertungen

- Furnace Temperature & PCE ConesDokument3 SeitenFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- Beamng DxdiagDokument22 SeitenBeamng Dxdiagsilvioluismoraes1Noch keine Bewertungen

- Instruction Manual 115cx ENGLISHDokument72 SeitenInstruction Manual 115cx ENGLISHRomanPiscraftMosqueteerNoch keine Bewertungen

- O'Dell v. Medallia, Inc. Et Al, 1 - 21-cv-07475, No. 1 (S.D.N.Y. Sep. 7, 2021)Dokument15 SeitenO'Dell v. Medallia, Inc. Et Al, 1 - 21-cv-07475, No. 1 (S.D.N.Y. Sep. 7, 2021)yehuditgoldbergNoch keine Bewertungen

- 2.1 DRH Literary Translation-An IntroductionDokument21 Seiten2.1 DRH Literary Translation-An IntroductionHassane DarirNoch keine Bewertungen

- Ice 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisDokument15 SeitenIce 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisBipin KrishnaNoch keine Bewertungen

- Revised Corporation Code - Non Stock Close and Special CorporationsDokument19 SeitenRevised Corporation Code - Non Stock Close and Special CorporationsVenziel PedrosaNoch keine Bewertungen

- Anviz T5 RFID ManualDokument52 SeitenAnviz T5 RFID ManualLuis Felipe Olaya SandovalNoch keine Bewertungen

- Epistemology and OntologyDokument6 SeitenEpistemology and OntologyPriyankaNoch keine Bewertungen

- Effect of Plant Growth RegulatorsDokument17 SeitenEffect of Plant Growth RegulatorsSharmilla AshokhanNoch keine Bewertungen

- Cocaine in Blood of Coca ChewersDokument10 SeitenCocaine in Blood of Coca ChewersKarl-GeorgNoch keine Bewertungen

- Strategic Capital Management: Group - 4 Jahnvi Jethanandini Shreyasi Halder Siddhartha Bayye Sweta SarojDokument5 SeitenStrategic Capital Management: Group - 4 Jahnvi Jethanandini Shreyasi Halder Siddhartha Bayye Sweta SarojSwetaSarojNoch keine Bewertungen

- Annex To ED Decision 2013-015-RDokument18 SeitenAnnex To ED Decision 2013-015-RBurse LeeNoch keine Bewertungen

- Ose Sample QuotationDokument37 SeitenOse Sample Quotationrj medelNoch keine Bewertungen

- Evolis SDK Use Latest IomemDokument10 SeitenEvolis SDK Use Latest IomempatrickNoch keine Bewertungen

- Reading Stressful Jobs 1 4Dokument4 SeitenReading Stressful Jobs 1 4Ivana C. AgudoNoch keine Bewertungen

- Shaker ScreenDokument2 SeitenShaker ScreenRiaz EbrahimNoch keine Bewertungen

- List of HTML TagsDokument5 SeitenList of HTML TagsdorinadidNoch keine Bewertungen

- Biscotti: Notes: The Sugar I Use in France, Is CalledDokument2 SeitenBiscotti: Notes: The Sugar I Use in France, Is CalledMonica CreangaNoch keine Bewertungen

- Waswere Going To Waswere Supposed ToDokument2 SeitenWaswere Going To Waswere Supposed ToMilena MilacicNoch keine Bewertungen