Beruflich Dokumente

Kultur Dokumente

Benoil Stripper Rubber Catalogue

Hochgeladen von

OgheneroOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Benoil Stripper Rubber Catalogue

Hochgeladen von

OgheneroCopyright:

Verfügbare Formate

The 8th International Chemical Engineering Congress & Exhibition (IChEC 2014)

Kish, Iran, 24-27 February, 2014

Optimization of Unloading Operation with Coiled Tubing

(Nitrogen Lifting) in One of the Southern Iranian Oil Fields

A.M. Fuladgar *, J.Moghadasi, H. Ghobadi, A.H. Haghi,

*

Petroleum Engineering Dept., Reservoir Operation Engineering, NISOC, Ahvaz, Iran

*

Fooladgar.a@nisoc.ir

Abstract

Nitrogen lifting is commonly used to enable a well to flow initially or bring a previously flowing

well back on production. This is one of the most typical coiled tubing operations carried out in the

Iranian south oilfields.

The limited number of coiled tubing trucks and large number of wells which require unloading

with N2 injection after workover or any other remedial jobs, highligths the significance of the time

spent for unloading of each wells. Some operational parameters such as injection rate, pressure,

depth , coiled tubing OD, choke size etc are employed to determine duration and costs of

unloading operations. In Iranian oilfields, these parameters are usually estimated based on personal

experience of operation managers during operation and their field observation that is not an

efficient manner.

This paper presents a nitrogen lifting operation for a workovered oil well located in a southern

oilfields of Iran that is unloaded with 7000 gal of nitrogen gas with 5 gal/min injection rate without

any predesign or simulation process. This research conducts an analysis to determice the optimum

value for the N2 injection parameters. The applied methodology comprised of simulation of the

well and coiled tubing system using a steady state multiphase flow simulation software, matching

model outputs with real welltest and flowing test data, simulation of N2 injection operation with

sensitivity analysis on various determinant operation parameters and obtaining the optimum value

of these parameters.

Simulation results indicated that since coiled tubing (CT) is run through a 3 1/2" tubing , the

annular friction loss is a limiting factor, a smaller diameter coiled tubing string allows higher

unloading rate. The results of sensitivity analysis on N2 rate indicated that increasing injection

rate to some extent, lowers hydrostatic pressure loss in the annulus and bottomhole pressure but

further increase of the N2 rate beyond a certain threshold value would increase the friction

pressure loss in the annulus and consequently increase bottomhole pressure and decrease

unloading rate. Simulation results with sensitivity to injection depth indicate that as gas injection

depth increases, the maximum attainable unloading rate increases.

Comparing the optimum designed nitrogen lifting operation with the realtime field observations

provides that the N2 injection rate is excessively higher than the required rate in this well. As N2

injection is a typical form of unloading procedure at NISOC, optimization method which presented

in this research, could make the projects more economic by reducing the routine time and cost of

these operations.

Keywords: Coiled tubing operation, Simulation, Optimization , Nitrogen lifting

Advanced Coupled Reservoir/Geomechanical Simulation Techniques…

Introduction

Coiled tubing has been used in various oilfield services applications including wellbore solids

cleanout, well unloading, hydraulic fracturing, coiled tubing drilling (CTD), acidizing, and

other applications [1]. Eventhough coiled tubing fracturing and coiled tubing drilling have

experienced significant growth in recent years (15 % of the revenue), solids cleanout and well

unloading are still the two most dominant coiled tubing applications (75% of the revenue).

Using coiled tubing to unload a well with nitrogen is a quick and cost-effective method to

remove the liquid load of the wellbore [2].

After workover operations, the killing or stimulation fluid must be removed from the tubing

string to return the well to the normal operation. Two techniques are commonly used to

unload the wells. First at all, using gas lift mandrels in the completion and pressurized gas in

the area to unload the well. Secondly, injecting nitrogen in the well column with CT [3]. This

is the most common method applied in south Iranian oilfields.

Generally, in South Iraninan oilfields acidizing treatments are accompanied by injection of

equaivallent of one well tublars volume of water or gasoil in the well as "post flush" during

acidizing treatment. Bringing such a well into production requires unloading of the injected

fluids with N2 injection. This operation is usually performed by injection of about 7000 gal

liquified N2 into the well by means of coiled tubing. The N2 lifting process does not follow-

up any predesigned operating condition. The nitrogen gas is injected in two or more depth

steps from 1000 m to 2000 m with injection rate of 5 to 15 gal liquid N2 per minute untill the

wellhead pressure rises to an acceptable value and the return fluid being almost oil. This kind

of operation usually result in excess N2 gas injection for unloading the well. Also the CT size

that is employed for this operation is only based on the availability of CT units nearest to well

location. While initial investigations indicates that in small tubing sizes larger CT OD may

cause the maximum injection rate and maximum production rate of the well during unloading

process to be limited.

Methodology for Optimization Nitrogen lifting Operation

In this paper the well and coiled tubing system was modeled and simulated using a steady

state multiphase simulation software. To setup the simulation model, the flow geometry must

first be defined.The geometry of the well and CT string inside the well is specified with

some input parameters such as CT length, diameter, and various wall thicknesses. The fluid

properties are matched with the lab PVT data and tuned in the model. For simulation of

multiphase pressure drops in the production path from bottomhole to wellhead the best

multiphase correlation through the most well known correlatinos have been examined in the

simulation software and the most precise corrolation is selected for simulation. Then

simulation model is developed to predict and calculate production conditions under various

injection conditions.

The metholology for designing optimum liquid unloading parameters includes generation of a

family of curves of unloading rate vs. gas injection rate for various assumed injection depth,

while holding CT size constant. Based on these curves, the optimum depth of injection can be

obtained as corresponding curve with minimum injection gas rate for the predefined

unloading rate. The similar method is used for determination of optimum CT size.

Results and Discussion

Case Study: Well A

The 8th International Chemical Engineering Congress & Exhibition (IChEC 2014)

Kish, Iran, 24-27 February, 2014

For this study a vertical oil well in Ragesefid oilfield with depth of 2600 m was selected. the

well is equipped with a 3 1/2" (ID = 2.992 in.) tubing to 1400 m without packer. The well

fluid enters the well through perforations (2600-2630 m) and passes through the 7" liner

(2600-2200 m) and a 9 5/8" casing (2200 to 1400 m ) and finally it flows into the annulus

between the 3 1/2" tubing and CT outside wall until it reaches to wellhead. The oil reservoir

thickness is 250 m (from 2250- 2500 m ). The well was undertaked an acidizing treatment

after workover and unloaded by injection of 7000 gal nitrogen gas by coiled tubing with

injection rate of 5 gal/min during 24 hr. After this operation the well is flowed with wellhead

pressure of 700 psia and production rate of 2000 STB/D.

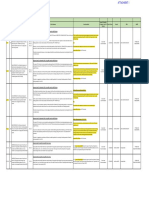

Determination of Optimum Injection depth

Fig.1 effect of injection depth on unloading rate

As it is illustrated in Fig.1, despite the injection depth equal to 2500m would resulted the

lower required N2 injection rate but considering the injection pressure and intervention time

as the economical and operational limiting factors, technical optimum injection depth for

unloading rate of 1500 STB/D (predicted natural flow rate of the well) is determined to be

2000 m

Determination of optimum CT Size (OD)

Fig.2 Investigation of effect of CT size (OD) on unloading rate

Advanced Coupled Reservoir/Geomechanical Simulation Techniques…

Obtimum CT size for this well clearly is distinguished to be CT with OD=1.25 ", the smallest

size available. This result confirms the findings of former investigators.

Prediction of Wellhead Pressure and unloading Rate during N2 injection operation

Percent Unloading N2 Injection Rate WHP Unloading Rate

% MMSCF/D Psia STB/D

10 0.33 266 1933

20 0.33 310 2284

30 0.33 350 2594

40 0.33 364 2714

50 0.33 400 2900

60 0.33 418 3137

70 0.33 440 3303

80 0.33 454 3463

90 0.33 475 3600

Conclusions

1- For a configuration of large tubing and a small CT, the most effective lifting method is to

inject the gas through the tubing.

2- when CT is run through a small ID tubing ,since the annular friction loss is a limiting

factor, a smaller diameter coiled tubing string allows higher unloading rate.

3- The results of sensitivity analysis on N2 rate indicated that increasing injection rate to

some extent, lowers hydrostatic pressure loss in the annulus and bottomhole pressure but

further increase of the N2 rate beyond a certain threshold value would increase the

friction pressure loss in the annulus and consequently increase bottomhole pressure and

decrease unloading rate.

4- Simulation results with sensitivity to injection depth indicate that as gas injection

depth increases, the maximum attainable unloading rate increases.

5- Comparison of Optimum designed nitrogen lifting operation with real operation that

is done in south oilfields according to realtime observations indicates considerable

excess N2 injection rate is applied for unloading this well.

Acknowledgements

The Authors of this paper acknowledge the support of NISOC company for submission

of this paper.

References

[1] Coiled Tubing Handbook, 3rd Edition, Gulf Publishing Company, Houston, Texas, 1998.

[2] Y. Zhou, E. Smalley : "Determination of Optimum N2 Rate for Unloading Gas Wells With

Coiled Tubing" , SPE 143337, SPE/ICoTA Coiled Tubing and Well Intervention Conference

and Exhibition held in The Woodlands, Texas, USA, 5–6 April 2011.

[3] P. Salim, and J. Li, BJ :" Simulation of Liquid Unloading From a Gas Well With Coiled

Tubing Using a Transient Software" , SPE 124195 , SPE Annual Technical Conference and

Exhibition held in New Orleans, Louisiana, USA, 4–7 October 2009.

Das könnte Ihnen auch gefallen

- Study of Cavitation Erosion On Hydraulic Turbine RunnersDokument7 SeitenStudy of Cavitation Erosion On Hydraulic Turbine RunnersAlberto NunciraNoch keine Bewertungen

- D 3011 DesignDokument29 SeitenD 3011 Designsaa naaNoch keine Bewertungen

- 04 - SPE 63197 - Shallow Gas KickDokument10 Seiten04 - SPE 63197 - Shallow Gas KickRachid Touati100% (1)

- 2019 - IJFTE - Mehul CD NozzleDokument6 Seiten2019 - IJFTE - Mehul CD NozzleMehul BambhaniaNoch keine Bewertungen

- D 3002 DesignDokument20 SeitenD 3002 DesignmargaretramosNoch keine Bewertungen

- Technology of Dynamic Kill Drilling For Drilling in The Superficial Layer of Deepwater PDFDokument6 SeitenTechnology of Dynamic Kill Drilling For Drilling in The Superficial Layer of Deepwater PDFNA NANoch keine Bewertungen

- Velocity String Helps To Revive A Standing Gas Well in Saudi ArabiaDokument14 SeitenVelocity String Helps To Revive A Standing Gas Well in Saudi Arabiaerdal aydin100% (1)

- Spe 133268 MS PDFDokument18 SeitenSpe 133268 MS PDFPhuc TruongNoch keine Bewertungen

- B.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service DescriptionDokument3 SeitenB.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service DescriptionJohnSmithNoch keine Bewertungen

- Beltranparedes 2010Dokument12 SeitenBeltranparedes 2010Abdillah MuharramNoch keine Bewertungen

- PIV Analysis of In-Cylinder Flow Structures Over ADokument13 SeitenPIV Analysis of In-Cylinder Flow Structures Over Aznadeem2Noch keine Bewertungen

- E3sconf Star2024 00027Dokument11 SeitenE3sconf Star2024 00027seherr719Noch keine Bewertungen

- CFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientDokument9 SeitenCFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientCharan RavulaNoch keine Bewertungen

- Spe 120632 MS PDokument0 SeitenSpe 120632 MS PMagaña AuryNoch keine Bewertungen

- SPE168279 - Optimizing Frac Plug Mill Outs in Horizontal Wells Using Coiled Tubing - TTSDokument10 SeitenSPE168279 - Optimizing Frac Plug Mill Outs in Horizontal Wells Using Coiled Tubing - TTSfkong16688Noch keine Bewertungen

- Prediction of Standpipe Pressure Ver 1Dokument6 SeitenPrediction of Standpipe Pressure Ver 1Dipankar ChowdhuryNoch keine Bewertungen

- Best Real Time Model Development of An Oil Well Drilling SystemDokument6 SeitenBest Real Time Model Development of An Oil Well Drilling SystemProf YoupaNoch keine Bewertungen

- Wells Subsurface Tutorials BabsDokument12 SeitenWells Subsurface Tutorials BabsMaría MarquinaNoch keine Bewertungen

- Geology & Geophysics: Coiled Tubing TechnologyDokument4 SeitenGeology & Geophysics: Coiled Tubing TechnologyUji PanuntunNoch keine Bewertungen

- 52 Mud LoggingDokument31 Seiten52 Mud LoggingHerly Vergiawan0% (1)

- Automatic Gas Influxes Detection in Offshore Drilling Based On MachineLearning TechnologyDokument12 SeitenAutomatic Gas Influxes Detection in Offshore Drilling Based On MachineLearning TechnologyLukombo N'LanduNoch keine Bewertungen

- CFD Simulation of Compressible Flow Inside A Gas Centrifuge Using OpenFOAMDokument8 SeitenCFD Simulation of Compressible Flow Inside A Gas Centrifuge Using OpenFOAMIJRASETPublicationsNoch keine Bewertungen

- Screw Expanders Increase Output and Decrease The CDokument16 SeitenScrew Expanders Increase Output and Decrease The CAbdullah KaracaoğluNoch keine Bewertungen

- Spe 170789 MS PDFDokument17 SeitenSpe 170789 MS PDFerikaberriomNoch keine Bewertungen

- Mist/Steam Cooling For Advanced Turbine SystemsDokument15 SeitenMist/Steam Cooling For Advanced Turbine SystemsRAVI KUMARNoch keine Bewertungen

- SPE-10709 Physics Based Well Design - Beyond The Learning CurveDokument5 SeitenSPE-10709 Physics Based Well Design - Beyond The Learning Curvedrilling moneytreeNoch keine Bewertungen

- Design of Coverging Diverging Nozzle Based On Method of Characteristics Using Matlab and Ansys FluentDokument27 SeitenDesign of Coverging Diverging Nozzle Based On Method of Characteristics Using Matlab and Ansys FluenttanishqNoch keine Bewertungen

- Energies 15 04259Dokument14 SeitenEnergies 15 04259Rigoberto José Martínez CedeñoNoch keine Bewertungen

- Application of Laser Technology For Oil and Gas Wells PerforationDokument13 SeitenApplication of Laser Technology For Oil and Gas Wells PerforationJail Arroyo LeonNoch keine Bewertungen

- Kel-1 GAs Lift1Dokument12 SeitenKel-1 GAs Lift1Indra ArdiansyahNoch keine Bewertungen

- Kim 2015 IOP Conf. Ser. Mater. Sci. Eng. 72 042044 PDFDokument8 SeitenKim 2015 IOP Conf. Ser. Mater. Sci. Eng. 72 042044 PDFHema KumarNoch keine Bewertungen

- Study On Bubble Formation at A Submerged Micro-HolDokument11 SeitenStudy On Bubble Formation at A Submerged Micro-HolMarc LarreNoch keine Bewertungen

- Topic 3 - Tubing Conveyed Perforating (TCP) - Group3Dokument17 SeitenTopic 3 - Tubing Conveyed Perforating (TCP) - Group3Harith NordinNoch keine Bewertungen

- Rasmus 2013Dokument19 SeitenRasmus 2013aidaNoch keine Bewertungen

- D-2005-Design - Vertical Sep With Mist EliminatorDokument36 SeitenD-2005-Design - Vertical Sep With Mist EliminatorJhon EspinosaNoch keine Bewertungen

- IPTC 10032 The Successful Application of 2000 PCP Wells in Daqing OilfieldDokument11 SeitenIPTC 10032 The Successful Application of 2000 PCP Wells in Daqing OilfieldJosé TimanáNoch keine Bewertungen

- Pipe Attached With NozzleDokument4 SeitenPipe Attached With NozzleAny BodyNoch keine Bewertungen

- PDC Bit Hydraulic Mud Rheological Simulation To MoDokument8 SeitenPDC Bit Hydraulic Mud Rheological Simulation To MojalalNoch keine Bewertungen

- Prosper GasliftDokument12 SeitenProsper Gasliftkurtbk100% (3)

- EasyChair Preprint 6570Dokument7 SeitenEasyChair Preprint 6570Hridey GuptaNoch keine Bewertungen

- S BmittedDokument13 SeitenS Bmittedhayel elnaggarNoch keine Bewertungen

- A Case Study in Flow Assurance of A Pipeline-Riser System Using OlgaDokument9 SeitenA Case Study in Flow Assurance of A Pipeline-Riser System Using OlgaAnonymous 8te2h1Noch keine Bewertungen

- Fluids Sampling and Analysis: Gas Condensate ServicesDokument6 SeitenFluids Sampling and Analysis: Gas Condensate ServicesehsanelahimirzaNoch keine Bewertungen

- Dec06feature PDFDokument4 SeitenDec06feature PDFAmgad_SNoch keine Bewertungen

- SWMM DataDokument9 SeitenSWMM DataCarlos SerranoNoch keine Bewertungen

- Well Control Simulation PDFDokument8 SeitenWell Control Simulation PDFSalem HalbaouiNoch keine Bewertungen

- Assignment 1 - ProsperDokument9 SeitenAssignment 1 - ProsperMuhammad Amirullah SanadiNoch keine Bewertungen

- SPE 153708 Development of A Static/Dynamic Model For Chac Field Based On A Novel Multidisciplinary WorkflowDokument19 SeitenSPE 153708 Development of A Static/Dynamic Model For Chac Field Based On A Novel Multidisciplinary WorkflowJoe LuisNoch keine Bewertungen

- SSOTE% - Research ResultsDokument24 SeitenSSOTE% - Research ResultsAhmed WagihNoch keine Bewertungen

- Evaluation of Technical Drilling OperationDokument56 SeitenEvaluation of Technical Drilling OperationAkuffo TheophilusNoch keine Bewertungen

- Turgo Spear Nozzle DesignDokument15 SeitenTurgo Spear Nozzle DesignCliff smythNoch keine Bewertungen

- Simulador Qrod v3 para Bombeo MecanicoDokument3 SeitenSimulador Qrod v3 para Bombeo MecanicobeymarNoch keine Bewertungen

- CFD Model of The CNGDokument8 SeitenCFD Model of The CNGTatiana VargasNoch keine Bewertungen

- Numerical and Experimental Analysis of Transient FDokument13 SeitenNumerical and Experimental Analysis of Transient FSynbedNoch keine Bewertungen

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingVon EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingBewertung: 5 von 5 Sternen5/5 (9)

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyVon EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNoch keine Bewertungen

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideVon EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Benoil Stripper Rubber CatalogueDokument4 SeitenBenoil Stripper Rubber CatalogueOgheneroNoch keine Bewertungen

- BJ Coiled Tubing Equipment Manual Version 1Dokument90 SeitenBJ Coiled Tubing Equipment Manual Version 1Franklyn Frank95% (39)

- Benoil Stripper Rubber Catalogue PDFDokument15 SeitenBenoil Stripper Rubber Catalogue PDFOgheneroNoch keine Bewertungen

- Benoil Stripper Rubber Catalogue PDFDokument15 SeitenBenoil Stripper Rubber Catalogue PDFOgheneroNoch keine Bewertungen

- Coiled TubingDokument32 SeitenCoiled TubingGeetha Bakki100% (2)

- Ammonia: A Company of Thyssenkrupp TechnologiesDokument28 SeitenAmmonia: A Company of Thyssenkrupp Technologiesenghisham100% (1)

- Pof 6Dokument100 SeitenPof 6Mohamed Omar IbrahimNoch keine Bewertungen

- ACL High Efficiency Burner Assembly Patented Burner: WarningDokument12 SeitenACL High Efficiency Burner Assembly Patented Burner: WarningUrt's ReelNoch keine Bewertungen

- Heat Exchanger PipingDokument39 SeitenHeat Exchanger PipingBhupender Sharma93% (15)

- Compressor Selection GuidelineDokument1 SeiteCompressor Selection Guidelinepradeep1987coolNoch keine Bewertungen

- CH - 5 Undersaturated Oil ReservoirsDokument26 SeitenCH - 5 Undersaturated Oil ReservoirszazoNoch keine Bewertungen

- Type - 4 Cascade TenderDokument24 SeitenType - 4 Cascade TenderrajNoch keine Bewertungen

- Questions Only. Questions (1) and (3) Are Mandatory. QuestionDokument3 SeitenQuestions Only. Questions (1) and (3) Are Mandatory. QuestionElzubair EljaaliNoch keine Bewertungen

- Nirma MPR - JULY 22Dokument38 SeitenNirma MPR - JULY 22Kiran Kumar PatraNoch keine Bewertungen

- Reguladores de PresionDokument7 SeitenReguladores de PresiondanielNoch keine Bewertungen

- SND Spray Nozzle Desuperheater-Installation Maintenance ManualDokument16 SeitenSND Spray Nozzle Desuperheater-Installation Maintenance ManualShameer Majeed100% (1)

- Interface HAZOP List From EPC HAZOP Action (Unit 323)Dokument1 SeiteInterface HAZOP List From EPC HAZOP Action (Unit 323)MAHMUDNoch keine Bewertungen

- Basics of Well CompletionDokument40 SeitenBasics of Well CompletionBevin Babu100% (4)

- (Vol I), 2005 Rules For Oil Recovery Vessels, 2005Dokument12 Seiten(Vol I), 2005 Rules For Oil Recovery Vessels, 2005Riyan PrayogoNoch keine Bewertungen

- Suntec Bomba PDFDokument2 SeitenSuntec Bomba PDFPedroNoch keine Bewertungen

- Stair Case Pressurization - DARDokument6 SeitenStair Case Pressurization - DARminn pyae son eNoch keine Bewertungen

- Presented By:-: Akshay Ts DTDM 6 SEM Roll No - 04Dokument23 SeitenPresented By:-: Akshay Ts DTDM 6 SEM Roll No - 04Deepak RameshNoch keine Bewertungen

- New Klee Rotary Vane Pump BrochureDokument29 SeitenNew Klee Rotary Vane Pump Brochurejia meng baiNoch keine Bewertungen

- Test Bank Chapter 5Dokument8 SeitenTest Bank Chapter 5teafNoch keine Bewertungen

- ENG - Injectors Rail Maintenance Guide LPG-CNG 3, 4 Cyl (May03)Dokument13 SeitenENG - Injectors Rail Maintenance Guide LPG-CNG 3, 4 Cyl (May03)Aleksandar NikolovskiNoch keine Bewertungen

- Spin Top CycloneDokument2 SeitenSpin Top CyclonegshdavidNoch keine Bewertungen

- wp109 Optimizing Inj Quill PerfDokument8 Seitenwp109 Optimizing Inj Quill PerfMichael MedinaNoch keine Bewertungen

- Groz Electric Oil Pump Opm 220Dokument1 SeiteGroz Electric Oil Pump Opm 220Manoj DoshiNoch keine Bewertungen

- Thermal Power Plant Project ReportDokument63 SeitenThermal Power Plant Project Reportasutoshjena28171% (24)

- Effect Injection On Air Lift PumpDokument6 SeitenEffect Injection On Air Lift PumpDavid Fransiskus SimarmataNoch keine Bewertungen

- Behavior of Gases: Charles' LAWDokument33 SeitenBehavior of Gases: Charles' LAWJennifer MagangoNoch keine Bewertungen

- File 000004Dokument291 SeitenFile 000004Tripoli ManoNoch keine Bewertungen

- Modular Throttle Valve NG4, Type QTM2Dokument2 SeitenModular Throttle Valve NG4, Type QTM2LibinNoch keine Bewertungen

- TENARIS - Supply Solutions For The HPIOKDokument2 SeitenTENARIS - Supply Solutions For The HPIOKEl_GasistaNoch keine Bewertungen

- Air CondDokument34 SeitenAir CondAmir Aiman67% (6)