Beruflich Dokumente

Kultur Dokumente

Colorite Beton 2031-7-2011

Hochgeladen von

jimdabrondCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Colorite Beton 2031-7-2011

Hochgeladen von

jimdabrondCopyright:

Verfügbare Formate

e

IN COMPLIANCE WITH

EUROPEAN STANDARD

EN 1504-2 (C)

t

PRINCIPLES

PI-MC-IR

o ri SURFACE PROTECTION

SYSTEMS FOR CONCRETE

ol ton

C B e

s

r

pant

an pai

ent

-tr

emirylic

S ac

ANTI CARBONATATION

SMOOTH FINISH

WHERE TO USE

For painting concrete structures, reinforced concrete

and general cementitious surfaces with a coat of semi-

transparent paint, leaving the “form-work” or “natural”

finish of the piece visible and homogenising the colour.

The special formula of the product makes it particularly

suitable for protecting surfaces against damage caused

by CO2, SO2 and sunlight. The long-lasting, durable

protection is also guaranteed by the product’s good

repellence to water and its moderate permeability to

vapour.

Some application examples

For painting concrete and reinforced concrete surfaces

where the colour of the substrate requires homogenising

while leaving the “form-work” or “natural” finish of the

cementitious structure visible.

Paint for protecting general cementitious surfaces

exposed to aggressive pollution agents in industrial

environments, such as exhaust gases and acid rain,

or to prevent damage due to carbonatation.

TECHNICAL CHARACTERISTICS

Colorite Beton is a semi-transparent paint for external

walls, made up of non-saponifiable, pure acrylic resin in

water dispersion.

Colorite Beton protects cementitious substrates against

damage caused by CO2 (carbonatation) and SO2.

Colorite Beton is resistant to all climatic conditions and

the aggressive attack of smog, salt and sunlight, and

provides a long-lasting protective coat for the substrate.

2031_colorite beton_gb (19.07.2011 - 3ª Bozza Corr. Ciano/Stampa)

rnite Colorite Beton protects the substrate and Application of the product

lo leaves an attractive finish which evens out the

colour without hiding the surface structure.

Colorite Beton is applied using traditional

methods with a brush, a roller, by air-spraying

CoBeto

or with an airless spray-gun system on top of

Colorite Beton is available in 4 shades of a coat of dry Malech primer.

grey in the standard range of colours. Further The protection cycle comprises the

colours may also be created according to application of at least two coats of

individual samples by using the ColorMap® Colorite Beton at a distance of 24 hours

automatic colouring system. between each coat under normal temperature

and humidity conditions, and in all cases

Colorite Beton meets the requirements when the underlying layer is completely dry.

of EN 1504-9 (“Products and systems for Examples of the final effect and finishes

protecting and repairing concrete structures: obtained using Colorite Beton are illustrated

definitions, requirements, quality control and in “the MAPEI colour in the projet” catalogue.

conformity assessment. General principles

for the use and application of systems”), and Cleaning

the requirements of EN 1504-2 (“Surface Brushes, rollers and other tools used for

applying the product may be cleaned with

protection system for concrete”) for class:

water before the Colorite Beton has dried

surface protection products – coating (C) –

off.

ingress protection (1.3) (PI) (ZA.1d) + moisture

control (2.2) (MC) and increasing resistivity

CONSUMPTION

(8.2) (IR) (ZA.1e). 0.25-0.3 kg/m2 (refers to two coats of the

product).

RECOMMENDATIONS

• Do not apply Colorite Beton on damp PACKAGING

substrates, or on substrates which are Colorite Beton is supplied in 20 kg plastic

not fully cured. drums.

• Do not apply Colorite Beton if the STORAGE

temperature is lower than +5°C or higher 24 months if stored in a dry place away from

than +35°C (the surface must be dry and sources of heat and at a temperature of

must not be in direct sunlight). between +5°C and +30°C. Protect from frost.

• Do not apply Colorite Beton if the level SAFETY INSTRUCTIONS FOR

of humidity is higher than 85%. PREPARATION AND APPLICATION

Colorite Beton is not considered a

• Do not apply Colorite Beton if it is about dangerous substance according to current

to rain or in windy weather. norms and regulations regarding the

classification of mixtures. Wear protective

• Please refer to the “Safety instructions for goggles and gloves. The usual precautions

preparation and application” section. taken when handling chemical products are

recommended.

APPLICATION PROCEDURE For further and complete information about

Preparation of the substrate a safety use of our product please refer to

New surfaces or surfaces which have been our latest version of the Material Safety

patched-up with repair mortar must be well Data Sheet.

cured, perfectly clean, sound and dry.

Remove all traces of oil and grease and parts PRODUCT FOR PROFESSIONAL USE.

which are not well-attached from the surface.

Seal any cracks which are present in the WARNING

substrate and repair the parts which are in Although the technical details and

poor condition. recommendations contained in this product

Seal off the porosity and smooth off any data sheet correspond to the best of our

uneven parts in the substrate. knowledge and experience, all the above

Apply a coat of Malech (ready-to-use) and, information must, in every case, be taken as

merely indicative and subject to confirmation

after 12-24 hours, apply the Colorite Beton.

after long-term practical application: for

this reason, anyone who intends to use the

Preparation of the product

product must ensure beforehand that it is

Dilute Colorite Beton with water.

suitable for the envisaged application: in

To help the product penetrate well into the every case, the user alone is fully responsible

substrate, especially if it is very compact and for any consequences deriving from the use

not very absorbent, we recommend diluting of the product.

the first coat with 20%-25% of water and,

after approximately 24 hours, the application Please refer to the current version of the

of a second coat diluted with 10%-15% of Technical Data Sheet, available from our

water. web site www.mapei.com

Make sure that the product is completely

homogenised when diluting. If possible, use

a low-speed drill to help with mixing. All relevant references for

If only a part of the product is to be prepared, the product are available

mix the Colorite Beton as is in its original upon request and from www.

container before pouring off the quantity mapei.com

required.

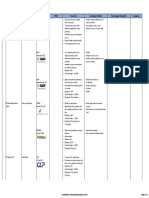

TECHNICAL DATA (typical values)

– Conformity with:– product certified according

to EN 1504-2 (Surface protection systems for

concrete), 2+ and 3 compliance certification

system

– EN 1504-2 classes: surface protection products

- coating - ingress protection (1.3) (ZA. 1d) +

moisture control (2.2) and increase in resistivity

(8.2) (ZA. 1e) (C, PI-MC-IR principles)

PRODUCT IDENTITY

Appearance: thick liquid

Colore: colour range or colours which can be obtained

with the ColorMap® colour system

Density (EN ISO 2811-1) (g/cm³): approx. 1.27

Brookfield viscosity (mPa·s): approx. 18,250

(5 shaft - 10 rpm)

Dry solids content (EN ISO 3251) (%): approx. 59

Storage: 24 months in the original packaging

Hazard classification according to EC 1999/45: none.

Before using refer to the “Safety instructions for

preparation and application” paragraph and the

information on the packing and Safety Data Sheet

Customs class: 3209 1000 00

APPLICATION DATA

Dilution ratio: 20-25% of water (first coat)

10-15% of water (second coat)

Waiting time betweeen two coats: minimum of 24 hours in normal humidity and

temperature conditions, and always with a completely

dry substrate

Application temperature: from +5°C to +35°C

Consumption (kg/m²): 0.25-0.3 (two coats)

FINAL PERFORMANCE

Colour variation after 1000 hours exposure

to a Weather-Ometer (ASTM G 155 cycle 1),

F.M. 4001, F.M. 4002, F.M. 4003, F.M. 4004 colour: ΔE < 1

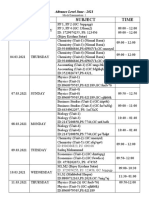

rnite PERFORMANCE CHARACTERISTICS FOR CE CERTIFICATION ACCORDING TO EN 1504-2, 2+

lo AND 3 COMPLIANCE CERTIFICATION SYSTEM CLASSES ZA.1d + ZA.1e (C, PI - MC - IR principles)

CoBeto STANDARD TEST RESULTS AND CONFORMITY TO REQUIREMENTS

(GB) A.G. BETA

UNI EN ISO 2409 oblique cut result/class: GT1, in conformity (≤ GT2)

UNI EN 1062-6 permeability to CO2 µ: 4,124,820

sD (m): 412

dry thickness according

to sD (m): 0.00010

result/class: in conformity (sD > 50 m)

UNI EN ISO 7783-1.2 permeability to water vapour µ: 3609

sD (m): 0.4

dry thickness according

to sD (m): 0.00010

result/class: I (sD < 5 m)

UNI EN 1062-3 capillary absorption and permeability w [kg/(m2h0,5)]: 0.02

to water

result/class: in conformity (w < 0.1)

UNI EN 1062-11 4.1 thermal compatibility: ageing: result/class: in conformity (adherence ≥ 0.8 N/mm2)

7 days at +70°C

Any reproduction of texts, photos and illustrations published

UNI EN 13687-1 thermal compatibility: freeze-thaw cycles result/class: in conformity (adherence ≥ 0.8 N/mm2)

here is prohibited and subject to prosecution

with immersion in de-icing salts

UNI EN 13687-2 thermal compatibility: thunder-shower result/class: in conformity (adherence ≥ 0.8 N/mm2)

UNI EN 13687-3 thermal compatibility: thermal cycles result/class: in conformity (adherence ≥ 0.8 N/mm2)

without immersion in de-icing salts

static UNI EN 1062-7 crack resistance crack-bridging ability (µm): 1117

result/class: A3 (> 0.5 mm)

dynamic UNI EN 1062-7 crack resistance result/class: B1

UNI EN 1542 direct traction adherence test result/class: in conformity (adherence ≥ 0.8 N/mm2)

EN 13501-1 reaction to fire euroclass: B s1 d0

UNI EN 13036-4 resistance to skid marks result/class: II (dry internal surface) (> 40 dry units)

UNI EN 1062-11:2002 4.2 artificial exposure to atmospheric agents result/class: in conformity

UNI EN 1081 anti-static behaviour result/class: I (explosives) (electrical resistance

> 104 and < 106Ω)

hazardous substances result/class: in conformity

FURTHER PERFORMANCE CHARACTERISTICS ACCORDING TO EN 1504-2 REGARDING

REQUIREMENTS FOR CLASSES ZA.1d + ZA.1e

2031-7-2011

STANDARD TEST RESULTS AND CONFORMITY TO REQUIREMENTS

UNI EN ISO 5470-1 abrasion resistance result/class: in conformity (Δ weight < 3000 mg)

UNI 7928 diffusion of chloride ions penetration (mm): 0.0

UNI EN ISO 2812-1 - NH4+ chemical resistance result/class: in conformity

BUILDING THE FUTURE

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Construct Orange LightDokument30 SeitenConstruct Orange LightjimdabrondNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- List Inspection ItemDokument1 SeiteList Inspection ItemjimdabrondNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Parralax SkillDokument6 SeitenParralax SkillAndrei CristianNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Construct Orange LightDokument30 SeitenConstruct Orange LightjimdabrondNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- Free Premium Business Template: Download NowDokument6 SeitenFree Premium Business Template: Download NowjimdabrondNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Spotify Drop DownDokument9 SeitenSpotify Drop DownjimdabrondNoch keine Bewertungen

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- MOS SS-HTB Tightening PartDokument9 SeitenMOS SS-HTB Tightening PartjimdabrondNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Power BLOX by One SkillDokument8 SeitenPower BLOX by One SkilljimdabrondNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- A Standard For Asphaltic Plug JointsDokument20 SeitenA Standard For Asphaltic Plug JointsbrelightsNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Catalog DuraLiteDokument8 SeitenCatalog DuraLitejimdabrondNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- FRP Skylight Subcontractor ListDokument2 SeitenFRP Skylight Subcontractor ListjimdabrondNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- (A3) Cementitious Waterproofing Applicator ListDokument1 Seite(A3) Cementitious Waterproofing Applicator ListjimdabrondNoch keine Bewertungen

- (A3) Cementitious Waterproofing Supplier ListDokument2 Seiten(A3) Cementitious Waterproofing Supplier ListjimdabrondNoch keine Bewertungen

- (A3) Cementitious Waterproofing Supplier ListDokument2 Seiten(A3) Cementitious Waterproofing Supplier ListjimdabrondNoch keine Bewertungen

- Construct Blue DarkDokument30 SeitenConstruct Blue DarkjimdabrondNoch keine Bewertungen

- (A4) Waterproof Paint Summary ListDokument1 Seite(A4) Waterproof Paint Summary ListjimdabrondNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SIKAgrout 215 M Mod J Cone TestDokument1 SeiteSIKAgrout 215 M Mod J Cone TestjimdabrondNoch keine Bewertungen

- Ultrasonic Drilling MonitoringDokument6 SeitenUltrasonic Drilling Monitoringjimdabrond100% (2)

- fc40 + Barchip Fiber (6 kg/m3)Dokument15 Seitenfc40 + Barchip Fiber (6 kg/m3)jimdabrondNoch keine Bewertungen

- M361 (English)Dokument2 SeitenM361 (English)jimdabrondNoch keine Bewertungen

- Nycon Materials Co.,LtdDokument2 SeitenNycon Materials Co.,LtdjimdabrondNoch keine Bewertungen

- 02.P63 Pilecap & Kolom (WBP)Dokument1 Seite02.P63 Pilecap & Kolom (WBP)jimdabrondNoch keine Bewertungen

- Grouting Tendon FormDokument2 SeitenGrouting Tendon FormjimdabrondNoch keine Bewertungen

- Energy Conservation Opportunities Sugar Industry IDokument8 SeitenEnergy Conservation Opportunities Sugar Industry INikhil MohiteNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Physics Chapter 2 Original TestDokument6 SeitenPhysics Chapter 2 Original TestJanina OrmitaNoch keine Bewertungen

- List of British StandardsDokument6 SeitenList of British StandardsPankajNoch keine Bewertungen

- Features Description: LT3598 6-String 30ma LED Driver With 1.5% Current MatchingDokument24 SeitenFeatures Description: LT3598 6-String 30ma LED Driver With 1.5% Current MatchingMick Thomson RcNoch keine Bewertungen

- Causal Inference For The Brave and True - Causal Inference For The Brave and TrueDokument2 SeitenCausal Inference For The Brave and True - Causal Inference For The Brave and TrueVkook ForeverNoch keine Bewertungen

- Writing and Reporting For The Media Workbook 12Th Edition Full ChapterDokument32 SeitenWriting and Reporting For The Media Workbook 12Th Edition Full Chapterdorothy.todd224100% (23)

- CASE ANALYSIS: DMX Manufacturing: Property of STIDokument3 SeitenCASE ANALYSIS: DMX Manufacturing: Property of STICarmela CaloNoch keine Bewertungen

- The Housekeeping Department: Learning Activity #1Dokument4 SeitenThe Housekeeping Department: Learning Activity #1Limar Geoff G. RosalesNoch keine Bewertungen

- Bid ProcessDokument85 SeitenBid ProcessRobiatol Adawiah Mohammad ShamsidiNoch keine Bewertungen

- Maths ReportDokument3 SeitenMaths ReportShishir BogatiNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- New Membership Application GemsDokument5 SeitenNew Membership Application Gemslaguila18Noch keine Bewertungen

- Sany - SCC8300 Crawler CraneDokument52 SeitenSany - SCC8300 Crawler CraneNunoNoch keine Bewertungen

- Essential Guide VLSI Aspirants FAQ Physical DesignDokument3 SeitenEssential Guide VLSI Aspirants FAQ Physical DesignRohith RajNoch keine Bewertungen

- Chapter 5: Attention and PerformanceDokument10 SeitenChapter 5: Attention and Performancerebela29Noch keine Bewertungen

- IQ, OQ, PQ: A Quick Guide To Process ValidationDokument9 SeitenIQ, OQ, PQ: A Quick Guide To Process ValidationGonzalo MazaNoch keine Bewertungen

- Rexroth HABDokument20 SeitenRexroth HABeleceng1979Noch keine Bewertungen

- Mock Examination Routine A 2021 NewDokument2 SeitenMock Examination Routine A 2021 Newmufrad muhtasibNoch keine Bewertungen

- GRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridayDokument3 SeitenGRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridaySheilaMarB.Esteban100% (1)

- Final Exam - Movie Analysis of Respeto - Sec90 - K. Dela CruzDokument9 SeitenFinal Exam - Movie Analysis of Respeto - Sec90 - K. Dela CruzKylie Dela CruzNoch keine Bewertungen

- 2017 NEC Table of ContentsDokument124 Seiten2017 NEC Table of ContentsFaheem PP13Noch keine Bewertungen

- UAE Branch AGM 2018/19 ElectionsDokument6 SeitenUAE Branch AGM 2018/19 ElectionsDavidNoch keine Bewertungen

- ISO 9000 Audit Checklist for Quality Management SystemsDokument28 SeitenISO 9000 Audit Checklist for Quality Management SystemsphilipalexjonesNoch keine Bewertungen

- Ventilation Plan For Confined Space EntryDokument9 SeitenVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Meinrad 2018 All Symbols With NumbersDokument4 SeitenMeinrad 2018 All Symbols With NumbersXer N. AcostaNoch keine Bewertungen

- Earthquake Faults and Tectonic Plate Boundaries ExplainedDokument21 SeitenEarthquake Faults and Tectonic Plate Boundaries ExplainedAngelo RemeticadoNoch keine Bewertungen

- Paper Velocity String SPE-30197-PADokument4 SeitenPaper Velocity String SPE-30197-PAPablo RaffinNoch keine Bewertungen

- Qc-Sop-0 - Drilling of PoleDokument7 SeitenQc-Sop-0 - Drilling of PoleAmeerHamzaWarraichNoch keine Bewertungen

- Fop 2.1Dokument11 SeitenFop 2.1Paramita HalderNoch keine Bewertungen

- Law As A Command of SovereignDokument12 SeitenLaw As A Command of SovereignAdv BL Dewasi100% (2)

- 10 - The Geological Interpretation of Well LogsDokument292 Seiten10 - The Geological Interpretation of Well LogsLorenza LorenzanaNoch keine Bewertungen