Beruflich Dokumente

Kultur Dokumente

NDT Magnetic Particle Inspection Procedure

Hochgeladen von

CharlesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

NDT Magnetic Particle Inspection Procedure

Hochgeladen von

CharlesCopyright:

Verfügbare Formate

TABLE OF CONTENT

1.0 SCOPE

2.0 EQUIPMENT

3.0 TECHNIQUE

4.0 EVALUATION OF INDICATIONS

5.0 ACCEPTANCE CRITERIA

6.0 REPORTING

7.0 PERSONNEL QUALIFICATIONS

8.0 REFERENCE DOCUMENTS

9.0 APPENDICES

PAGE 1/5 REV. 1

MAGNETIC PARTICLE INSPECTION PROCEDURE NUMBER SIS/NDT/550

1.0 SCOPE

1.1 This Magnetic Particle Inspection procedure outlines the equipment, technique, surface

preparation and acceptance/rejection criteria for the testing of structural Steel welded joints.

The extent of the examination on weldments depends on contract Specification.

1.2 This procedure is designed to comply with the requirements of ASME V SEC IIX

2.0 EQUIPMENT

2.1 Yoke Technique Utilizing:

Electro-magnetic yoke (240/110 V.A.C.), Y6

to detect surface discontinuities shall be used

2.2 Calibration Test:

Electro-Magnetic Yoke, Y6 (240/110 V.A.C.)

a) Each piece of magnetising equipment shall be calibrated at least once a year in accordance

with ASME V SEC IIX

a) A test to demonstrate the minimum lifting power of 4.5kg (10 lbs.), as recommended in

ASME V SEC IIX, will be carried out daily on a test weight of 4.6kg (10.13 lbs.). Results to

be reported on a record sheet.

c) Inspection Medium used shall be of wet type. Wet particle black magnetic ink shall be used

or aerosols type 7HF magnetic black ink.

d) White background contrast medium shall be white emulsion paint or Magnaflux 9WCP rapid

drying lacquer (or equivalent).

e) Particles shall be used within the temperature range limitations by the manufacturer and

minimum flash point shall be 140 F.

f) When Magnetic Particle Inspection is needed to be done on surfaces at high temperature, dry

magnetic particle shall be used.

7 PAGE 2/7 REV. 1

MAGNETIC PARTICLE INSPECTION PROCEDURE NUMBER SIS/NDT/550

3.0 TECHNIQUE

3.1 Prior to examination, the surface to be examined and all adjacent areas within at least one inch

of testing area shall be dry and free of all dirt, grease, scale, welding flux and spatter, oil

extraneous matter that may interfere with the examination.

3.2 Areas to be tested shall be painted with coat of white emulsion paint or white lacquer and be

complete dry before commencement of testing.

3.3 The inspection area shall be provided with adequate lighting to facilitate examination of the test

part for indication.

3.4 The Yoke shall be placed on the centre of the area to be inspected. The distance between the

poles shall not exceed 8inches (203mm) and good contact shall exist between the poles and the

item to be inspected. Place the yoke over the weld on the plate with its legs or poles equally

spaced from the weld.

3.5 The magnetising field adequacy shall be checked by using a “BURMAH-CASTROL’’ magnetic

flux indicator Type I BS 4134 (or equivalent )

3.6 Apply the ink while the magnetic force is maintained.

3.7 Interpret and evaluate any indication while magnetising force is on.

3.8 The magnetic field shall be applied at a minimum twice in each direction at 90 degree positions,

on each section of weld overlap of each test section. This will ensure proper magnetic coverage

of the surface and therefore enhance the detection of both transverse and longitudinal defects

4.0 EVALUATION OF INDICATIONS

4.1 Discontinuities and defects will be indicated by retention of the magnetic particles. All such

indications are not necessarily defects, however, excessive surface roughness, magnetic

permeability variations (such as at the edge of heat affected zones), etc., may produce similar

indications. If indications are believed to be non-relevant, each type of indication shall be

explored to determine if relevant linear discontinuities are present.

5.0 ACCEPTANCE CRITERIA

5.1 When magnetic particle testing is used, it shall be in accordance with ASME V SEC IIX. The

yoke technique shall be used in accordance with ASME V SEC IIX.. And the standard of

acceptance shall be in accordance with ASME V SEC IIX.

7 PAGE 3/7 REV. 1

MAGNETIC PARTICLE INSPECTION PROCEDURE NUMBER SIS/NDT/550

6.0 REPORTS

6.1 A report form that clearly identifies the work and the area of inspection, equipment and

consumables used shall be completed by the NDT Technician at the time of inspection.

A detailed report and sketch showing the location along the weld axis, location within

the weld cross section, size extent, orientation, and classification for each discontinuity

shall be completed for each weld in which significant indications are found.

6.2 When specified, discontinuities approaching rejectable size, particularly those about which there

is some doubt in their evaluation, shall also be reported. Area for which complete inspection

was not practicable shall also be noted, along with the reason why.

6.3 When necessary, a technique sketch will be added illustrating part geometry, magnetizing

technique and areas of part examination

7.0 PERSONNEL QUALIFICATIONS

7.1 Personnel performing this inspection shall be qualified in accordance with

the current edition of American Society for Non Destructive Testing

Recommended Practice No. SNT-TC-IA or the equivalent

8.0 REFERENCE DOCUMENTS

8.1 CLIENT SPECIFICATION

8.2 ASMR V SEC IIX

9.0 APPENDICES

Appendix 1 - Magnetic Particle Inspection Report Format

Appendix 2 – MPI Technique Sheet

7 PAGE 4/7 REV. 1

MAGNETIC PARTICLE INSPECTION PROCEDURE NUMBER SIS/NDT/550

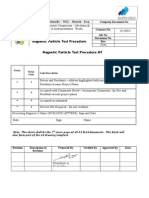

MAGNETIC PARTICLE TEST REPORT QC Report No.

Contract Number: Project:

Document Number: Quality Plan / I.T.P. Number: QC Report Date:

Document Revision: Inspection Class: Technical Specification:

Drawing Number(s): Location: Material Type:

Line Number: Plant / System: Thickness:

Welding SMA GTA GMA FCA SA Othe

GAS Diameter:

process W W W W W r

Test Procedure No.: Test Point: Before Welding [ ] After Welding [ ]

Equipment: Yoke [ ] Prod [ ] Distance (Prod)

Magnetic Field Indicator:

mm

Liquid Particle Brand: Dry Particle Brand: Fluorescent: Yes [ ] No [ ]

Result

Joint No.

Welder Scope Type of Defect

Inspected By Date

No. Defect Location Acc Rej

Tested

%

Endorsements Swift Inspection Services Ltd Client

Name

Sign

Date

7 PAGE 5/7 REV. 1

MAGNETIC PARTICLE INSPECTION PROCEDURE NUMBER SIS/NDT/550

MPI. TECHNIQUE SHEET NO…………….

PROJECT ………………………………………. CLIENT……………….….........………….

CONTRACT NO……………………………….. JOB NO…………………..…….....……….

LOCATION…………………………………….. CODE …………….…………..………..…...

ITEM TESTED…………………………………. THICKNESS……..……………………..….

ACCEPTANCE SPEC………………………….. DRAWING NO……………………………..

MPI. PROCEDURE NO…………………………. REF. REV. NO. …………………………

EQUIPMENT …………………………….. MODEL.……….…………………………….

SERIAL NO ……………………………… TECHNIQUE NO………………..…………

CONSUMABLES ….…………………………………………

SENSITIVITY…………………….………………………………….

COMMENTS……………………………………………………………………………………..

TECHINQUE SKETCH

TECHNICIAN...............................................

SIGN/DATE..........................................

7 PAGE 6/7 REV. 1

MAGNETIC PARTICLE INSPECTION PROCEDURE NUMBER SIS/NDT/550

7 PAGE 7/7 REV. 1

Das könnte Ihnen auch gefallen

- Side Door Elevator OperationsDokument32 SeitenSide Door Elevator OperationsAnthony WaaliaNoch keine Bewertungen

- PENETRANT TEST PROCEDURE (PT Procedure)Dokument9 SeitenPENETRANT TEST PROCEDURE (PT Procedure)Senthil Kumaran100% (1)

- RT ProcedureDokument18 SeitenRT Procedure1339979Noch keine Bewertungen

- PTDokument28 SeitenPTglazetm100% (1)

- EPRI Guidelines For The Evaluation of Seam Welded High Energy Piping PDFDokument392 SeitenEPRI Guidelines For The Evaluation of Seam Welded High Energy Piping PDFManuel L LombarderoNoch keine Bewertungen

- UT ProcedureDokument14 SeitenUT Procedurepoodook100% (3)

- TUV SUD - MT Procedure Rev.05Dokument11 SeitenTUV SUD - MT Procedure Rev.05HassanNoch keine Bewertungen

- Dec 09Dokument55 SeitenDec 09c_nghia100% (1)

- RT Procedure 10.09.16Dokument9 SeitenRT Procedure 10.09.16mukeshsingh6Noch keine Bewertungen

- NIAC Standard Checklist Rev 10Dokument40 SeitenNIAC Standard Checklist Rev 10Fernando RomeroNoch keine Bewertungen

- Sample Penetrant Testing ProcedureDokument9 SeitenSample Penetrant Testing Procedurerahim80ab100% (1)

- Magnetic Particle Test Procedure Magnetic Particle Test Procedure MTDokument14 SeitenMagnetic Particle Test Procedure Magnetic Particle Test Procedure MTsamer8saif100% (3)

- 00.ISO 9712 Scheme SGNDTDokument41 Seiten00.ISO 9712 Scheme SGNDTVuong Tran VanNoch keine Bewertungen

- ATS Holiday Test ReportDokument1 SeiteATS Holiday Test ReportAnonymous uJzSZ5100% (1)

- Introduction To NDTDokument50 SeitenIntroduction To NDTSuresh SenanayakeNoch keine Bewertungen

- LPT Written ProcedureDokument8 SeitenLPT Written ProcedureManikantaSumanthNoch keine Bewertungen

- MT ProcedureDokument9 SeitenMT ProcedureTouil Houssem100% (1)

- ThermographyDokument9 SeitenThermographybabakfazelNoch keine Bewertungen

- Form PAUTDokument2 SeitenForm PAUTLuong Ho Vu100% (1)

- Magnetic Particle Examination of WeldsDokument4 SeitenMagnetic Particle Examination of WeldsshruthiNoch keine Bewertungen

- Penetrant PresentationDokument20 SeitenPenetrant PresentationJayesh100% (3)

- QA QC ManualDokument25 SeitenQA QC ManualWaldo At100% (1)

- Dye Penetrant Inspection ProcedureDokument5 SeitenDye Penetrant Inspection ProcedureaezeadNoch keine Bewertungen

- NDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Dokument10 SeitenNDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Md Abu Hanif RajuNoch keine Bewertungen

- 00 Saip 11 - 03102016 PDFDokument21 Seiten00 Saip 11 - 03102016 PDFPandhu100% (1)

- Itp Vessel PDFDokument4 SeitenItp Vessel PDFBUDAPESNoch keine Bewertungen

- NDTDokument42 SeitenNDTshahazad100% (1)

- NDT Weld Visual Inspection ProcedureDokument4 SeitenNDT Weld Visual Inspection Procedureg_sancheti100% (2)

- Pmi Testing ProcedureDokument4 SeitenPmi Testing ProcedureDhanushNoch keine Bewertungen

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Dokument22 SeitenP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNoch keine Bewertungen

- ASTM A106 Seamless Carbon Steel Pipe For High Temperature Service PDFDokument9 SeitenASTM A106 Seamless Carbon Steel Pipe For High Temperature Service PDFsingaravelan narayanasamyNoch keine Bewertungen

- Holiday Detection ProcedureDokument4 SeitenHoliday Detection Proceduregst ajah100% (1)

- Liquid Penetrant Inspection ProcedureDokument21 SeitenLiquid Penetrant Inspection ProcedureJeffrey HartNoch keine Bewertungen

- NDT Method Magnetic Particle InspectionDokument23 SeitenNDT Method Magnetic Particle Inspectionabhaymehta67Noch keine Bewertungen

- Radio Graphic ExaminationDokument33 SeitenRadio Graphic ExaminationSakthi PanneerSelvam Tanjai100% (6)

- PT Quiz & Ans 2Dokument6 SeitenPT Quiz & Ans 2Goutam Kumar Deb100% (1)

- Welding Qualification As Per AWS D1.1Dokument19 SeitenWelding Qualification As Per AWS D1.1Ouni AchrefNoch keine Bewertungen

- Scaffold Erect ProceduresDokument4 SeitenScaffold Erect ProceduresDak SerikNoch keine Bewertungen

- PWHT Requirement As Per API-650Dokument1 SeitePWHT Requirement As Per API-650hgagselim2012Noch keine Bewertungen

- MT Work InstructionDokument3 SeitenMT Work Instructionpandab bkNoch keine Bewertungen

- ASNT III Basic SyllabusDokument8 SeitenASNT III Basic SyllabusDESTINY SIMON67% (3)

- Phased Array Inspection ProcedureDokument10 SeitenPhased Array Inspection ProcedurenathgsurendraNoch keine Bewertungen

- LPT As Per Asme & IsoDokument2 SeitenLPT As Per Asme & IsosbmmlaNoch keine Bewertungen

- Visible Penetrant Examination Using The Water-Washable ProcessDokument6 SeitenVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANoch keine Bewertungen

- Writen Practice of Qualification and Certification SHDokument15 SeitenWriten Practice of Qualification and Certification SHSisira Chandrasoma100% (3)

- Subic Drydoc NDT Quality ManualDokument14 SeitenSubic Drydoc NDT Quality ManualHarry Doble100% (2)

- SAWAED'S LIQUID PENETRANT TEST PROCEDUREDokument7 SeitenSAWAED'S LIQUID PENETRANT TEST PROCEDUREAlam MD SazidNoch keine Bewertungen

- En 1473-2016Dokument138 SeitenEn 1473-2016groxoNoch keine Bewertungen

- Non Destructive Examination Procedures (NDE) Tank 500-TA-008 A/BDokument7 SeitenNon Destructive Examination Procedures (NDE) Tank 500-TA-008 A/BNenad TomicNoch keine Bewertungen

- Hardness Testing Rev 00Dokument8 SeitenHardness Testing Rev 00muslim100% (1)

- Ultrasonic Inspection NDT Sample Test Report FormatDokument3 SeitenUltrasonic Inspection NDT Sample Test Report FormatArivazhagan Art0% (1)

- BS en 10228-2 2016Dokument16 SeitenBS en 10228-2 2016Morteza ShakerienNoch keine Bewertungen

- PMI Procedure for Verifying Alloy Elements in Metals by XRFDokument2 SeitenPMI Procedure for Verifying Alloy Elements in Metals by XRFMohamed NabilNoch keine Bewertungen

- PMI Guide for Ferrous and Nonferrous AlloysDokument8 SeitenPMI Guide for Ferrous and Nonferrous AlloysJhonny Rafael Blanco CauraNoch keine Bewertungen

- RT Exm Astar PDFDokument1 SeiteRT Exm Astar PDFSASINoch keine Bewertungen

- ADOR Booklet F Web FDokument132 SeitenADOR Booklet F Web FbadesharamkNoch keine Bewertungen

- Procedure For Ferrit TestingDokument11 SeitenProcedure For Ferrit TestingKarrar TalibNoch keine Bewertungen

- PENETRANT OIL TEST TANKS PROCEDUREDokument4 SeitenPENETRANT OIL TEST TANKS PROCEDUREhasan_676489616Noch keine Bewertungen

- Dye Penetrant TestingDokument20 SeitenDye Penetrant TestingRamesh RNoch keine Bewertungen

- PAHARPUR COOLING TOWERS MAGNETIC PARTICLE TEST REPORTDokument1 SeitePAHARPUR COOLING TOWERS MAGNETIC PARTICLE TEST REPORTGoutam Kumar DebNoch keine Bewertungen

- Ea 4 15 G Rev01 May 2015 Rev PDFDokument24 SeitenEa 4 15 G Rev01 May 2015 Rev PDFandrej_voloscuk13100% (1)

- DFT Measurement Worksheet: Paint InspectionDokument1 SeiteDFT Measurement Worksheet: Paint Inspectionjay nathNoch keine Bewertungen

- 6.4 - NDT-Magnetic Particle ExaminationDokument38 Seiten6.4 - NDT-Magnetic Particle ExaminationKatsaras SotirisNoch keine Bewertungen

- 12 MT ProcedureDokument17 Seiten12 MT ProcedureThân KhaNoch keine Bewertungen

- Liquid Penetrant TestingDokument20 SeitenLiquid Penetrant TestingsanjibkrjanaNoch keine Bewertungen

- Approval of NDT PersonnelDokument8 SeitenApproval of NDT Personnelapi-3703379100% (1)

- Welding of RailsDokument15 SeitenWelding of RailsRajha RajeswaranNoch keine Bewertungen

- Liquid Penetrant Testing Procedure - IDokument2 SeitenLiquid Penetrant Testing Procedure - IManivannanMudhaliarNoch keine Bewertungen

- 2009FDokument26 Seiten2009FdaimaheshNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Saudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Dokument6 SeitenSaudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Ma.socorro SaballaNoch keine Bewertungen

- Saudi Aramco Test ReportDokument8 SeitenSaudi Aramco Test ReportMa.socorro SaballaNoch keine Bewertungen

- LNG-80-100937-RA-6065-00023-0000 HT PipingDokument7 SeitenLNG-80-100937-RA-6065-00023-0000 HT PipingMohammad AftabNoch keine Bewertungen

- Safety Data Sheet for Photographic Developer ConcentrateDokument7 SeitenSafety Data Sheet for Photographic Developer ConcentrateCharlesNoch keine Bewertungen

- G135, PART A: Safety Data SheetDokument8 SeitenG135, PART A: Safety Data SheetCharlesNoch keine Bewertungen

- Crane Hooks and Lifting AidsDokument8 SeitenCrane Hooks and Lifting AidsCharlesNoch keine Bewertungen

- LC-2D Ultrasonic Thickness GaugeDokument1 SeiteLC-2D Ultrasonic Thickness GaugeCharles OnyechereNoch keine Bewertungen

- Peru LNG Export Project Piles Inspection and Testing PlanDokument7 SeitenPeru LNG Export Project Piles Inspection and Testing PlandietersimaNoch keine Bewertungen

- E 9604Dokument4 SeitenE 9604dimdaliak_985662241Noch keine Bewertungen

- Weld scanning calculations and techniques for flat platesDokument1 SeiteWeld scanning calculations and techniques for flat platesjavierNoch keine Bewertungen

- 16-Preiss-Study en 13445-Asme VIIIDokument26 Seiten16-Preiss-Study en 13445-Asme VIIISivi NallamothuNoch keine Bewertungen

- CorrosionDokument5 SeitenCorrosionTHIRU.SNoch keine Bewertungen

- N SNT Tc1a PDFDokument4 SeitenN SNT Tc1a PDFRyan Early100% (1)

- The Revised VGB-S-506pg9Dokument1 SeiteThe Revised VGB-S-506pg9retrogrades retrogradesNoch keine Bewertungen

- Handbook of Plastics Testing and Failure AnalysisDokument13 SeitenHandbook of Plastics Testing and Failure AnalysisAndrei Jose GilNoch keine Bewertungen

- Calibrating Phased Arrays for Full Matrix Capture (FMCDokument10 SeitenCalibrating Phased Arrays for Full Matrix Capture (FMCPetrNoch keine Bewertungen

- Annexure III Scope of Work and Special ConditionsDokument7 SeitenAnnexure III Scope of Work and Special Conditionsraj1508Noch keine Bewertungen

- Practica Normalizada Agencias E543Dokument10 SeitenPractica Normalizada Agencias E543JHONATAN ROBERTO FLORES JOAQUINNoch keine Bewertungen

- Repair Procedure F - 23202 NewDokument5 SeitenRepair Procedure F - 23202 NewMohd Shafuaaz KassimNoch keine Bewertungen

- Offshore Mooring Chain Cables and AccessoriesDokument8 SeitenOffshore Mooring Chain Cables and Accessoriesscofiel1Noch keine Bewertungen

- CVDokument3 SeitenCVsenthil rajaNoch keine Bewertungen

- A1005Dokument6 SeitenA1005hamidharvardNoch keine Bewertungen

- PO Piping, Painting, FF Work Package - MGPDokument8 SeitenPO Piping, Painting, FF Work Package - MGPIlmi Amalia SholikhaNoch keine Bewertungen

- 000-API 510 Pressure Vessel Iinspector Preparation Course BROCHUREDokument9 Seiten000-API 510 Pressure Vessel Iinspector Preparation Course BROCHUREInstech Premier Sdn BhdNoch keine Bewertungen