Beruflich Dokumente

Kultur Dokumente

Motionpro Double-Wishbone Suspension: - Kinematic Modeling, Simulation and Optimization of A

Hochgeladen von

vs.krishnakanthOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Motionpro Double-Wishbone Suspension: - Kinematic Modeling, Simulation and Optimization of A

Hochgeladen von

vs.krishnakanthCopyright:

Verfügbare Formate

MotionPro - Kinematic Modeling, Simulation and Optimization of a

Double-Wishbone Suspension

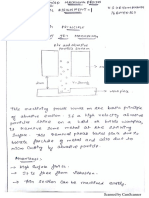

The dynamic stability of a vehicle, as well as fuel efficiency

and tire wear, is directly affected by the kinematic behavior

of the suspension mechanism. A great deal of effort is need-

ed to achieve the best possible movement of the wheel

camber, caster and toe-in as the suspension responds to a

bump in the road. This is particularly complex to achieve in

a double-wishbone suspension because there are ten joints

that influence the geometry of the system, as well the posi-

tions of the centers of the wheel and the steering cylinder.

These are known as the “Hard Points” and are defined as

coordinates in space, relative to a global reference frame,

when the suspension is designed.

The challenge is to define these hard points in order to

achieve the desired kinematics for the vehicle. Using Maple

and DynaFlexPro, it is very easy to graphically define the “The ability to turn these types of calculations around

topology of the mechanism using blocks and lines, from very quickly saves us a lot of time. This in itself is very

which the equations that define camber, caster and toe-in useful, but the ability to automatically fit the responses

are automatically derived in parametric terms (that is, as to published results is very exciting indeed.”

symbolic variables that have yet to be assigned numerical

John McPhee - Chief Scientist, MotionPro Inc

values).

Once the model has been defined, the engineer can enter

the numeric values for the x,y,z coordinates of each hard

point. Maple then solves the resulting system of ODEs to

produce the camber, caster and toe-in over a given vertical

displacement applied to the wheel (in this case, a sine wave

of amplitude 100mm to represent a bump and rebound).

These are the results for a given set of hard-point values,

defined prior to performing the calculations. Normally,

these values are compared with standard curves to ensure

that they comply with the desired kinematics for the

vehicle. Of course, on a first pass this is very unlikely and

the engineer will need to adjust the hard points to give the Once you have optimized the model you can then export

desired curve, which can be very painstaking and time-con- it to Simulink as an s-Function block using BlockBuilder for

suming. Simulink, so you have a very high fidelity component for

simulating the vehicle, particularly in real-time for hard-

ware-in-the-loop testing in the lab but with close-to-road

conditions.

You can try out an interactive version of this

Maple application at www.maplesoft.com/vehicle

A more efficient method is to import the standard curves

as data sets and use the Global Optimization Toolbox for

Maple. Using the imported curves as the objective func-

tions, you can identify which hard points can be moved

(very often, there are only a few that can be moved because

of other design constraints) and by how much. The Global

Optimization toolbox will then find the “best-fit” coor-

dinates that will produce the kinematics closest to the

desired curves. www.maplesoft.com | info@maplesoft.com

© Maplesoft, a division of Waterloo Maple Inc., 2007. Maplesoft, and Maple are trademarks of Waterloo Maple Inc. All other trademarks are the property of their respective owners.

Das könnte Ihnen auch gefallen

- Research Collection: Comprehensive Locomotion Performance Evaluation of All-Terrain RobotsDokument7 SeitenResearch Collection: Comprehensive Locomotion Performance Evaluation of All-Terrain RobotsNishit PachpandeNoch keine Bewertungen

- ADAMS-MATLAB Co-Simulation of A Serial ManipulatorDokument6 SeitenADAMS-MATLAB Co-Simulation of A Serial Manipulator阳智Noch keine Bewertungen

- A Tool For Lap Time Simulation PDFDokument5 SeitenA Tool For Lap Time Simulation PDFRodrigo BobNoch keine Bewertungen

- 2007-Performance Comparison of Roughterrain Robots - Simulation and Hard WearDokument24 Seiten2007-Performance Comparison of Roughterrain Robots - Simulation and Hard Wearmishel jonNoch keine Bewertungen

- Brochure LMS Virtual - Lab MotionDokument20 SeitenBrochure LMS Virtual - Lab MotionAldo A. MamaniNoch keine Bewertungen

- D74a PDFDokument10 SeitenD74a PDFAndyNoch keine Bewertungen

- Structural and Modal Analysis of Scooter Frame: D.Mohankumar, R. Sabarish, Dr. M. PremjeyakumarDokument10 SeitenStructural and Modal Analysis of Scooter Frame: D.Mohankumar, R. Sabarish, Dr. M. PremjeyakumarChu Ngọc TúNoch keine Bewertungen

- Modelling of Robotic Single Peg-In-Hole Assembly UDokument12 SeitenModelling of Robotic Single Peg-In-Hole Assembly UMohammed AamerNoch keine Bewertungen

- MBD PDFDokument53 SeitenMBD PDFMina ZakariaNoch keine Bewertungen

- Basic of Dynamic Simulation Auto Desk InventorDokument24 SeitenBasic of Dynamic Simulation Auto Desk Inventorranganathan0818Noch keine Bewertungen

- MotorcycleDokument4 SeitenMotorcycleAlejo PerezNoch keine Bewertungen

- Real Time SimulationDokument7 SeitenReal Time SimulationkumarNoch keine Bewertungen

- Whats Newb FGDFDokument20 SeitenWhats Newb FGDFHumayun NawazNoch keine Bewertungen

- Training CST 3Dokument50 SeitenTraining CST 3Trần PhanNoch keine Bewertungen

- 工程吊車之物理行為模擬 Physics-Based Simulation of Detailed Erection Activities of Construction CranesDokument10 Seiten工程吊車之物理行為模擬 Physics-Based Simulation of Detailed Erection Activities of Construction CranesDanut CalugarNoch keine Bewertungen

- Landing GearDokument12 SeitenLanding GearcmpmarinhoNoch keine Bewertungen

- AA V2 I4 Multibody DynamicsDokument3 SeitenAA V2 I4 Multibody DynamicsArnab DuttaNoch keine Bewertungen

- Twu GM Final 3232012Dokument10 SeitenTwu GM Final 3232012matmeanNoch keine Bewertungen

- Model-Based Design of An LQR Controller For A Single Inverted Rotary PendulumDokument1 SeiteModel-Based Design of An LQR Controller For A Single Inverted Rotary PendulumSahil BhattNoch keine Bewertungen

- From The Farm To The Home: Dem Improves The World: Titus SgroDokument4 SeitenFrom The Farm To The Home: Dem Improves The World: Titus SgroUmut CırıkNoch keine Bewertungen

- Design of High-Speed Cam Profiles For Vibration Reduction Using Command Smoothing TechniqueDokument7 SeitenDesign of High-Speed Cam Profiles For Vibration Reduction Using Command Smoothing TechniqueArcenio GutierrezNoch keine Bewertungen

- A New Methodology To Optimize Spiral Bevel Gear TopographyDokument4 SeitenA New Methodology To Optimize Spiral Bevel Gear TopographyBiden LeNoch keine Bewertungen

- Computational Multicopter DesignDokument10 SeitenComputational Multicopter DesignMohd BabarNoch keine Bewertungen

- Handout 2946 MA2946-L PDFDokument24 SeitenHandout 2946 MA2946-L PDFClaudio ColuccioNoch keine Bewertungen

- Project ProposalDokument11 SeitenProject ProposalKevin Christian PlataNoch keine Bewertungen

- Modelamiento Implicito - VULCANDokument15 SeitenModelamiento Implicito - VULCANChristian CRNoch keine Bewertungen

- New Calculations From Hydrocomp Using Quantitative Relational ElementsDokument4 SeitenNew Calculations From Hydrocomp Using Quantitative Relational Elementstheleepiper8830Noch keine Bewertungen

- TheFocus 55 PDFDokument7 SeitenTheFocus 55 PDFYousefNoch keine Bewertungen

- Real Time Simulation of Complex Automatic Transmission ModelsDokument20 SeitenReal Time Simulation of Complex Automatic Transmission ModelsSudev NairNoch keine Bewertungen

- Flight Simulators Using Parallel RobotsDokument23 SeitenFlight Simulators Using Parallel RobotsAngela Birlea100% (1)

- Finite Element Based Analysis of Rotating Robot PedestalDokument5 SeitenFinite Element Based Analysis of Rotating Robot PedestalAnonymous kw8Yrp0R5rNoch keine Bewertungen

- On Solving The Inverse Kinematics Problem Using Neural NetworksDokument7 SeitenOn Solving The Inverse Kinematics Problem Using Neural NetworksAlejandro CastilloNoch keine Bewertungen

- Full Vehicle Durability Using Abaqus/Standard To Abaqus/Explicit Co-Simulation 2011Dokument4 SeitenFull Vehicle Durability Using Abaqus/Standard To Abaqus/Explicit Co-Simulation 2011SIMULIACorpNoch keine Bewertungen

- Ds Adams-Machinery LTR WDokument2 SeitenDs Adams-Machinery LTR WAydinNoch keine Bewertungen

- ChapterDokument1 SeiteChaptersenthilkumarksk5585Noch keine Bewertungen

- (Brief Report) : Abaqus Fe-SafeDokument3 Seiten(Brief Report) : Abaqus Fe-SafeDigantNoch keine Bewertungen

- The Cosmos Companion: Using Cosmosmotion Loads in CosmosworksDokument25 SeitenThe Cosmos Companion: Using Cosmosmotion Loads in CosmosworksNurul HudaNoch keine Bewertungen

- Minimum-Time Trajectory Planning and Control of A Pick-and-Place Five-Bar Parallel RobotDokument10 SeitenMinimum-Time Trajectory Planning and Control of A Pick-and-Place Five-Bar Parallel Robotibrahimgulay15Noch keine Bewertungen

- Auto Full Vehicle Durability Using Abaqus Standard 11Dokument4 SeitenAuto Full Vehicle Durability Using Abaqus Standard 11TimNoch keine Bewertungen

- A Tool For Rapid Vehicle Suspension Design PDFDokument10 SeitenA Tool For Rapid Vehicle Suspension Design PDFmikael bezerra cotias dos santosNoch keine Bewertungen

- Sloshing in A Tank Modelled Using SPH As An Example in AbaqusDokument11 SeitenSloshing in A Tank Modelled Using SPH As An Example in AbaqusPravinkumarGhodake100% (1)

- Star CCM+: 3D-CAD ModelerDokument4 SeitenStar CCM+: 3D-CAD ModelerlukhmanNoch keine Bewertungen

- Performing A Parametric Brake Squeal Analysis in Ansys WB and Optislang 569ff01c1de92Dokument91 SeitenPerforming A Parametric Brake Squeal Analysis in Ansys WB and Optislang 569ff01c1de92Jitendra ItankarNoch keine Bewertungen

- Basicsofsap2000 160501061643Dokument6 SeitenBasicsofsap2000 160501061643Sajid HanifNoch keine Bewertungen

- Realis IgniteDokument6 SeitenRealis IgniteGodwin JerryNoch keine Bewertungen

- Data 01Dokument2 SeitenData 01aula8045040Noch keine Bewertungen

- Modelling Flexible Parts For Virtual Reality Assembly SimulationDokument10 SeitenModelling Flexible Parts For Virtual Reality Assembly SimulationFeby AbrahamNoch keine Bewertungen

- Design and Analysis of Railway Casnub Bogie Using FemDokument5 SeitenDesign and Analysis of Railway Casnub Bogie Using FemmiladNoch keine Bewertungen

- Simulational and Experimental DeterDokument23 SeitenSimulational and Experimental Deteryellowish123Noch keine Bewertungen

- APC Fauricia 2009Dokument5 SeitenAPC Fauricia 2009Charlie TejNoch keine Bewertungen

- Dynamic Model Identification For Industrial Robots: Integrated Experiment Design and Parameter EstimationDokument14 SeitenDynamic Model Identification For Industrial Robots: Integrated Experiment Design and Parameter Estimationسمية عصامNoch keine Bewertungen

- Scara RobotDokument13 SeitenScara RobotMuhammad Ikhsan Al-fatihNoch keine Bewertungen

- Analyze Contact Patterns For Uav Helicopter Transmission in Prototype TrialsDokument4 SeitenAnalyze Contact Patterns For Uav Helicopter Transmission in Prototype TrialsS.Mohana sundaramNoch keine Bewertungen

- Zhang Yao Juan 2011Dokument4 SeitenZhang Yao Juan 2011Gia Phạm HoàngNoch keine Bewertungen

- Hwsolvers12.0.220 ReleaseNotesDokument40 SeitenHwsolvers12.0.220 ReleaseNotesporukiNoch keine Bewertungen

- Cosmosmotion Advanced TrainingDokument38 SeitenCosmosmotion Advanced TrainingRene D. ArrietaNoch keine Bewertungen

- Honda DurabilityDokument3 SeitenHonda DurabilityrcpawarNoch keine Bewertungen

- Motions Simulation 2010 ENG FINALDokument16 SeitenMotions Simulation 2010 ENG FINALLorenzoNoch keine Bewertungen

- TIME SERIES FORECASTING. ARIMAX, ARCH AND GARCH MODELS FOR UNIVARIATE TIME SERIES ANALYSIS. Examples with MatlabVon EverandTIME SERIES FORECASTING. ARIMAX, ARCH AND GARCH MODELS FOR UNIVARIATE TIME SERIES ANALYSIS. Examples with MatlabNoch keine Bewertungen

- LSM Da4 - 16BME0860Dokument5 SeitenLSM Da4 - 16BME0860vs.krishnakanthNoch keine Bewertungen

- Deep Drawing of Fiber Metal Laminates For Automotive Lightweight StructuresDokument5 SeitenDeep Drawing of Fiber Metal Laminates For Automotive Lightweight Structuresvs.krishnakanthNoch keine Bewertungen

- Solar Thermal PDFDokument1 SeiteSolar Thermal PDFvs.krishnakanthNoch keine Bewertungen

- Café Coffee Day (CCD) : A Case Analysis: SSRN Electronic Journal September 2011Dokument15 SeitenCafé Coffee Day (CCD) : A Case Analysis: SSRN Electronic Journal September 2011vs.krishnakanthNoch keine Bewertungen

- Soft SkillDokument15 SeitenSoft Skillvs.krishnakanthNoch keine Bewertungen

- Liquid PenetrantDokument4 SeitenLiquid Penetrantvs.krishnakanthNoch keine Bewertungen

- Ultra SonicDokument4 SeitenUltra Sonicvs.krishnakanthNoch keine Bewertungen

- Mechanical Engineering: The "Gears" of FutureDokument10 SeitenMechanical Engineering: The "Gears" of Futurevs.krishnakanthNoch keine Bewertungen

- Ultrasonic TestingDokument6 SeitenUltrasonic Testingvs.krishnakanthNoch keine Bewertungen

- Thickness of FilmDokument4 SeitenThickness of Filmvs.krishnakanthNoch keine Bewertungen

- (U - oV.-M : ) DoteDokument3 Seiten(U - oV.-M : ) Dotevs.krishnakanthNoch keine Bewertungen

- Electrochemical Machining - Special Equipment and Applications in Aircraft IndustryDokument8 SeitenElectrochemical Machining - Special Equipment and Applications in Aircraft Industryvs.krishnakanthNoch keine Bewertungen

- Advanced MachiningDokument21 SeitenAdvanced Machiningvs.krishnakanthNoch keine Bewertungen

- School of Mechanical Engineering: Digital Assignment - II, September 2018-19 B.Tech. (BME/BPI), Fall Semester-2018-19Dokument1 SeiteSchool of Mechanical Engineering: Digital Assignment - II, September 2018-19 B.Tech. (BME/BPI), Fall Semester-2018-19vs.krishnakanthNoch keine Bewertungen

- Abrasive Jet MachiningDokument20 SeitenAbrasive Jet Machiningvs.krishnakanthNoch keine Bewertungen

- Digital Assignment-1 DUE DATE: 31-08-2018 Question-1Dokument1 SeiteDigital Assignment-1 DUE DATE: 31-08-2018 Question-1vs.krishnakanthNoch keine Bewertungen

- Ajm PDFDokument14 SeitenAjm PDFvs.krishnakanthNoch keine Bewertungen

- Scanned by CamscannerDokument6 SeitenScanned by Camscannervs.krishnakanthNoch keine Bewertungen

- Fall 18-19 Reg Schedule PDFDokument1 SeiteFall 18-19 Reg Schedule PDFvs.krishnakanthNoch keine Bewertungen

- BX-74 / BX-78: Sliding Gate Operator BX SeriesDokument24 SeitenBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovNoch keine Bewertungen

- LCD TV W DVD PDFDokument5 SeitenLCD TV W DVD PDFINJESBGNoch keine Bewertungen

- DNF Stand PipeDokument3 SeitenDNF Stand PipeChristopher BrownNoch keine Bewertungen

- Pavement Evaluation and Overlay Des - DR MSA - LatestDokument103 SeitenPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruNoch keine Bewertungen

- Bsee201 B - Fluid MechanicsDokument150 SeitenBsee201 B - Fluid MechanicsMarvin GagarinNoch keine Bewertungen

- Bends - Route SelectionDokument6 SeitenBends - Route SelectionanishsrNoch keine Bewertungen

- ARO Pump ManualDokument8 SeitenARO Pump Manualrazaq athabNoch keine Bewertungen

- Tutorial Questions and Answers - 2011Dokument10 SeitenTutorial Questions and Answers - 2011Jan ScarNoch keine Bewertungen

- Códigos de Falhas Hyundai R3607ADokument13 SeitenCódigos de Falhas Hyundai R3607AGuemep GuemepNoch keine Bewertungen

- Griet DSP ProgramsDokument14 SeitenGriet DSP ProgramsJaipaul CheernamNoch keine Bewertungen

- Advance Concrete PDFDokument33 SeitenAdvance Concrete PDFUdom RithNoch keine Bewertungen

- Foundation Construction Challenges at 100 11th Avenue in Manhattan - Secant Pile Wall by Andrew Cushing, Et. Al.Dokument8 SeitenFoundation Construction Challenges at 100 11th Avenue in Manhattan - Secant Pile Wall by Andrew Cushing, Et. Al.Andrew CushingNoch keine Bewertungen

- Technical InformationDokument8 SeitenTechnical Informationmyusuf_engineerNoch keine Bewertungen

- Manual Aspire 5551Dokument210 SeitenManual Aspire 5551Arnaud NetoNoch keine Bewertungen

- Manual PSW 2600Dokument18 SeitenManual PSW 2600Jc C. GomezNoch keine Bewertungen

- AE Yanmar 6GL UTDokument151 SeitenAE Yanmar 6GL UTMehdi Es-SafiNoch keine Bewertungen

- GeomediaDokument37 SeitenGeomediaEdilson MahumaneNoch keine Bewertungen

- Heavy Duty 2.5 Ton Long Frame Floor Jack Product ManualDokument3 SeitenHeavy Duty 2.5 Ton Long Frame Floor Jack Product ManualChris Epler100% (2)

- TDS Tixatrol STDokument2 SeitenTDS Tixatrol STJose E BatistaNoch keine Bewertungen

- Below Which Not More Than 5 Percent of The Test Results Are Expected To Fall"Dokument13 SeitenBelow Which Not More Than 5 Percent of The Test Results Are Expected To Fall"shravan iitmNoch keine Bewertungen

- Hayward Super II Pump Model SP3005X7 ManualDokument14 SeitenHayward Super II Pump Model SP3005X7 ManualhsmerkelNoch keine Bewertungen

- Electromagnetic CompatibilityDokument12 SeitenElectromagnetic Compatibilityoadipphone7031Noch keine Bewertungen

- Flight DynamicsDokument57 SeitenFlight DynamicsDexto100% (2)

- Cable TrenchDokument57 SeitenCable TrenchHari Krishna AaryanNoch keine Bewertungen

- Confined Space Entry Permit ACC JamulDokument1 SeiteConfined Space Entry Permit ACC JamulathulpcucekNoch keine Bewertungen

- Deaton FE Slab DesignDokument57 SeitenDeaton FE Slab DesignMohamed AliNoch keine Bewertungen

- E-Line DLDokument21 SeitenE-Line DLiulian17dNoch keine Bewertungen

- SensoNODE Catalog 3864 Feb 2015Dokument28 SeitenSensoNODE Catalog 3864 Feb 2015btsgr parkerNoch keine Bewertungen

- Aerospace MaterialsDokument68 SeitenAerospace MaterialsAykut Üçtepe100% (1)

- Module D Exercise ModD - QB09 - EngDokument4 SeitenModule D Exercise ModD - QB09 - Engapi-3812894Noch keine Bewertungen