Beruflich Dokumente

Kultur Dokumente

Using Manual (Rig) Tongs

Hochgeladen von

Abdul Hameed OmarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Using Manual (Rig) Tongs

Hochgeladen von

Abdul Hameed OmarCopyright:

Verfügbare Formate

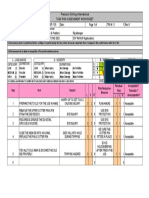

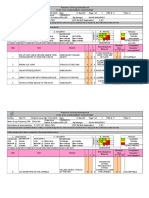

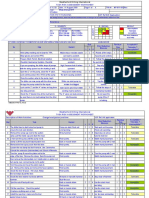

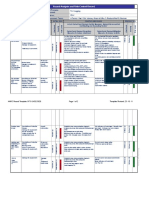

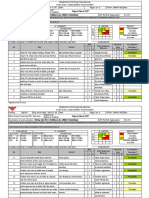

Precision Drilling International

TASK RISK ASSESSMENT WORKSHEET

Facility: Rig 787 Original Issue Date: SEP-19-05 Date: Page 1 of TRA # : 29 1 Rev:0

Supervisor:

Work Group Preparing TRA:

(Name & Position) Rig Manager

Description of work activities: USING RIG TONGS SOP Ref # (If Applicable):

List unusual physical or operational factors, existing or expected during this tour, which will cause a departure from or changes to the content below within this TRA:

List the measures to be taken in recognition of the points mentioned above:

L - LIKELIHOOD S - SEVERITY R - RATING RESULT

SEVERITY

CATEGORY DEFINITION CATEGORY DEFINITIONS L 1 2 3 Acceptable

LOW (1) Remote LOW (1) Minor Injury No Damage No Pollution M 2 4 6 Tolerable

MEDIUM (2) Possible MEDIUM (2) Serious Injury Minor Damage Minor Pollution H 3 6 9 Unacceptable

HIGH (3) Probable HIGH (3) Major Injury Major Damage Major Pollution L M H TRA Policy Reference

IS THERE A SAFER WAY TO COMPLETE THE JOB? ARE THERE ALTERNATIVES WITH LESS RISK? LIKELIHOOD 03-31-PRO

Residual Acceptable?

Risk Reduction

Step Task Hazard Risk Tolerable ?

Measure

L S R L S R Unacceptable?

USE THE HANDLES

1 PUSH THE TONG TO TOOL JOINT HAND INJURY 3 3 9 ONLY 0 Acceptable

BE PREPAIRED TO

MOVE BACK OUT

OF THE TURNING

THE TONG SLIPT, DIES IN TONG RANGE.

2 PULLING ON THE CHAIN BAD CONDITION 3 3 9 BE SURE

CHECK NODIES.

THE 0

RESEDUAL

TORQUE, USE

HANDLE ALL TIME.

AFTER MAKE-UP IS COMPLETED, OPEN THE STRUCK BY THE TONG, SECURE THE

3 TONG HEADS HAND INJURY. 3 3 9 TONG. 0

PERIODICALLY

CHECK TONGS

FOR WEAR TO

4 REPEAT THE PREVIOUS STEPS. STRUCK BY THE TONG, 3 3 9 DIES. 0

0 0

0 0

0 0

Das könnte Ihnen auch gefallen

- Precision Drilling International Task Risk Assessment WorksheetDokument2 SeitenPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNoch keine Bewertungen

- Change Out Rig Tong DiesDokument1 SeiteChange Out Rig Tong DiesAbdul Hameed OmarNoch keine Bewertungen

- Precision Drilling International Task Risk Assessment WorksheetDokument1 SeitePrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNoch keine Bewertungen

- Lay Down Drill PipeDokument2 SeitenLay Down Drill PipeAbdul Hameed OmarNoch keine Bewertungen

- Precision Drilling International Task Risk Assessment WorksheetDokument2 SeitenPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNoch keine Bewertungen

- Install 500 Ton Slips & ElevatorDokument1 SeiteInstall 500 Ton Slips & ElevatorAbdul Hameed OmarNoch keine Bewertungen

- Daily Checks (Floorman)Dokument1 SeiteDaily Checks (Floorman)Abdul Hameed OmarNoch keine Bewertungen

- Precision Drilling International Task Risk Assessment WorksheetDokument2 SeitenPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNoch keine Bewertungen

- MP-005 Change Relief Valve On Mud Pump.Dokument2 SeitenMP-005 Change Relief Valve On Mud Pump.khurramNoch keine Bewertungen

- Bop Ram ChangeDokument2 SeitenBop Ram ChangeAbdul Hameed OmarNoch keine Bewertungen

- MP-001 Change Head and Liner of Mud PumpDokument3 SeitenMP-001 Change Head and Liner of Mud PumpkhurramNoch keine Bewertungen

- Working On Mud PumpDokument1 SeiteWorking On Mud PumpAbdul Hameed OmarNoch keine Bewertungen

- Rigging Down Shooting NippleDokument2 SeitenRigging Down Shooting NippleAbdul Hameed Omar100% (1)

- IADC Incident StatisticsDokument15 SeitenIADC Incident StatisticsAnisBelhajAissaNoch keine Bewertungen

- BOP Nipple Down 17-May-2010Dokument1 SeiteBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- Rig Specific Emergency Response Plan Rev1Dokument33 SeitenRig Specific Emergency Response Plan Rev1bilou100% (1)

- RM-001 Rig Move TRADokument7 SeitenRM-001 Rig Move TRAcenim2004Noch keine Bewertungen

- Safety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonsDokument4 SeitenSafety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonskhaledNoch keine Bewertungen

- Risk Assessment Report: ON Sun CaterersDokument14 SeitenRisk Assessment Report: ON Sun CaterersRaichel SuseelNoch keine Bewertungen

- IRP 22 Risk Register 2015Dokument29 SeitenIRP 22 Risk Register 2015Khuda BukshNoch keine Bewertungen

- Monthly Hse Rig InspectionDokument7 SeitenMonthly Hse Rig InspectionHidacio Da LimiaNoch keine Bewertungen

- EDC-61 Rig SurveyDokument14 SeitenEDC-61 Rig SurveyMostafa Elghifary100% (1)

- LWD Log Quality Control Manual Rev5Dokument57 SeitenLWD Log Quality Control Manual Rev5Josué SánchezNoch keine Bewertungen

- Dismantling of Concrete Pump TowerDokument1 SeiteDismantling of Concrete Pump TowerChandruNoch keine Bewertungen

- Have You Been SET-UP? A Brief Discussion On Job Hazard Analysis (Jha)Dokument30 SeitenHave You Been SET-UP? A Brief Discussion On Job Hazard Analysis (Jha)Ian KoNoch keine Bewertungen

- IDC SOP # XX Laying Down Drill Pipe From DerrickDokument4 SeitenIDC SOP # XX Laying Down Drill Pipe From DerrickkareemNoch keine Bewertungen

- RA Every ActvityDokument38 SeitenRA Every ActvityvijayNoch keine Bewertungen

- Visible Safety and Induction: Hse Management Visit ChecklistDokument6 SeitenVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNoch keine Bewertungen

- Safety Communications Log Sheet 2008Dokument1 SeiteSafety Communications Log Sheet 2008Abdul Hameed OmarNoch keine Bewertungen

- Risk AssesmentDokument2 SeitenRisk Assesmentsabu1995Noch keine Bewertungen

- Risk Assessment GardenDokument2 SeitenRisk Assessment GardenMatthew BaguleyNoch keine Bewertungen

- Viking H Se ManualDokument168 SeitenViking H Se ManualAF Dowell MirinNoch keine Bewertungen

- Risk Assessment and Method Statement Hollowcore Plank Installation With CraneDokument17 SeitenRisk Assessment and Method Statement Hollowcore Plank Installation With CraneA123Y123Noch keine Bewertungen

- Wide Communication Project Risk Register: ID Risk Factor Qualitative Risk Ranking LOW Medium HighDokument6 SeitenWide Communication Project Risk Register: ID Risk Factor Qualitative Risk Ranking LOW Medium HighAIDO SEGUNNoch keine Bewertungen

- HSE-RA-067 Threading Machine - Rev 0Dokument14 SeitenHSE-RA-067 Threading Machine - Rev 0عمروNoch keine Bewertungen

- Cairn Energy - Oil Spill Contingency Plan - 2011 - PublicDokument220 SeitenCairn Energy - Oil Spill Contingency Plan - 2011 - PublicQHSE Manager100% (1)

- Tennin HAZOPDokument4 SeitenTennin HAZOPMohamed SamirNoch keine Bewertungen

- Harc TLC Kd-1revisiDokument2 SeitenHarc TLC Kd-1revisitanjungkasri rayaNoch keine Bewertungen

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDokument1 SeiteAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNoch keine Bewertungen

- JSA HEMP Well Services Pg36-40Dokument5 SeitenJSA HEMP Well Services Pg36-40Ashok SureshNoch keine Bewertungen

- Running TubingDokument3 SeitenRunning TubingAbdul Hameed OmarNoch keine Bewertungen

- Moving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaDokument28 SeitenMoving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaHSE PT. GROGOL SARANA TRANSJAYANoch keine Bewertungen

- JSA HEMP Well Services Pg25-30Dokument5 SeitenJSA HEMP Well Services Pg25-30Ashok SureshNoch keine Bewertungen

- Oil Rig Inspection ChecklistDokument17 SeitenOil Rig Inspection ChecklistAhmedNoch keine Bewertungen

- Sa-07-09.PDF 4 Part ShackleDokument2 SeitenSa-07-09.PDF 4 Part ShackleSafety VirtueNoch keine Bewertungen

- Moving Convoy Wide Load - RA-R9-01-014-01Dokument2 SeitenMoving Convoy Wide Load - RA-R9-01-014-01cmrig74Noch keine Bewertungen

- 4.4.6 Hazard Identification Risk Assessment and Control Rev 0Dokument8 Seiten4.4.6 Hazard Identification Risk Assessment and Control Rev 0chemist_tmaNoch keine Bewertungen

- MRF-08 - Top Drive GreasingDokument1 SeiteMRF-08 - Top Drive GreasingAbdul Hameed OmarNoch keine Bewertungen

- Process and Risk Assessment Template All Faculty January 2015Dokument6 SeitenProcess and Risk Assessment Template All Faculty January 2015hungonline07Noch keine Bewertungen

- Risk RegisterDokument24 SeitenRisk Registervikrant911100% (2)

- Caustic Soda: Safety Data SheetDokument6 SeitenCaustic Soda: Safety Data SheetmikeNoch keine Bewertungen

- Level Iii - Ims Operational Control Procedures Manual TITLE: Safe Handling of Tools Effective Date: January 21, 2018Dokument9 SeitenLevel Iii - Ims Operational Control Procedures Manual TITLE: Safe Handling of Tools Effective Date: January 21, 2018arunkumar panigrahi100% (1)

- Dropped Object Awareness and Prevention SPSDokument54 SeitenDropped Object Awareness and Prevention SPSahmadNoch keine Bewertungen

- Rig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickDokument5 SeitenRig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickMalik Muhammad Nauman ZiaNoch keine Bewertungen

- IBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Dokument51 SeitenIBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Boedi Syafiq100% (1)

- Rig 812-A-017-JHA Man Riding SOPDokument5 SeitenRig 812-A-017-JHA Man Riding SOPMalik Muhammad Nauman ZiaNoch keine Bewertungen

- 4.01 IOEC Rigs Commisioning Project HSE PlanDokument59 Seiten4.01 IOEC Rigs Commisioning Project HSE Planhshobeyri100% (2)

- #101 - Oilfield HSE Inspection HandbookDokument30 Seiten#101 - Oilfield HSE Inspection HandbookEagle EyeNoch keine Bewertungen

- DW-002 String Up New Drilling Line, Mast Up.Dokument4 SeitenDW-002 String Up New Drilling Line, Mast Up.khurramNoch keine Bewertungen

- JHA Grass CutterDokument2 SeitenJHA Grass Cutterjohn jaycoh veranoNoch keine Bewertungen

- 39 - Buckling & Wellhead Load After CementingDokument2 Seiten39 - Buckling & Wellhead Load After CementingAbdul Hameed OmarNoch keine Bewertungen

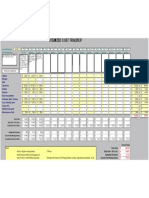

- 10 - Simple Mud Engineerv1.22Dokument22 Seiten10 - Simple Mud Engineerv1.22Abdul Hameed OmarNoch keine Bewertungen

- Wo Cost TrackerDokument1 SeiteWo Cost TrackerAbdul Hameed OmarNoch keine Bewertungen

- Subsea AccumulatorsDokument4 SeitenSubsea AccumulatorsAbdul Hameed OmarNoch keine Bewertungen

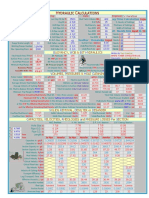

- Drilling Application: Name of Company: Well Name & Number: DateDokument1 SeiteDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNoch keine Bewertungen

- Hydraulic Calculations MudpumpDokument1 SeiteHydraulic Calculations MudpumpSudish BhatNoch keine Bewertungen

- Data Input Sheet: A Worksheet From Well Control TOOLKIT - .Dokument4 SeitenData Input Sheet: A Worksheet From Well Control TOOLKIT - .Abdul Hameed OmarNoch keine Bewertungen

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDokument3 SeitenMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarNoch keine Bewertungen

- Ideal Kick Removal: Drill Hole DataDokument2 SeitenIdeal Kick Removal: Drill Hole DataAbdul Hameed OmarNoch keine Bewertungen

- Drilling Application: Name of Company: Well Name & Number: DateDokument1 SeiteDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNoch keine Bewertungen

- 1260707829bop Test FormDokument4 Seiten1260707829bop Test FormAbdul Hameed Omar100% (1)

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Dokument1 SeiteDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNoch keine Bewertungen

- 1260707780BOP Equipment Failure ReportDokument1 Seite1260707780BOP Equipment Failure ReportAbdul Hameed OmarNoch keine Bewertungen

- 1260709146e - Hydraulics PDFDokument9 Seiten1260709146e - Hydraulics PDFAbdul Hameed OmarNoch keine Bewertungen

- Allowable Drilling Torque: Calculations 30,577 4.855 21.733 4.154 0.362 0.2Dokument1 SeiteAllowable Drilling Torque: Calculations 30,577 4.855 21.733 4.154 0.362 0.2Abdul Hameed OmarNoch keine Bewertungen

- TDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTDokument1 SeiteTDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTAbdul Hameed OmarNoch keine Bewertungen

- Assortment of Mini ApplicationsDokument1 SeiteAssortment of Mini ApplicationsAbdul Hameed OmarNoch keine Bewertungen

- New TDS 11 CourseDokument171 SeitenNew TDS 11 CourseAbdul Hameed Omar100% (3)

- Asset RegisterDokument101 SeitenAsset RegistertothemNoch keine Bewertungen

- TMSi Train-Matrix 2009Dokument30 SeitenTMSi Train-Matrix 2009api-3713539100% (1)

- Job Safety Analisis (JSA) FormDokument4 SeitenJob Safety Analisis (JSA) FormMrafley PratamaNoch keine Bewertungen

- USARAF 200-06 - Pam - Hazardous Materials Management - 2011 08 01Dokument19 SeitenUSARAF 200-06 - Pam - Hazardous Materials Management - 2011 08 01Seamus OhanragainNoch keine Bewertungen

- SWP Working Safely at Height Version 2.01Dokument7 SeitenSWP Working Safely at Height Version 2.01marvinNoch keine Bewertungen

- Roles and Responsibilities For Risk AssessmentDokument2 SeitenRoles and Responsibilities For Risk AssessmentHawaNoch keine Bewertungen

- Sewer Smoke Testing NoticeDokument2 SeitenSewer Smoke Testing Noticeapi-442300261Noch keine Bewertungen

- (Richard F. Fellows, Anita M. M. Liu) Research Met (BookFi)Dokument2 Seiten(Richard F. Fellows, Anita M. M. Liu) Research Met (BookFi)hayelomNoch keine Bewertungen

- (Safety & Health Officer) : Regulations 1997-ShoDokument9 Seiten(Safety & Health Officer) : Regulations 1997-ShoNor Hamizah HassanNoch keine Bewertungen

- Job Safety Analysis (Jsa) and Risk Assessment Form: WastonoDokument8 SeitenJob Safety Analysis (Jsa) and Risk Assessment Form: WastonoPutra FeraNoch keine Bewertungen

- JSA Air CompressorDokument2 SeitenJSA Air Compressorshanvisa100% (4)

- Topic Presentation ScheduleDokument1 SeiteTopic Presentation ScheduleNathaniel PaguioNoch keine Bewertungen

- Rappelling Narrative ReportDokument6 SeitenRappelling Narrative ReportPersia BangeroNoch keine Bewertungen

- JSA For Grouting and Air Blowing1Dokument3 SeitenJSA For Grouting and Air Blowing1Mohammed MinhajNoch keine Bewertungen

- The Most Secret List of Soe Agents: JDokument37 SeitenThe Most Secret List of Soe Agents: JeliahmeyerNoch keine Bewertungen

- First AidDokument47 SeitenFirst AidAdrian NikoChoieNoch keine Bewertungen

- Assessing Risk Asimplified Methodology For Prejob Planning in Oil and Gas ProductionDokument8 SeitenAssessing Risk Asimplified Methodology For Prejob Planning in Oil and Gas Productionkenoly123Noch keine Bewertungen

- Health and Safety T-NETDokument229 SeitenHealth and Safety T-NETPieter HerbstNoch keine Bewertungen

- Safety Engineering For OIl Gas Industry Operational PlantDokument37 SeitenSafety Engineering For OIl Gas Industry Operational Plantjacobpm2010100% (1)

- Register of Hazards and Risks: (OHSAS 18001:2007)Dokument2 SeitenRegister of Hazards and Risks: (OHSAS 18001:2007)Anonymous ZBMKga2LINoch keine Bewertungen

- Daily Activity Report PDFDokument2 SeitenDaily Activity Report PDFjaggi7921Noch keine Bewertungen

- General Nutrition Requirement, Energy Aspect of DietDokument45 SeitenGeneral Nutrition Requirement, Energy Aspect of DietitiscassandraNoch keine Bewertungen

- 1jb18ec021 Phase 3 AicteDokument17 Seiten1jb18ec021 Phase 3 AicteAdityaKanbargiNoch keine Bewertungen

- Asbestos On Ships: PurposeDokument2 SeitenAsbestos On Ships: Purposeinmran.gNoch keine Bewertungen

- Brochure Saf T Data Guide 3988Dokument1 SeiteBrochure Saf T Data Guide 3988Rafael Guzmán RestrepoNoch keine Bewertungen

- ISO 14001 Waste Management Checklist: General Waste Management Non-Hazardous Waste Hazardous Waste DoneDokument4 SeitenISO 14001 Waste Management Checklist: General Waste Management Non-Hazardous Waste Hazardous Waste DoneWashington coaquira ccahuaNoch keine Bewertungen

- Abrasive Blasting: COSHH Essentials in Construction: Silica Engineering and RPEDokument4 SeitenAbrasive Blasting: COSHH Essentials in Construction: Silica Engineering and RPEAditya PrajasNoch keine Bewertungen

- OhsDokument42 SeitenOhsapi-242717528Noch keine Bewertungen

- Hazard Analysis TemplateDokument3 SeitenHazard Analysis Templateizzat ezmanNoch keine Bewertungen

- Student Name:: Welcome To "Introduction To ISO 22000 Food Safety Management Systems"Dokument15 SeitenStudent Name:: Welcome To "Introduction To ISO 22000 Food Safety Management Systems"frawatNoch keine Bewertungen

- Process Control in The Food Industry - HACCPDokument4 SeitenProcess Control in The Food Industry - HACCPJonatan VenegasNoch keine Bewertungen