Beruflich Dokumente

Kultur Dokumente

Ferment Ers

Hochgeladen von

Yitzhar Leal0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten2 SeitenFermentadores equipos tipos usos

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenFermentadores equipos tipos usos

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten2 SeitenFerment Ers

Hochgeladen von

Yitzhar LealFermentadores equipos tipos usos

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

FERMENTERS dimensions are 100 m (328 ft) in height and 10 m (33 ft) in

The term fermentation formerly distinguished processes diameter.

from which air was absent, but the term has now been extended

to aerobic processes. Bioprocessing is usually aseptic (free of

unwanted organisms) in vessels held under positive pressure of

sterile air to resist entry of contaminating microorganisms. A

few processes such as the production of pathogenic organisms

for medical purposes or for biological warfare operate below

atmospheric pressure because safety of the plant operators is

more important than the integrity of the product.

Older processes such as manufacture of pickles had no

special measures against contamination, but many of these have

been converted to aseptic operations to prevent impairment of

product quality by foreign organisms. Biological waste

treatment employs elective cultures of microorganisms in

relatively crude, open equipment.

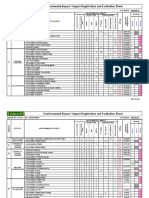

Activities associated with bioreactors include gas/liquid

contacting, on-line sensing of concentrations, mixing, heat FIG. 24-3 Conventional batch fermenter. A) agitator motor; B)

speed reduction unit; C) air inlet; D) air outlet; E) air bypass

transfer, foam control, and feed of nutrients or reagents such as

valve; F) shaft seal; G) sight glass with light; H) sight-glass

those for pH control. The workhorse of the fermentation clean-off line; I) manhole with sight glass; J ) agitator shaft; K)

industry is the conventional batch fermenter shown in Fig. 24- paddle to break foam; L) cooling-water outlet; M) baffle; N)

3. Not shown are ladder rungs inside the vessel, antifoam probe, cooling coils; O) cooling-water inlet; P ) mixer; Q) sparger; R)

antifoam system, and sensors (pH, dissolved oxygen, shaft bearing and bracket; S) outlet (steam seal not shown); T )

temperature, and the like). Note that coils may lie between sample valve (steam seal not shown).

baffles and the tank wall or connect to the top to minimize

openings below the water level, and bottom-entering mixers are

used frequently.

There is extensive process piping, and copper or brass

fittings are taboo for some processes because of highly

deleterious effects of copper (more than 50 percent reduction in

yield has been noted in penicillin fermentations when a bronze

valve was in a feed line). Cooling coils must be used for larger

tanks because the heat-transfer area of a jacket is inadequate for

cooling from sterilization temperature to operating temperature

in a reasonable time. Some features of interest for a

conventional fermenter are that (1) a bypass valve in the air

system allows diversion of air so that foaming is not excessive

and the redox potential is not too high during the early stage of

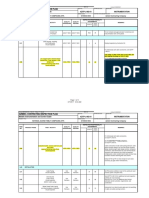

A few variations on the standard fermenter have been

fermentation when the inoculum is becoming established; (2)

attempted, but none has become popular. An obsolete design in

antifoam is added when excessive foam reaches a conductive or

which the fermenter was rotated to aerate the medium is shown

capacitive electronic probe; (3) all piping is sterilized by the use

in Fig. 24-5. Performance was unsatisfactory, and the units were

of steam and is protected by steam until put into use; (4) the

turned on end, with spargers and agitation added. One of the

level of liquid when filling the vessel is determined by reference

largest fermenters used for antibiotics is a horizontal cylinder

to a calibration chart based on points in the tank such as a rung

with several agitators, as in Fig. 24-6. Multiple agitator motors

on the ladder; (5) the weight of the tank contents can be

and shafts have also been used with vertical cylindrical vessels.

determined by the hydrostatic balance against air bubbled

slowly through the sparger; and (6) pumps are very uncommon Another innovative design is the toroidal fermenter shown

because it is so easy to force fluid from a pressurized vessel. in Fig. 24-7. Motion in an axial direction allows intimate mixing

with air. A special case of the air-lift fermenter is shown in Fig.

The need for highly cost-efficient oxygen transfer in

24-8. The feed enters at moderate pressure and is drawn

fermentations such as those with hydrocarbon feedstocks has

downward to regions of very high hydrostatic pressure that

led to air-lift fermenters as shown in Fig. 24-4. The world’s

provides a great driving force for gas transfer. In the other leg,

largest industrial fermenter wasdesigned for producing single-

lowering pressure allows gases to expand to induce circulation.

cell protein from hydrocarbons at Billingham, England, U.K. Its

Experimental units have been built in elevator shafts.

Ethanol fermentation is a particularly good example of

product accumulation inhibiting the microbial culture. Most

strains of yeast have a much slower alcohol production rate

when ethanol reaches about ten percent, and the wine or saki

strains that achieve over 20 percent by volume of ethanol are

very, very slow. A system known as the Vacuferm for removal

of alcohol by distillation as it is formed is shown in Fig. 24-9.

The vacuum is adjusted to the vapor pressure of the alcohol-

water solution at the fermentation temperature, 30 to 40C (86

to 104F). Volumetric productivity is far better than that of a

conventional fermenter, but there is a killing disadvantage of

having to recompress large volumes of vapor so that alcohol can

be condensed with normal cooling water instead of expensive

cold brine. Furthermore, the large amounts of carbon dioxide

generated by fermentation are evacuated and recompressed

along with the alcohol and water vapors. A far better design is

shown in Fig. 24-10, where the fermenter operates at normal

pressure so that carbon dioxide escapes, and broth is circulated

through the flash pot for vaporization of the ethanol. Although

this system may seem to have attractive energy economy

because metabolic heat is removed as the vapor flashes, initial

investment and the cost of pumping the vapors are high.

Operating the ethanol fermentation at higher temperatures with

thermophillic organisms has better economics in terms of

milder vacuum and less recompression because of the higher

vapor pressure, but evolving carbon dioxide can strip out

product. Other alternatives for overcoming inhibition by the

product are extraction from the fermentation broth with an

immiscible solvent and/or operating with very dense cultures so

that low productivity per cell is compensated by having many

more cells.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- 690B Systems Reference Guide PDFDokument11 Seiten690B Systems Reference Guide PDFBrian AdrianNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Warmate enDokument12 SeitenWarmate enSonia RainaNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Exemptions Granted To Large Taxpayers January, 2010 To September, 2014 PDFDokument82 SeitenExemptions Granted To Large Taxpayers January, 2010 To September, 2014 PDFRashid BumarwaNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- SD SeriesDokument3 SeitenSD SeriesAlison ThompsonNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Axiom: Owner's ManualDokument16 SeitenAxiom: Owner's ManualĐứcThọNoch keine Bewertungen

- Lesson Plan ECM442Dokument2 SeitenLesson Plan ECM442Hatake Zul FadhliNoch keine Bewertungen

- Manual Reductor Dodge TDT7Dokument8 SeitenManual Reductor Dodge TDT7DANIELNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- 7020 - Liquid Soap ThickenerDokument2 Seiten7020 - Liquid Soap Thickenerzuber ahmedNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Toyota Ebook PDFDokument47 SeitenToyota Ebook PDFOliver Rivero100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- PK 24 - Bustos Transport Code Excerpts)Dokument56 SeitenPK 24 - Bustos Transport Code Excerpts)fernan tadeoNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- RTMST 2013Dokument327 SeitenRTMST 2013palpandi.mNoch keine Bewertungen

- Cycloc Data Sheet SoloDokument13 SeitenCycloc Data Sheet SoloJuli RayuliNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- 4.2 - Risk Assessment ProjectDokument3 Seiten4.2 - Risk Assessment ProjectMuhammad Nauman100% (1)

- Scale Model Muscle CarsDokument89 SeitenScale Model Muscle CarsFlakito Uri100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Cycle Time of Transit Mixer: DateDokument3 SeitenCycle Time of Transit Mixer: DateAtulJainNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Mercer Valve 1400 Series BrochureDokument8 SeitenMercer Valve 1400 Series BrochureAnonymous 7GuboLxjQNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Norms-Cabinet-Final Print - DoR PDFDokument309 SeitenNorms-Cabinet-Final Print - DoR PDFBinod ThapaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Biogastrain Produktblad 2005Dokument2 SeitenBiogastrain Produktblad 2005adamyogiNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Date 2 JANUARY 2022 Quotation TO: Mrs.Dokument5 SeitenDate 2 JANUARY 2022 Quotation TO: Mrs.43MOHAMMED SIDDIQ MOHIUDDINNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- TasksDokument2 SeitenTasksParag PatilNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Environmental Aspect / Impact Registration and Evaluation SheetDokument3 SeitenEnvironmental Aspect / Impact Registration and Evaluation SheetrewrtegamingNoch keine Bewertungen

- AZITP-J-902-01 Rev 00 Metallic Instrument and Control CableDokument5 SeitenAZITP-J-902-01 Rev 00 Metallic Instrument and Control CableVinay YadavNoch keine Bewertungen

- Autocar Spare Parts Price SurveyDokument10 SeitenAutocar Spare Parts Price SurveyDeepak ShoriNoch keine Bewertungen

- Man Dio55 UkDokument18 SeitenMan Dio55 UkQuang BáchNoch keine Bewertungen

- Aftercooler - Test PDFDokument6 SeitenAftercooler - Test PDFDaniel Castillo Peña100% (1)

- Boq Andheri For Piles and Pile CapsDokument2 SeitenBoq Andheri For Piles and Pile Capsnavinderpal67% (3)

- ECM Service GuideDokument18 SeitenECM Service Guidemegan1407Noch keine Bewertungen

- MD Isocracking v2Dokument2 SeitenMD Isocracking v2Materia GrisNoch keine Bewertungen

- Zeon Productguide 20150717Dokument16 SeitenZeon Productguide 20150717khushboo.mamtani2932Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Mazda 8 MPV LY3P - Workshop ManualDokument1.923 SeitenMazda 8 MPV LY3P - Workshop ManualRoman88% (8)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)