Beruflich Dokumente

Kultur Dokumente

Easa Airworthiness Directive: AD No.: 2013-0069

Hochgeladen von

AxelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Easa Airworthiness Directive: AD No.: 2013-0069

Hochgeladen von

AxelCopyright:

Verfügbare Formate

EASA AD No.

: 2013-0069

EASA AIRWORTHINESS DIRECTIVE

AD No.: 2013-0069

Date: 18 March 2013

Note: This Airworthiness Directive (AD) is issued by EASA, acting in accordance with Regulation

(EC) No 216/2008 on behalf of the European Community, its Member States and of the

European third countries that participate in the activities of EASA under Article 66 of that

Regulation.

This AD is issued in accordance with EU 748/2012, Part 21.A.3B. In accordance with EC 2042/2003 Annex I, Part M.A.301, the

continuing airworthiness of an aircraft shall be ensured by accomplishing any applicable ADs. Consequently, no person may operate an

aircraft to which an AD applies, except in accordance with the requirements of that AD, unless otherwise specified by the Agency [EC

2042/2003 Annex I, Part M.A.303] or agreed with the Authority of the State of Registry [EC 216/2008, Article 14(4) exemption].

Design Approval Holder’s Name: Type/Model designation(s):

EUROCOPTER AS 332 and EC 225 helicopters

TCDS Number: EASA.R.002

Foreign AD: Not applicable

Supersedure: None

Hydraulic Power / Rotors Flight Control – Main Gearbox

ATA 29, 67

Compartment / Hydraulic Flexible Pipes – Inspection / Replacement

Manufacturer(s): Eurocopter (formerly EUROCOPTER France).

Applicability: AS 332 C, AS 332 C1, AS 332 L, AS 332 L1, AS 332 L2 and EC 225 LP

helicopters, all serial numbers.

Reason: In-flight loss of left hand (LH) hydraulic pressure was reported on a helicopter

equipped in the Main Gearbox (MGB) compartment with hydraulic flexible pipes

fitted with surrounding fire-resistant protection sheath. The subsequent

investigation revealed that the pressure loss was caused by a hydraulic fluid

leakage from an hydraulic pressure pipe of the MGB compartment located

between the forward main rotor servo-control and the hydraulic manifold. The

failed flexible pipe, supplied by TECALEMIT, burst due to severe corrosion on

the metal braid of the pipe underneath its fire-resistant protection sheath. This

corrosion was a result of a large tear damage found on the pipe fire-resistant

sheath, enabling humidity to enter between the sheath and the metal braid.

Following this incident, Eurocopter issued Service Bulletin (SB)

No.AS332-05.00.92 and SB No.EC225-05-027, as applicable to helicopter

model, recommending repetitive inspection of the fire-resistant sheath of all the

hydraulic flexible pipes located in the MGB compartment, and launched the

update of both Aircraft Maintenance Manual and Maintenance Program

accordingly.

In the meanwhile, new cases of in-flight hydraulic pressure loss were reported,

for which the same root cause, significant tears on the protection sheath of

other MGB hydraulic flexible pipes manufactured by TECALEMIT, was

identified. This repetition of similar incidents evidenced the potential of a higher

number of damaged hydraulic pipes than initially appreciated and the

reanalysis of the issue concluded that severe sheath damages are more critical

TE.CAP.00110-003 © European Aviation Safety Agency. All rights reserved. 1/3

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

EASA AD No.: 2013-0069

on TECALEMIT hydraulic flexible pipes than on other equivalent parts from

different supplying sources.

This condition, if not detected and corrected, could lead, in case of

simultaneous LH and right hand (RH) hydraulic system leakage, to loss of

hydraulic systems and consequent loss of helicopter control.

For the reasons described above, this AD requires a one-time inspection of the

TECALEMIT flexible pipes installed on both LH and RH hydraulic system

circuits located in the MGB compartment and, depending on findings,

replacement of damaged pipes.

Effective Date: 01 April 2013

Required Action(s) Required as indicated, unless accomplished previously:

and Compliance

(1) Within 110 flight hours (FH) or 3 months, whichever occurs first after the

Time(s):

effective date of this AD, inspect to identify hydraulic flexible pipes installed

on both LH and RH hydraulic circuits in the helicopter MGB compartment.

A review of helicopter delivery or maintenance records is acceptable to

determine the installed hydraulic flexible pipe manufacturer, provided the

flexible pipe manufacturer can be determined from that review.

(2) If, during the identification as required by paragraph (1) of this AD,

TECALEMIT flexible pipes are found to be installed on both, LH and RH,

hydraulic circuits in the helicopter MGB compartment, within 110 FH or

3 months, whichever occurs first after the effective date of this AD, inspect

all TECALEMIT hydraulic flexible pipes installed in the MGB compartment

in accordance with the instructions of paragraph 3 of Eurocopter SB

No.AS332-05.00.92 or SB No.EC225-05.027, as applicable to helicopter

model.

Note 1: The name of the flexible pipe manufacturer may not be indicated on the

pipe. However, the Part Number (P/N) of a TECALEMIT hydraulic flexible pipe

starts with “66”.

(3) If, during the inspection as required by paragraph (2) of this AD, at least

one TECALEMIT pipe is found damaged on both LH and RH hydraulic

circuits, within the compliance time as specified in Table 1 of this AD, as

applicable, replace each damaged hydraulic flexible pipe with a

serviceable part in accordance with the instructions of paragraph 3.B.3 of

Eurocopter SB No.AS332-05.00.92 or EC225 SB No.EC225-05.027, as

applicable to helicopter model.

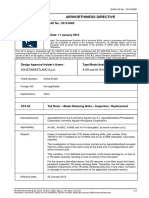

Table 1

Hydraulic Flexible Pipe

Compliance Time

Condition / Location

Severe sheath damage Before next flight after the

(see note 2) detected on inspection as required by

the RH hydraulic system paragraph (2) of this AD

Less critical sheath Within 300 FH or 6 months,

damage (see note 3) whichever occurs first after the

detected on the RH effective date of this AD

hydraulic system

Any damage detected on Within 600 FH or 12 months,

the LH hydraulic system whichever occurs first after the

effective date of this AD

Note 2: Severe sheath damage is defined as any sheath tear or cut or open

cracking that shows the pipe metallic braid underneath, when pinching or

twisting the sheath.

Note 3: Less critical sheath damage is defined as any other sheath damage

TE.CAP.00110-003 © European Aviation Safety Agency. All rights reserved. 2/3

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

EASA AD No.: 2013-0069

(e.g. notch, light tear or crack, friction mark, gaping) as specified in paragraph 3

of Eurocopter SB No.AS332-05.00.92 or SB No.EC225-05.027, as applicable to

helicopter model.

Ref. Publications: Eurocopter SB No.AS332-05.00.92, revision 0 dated 24 September 2012,

Eurocopter SB No.EC225-05.027, revision 0 dated 24 September 2012.

The use of later approved revisions of these documents is acceptable for

compliance with the requirements of this AD.

Remarks: 1. If requested and appropriately substantiated, EASA can approve

Alternative Methods of Compliance for this AD.

2. This AD was posted on 27 February 2013 as PAD 13-039 for consultation

until 13 March 2013. No comments were received during the consultation

period.

3. Enquiries regarding this AD should be referred to the Safety Information

Section, Executive Directorate, EASA. E-mail: ADs@easa.europa.eu.

4. For any question concerning the technical content of the requirements in

this AD, please contact:

EUROCOPTER (STDI) – Aéroport de Marseille Provence,

13725 Marignane

Cedex, France; telephone +33 (4) 42 85 97 97; facsimile +33 (4) 42 85 99

66; E-mail: Directive.technical-support@eurocopter.com.

TE.CAP.00110-003 © European Aviation Safety Agency. All rights reserved. 3/3

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

Das könnte Ihnen auch gefallen

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- Easa Ad CF-2021-51R1 1Dokument3 SeitenEasa Ad CF-2021-51R1 1Heiko Oliva LiberjenNoch keine Bewertungen

- Easa Ad F-2004-164 2Dokument2 SeitenEasa Ad F-2004-164 2Kaung MyatToeNoch keine Bewertungen

- Easa Ad 2006-0112R1 1Dokument2 SeitenEasa Ad 2006-0112R1 1Sa Be MirNoch keine Bewertungen

- Easa Notification of A Proposal To Issue AN Airworthiness DirectiveDokument2 SeitenEasa Notification of A Proposal To Issue AN Airworthiness Directivedsgarcia26Noch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2011-0090R1Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2011-0090R1ktsaknakis_1Noch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2013-0091Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2013-0091piterNoch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2007-0065R2 (Correction: 22 March 2011)Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2007-0065R2 (Correction: 22 March 2011)Sa Be MirNoch keine Bewertungen

- Easa Ad 2022-0204R1 1Dokument7 SeitenEasa Ad 2022-0204R1 1Antonio MateosNoch keine Bewertungen

- Easb Ec-130-05-A014 R2Dokument16 SeitenEasb Ec-130-05-A014 R2unklekoNoch keine Bewertungen

- HvacDokument13 SeitenHvacahmedNoch keine Bewertungen

- AOT-A32N016-19 Rev 00Dokument13 SeitenAOT-A32N016-19 Rev 00Edwar ZulmiNoch keine Bewertungen

- Airworthiness Directive: Airbus Industrie A330 Series AeroplanesDokument2 SeitenAirworthiness Directive: Airbus Industrie A330 Series AeroplanesMehdi LayachiNoch keine Bewertungen

- Gas Cartridge ActuatorDokument2 SeitenGas Cartridge ActuatorJavier Guillermo Nuñez Valdivia0% (1)

- Easa Airworthiness Directive: AD No.: 2015-0213Dokument2 SeitenEasa Airworthiness Directive: AD No.: 2015-0213philip00165Noch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2012-0118Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2012-0118universidad depacho1Noch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2012-0118Dokument426 SeitenEasa Airworthiness Directive: AD No.: 2012-0118andres orjuelaNoch keine Bewertungen

- Easa Ad 2013-0202 1Dokument3 SeitenEasa Ad 2013-0202 1Sami JarradiNoch keine Bewertungen

- Airworthiness Bulletin: AWB Issue: Date: 1. EffectivityDokument3 SeitenAirworthiness Bulletin: AWB Issue: Date: 1. EffectivityhakimiNoch keine Bewertungen

- Interstate Aviation Committee Aviation Register Airworthiness DirectiveDokument3 SeitenInterstate Aviation Committee Aviation Register Airworthiness DirectivebelazharNoch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2013-0302Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2013-0302izmitlimonNoch keine Bewertungen

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Dokument4 SeitenAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)hernanrusNoch keine Bewertungen

- Easa Emergency Airworthiness Directive: AD No.: 2011-0023-EDokument3 SeitenEasa Emergency Airworthiness Directive: AD No.: 2011-0023-ESantiago ArroyoNoch keine Bewertungen

- Flight Manual CDL A319 132Dokument714 SeitenFlight Manual CDL A319 132DithelNoch keine Bewertungen

- Easa Ad 2011-0186 1Dokument2 SeitenEasa Ad 2011-0186 1jbanawazNoch keine Bewertungen

- Easa Ad 2009-0072R1 1Dokument2 SeitenEasa Ad 2009-0072R1 1BeyondXtreamNoch keine Bewertungen

- Eu 202002582Dokument6 SeitenEu 202002582Nishantha DesilvaNoch keine Bewertungen

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Dokument6 SeitenAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)jackNoch keine Bewertungen

- Easa Ad 2021-0185R2Dokument4 SeitenEasa Ad 2021-0185R2Marty SmallwoodNoch keine Bewertungen

- Easa Ad 2023-0175 1Dokument5 SeitenEasa Ad 2023-0175 1storgemateoNoch keine Bewertungen

- Airworthiness Directive: We RecommendDokument7 SeitenAirworthiness Directive: We RecommendErnesto ZamoraNoch keine Bewertungen

- Easa Ad 2023-0013 1Dokument5 SeitenEasa Ad 2023-0013 1hugoNoch keine Bewertungen

- Easa Airworthiness Directive: Intertechnique, Zodiac Aircraft SystemsDokument2 SeitenEasa Airworthiness Directive: Intertechnique, Zodiac Aircraft Systemsktsaknakis_1Noch keine Bewertungen

- Notification of A Proposal To Issue An Airworthiness DirectiveDokument4 SeitenNotification of A Proposal To Issue An Airworthiness Directivecf34Noch keine Bewertungen

- Easa Ad 2022-0028 1Dokument5 SeitenEasa Ad 2022-0028 1Syed BellaryNoch keine Bewertungen

- Engine Systems PDFDokument5 SeitenEngine Systems PDFteknikpembakaran2013Noch keine Bewertungen

- Fot-999-0055-22-00 - Loss of Bleed Air Leak Detection CapabilityDokument4 SeitenFot-999-0055-22-00 - Loss of Bleed Air Leak Detection CapabilitySofia SchererNoch keine Bewertungen

- EASBAS550050041ENR3Dokument16 SeitenEASBAS550050041ENR3SIPAMOPS BENGPUSPENERBADNoch keine Bewertungen

- FAA 2020 0578 0003 - Attachment - 1Dokument71 SeitenFAA 2020 0578 0003 - Attachment - 1Ümit KazanNoch keine Bewertungen

- AOM 2021-05 - Potential Temporary Loss of All Cockpit Display Systems (CDS) - EASA AD 2023-0078Dokument76 SeitenAOM 2021-05 - Potential Temporary Loss of All Cockpit Display Systems (CDS) - EASA AD 2023-0078Rohit ChekuriNoch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2011-0072Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2011-0072Raymond ZamoraNoch keine Bewertungen

- AOM 2024-04 Issue 1 - Rudder Travel Limiting Unit (TLU) Lever InspectionDokument11 SeitenAOM 2024-04 Issue 1 - Rudder Travel Limiting Unit (TLU) Lever InspectionAnup Kumar DebnathNoch keine Bewertungen

- Ad2012 0177Dokument4 SeitenAd2012 0177Milica MilicicNoch keine Bewertungen

- Superseded: Airworthiness DirectiveDokument3 SeitenSuperseded: Airworthiness DirectiveBahadorNoch keine Bewertungen

- Airworthiness Directive: Federal Register Information Header InformationDokument3 SeitenAirworthiness Directive: Federal Register Information Header InformationRebeca SerranoNoch keine Bewertungen

- Easa Ad 2021-0281 1Dokument5 SeitenEasa Ad 2021-0281 1Guillermo GonzálezNoch keine Bewertungen

- AIR CRUISERS 004-25-87 R3 Dt. 07.02.20Dokument10 SeitenAIR CRUISERS 004-25-87 R3 Dt. 07.02.20Pradeep K s100% (1)

- EASA AD 2015-0036 R03 Dt. 20.07.21Dokument4 SeitenEASA AD 2015-0036 R03 Dt. 20.07.21Pradeep K sNoch keine Bewertungen

- Easa Ad 2023-0094Dokument8 SeitenEasa Ad 2023-0094hernanrusNoch keine Bewertungen

- 6C941B79AC0941349600410D84ECE6E7Dokument38 Seiten6C941B79AC0941349600410D84ECE6E7Putra AdamNoch keine Bewertungen

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Dokument3 SeitenAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Carlyson SilvaNoch keine Bewertungen

- 212 TB 09 210Dokument5 Seiten212 TB 09 210Jose Edwin Roldan RiosNoch keine Bewertungen

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Dokument4 SeitenAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNoch keine Bewertungen

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Dokument3 SeitenAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNoch keine Bewertungen

- Alert Service Bulletin: ASB MBB-BK117 C-2-67A-015Dokument6 SeitenAlert Service Bulletin: ASB MBB-BK117 C-2-67A-015Raymond ZamoraNoch keine Bewertungen

- Trafo RTCCDokument363 SeitenTrafo RTCCKrishna Chandavar0% (1)

- Easa Ad 2007-0087 2Dokument2 SeitenEasa Ad 2007-0087 2NICOLAS ARANGONoch keine Bewertungen

- Easa Ad 2024-0079 1Dokument4 SeitenEasa Ad 2024-0079 1vitalijusNoch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2015-0203Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2015-0203PhilNoch keine Bewertungen

- Easa Ad 2013-0009 1Dokument3 SeitenEasa Ad 2013-0009 1Yuri SilvaNoch keine Bewertungen

- Airbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 LowDokument46 SeitenAirbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 LowAxelNoch keine Bewertungen

- 130 18 101 01 E Technical-DataDokument82 Seiten130 18 101 01 E Technical-DataAxel100% (1)

- 135 T3H P3H Technical Data Low ResolutionDokument126 Seiten135 T3H P3H Technical Data Low ResolutionAxel100% (2)

- Airbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 Low PDFDokument120 SeitenAirbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 Low PDFAxelNoch keine Bewertungen

- H135 Brochure 2018Dokument8 SeitenH135 Brochure 2018AxelNoch keine Bewertungen

- H130 Brochure 2018Dokument8 SeitenH130 Brochure 2018Axel100% (1)

- 145 - D-2 - 18.101.01 - E - Technical - Data - LQDokument108 Seiten145 - D-2 - 18.101.01 - E - Technical - Data - LQAxel0% (2)

- Ec 225LP Hlo 1 Easa PMV SRD PDFDokument1 SeiteEc 225LP Hlo 1 Easa PMV SRD PDFAxelNoch keine Bewertungen

- AAIB Bulletin 7-2014 v2Dokument102 SeitenAAIB Bulletin 7-2014 v2AxelNoch keine Bewertungen

- CAP 1145 Offshore Helicopter Review and Annexes 24214 PDFDokument293 SeitenCAP 1145 Offshore Helicopter Review and Annexes 24214 PDFAxelNoch keine Bewertungen

- Ec225 2013 230 Hrs PDFDokument1 SeiteEc225 2013 230 Hrs PDFAxelNoch keine Bewertungen

- EASBAS332630083ENR0Dokument25 SeitenEASBAS332630083ENR0AxelNoch keine Bewertungen

- Eurocopter AS332-EC225Dokument15 SeitenEurocopter AS332-EC225Axel50% (2)

- Easa Airworthiness Directive: AD No.: 2013-0069Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2013-0069AxelNoch keine Bewertungen

- Ec225 2013 230 HrsDokument1 SeiteEc225 2013 230 HrsAxelNoch keine Bewertungen

- HSSG May Newsletter - G-REDW DitchingDokument5 SeitenHSSG May Newsletter - G-REDW DitchingUnion userNoch keine Bewertungen

- Easa Airworthiness Directive: AD No.: 2013-0069Dokument3 SeitenEasa Airworthiness Directive: AD No.: 2013-0069AxelNoch keine Bewertungen

- 225 LP 18.101.01 eDokument84 Seiten225 LP 18.101.01 eAxel100% (5)

- EASBAS332630083ENR0Dokument25 SeitenEASBAS332630083ENR0AxelNoch keine Bewertungen

- Havarirapport For Helikopterstyrt I Nordsøen 2009 PDFDokument209 SeitenHavarirapport For Helikopterstyrt I Nordsøen 2009 PDFAxelNoch keine Bewertungen

- Rotor 100 UkDokument36 SeitenRotor 100 UkAxelNoch keine Bewertungen

- Eurocopter AS332-EC225Dokument15 SeitenEurocopter AS332-EC225Axel50% (2)

- Super PumaDokument10 SeitenSuper PumaAxelNoch keine Bewertungen

- H225 Brochure 2018Dokument8 SeitenH225 Brochure 2018AxelNoch keine Bewertungen

- AAIB Bulletin 7-2014 v2Dokument102 SeitenAAIB Bulletin 7-2014 v2AxelNoch keine Bewertungen

- AAIB Bulletin 7-2014 v2Dokument102 SeitenAAIB Bulletin 7-2014 v2AxelNoch keine Bewertungen

- RescueSwimmer 1-2014 LRDokument40 SeitenRescueSwimmer 1-2014 LRAxelNoch keine Bewertungen

- The Casbah 29 (1986) - 01 September 2015Dokument13 SeitenThe Casbah 29 (1986) - 01 September 2015Ishaan BlundenNoch keine Bewertungen

- LivePerson Chat ReportsDokument23 SeitenLivePerson Chat ReportsEdenEtfNoch keine Bewertungen

- Forging 2Dokument17 SeitenForging 2Amin ShafanezhadNoch keine Bewertungen

- Isuzu 4be1 Engine Manual KolesooreDokument5 SeitenIsuzu 4be1 Engine Manual KolesooreRaymart Dealca75% (8)

- Solar Smart Irrigation SystemDokument22 SeitenSolar Smart Irrigation SystemSubhranshu Mohapatra100% (1)

- 4th Party LogisticsDokument3 Seiten4th Party Logisticsch_salmanNoch keine Bewertungen

- Summer 2019 - OSD Exam Paper MS - FINALDokument13 SeitenSummer 2019 - OSD Exam Paper MS - FINALAsifHossainNoch keine Bewertungen

- Dahua Network Speed Dome & PTZ Camera Web3.0 Operation ManualDokument164 SeitenDahua Network Speed Dome & PTZ Camera Web3.0 Operation ManualNiksayNoch keine Bewertungen

- Best Evidence Rule CasesDokument5 SeitenBest Evidence Rule CasesRemy Rose AlegreNoch keine Bewertungen

- 54 Sale1Dokument6 Seiten54 Sale1vakilarunNoch keine Bewertungen

- 10 Me 42 BDokument144 Seiten10 Me 42 BdineshNoch keine Bewertungen

- RFP For Corporate Engagement Platform PDFDokument28 SeitenRFP For Corporate Engagement Platform PDFAnupriya Roy ChoudharyNoch keine Bewertungen

- Quiz 1 - Domain Modeling With Answer KeyDokument5 SeitenQuiz 1 - Domain Modeling With Answer Keyprincess100267% (3)

- RRLDokument4 SeitenRRLWen Jin ChoiNoch keine Bewertungen

- Internal/External Permanent Opportunity: P: S: $51,487.97 - $62,766.29 D: F #: TCHC#10LS29 L: # P: 1Dokument3 SeitenInternal/External Permanent Opportunity: P: S: $51,487.97 - $62,766.29 D: F #: TCHC#10LS29 L: # P: 1a4agarwalNoch keine Bewertungen

- Aga 11Dokument7 SeitenAga 11elijbbNoch keine Bewertungen

- Operations Management: Green Facility Location: Case StudyDokument23 SeitenOperations Management: Green Facility Location: Case StudyBhavya KhattarNoch keine Bewertungen

- ISM JRF BrochureDokument37 SeitenISM JRF BrochureVikas Patel100% (1)

- Workflows in RUP PDFDokument9 SeitenWorkflows in RUP PDFDurval NetoNoch keine Bewertungen

- RW01 Concrete Masonry - Reinforced Cantilever Retaining WallsDokument81 SeitenRW01 Concrete Masonry - Reinforced Cantilever Retaining WallshaixdproNoch keine Bewertungen

- Indian - Origin Girls Bag Google Science Honour - Yahoo! India EducationDokument3 SeitenIndian - Origin Girls Bag Google Science Honour - Yahoo! India EducationRiyaz RafiqueNoch keine Bewertungen

- Project JavascriptDokument58 SeitenProject JavascriptashwinNoch keine Bewertungen

- PDF 20699Dokument102 SeitenPDF 20699Jose Mello0% (1)

- Health Wellness Subject For Middle School 6th Grade Mental Emotional and Social HealthDokument64 SeitenHealth Wellness Subject For Middle School 6th Grade Mental Emotional and Social Healtharaa arifinNoch keine Bewertungen

- Lateral Pile Paper - Rev01Dokument6 SeitenLateral Pile Paper - Rev01YibinGongNoch keine Bewertungen

- Icd-10 CM Step by Step Guide SheetDokument12 SeitenIcd-10 CM Step by Step Guide SheetEdel DurdallerNoch keine Bewertungen

- 13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkDokument20 Seiten13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkAbidullahNoch keine Bewertungen

- LabVIEW Core 3 2013 - Course ManualDokument135 SeitenLabVIEW Core 3 2013 - Course Manualtalaindio100% (2)

- Job Schedule Sheet: 'Lead Time Monitoring GraphDokument48 SeitenJob Schedule Sheet: 'Lead Time Monitoring GraphEndraNoch keine Bewertungen

- Geometric Latent Diffusion ModelDokument18 SeitenGeometric Latent Diffusion ModelmartaNoch keine Bewertungen