Beruflich Dokumente

Kultur Dokumente

PCS Question Bank

Hochgeladen von

Anonymous 9xO18CwYOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PCS Question Bank

Hochgeladen von

Anonymous 9xO18CwYCopyright:

Verfügbare Formate

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

ARS College of Engineering

(Approved by AICTE, New Delhi & Affiliated to Anna University-Chennai)

Sattamangalam, Maraimalai Nagar, Chennai-603 209

DEPARTMENT OF CIVIL

ENGINEERING

REGULATION – 2013

CE 6702 – PRESTRESSED CONCRETE

SOLVED ANNA UNIVERSITY QUESTION BANK

Prepared by,

VINOTHKUMAR.T

Assistant Professor

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 1

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

CE6702 PRESTRESSED CONCRETE STRUCTURES

L T PC

3 0 03

OBJECTIVES:

To introduce the need for prestressing as well as the methods, types and

advantages of prestressing to the students. Students will be introduced to the

design of prestressed concrete structures subjected to flexure and shear.

UNIT I INTRODUCTION – THEORY AND BEHAVIOUR 9

Basic concepts – Advantages – Materials required – Systems and methods of

prestressing – Analysis of sections – Stress concept – Strength concept – Load

balancing concept – Effect of loading on the tensile stresses in tendons – Effect of

tendon profile on deflections – Factors influencing deflections – Calculation of

deflections – Short term and long term deflections - Losses of prestress – Estimation

of crack width.

UNIT II DESIGN FOR FLEXURE AND SHEAR 9

Basic assumptions for calculating flexural stresses – Permissible stresses in

steel and concrete as per I.S.1343 Code – Design of sections of Type I and Type II

post-tensioned and pre-tensioned beams – Check for strength limit based on I.S. 1343

Code – Layout of cables in post-tensioned beams – Location of wires in pre-tensioned

beams – Design for shear based on I.S. 1343 Code.

UNIT III DEFLECTION AND DESIGN OF ANCHORAGE ZONE 9

Factors influencing deflections – Short term deflections of uncracked

members – Prediction of long term deflections due to creep and shrinkage – Check for

serviceability limit state of deflection. Determination of anchorage zone stresses in

post-tensioned beams by Magnel’s method, Guyon’s method and IS1343 code –

design of anchorage zone reinforcement – Check for transfer bond length in pre-

tensioned beams.

UNIT IV COMPOSITE BEAMS AND CONTINUOUS BEAMS 9

Analysis and design of composite beams – Methods of achieving continuity in

continuous beams – Analysis for secondary moments – Concordant cable and linear

transformation – Calculation of stresses – Principles of design.

UNIT V MISCELLANEOUS STRUCTURES 9

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 2

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Design of tension and compression members – Tanks, pipes and poles – Partial

prestressing – Definition, methods of achieving partial prestressing, merits and

demerits of partial prestressing.

TOTAL: 45 PERIODS

OUTCOMES:

Student shall have a knowledge on methods of prestressing and able to design

various prestressed concrete structural elements.

TEXT BOOKS:

1. Krishna Raju N., "Prestressed concrete", 5th Edition, Tata McGraw Hill

Company, New Delhi, 2012

2. Pandit.G.S. and Gupta.S.P., "Prestressed Concrete", CBS Publishers and

Distributers Pvt. Ltd, 2012.

REFERENCES:

1. Rajagopalan.N, "Prestressed Concrete", Narosa Publishing House, 2002.

2. Dayaratnam.P., "Prestressed Concrete Structures", Oxford and IBH, 2013.

3. Lin T.Y. and Ned.H.Burns, "Design of prestressed Concrete Structures", Third

Edition, Wiley India Pvt. Ltd., New Delhi, 2013.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 3

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

UNIT-1

INTRODUCTION – THEORY AND BEHAVIOUR

Part A

1. Why high strength steelis essential for prestressed concrete? (AU: MAY/JUNE

2016, NOV/DEC 2015, APRIL/MAY 2015, NOV/ DEC 2012, NOV/DEC 2009,

APR/MAY 2017)

The normal loss of stress in steel is generally about 100 to 240N/mm 2 and it is a

small portion of the initial stress, the stress in steel in the initial stages must be very

high, about 1200 to 2000N/mm2. These high stress ranges are possible only with the

use of high strength steel.

2. List the loss of prestress? (AU: APRIL/MAY 2015, NOV/DEC 2013,

MAY/JUNE 2009, NOV/DEC 2016)

Types of loss Pre-tensioning Post-tensioning

Elastic deformation Yes 1. No loss occurs when wires are

tensioned simultaneously.

2. Loss occurs when wires are

tensioned successively.

Relaxation of stress in steel Yes Yes

Shrinkage of concrete Yes Yes

Creep of concrete Yes Yes

Anchorage slip No Yes

Friction loss No Yes

3. State the advantages of PSC members?(AU: NOV/DEC 2012, MAY/JUNE

2012)

Lighter and slender members than is possible with RC members.

In prestressed members, dead loads may be counter-balanced by eccentric

prestressing.

Improves durability under aggressive environmental conditions.

Long span structures are possible so that saving in weight is significant & thus

it will be economic.

Factory products are possible.

Prestressed members are tested before use.

Prestressed concrete structure gives warning before collapse.

4. What is the principle of post-tensioning? (AU: NOV/DEC 2014)

Wedge action producing a frictional grip on the tendons

Direct bearing from the rivet or bolt heads formed at the end of the wires

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 4

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Looping the wires around the concrete

5. What is chemical prestressing? (AU: NOV/DEC 2014)

Self-stressing or chemical prestressing of concrete was made possible by the

development of expanding cements. Expanding cements consists of 75% Portland

cement, 15% high alumina cement and 10% gypsum, which results in the formation

of calcium sulpho aluminate.

6. What are the classifications of prestressed concrete structures? (AU:

NOV/DEC 2013)

According to national codes, prestressed concrete structures are grouped into

Class 1: No tensile stresses are permitted and fully prestressed

Class 2: limited tensile stress of magnitude exceeding modulus of rupture is

permitted and moderately prestressed

Class 3: tensile stress of magnitude exceeding both modulus of rupture and

visible cracks of limited width are permitted and partially prestressed/ limited

prestress

7. What are the various methods of prestressing? (AU: MAY/JUNE 2013)

Generation of compressive force between the structural element

Development of hoop compression in cylindrical shaped structures

Use of longitudinally tensioned steel embedded in concrete

Use of principle of distortion

Use of deflected structural steel section embedded in concrete

By using expanding concrete

8. What are the systems of prestressing? (AU: MAY/JUNE 2013)

Pretensioning system

Post tensioning system

Thermo-electric system

Chemical system

9. Define load balancing concept? (AU: MAY/JUNE 2012, MAY/JUNE 2010)

Load balancing concept is primarily balancing a portion of load on the structure by

choosing the proper profile for the cable, appropriate to the moments due to dead

weught and applied loads.

10. Explain concordant prestressing? (AU: NOV/DEC 2011)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 5

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Prestressing of members in which the cables follow concordant profile is called

concordant prestressing. In case of statically indeterminate structures, concordant

prestressing does not cause any change in support reaction

11. What is the permissible limit for shrinkage of concrete for pretensioned and

post-tensioned members as per IS 1343? (AU: NOV/DEC 2010)

The loss of prestress due to shrinkage of concrete is total residual strain having a

value of 300 x 10-6 for pretensioning and for post-tensioning. The loss of

stress in steel due to shrinkage of concrete =total residual strain x modulus of

elasticity.

12. What is meant by relaxation of steel? (AU: NOV/DEC 2010)

The relaxation of prestressing steel defined as the reduction of stress under

constant strain, is due to creep. For tendons at higher temperatures or subjected to

large lateral loads, greater relaxation losses as specified by the engineer-in-charge

shall be allowed for. No reduction in the value of the relaxation losses should be made

for a tendon with a load equal to or greater than the relevant jacking force that has

been applied for a short time prior to the anchoring of the tendon.

13. What is meant by pressure or thrust line? (AU: NOV/DEC 2009, NOV/DEC

2010, APRIL/MAY 2010, APR/MAY 2017)

At any section of a beam, the combined effect of prestressing force and the

externally applied load will result in a distribution of concrete stresses that can be

resolved into a single force. The locus of the points of application of this force in any

beam is called pressure line

14. Briefly explain thermo-electric prestressing? (AU: APRIL/MAY 2008,

MAY/JUNE 2002)

The method of prestressing by heat tendons, achieved by passing an electric

current in the high tensile wires is generally referred to as thermo-electric

prestressing. Temperature increase takes place within 3-5 minutes, may be of

atemperature of 300-400°C. Expansion of the bar is about 0.4-0.5% of its original

length. After cooling the bars tries to shorten but by fixed anchors at the two ends

compression in concrete is induced.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 6

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

15. What do you understand by unbounded tendon? (AU: MAY/JUNE 2016,

NOV/DEC 2014)

If grouting is not done and the tendons are connected to the concrete element only

at the ends where it is anchored, tendons are called as unbounded tendons.

16. What is principle of pretensioning? (AU: NOV/DEC 2011)

The basic principle of prestressing is to produce by any suitable means, sufficient

compressive stressed in all those parts of concrete whose tensile stresses would occur.

17. Explain Hoyer’s effect in prestressed concrete? (AU: MAY/JUNE 2009,

NOV/DEC 2010)

For mass production of pretensioned elements, the long-time process developed

by Hoyer is generally used in factory. In this method the tendons are stretched

between two bulk heads several hundred meters apart so that a number of similar units

may be cast along the same group of tensioned wires. The wires or strands are

tensioned with the use of hydraulic jacks or by a moveable stressing machine.

18. State the reasons for which high tensile concrete is necessary in prestressed

concrete construction? (AU: MAY/JUNE 2009)

To withstand high compressive stress due to prestress at early stages

To offer higher resistance to tension, shear, bond and bearing

To have lesser shrinkage effect

To have higher modulus of elasticity and smaller creep and resulting

lesser loss of prestress

19. What is axial prestressing? (NOV/DEC 2016)

A member in which the entire cross section of concrete has a uniform

compressive prestress is called axial prestress. In this type of prestressing, the centroid

of the tendon coincides with that of concrete section.

Part B

1. A simply supported PSC beam of cross section 500mm wide and 800mm

deep is loaded with UDL of 50kN/m on span 10m. Obtain the stress

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 7

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

distribution at mid span by stress and strength concept, if prestressing force

is 1200kN applied eccentrically of 100mm from the bottom.

Solution:

Given data:

B=500mm

D=800mm

Live Load=50kN/m

L=10m

P=1200kN

E=400-100=300mm

A=500 × 800 =400 × 103mm2

Zt = = =

Zt = Zb = (500 × 8002)/6 = 53.33 × 106mm3

Uniform stress= = (1200 × 103)/(400× 103)= 3N/mm2

Stress due to eccentricity=

= (1200×103×300)/(53.3×106)= 6.75N/mm2

Dead load= WD= 24×0.5×0.8= 9.6kN/m

Moment due to dead load= MD= WDl2/8 = (9.6×102)/8=120kN/m

Moment due to live load= ML= WLl2/8 = (50×102)/8=625kN/m

Stress due to live load= ML/Z=(625× 106)/(53.33× 106)= 11.72N/mm2

Stress due to dead load= MD/Z=(120× 106)/(53.33× 106)= 2.25N/mm2

Stress Concept:

i. Stress @ top= - + MD/Z + ML/Z

=3- 6.75+2.25+11.72

=10.22N/mm2(Comp.)

ii. Stress @ bottom= + - MD/Z - ML/Z

=3+6.75-2.25-11.72

=-4.22 N/mm2(Tension)

Strength Concept:

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 8

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

a=M/P=(MD+ML)/P=((120+625)×106)/(1200× 103)=620.83mm

Stress @ top= + =10.22 N/mm2

Stress @ bottom= – =-4.22 N/mm2

2. A prestressed concrete beam of section 150mm wide and 350mm deep is used

over an effective span of 8m to support a UDL of 6kN/m, which includes the

self-weight of the beam. The beam is prestressed by straight cable carrying a

force of 200kN and located at eccentricity of 50mm. Determine the location

of thrust-line in the beam and plot its position at quarter and central span

section.

Given data:

B=150mm

D=350mm

Live Load=6kN/m

L=8m

P=200kN

e=50mm

A=350 × 150 = 52500mm2

Zt = = =

Zt = Zb = (150 × 3502)/6 = 3.05 × 106mm3

Uniform stress= = (200 × 103)/(52500)= 3.8N/mm2

Stress due to eccentricity=

= (200×103×50)/(3.05×106)= 3.27 N/mm2

Moment due to DL & LL= M= Wl2/8 = (6×82)/8=48kNm

Stress due to DL & LL= = (48×106)/ (3.05×106)=15.73 N/mm2

Resultant stress @ central axis

i. Stress @ top= - +

=3.8- 3.27+15.73

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 9

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

=16.26 N/mm2

ii. Stress @ bottom= + -

= 3.8 + 3.27-15.73

=-8.66 N/mm2

Shift of pressure line from cable line @ centre=

= (48×106)/ (200×103)=240mm

To find moment @ quarter span

RA + RB = 6 × 8 =48kN

M@A=0,

RB (8)- 6 × 8 × = 0

RB = 24kN

RA = 24kN

Mxx = RA (2)- 6 × 2 × = 36 kNm

Bending stress @ quarter span=(36×106)/(3.05×106)=11.8 N/mm2

Resultant stress @ quarter span section

@top = 3.8 - 3.27 + 11.8 = 12.33N/mm2

@bottom = 3.8 + 3.27 - 11.8 = -4.73N/mm2

Shift of pressure line=(36×106)/(200×103)=180mm

3. A rectangular prestressed beam 150mm wide and 300mm deep is used over

an effective span of 10m. The cable with zero eccentricity at the supports and

linearly varying to 50mm at the centre carries an effective prestressing force

of 500kN. Find the magnitude of the concentrated load located at the centre

of the span for the following conditions at the centre of span section:

a. If the load counteracts the bending effect of the prestressing force

(neglecting self-weight of the beam and

b. If the pressure line passes through the upper kern of the section

under the action of external load, self-weight and prestress.

Solution;

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 10

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

A= 150×300 = 45×103mm2

Z= bD2/6 = 2.25×106mm3

a) W= 2Psinᶿ

For very small values of ᶿ, sinᶿ=tanᶿ

tanᶿ=

W= =10kN

b) Self weight of beam = 24× 0.15× 0.3

WD= 1.08kN/m

Moment due to self weight of beam = Wl2/8

MD=13.5kNm

Stress due to self weight = ± MD/Z

= (13.5×106)/(2.25×106)

= ±6 N/mm2

Let WL be the concentrated load @ centre of span.

ML = (WLl) / 4= (WL × 10)/4 =2.5 WL

Stress due to prestressing force = +

=((500×103)/(45×103)) + ((500×103×50)/(2.25×106))

=11.11 + 11.11

=22.22N/mm2

If the pressure line Passes through upper bas @ the section, stress @

bottom fibre = 0,

+ - MD/Z - ML/Z=0

.22 = 6+(((2.5 × WL) ×106)/(2.25×106))

.22 – 6 + 1.11 WL

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 11

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

WL = 14.61 Kn

4. A prestressed concrete beam support an imposed load of 3kN/m over a

simply supported span of 10m. The beam has I section with an overall depth

of 450mm. The thickness of flange and web are 75mm and 100mm

respectively. The flange width is 200mm. The density of concrete is 24kN/m 3.

The beam is prestressed with an effective prestressing force of 350kN at a

suitable eccentricity such that the resultant stress at soffit of beam at the mid

span is zero. Find the eccentricity required for the force. Also calculate the

stresses at the top of the section.

Solution:

L.L= 3kN/m

L=10m, P= 350kN

A=(200×75)×2 + (300×100)=60×103 mm2

Z = BD2/6-bD2/6 =((200×4502)/6) –((100×3002)/6)

=5.25× 106 mm3

Stress @ Soffit =0

+ - MD/Z - ML/Z=0

Dead load = (24×(60×103))/ 106= 1.44kN/m

Moment due to dead load = (1.44×102)/8

=18kNm

Moment due to live load = (3×102)/8=37.5kNm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 12

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

((350×103)/(60×103))+((350×103×e)/(5.25×106))-((18×106)/(5.25×106))-((37.5×106)/

(5.25×106))=0

5.83 + 0.066e – 3.42 -7.14 = 0

0.66e = 4.73

e = 71.67mm

Stress @ top

= - + MD/Z + ML/Z

=((350×103)/(60×103))-((350×103×71.67)/(5.25×106))+ 3.42 + 7.14

=5.83 – 4.77 + 3.42 +7.14

= 11.62 N/mm2 (Comp.)

5. A PSC beam 250mm x 360mm has a span of 12m. The beam is prestressed

by steel wires of area 350mm2 at uniform eccentricity of 60mm with an

initial prestress of 1250N/mm2. Determine the loss of stress in wires

a. If the beam is pre-tensioned

b. If the beam is post-tensioned

Es = 210 kN/mm2, Ec = 35 kN/mm2, relaxation of stress in steel = 5% of initial

stress for both pretensioned and post-tensioned, anchorage slip = 1.25mm, k

= 0.0015/m. Adopt creep and shrinkage coefficients as per IS 1343.

Solution:

Given data:

L=10m, stress=1200N/mm2

µ=0.55

Slope=1 in 24

Ap=600mm2

K=0.0015/m

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 13

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Slope @ each end =0.04 = 1/24

Cumulative angle between two tangents, α = 2 × 0.04 =0.08 radians

Initial prestressing force=1200 × 600 =720kN

Loss of stress due to friction = Po(µα + kx)

=720(0.55×0.08 + 0.0015×10)

=42.48N/mm2

Loss due to anchorage slip=∆G/L

=(3×210×103)/(10×1000)

=63N/mm2

Total Loss = 42.48 63 =105.48kN

% loss of prestress = (105.48×100) /1200

=8.79%

Loss of force = 105.48×600 =63.28kN

Final force in cable = 720-63.28 =656.72kN

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 14

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

UNIT 2

DESIGN FOR FLEXURE AND SHEAR

PART A

1. What are the various types of flexural failures encountered in prestressed

concrete members?(AU: NOV/DEC 2011, NOV/DEC 2016)

Fracture of steel in tension

Failure of under reinforced section

Failure of over reinforced section

Other modes of failure

2. What are types of shear cracks in prestressed concrete members?

Web Shear crack

Flexural shear crack

3. Explain conventional failure of an over reinforced prestressed concrete

beam. (AU: APRIL/MAY 2010)

Over reinforced members fail by sudden crushing of concrete, the failure is

observed by small deflections and narrow cracks. The area of steel is large, the

stress developed in steel at failure may not reach the tensile strength. The sudden

failure without any warning in the form of excessive deflections and widespread

cracks, so over reinforced sections are not used.

4. Enumerate failure due to web-shear failure(AU: NOV/DEC 2011)

Web shear cracks generally starts from the interior points, when the local principal

tensile stress exceeds the tensile strength of concrete. Web shear cracks are likely

to develop in highly prestressed beams with thin webs, particularly when the beam

is subjected to large concentrated load near to supports.

5. What are assumptions made in strain compatibility method?(AU: NOV/DEC

2015, NOV/DEC 2011, NOV/DEC 2016)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 15

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

The stress distribution in the compression zone of concrete can be defined by

means of coefficients applied to the characteristics compressive strength and

average compressive stress and the position of the centre of compression can

be assessed.

The distribution of concrete strain is linear ( plane sections normal to axis

remains plane after bending

The resistance of concrete in tension is neglected

The maximum compressive strain in concrete at failure reaches the particular

value.

6. Define kern distance.(AU: APRIL/MAY 2010)

Kern is the core area of the section in which if the load applied tension will not

be induced in the section K t = Zb/A, Kb = Zt/A. If the load applied at Kt

compressive stress will be maximum at the top most fibre and zero stress will be at

the bottom most fibre. If the load applied at K b compressive stress will be the

maximum at the bottom most fibre and zero stress will be at the top most fibre.

7. What is effective reinforcement ratio?

Effective reinforcement ratio =

where, Ap = Area of prestressing

fp = prestress

b = width of the beam

d= depth of the beam

fck = characteristics compressive strength of concrete

8. How will you improve the shear resistance of concrete beam using

prestressing techniques?(AU: MAY/JUNE 2012)

Horizontal or axial prestressing

Prestressing by inclined or sloping cables

Vertical or transverse prestressing

9. How will you classify a structure as Type II or class 2 structure? (AU:

APR/MAY 2017)

For Type 2 members, limited tensile stress of magnitude exceeding modulus of

rupture is permitted and moderately prestressed. The allowable tensile stress in

concrete as per IS 1343-1980 is same for transfer and service load conditions. The

value is 3 N/mm2, which can be increased to 4.5N/mm2 for temporary loads.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 16

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

10. What are the stages of loading to be considered in design of prestressed

concrete section in flexure? (AU: MAY/JUNE 2009)

Two stages of loading are to be considered in design of prestressed concrete

section for flexure

a. Transfer of prestressing force

b. At working stage

2. What are the codes provisions (IS: 1343 -1980) for bond and transmission

length? (AU: MAY/JUNE 2012)

As perIS: 1343: 1980, transmission length is expressed in terms of the

diameter of wire. The concrete strength shall not be less than 35N/mm 2 and the

wires of diameter not exceeding 5mm and strands of diameter not exceeding

18mm.

3. What are the ways of transmission of prestressing force from steel to

concrete through bond?

The transmission of prestressing force from steel to concrete through bond

comprising of

i. Adhesion

ii. Friction

iii. Shear resistance (dilatency)

4. What is transmission length and cracking load?

The length of the bond anchorage of the prestressing wire from the end of the

pretensioned members to the point of full steel stress is called transmission length.

The load on the structural element corresponding to the first visible crack is known

as cracking load.

5. What is debonding? (AU: NOV/DEC 2008)

Prevention of bond between the steel wire and the surrounding concrete is

called debonding.

6. What is proof stress?

The tensile stress in steel which produces a residual strain of 0.2% of original

gauge length on unloading is called proof stress.

7. Give the ultimate shear resistance of sections uncracked under flexure

according to IS 1343?

IS 1343-1980, page 46, section 22.4.1

8. What is strain compatibility method? (AU: NOV/DEC 2016)

The method of estimating the flexural strength of prestressed concrete sections

is based on the compatibility of strains and equilibrium of forces acting on the

section at the stage of failure.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 17

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

9. What is the difference between bonded and unbonded tendon?

Bonded tendon Unbounded tendon

Prestressed concrete member in which A method of construction in which the

prestress is imparted to concrete through tendons are not bonded to the surrounding

bond between the tendons and concrete. The tendons may be placed in

surrounding concrete ducts formed in concrete members or they

may be placed outside the concrete

section.

PART B

1. A prestressed concrete beam of effective span 16m is of rectangular section

400mm wide and 1200mm deep. The tendons consist of 3300mm 2 of strands

of characteristics strength 1700 N/mm2, effective prestress of 910 N/mm2. The

strands are located 870mm from the top face of the beam. If f cu = 60N/mm2,

estimate the flexural strength of section as per IS: 1343-1983 for the

following cases: (a) bonded tendon (b) unbounded tendons.

Solution:

Given data:

L=16mm

B=400mm

D=1200mm

Ap=3300mm²

fp=170ON/mm²

fcu=60N/mm²

d=870mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 18

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

1) Bonded tendon:

A p × fp 3300 × 1700 = 0.268

=

fck× b × d 60 × 400 × 870

From IS 1343, page 59, table 11

A p × fp fcu Xu

b × d × fck 0.87 fb d

0.25 0.9 0.488

0.3 0.85 0.588

0.268 X Y

0.3-0.25 0.85-0.9

= = 0.882

0.3-0.268 0.85-X

fpu

= 0.882

0.87 × fp

Fpu=0.882 × 0.87 ×1700

= 1304.48 N/mm²

Xu/d=0.583-0.488/0.588-Y

Y=0.524

Xu/d=0.524

Xu=0.524 × 870 =455.88mm

Mu = fpu×Ap ( d – 0.42 Xu )

= 1304.48 × 3300 ( 870 – 0.42 × 455.88 )

=2920.9 KNm

2) Unbonded tendon:

Ap × fpc/fck × b × d=3300 × 910/60 × 400 × 870 =0.143

Eff span 16000

= 18.39 =20 =

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 19

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Eff depth 870

Ap × fpe Xu fcu

= =

fck × b × d d fpe

0.10 0.32 1.26

0.15 0.46 1.20

0.143 Y X

X = 1.21

fpu/fpe = 1.21

fpu = 1.21 × 910

=1101.1 N/mm²

By interpolation method

Y = 0.44

Xu/d =0.44

Xu =0.44 × 870 =382.8mm

Mu = fpu × Ap (d-0.42 Xu )

= 1101.1 × 3300 ( 870 – 0.42 × 382.8 )

Mu= 2577 KNm.

2. A PSC T-section has 1200mm x 150mm flange, 300mm x 1500mm rib and

area of wires used is 4700mm2at 1600mm from the top of flange. Calculate

the flexural strength of beam using M40 and Fe1600.

Solution

Given data:

bf = 1200mm

bw = 300mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 20

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

As = 4700 mm²

fck = 40 N/mm²

Df = 150 mm 1200mm

Dw = 1500mm 150mm

d =1600mm

fp = 1600 N/mm² 1600mm

solution: 1500mm

Ap = Apw + Apf

Apf = 0.45 fck (b-bw ) Dp/fp

= 0.45 ×40 ( 1200 – 300 ) ( 150/1600)

300mm

= 1518mm²

Ap = (4700-1500 ) = 3182mm²

Apw × fp 3182 × 1600

= = 0.265

bwd × fck 300 × 1600× 40

fpu

= 1.00

0.87 fp

fpu = 0.87 × 1600

= 1392 N/mm²

Xu/d =0.56, Xu = 0.56 × 1600 =896mm

Mu = fup × Apw ( d-0.42 Xu) + 0.45 × fck (b-bw) × Df (d-0.5Df )

= 1392 × 3182 (1600-(0.42 ×896 )+0.45 ×40 × (1200-300) × 150(1600-75)

Mu =9125 KNm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 21

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

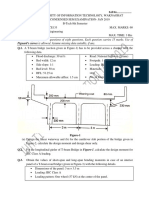

3. A cantilever portion of a prestressed concrete bridge with rectangular cross

section 600mm wide and 1650mm deep, is 8m long and carries a reaction of

350kN from the suspended span at free end, together with UDL of 60kN/m

inclusive of its own weight. The beam is prestressed by 7 cables each

carrying a force of 1000kN, of which three are located at 150 mm, three at

400mm and one at 750mm from top edge. Calculate the magnitude of

principal stresses at a point 550mm from the top of cantilever at the support

section.

Given data:

b = 600mm

d = 1650mm

l = 8mm

R =350 KN

L.L = 60 KN/m

P = 1000KN × 7 = 7000 KN

Solu :

Y= 3 × 150 + 3 × 400 × 1 × 750 = 343mm

3+3+1

e = 825 – 343 = 482mm

Moment due to prestressing force,

Pe = 7000 × 0.482 = 3372 KNm

Moment due to external load,

= ( 350 × 8 ) + 60 × 8²/2

= 4720 KNm

Maximum shear @ support = 350 + 60 × 8

=830 KN

I = bd³/12 = 600 × 1650³/12

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 22

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

= 225 × 10mm

Resultant direct stress @ 550mm from top

= 7000 × 10³

+ 3374 × 10 × 275 4720 × 10 × 275

600 × 1650 225 × 10 225 × 10

= 5.43 N/mm²

Maximum shear stress @ 550m from top

= V / Ib ( AY’)

830 × 103

= ( 600 × 550 × 550 )

225 × 109 × 600

=1.1 N/mm²

Maximum and minimum principal stress

2+ 2

= 5.43/2 ± 0.5

= 5.65 N/mm² ( compression )

= - 0.21 N/mm² (tension )

4. A prestressed girder of rectangular cross section 150mm wide and 300mm

deep is to be designed to support an ultimate shear force of 130kN. The

uniform prestress across the section is 5kN/mm2. Using M40 and Fe415

HYSD bars of 8mm diameter, design suitable shear reinforcement as per IS

code.

Given data:

b = 150mm

D = 300mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 23

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

V = 130 KN

d = 250mm

fcp = 5 N/mm²

fck = 40 N/mm²

According to IS 1343 – 1980 , page 46

Vc = 0.67 bw D ft² + 0.8 fcp ft

= 0.67 × 150 × 300 1.518 + 0.8 × 5 × 1.518

Vc = 87.26 KN

ft= 0.24 = 0.24 ×

= 1.518 N/mm²

Balance shear = V – Vc

= 130 – 87.26

= 42.74 KN

Using 8mm dia 2 legged stirrups , the spacing of stirrups

Su = Asv × 0.87 × fy × d

V – Vc

= 0.87 × 2 × /4 × 8² × 250 × 415

42.74 × 10

= 212.28mm > 0.75 d

> 187.5mm

Adopt 8mm dia two legged stirups @ 180mm c/c spacing.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 24

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

5. The cross section of prestressed concrete beam is unsymmetrical T-section with

following data: Overall depth = 1300mm, Thickness of web = 150mm, M45,

Distance of top and bottom fibres from centroid = 545mm and 755mm

respectively. At a particular section, M= 2130kNm and V= 237kN, effective

depth = 1100mm. Effective prestress at the extreme tensile face of the beam =

19.3N/mm2. I = 665 x 108 mm4, Ap = 2310mm2, fp = 1500N/mm2, effective stress

in tendons after all losses = 890N/mm2. Estimate the flexure shear resistance of

the section as per IS code.

Given data:

M = 2130 KNm V = 237 KN d = 1100mm

fck = 45 N/mm² fep = 19.3 N/mm² Ap = 2310 N/mm²

I = 665×10 mm² fp = 1500 N/mm² fpe = 890 N/mm²

IS 1343 page 46,

Vcp = (1-(0.55 ×fpe/fp)

bw d + (Mo/M) V

M0 = 0.8 fep× I/Yb

= 0.8 × 19.3 × I / 755

= 136 × 10×Nmm

Table 6,

100 Ap 100 × 2310

= = 1.40

bwd 150 × 1100

= 0.77 N/mm²

1.25 0.74 1.4-1.25 X – 9.74 X = 0.77

=

1.50 0.79 1.4 – 1.5 X – 0.79

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 25

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

1.4 X

Vd = 1- 0.55 × 890 × 0.77 × 150 ×1100 + (136 × 10 /2130 × 10 ) × 237 ×10

1500

= 240 KN > 237 KN

Provide minimum shear reinforcement .

UNIT 3

DEFLECTION AND DESIGN OF ANCHORAGE ZONE

PART A

1. List down the factors influencing the deflection of prestressed concrete

members? (AU: MAY/JUNE 2016, NOV/DEC 2015, MAY/JUNE 2012)

The factors influencing the deflection are

Imposed load and self-weight

Magnitude of prestressing force

Cable profile

Moment of inertia

Modulus of elasticity of concrete

Span of the member

Relaxation of stress in steel, shrinkage and creep

Fixity conditions

2. What are the forces considered in the calculation of deflection of prestressed

concrete beams? (AU: APRIL/MAY 2010)

The forces considered in calculation of deflection are

Prestressing force

Dead load

Live load or imposed load

3. Enumerate effect on tendon profile on deflections (AU: MAY/JUNE 2012)

Tendons are located with eccentricities towards the soffit of beams to counteract

the sagging bending moments due to transverse loads. Consequently, the concrete

beams deflect upwards on the application or transfer of prestress. Since the

bending moment at every section is the product of the prestressing force and

eccentricity, the tendon profile itself will represent the shape of BMD.

4. What is meant by anchorage zone? What is its length? (AU: NOV/DEC 2015,

NOV/DEC 2016)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 26

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

The zone between the end of the beam and the section where only the longitudinal

stress exists is generally referred to as anchorage zone or end block. The length is

taken equal to the depth of the beam.

5. What are the functions of end blocks? (AU: NOV/DEC 2013, MAY/JUNE

2013, APR/MAY 2017)

The forces on the end block of the post tensioned prestressed concrete member

are physical concept of state of stress in transverse direction.

The curvature of the struts, being convex towards the centre line of the block,

induces compressive stresses in zone.

6. Draw a sketch showing the stress distribution in end block by double anchor

plate (AU: APRIL/MAY 2010)

7. Draw the idealised stress distribution in end block by single anchor plate?

8. What is meant by spalling force?

The surface at end section just adjacent to the anchor plate is subjected to tensile

force which is called spalling force.

9. What is meant by bursting force? (AU: NOV/DEC 2016)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 27

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

The material along the axis of concentrated forces is subjected to a transverse

tensile force called bursting force.

10. What is zone of transmission in end block of prestressed concrete structures?

(AU: MAY/JUNE 2009)

The zone between the end of the beam and the section where only longitudinal

stresses exists is referred as end block or anchorage zone. The length is taken as

equal to depth of the beam. This zone is called as transmission zone.

11. What are the methods used to analyse the stress in anchorage zone?

Magnel’s method

Guyon’s method

Zielinski and Rowe’s method

IS 1343 method

12. Sketch the pattern of reinforcement in anchorage zone

13. Why anchorage zone needs specific analysis and design?

The transverse stresses developed in the anchorage zone are tensile in nature over

a large length and since concrete is weak tension, adequate reinforcement must be

provided to resist this tension.So, anchorage zone needs specific analysis and

design.

14. How will you compute the bursting tensile force in end block by IS 1343?

IS 1343-1980, page no.36, Section: 18.6.2.2.

15. Explain Magnel’s method of stress distribution in anchorage zone.

In this method, the end block is considered as deep beam subjected to

concentrated loads due to anchorages on one side and to normal and tangential

distributed loads from the linear direct stress and shear stress distribution from

the other side.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 28

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

16. Briefly explain the Guyon’s method for the end block with evenly distributed

force system.(AU: NOV/DEC 2010).

When the forces are arranged such that the resultant of the stress distribution at

the distance equal to the depth of end block coincides with the line of action of

the forces, then the forces are considered to be evenly distributed. For eccentric

forces and multiple cables, the symmetric prism method may be used.

17. Draw the tensile stress distribution in end anchorage plate?

18. How is spalling tension taken care in the anchorage zone?

Spalling tension is developed on the edge surfaces on the beam adjacent of the

anchor plate. The spalling stress is directly proportional to the bearing stresses

imposed and inversely proportional to the interval of bearing forces. In most of the

cases the spalling forces is in the range of 0.3P/A to 0.4P/A.

19. Why control of deflection is very essential? (AU: APR/MAY 2017)

The deflection is necessary to check the performance of flexural members at

serviceability limit state. Since prestressed concrete members are slender than

reinforced concrete members, check for deflection is more important. Deflections in a

prestressed concrete is usually checked at transfer and service condition.

20. Define degree of prestressing.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 29

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

A measure of the magnitude of prestressing force related to resultant stress

occurring in structural member at working loadis called as degree of prestressing.

PART B

1. The end block of post-tensioned bridge girder is 500mm wide and 1000mm

deep. Two cables, each compressing 90HTS wires of 7mm diameter are

anchored using square plate of side length 400mm with their centre located at

500mm from the top and bottom edges of the beam. The jacking force in each

cable is 4000kN. Design suitable anchorage zone reinforcement using Fe415

HYSD bars as per IS code.

1. Given data:

b=500mm

d=1000mm

Pa=4000 KN

2yp0=400mm

Solution:

2yp0=400mm

2y0=500mm

Distribution ratio=( 2yp0/ 2y0)

=400/500

=0.8

Tensile force,fbsr= Pk [0.32 - 0.3( yp0/ y0)]

=4000×[0.32 – (0.3×0.8)]

=320 KN

Use 10mm diameter, no of bars=[ (320×10³) / ( 0.87×200×78.54) ]

=18.73 ~ 18 Nos.

The reinforcement are arranged in zone between 0.2y0 &y0

0.2 y0= 0.2×(500/2)

y0 = 250mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 30

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

18 Nos of 10 mm dia bars arranged @ 50 mm spacing

2. The end block of post-tensioned PSC beam of 300mm wide and 300mm deep

is subjected to concentric anchorage force of 832.8kN by Freyssinet

anchorage of area 11720mm2. Design and detail the anchorage reinforcement

for end block.

Given data:

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 31

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

b=100mm

d=200mm

P=100 KN

Anchor plate

Solution:

Direct stress= P/A =[(100×10³) / (200×100)]

=5 N/mm²

The principle tensile stresses are critical @ x =0.5h

For section xx (centre of plate)

X=0.5

From the table, K1= -5, K2=2, K3=1.25

M= [(5×100×(200/2)) × (100/2)] - [((100×10³)/2) × (50/4)]

=1875×10³Nmm

V=0 & H=0

Fv= -5×[(1875×10³)/(100/200²)]

= -2.35 N/mm²

Fh= 5 N/mm²

Fmin=[((5-2.35)/2) – ((1/2)×((5+2.35)²+0)1/2)]

= -2.35 N/mm²

Fbsr=(2/3)×150×2.35×100

=23500 N

For section yy: (passing through edge of plate)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 32

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

=0.5h

=100mm from end

Principal tensile stress

Fmin=[((-1.75+5)/2) – ((1/2)×((5+1.75)²+(4×(-2.35)²)))1/2]

= -2.475 N/mm²

tan2ɵ=(2Ʈ/(fv-fb))

=((2×(-2.35))/(-1.75-5))

=0.7

2ɵ=35°

ɵ=17.5°

Tensile stress components in vertical direction

=2.475×sec17.5°

=2.6 N/mm²

Bursting tension,

Fbsr=((2/3)×2.6×150)×100

=26000 N.

3. A prestressed concrete beam of span 8mhaving rectangular cross section of

150mm wide and 300mm deep. The beam is prestressed by parabolic cable

having eccentricity of 75mm below the centroidal axis at the centre and 25mm

above the centroidal axis at the supports. The initial force in the cable is

350kN. The beam supports three concentrated loads of 10kN each at interval

of 2m. Ec=38kN/mm2

a) Neglecting losses of prestress, estimate the short term deflection due to

prestress and self-weight

b) Allowing 20% loss in prestress, estimate long term deflection under

prestress, self-weight and live load. Assume creep coefficient as 1.8

Given data:

b=300mm

d=300mm

P=832.84 N

Area of anchorage=11720 mm²

Solution:

Fc=((832.8×10³)/(300×300)) =9.253 N/mm²

Side of square

2yp0=(11720)1/2

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 33

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

=108.26mm ≈ 110mm

2y0=300mm

Distribution ratio,

=( )

=(110/300) =0.37

Bursting tensile force,

Fbsr =Pre×(0.32-(0.3×( )))

=832.8×10³(0.32-(0.3×0.37)

=171.88 N

Using 10mm dia rods of 250 N/mm² (yield stress)

No of bars required =(174888/(0.87×250×( )×10²))

=10.25 Nos

Says =10 nos

The reinforcement is arranged in zone b/w

0.2y0=0.2×150

=30mm

Y0=150mm

Detailing:

4. The concrete beam of rectangular section, 100mm wide and 300mm deep, is

stressed by 3 cables, each carrying an effective force of 200kN. The span of

the beam is 12m. The first cable is parabolic with eccentricity of 50mm

below the centroidal axis at the centre of span and 50mm above the

centroidal axis at the supports. The second cable is parabolic with zero

eccentricity at the support and 50mm eccentricity at the centre of span. The

third cable is straight with uniform eccentricity of 50mm below the

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 34

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

centroidal axis. If the beam supports a UDL of 6kN/m and E c= 38kN/m2,

estimate the instantaneous deflection at

a) prestress+ self-weight of the beam

b) prestress+ self-weight + live load

Given data:

P=350 KN

L=8m

E1 = 75mm

E2 = 25mm

b=150mm

D = 300 mm

I= = = 337.5 106 mm4

Ec=38 KN/mm2

Deflection due to presterssing force

= (Pl2/48EI) (-5e1+e2)

=[((350×10³×(8×10³)²)/(48×38×10³×337.5×106))]×[(-5×75)×25]

= -12.7mm (upward)

Deflection due to dead load

Self weight of beam,w0=(24×0.3×0.240)

=1.08 KN/m

D =[(5×1.08×(8×10³)4)/(384×38×10³×337.5×106)]

=4.5mm (downward)

Deflection due to prestress and self weight

= -12.7+4.5mm

= -8.5mm (upward)

Deflection due to live load

MA=MB=0

MC=ME=(15×2) =30KNm

MD=((15×4) – (10×2))

=40KNm

L=((A×x)/(E×I))

From BMD,

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 35

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

A1=((1/2)×2×30) =30m², A2=(2×30)=60m²

X1=((2/3)×2) =1.33m, X2=(2×(2/2))=3m

A3=((1/2)×2×10)=10m²

X3=(2+((2/3)×2))=3.33m²

L=((Ax1+Ax2+Ax3)/(EI))

=[((30×1.33+60×3+10×3.33)×106)/(38×103×337.5×106)]

=19.75mm (downward)

Long term deflection=(1+ )×( D+ L +Ƞ P)

=(1+1.08)×(0.8×19.75+4.5-8.5) =33mm(downward)

5. A simply supported beam is having dimensions 200mm x 450mm is post

tensioned with two cables of each having area of 150mm 2. The first cable is

parabolic with an eccentricity of 70mm at mid span and zero at support

whereas the second cable is having straight profile with uniform eccentricity

of 70mm throughout. The initial prestress applied to each cable is 1100

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 36

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

N/mm2. The modulus of elasticity of concrete is 40 kN/mm2. The length of the

beam is 7.5m carry two point load of 25kN at 1/3rd of span. Determine

a. The instantaneous deflection at the centre of span and

b. The deflection at the centre of span after 2 years, assuming 18% loss in

prestress and effective modulus of elasticity to be 3/4 th of the short term

modulus of elasticity.

Given data:

b=150mm

D=300mm

P=200KN

Live load=6KN/m

Ec=38KN/mm²

Self weight of beam=(0.15×0.3×24)=1.08KN/m

I= = =337.5×106mm4

Deflection due to self weight:

D =

=22.43mm (downward)

Deflection due to live load:

L =

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 37

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

=126.3mm (downward)

Deflection due to cable 1:

e1=50mm e2=50mm

SP1=((200×10³×12000²)/(48×38×10³×337.5×10⁶))×(-5×50+50)

= -9.357mm(upward)

Deflection due to cable 2:

e1=50mm e2=0

SP2=(Pl2/48EI) (-5e1+e2)

= -11.696mm (upward)

Deflection due to cable 3:

SP3= -((P×e×l²)/(8EI))

= -((200×10³×50×(12×10³)²)/(8×38×10³×337.5×10⁶))

= -14.035mm (upward)

Deflection due to prestress= SP1+ SP2+ SP3

= -(9.35+11.696+14.085)

= -35.08mm (upward)

a.) Deflection due to prestress+self weight = -35.088+22.737

= -12.351mm (upward)

b.) Prestress+self weight +live load= -35.08+22.73+126.314

=113.16mm (downward).

UNIT 4

COMPOSITE BEAMS AND CONTINUOUS BEAMS

PART A

1. Define propped construction.(AU: MAY/JUNE 2016, NOV/DEC 2015,

NOV/DEC 2013, MAY/JUNE 2013)

The dead load stress developed in the precast prestressed units can be minimized

by propping them while casting the concrete in sit-this method of construction is

termed as propped construction

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 38

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

2. How to achieve compositeness between precast and cast in situ part? (How

do you form bonding between prestressed units and reinforced units)(AU:

MAY/JUNE 2016, NOV/DEC 2015, NOV/DEC 2014, NOV/DEC

2013,MAY/JUNE 2013, , NOV/DEC 2016)

In structural system prestressed concrete is often combined with other materials

such as reinforced concrete for the sake of economy and efficiency. The resulting

structure formed by two are more material is called composite construction .So the

combination of two are more material is called composite construction .So the

combination of two materials acting as a monolithic action called composite action in

prestressed concrete structure

3. What is the difference between propped and unpropped composite

construction? (AU: APRIL/MAY 2015, NOV/DEC 2016)

The dead load stress developed in the precast prestressed units can be minimized

by propping them while casting the concrete in situ. This method of construction is

termed as propped construction.

If the precast units are not propped while placing them in situ concrete, stresses

are developed in the unit due to the self-weight of the member and the dead weight of

the in situ concrete. This method of construction is referred to as unpropped

construction.

4. What is the effect of differential shrinkage in composite beam? (AU:

APRIL/MAY 2015

The in-situ concrete in a composite beam is of relatively lower grade (M-15 or

M-20) and as correspondingly higher water-cement ratio. On the other hand, the

precast prestressed concrete is higher grade and most of its shrinkage as already

occurred before the placement of in-situ concrete. Consequently, the in-situ concrete

shrinks more than the precast concrete.

5. What is meant by unpropped construction? (AU: APR/MAY 2017)

If the precast units are not propped while placing them in situ concrete, stresses

are developed in the unit due to the self-weight of the member and the dead weight of

the in situ concrete. This method of construction is referred to as unpropped

construction.

6. What are the advantages of composite construction? (AU: APR/MAY 2017)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 39

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Appreciable saving in the cost of steel in a composite member compared with a

reinforced or prestressed concrete member.

Sizes of precast prestressed units can be reduced due to the effect the member

Low ratio of size of the precast unit that of whole composite member

In many cases, precast prestressed units serve as supports and dispense with the

formwork for placement of in-situ concrete

Composite member are ideally suited for constructing bridge decks without the

disruption of normal traffic.

7. Explain with neat sketches, the stress developed due to differential shrinkage

in structural elements comprising of precast prestress element and cast in

situ concrete element?

A reasonably estimation of stresses developed due to differentially shrinkage may

be made using the following assumption:

1. The shrinkage is uniform over the in-situ part of the section and

2. Effect of creep and increase in modulus of elasticity with age and the component

of shrinkage, which is common to both the units, is negligible.

8. Define composite construction?(AU: NOV/DEC 2009)

Composite construction of providing monolithic action between i) prefabricated

units steel beams, precast reinforced or prestressed concrete beams and ii) cast- insitu

concrete. This method is found to provide greater structure efficiency compared with

the conventional methods of construction. The resulting structure formed by two or

more materials is called composite construction.

9. Draw the any four types of composite prestressed concrete sections.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 40

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

10. What are the advantages of continuous members?

i. The bending moments are evenly distributed between the centre of the span

and the supports of the members.

ii. Reduction in the size of members results in the lighter structures.

iii. Ultimate load carrying capacity is high.

iv. Continuity of the members in framed structures leads to increased stability.

v. Reduction in the numbers of anchorages.

11. What are the methods of achieving continuity in continuous members?

i. Continuous cable

ii. Straight cable.

iii. Cap cable.

iv. Straight tendon.

12. What is cap cable?

A short curved tendon arrangement at the interior support of a continuous

beam. The anchors are in the compression zone, while the curve portion is in the

tensile zone.

13. What is concordant cable profile in continuous beams?

A tendon profile in which the eccentricity is proportional at all cross sections

to the bending moments caused by any loading on a rigidly supported statically

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 41

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

indeterminate structure is a concordant profile. Stressing a tendon laid to such a

profile does not induce any redundant reactions and hence the secondary moments

are zero.

14. What is meant by primary and secondary moment?

The primary moment is the apparent bending moment at a section in a statically

indeterminate structure due to the actual eccentricity of the tendons from the

centroidal axis. The secondary moments are additional moments induced at a section

of a statically indeterminate structure due to the redundant reactions developed as a

consequence of prestressing the structure.

15. Explain with neat sketches, the stress developed due to differential shrinkage

in structural elements comprising of precast prestress element and cast in

situ concrete element?

A reasonably estimation of stresses developed due to differentially shrinkage may

be made using the following assumptions

The shrinkage is the uniform over the in-situ part of the section and

Effects of the creep and increase in the modulus of elasticity with age and the

component of shrinkage, which is common to both the units is negligible.

16. What are the methods used to analyse continuous beam?

i. Three moment theorem

ii. Consistent deformation method

iii. Tendon reaction (or) Equivalent load method

17. State Guyon’s theorem of continuous beams?

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 42

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

“In a continuous prestressed beam, if the tendon profile is displaced vertically

at any of the intermediate supports by any moments, but without altering its intrinsic

shape between the supports, the resultant line of thrust is unchanged.’’

18. What is linear transformation of cable?

A transformation profile is any tendon profile consisting of straight lines

between the rigid supports and having zero eccentricity at simple end supports. A

tendon following such a profile will produce support reactions and uniform

longitudinal compression but no bending moments.

19. What is moment redistribution ratio?

The moment redistribution ratio βb as,

βb = (Moment at a section after redistribution/Moment at the section

before redistribution) ≤ 1.

PART B

1. A prestressed pre-tensioned beam of rectangular section has 100mm wide

and 200mm deep. The beam, with an effective span of 5m, is prestressed by

tendons with their centroid coinciding with the bottom kern. The initial force

in tendons is 150kN. The loss of prestress may be assumed as 15%. The beam

is incorporated in a composite T-beam by casting a top flange of 400mm

wide and 40mm thick. If the composite beam supports a live load of

8kN/mm2, calculate the resultant stress developed in precast and in situ

concrete assuming pre-tensioned beam as propped and unpropped

construction. Assume the same modulus of elasticity for concrete in precast

beam and in situ cast slab.

GIVEN DATA

b=100 mm

d=200 mm

P=150 KN

Ƞ=0.85

LL=8 KN/m2

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 43

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

SOLUTION

A=100 × 200 = 20000 mm2

Zt =Zb = = 666666.67 mm3

Kt = Kb = = 33.33 mm

e = 33.33 mm

P = 150 KN

Stress due to prestress,

@ top = –

= -

@ bottom = + = 15 N/mm2

Effective prestress after loss = 0.35 × 15 = 12.75 N/mm2

Self weight of precast beam = 0.1 × 0.2 × 24 = 0.48 KN/m

Self weight moment = = KN/m

Stress due to self weight @ top & bottom = = 2.25 N/ mm2

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 44

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Self weight of cast insitu slab = 0.04 × 0.4 × 24 = 0.384 KN/m

Moment due to self weight of slab = = 1.2 KN-m

Stress due to self weight of cast insitu slab = = = 1.8 N/mm2

Sectional properties of composite section

Yt = = 86.67 mm

Yb = 240 – 86.67 = 153.33 mm

I= + (400 × 40 × 66.672) + + (200 × 100 × 53.332)

= 196.8 × 106 mm4

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 45

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Zt = = 2.27 × 106 mm3

Zb = = 1.28 × 106 mm3

Live load on composite action = 0.4 × 1 × 8000 = 3200 N/m

Moment due to live load = = 10000 N m

Live load stress

@ top = = = 4.4 N/mm2

@ bottom = = = 7.79 N/mm2

Stress due to cast insitu weight

@ top = = 0.529 N/mm2

@ bottom = = 0.935 N/mm2

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 46

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

UNPROPPED CONDITION

PROPPED CONDITION

2. A rectangular pretensioned concrete beam has 100mm wide and 230mm depth

and the prestress after all losses is 12N/mm 2 at the soffit and zero at top. The

beam is incorporated in composite Tee beam by casting a top flange of 300mm

wide and 50mm thick. Calculate the maximum UDL that can support a simply

supported span 4.5m, without any tensile stress occurring (i) if the slab is

externally supported while casting and (ii) if the pre-tensioned beam supports the

weight of slab while casting.

Given data

b = 100 mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 47

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

d = 230 mm

fp = 12 N/mm2

SOLUTION

A = 100 × 230 = 23000 mm2

I= = = 101.39 × 106

Zt = Zb = = = 881.67 × 103 mm3

Yt = = 109.74 mm

Yb = 280 - 109.74 = 170.26 mm

I= + (300 × 50) × (109.74 – 50/2) 2 + + (100 × 300) × (170.26

– 230/2)2

= 282.46 × 106 mm4

Zb = = 1.66 × 106 mm3

Zt = = 2.57 × 106 mm3

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 48

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Self weight of cast insitu slab is,

= 0.3 × 0.05 × 25 = 0.375 KN/m

Moment due to self weight of slab

= = = 0.633 KN-m

i. Slab is extremely supported

Stress @ bottom of the beam due to self weight of cast insitu slab

= = 0.38 N/mm2

Stress @ soffit of beam = 12 N/mm2

Net stress available @ bottom = 12 – 0.38 = 11.62 N/mm2

Moment due to UDL @ zero stress @ bottom

M = f×Zb = 11.62 × 1.66 × 106 = 19.28 × 106 N-mm

Live load = = 7.62 KN/m

ii. The pretensioned beam of beam support the weight of slab

= = = 0.718 N/mm

Net stress available = 12 - 0.718 = 11.282 N/mm2

3. A composite T-section girder consists of a pre-tensioned rectangular beam

120mm wide and 240mm deep, with an insitu cast slab, 360mmwide and

60mm deep laid over the beam. The pretensioned beam contains 8 wires of

5mm diameter, located 30mm from the soffit. The tensile strength of HTS

wires is 1600N/mm2 and cube strength of 20N/mm2.

(i) Estimate the flexural strength of composite section

(ii) Calculate the ultimate shear which causes separation of two parts of the

girder if the contact surface is roughened to withstand a shear stress of

1N/mm2.

GIVEN DATA

bw = 120 mm

d = 240 mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 49

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

b = 360 mm

Df = 60 mm

Ap = 8 × × 52 = 160 mm2

fp = 1600 N/mm2

fck = 20 N/mm2

SOLUTION

= = 0.155 N/mm2

IS 1343,

=1 & = 0.326

fpu = 1392 N/mm2 xu = 0.326 × 240 = 78 mm

xu > Df ,

Mu = fpu Apw (d – 0.42 xu) + 0.45fck (b – bw) × Df (d – 0.5 Df )

Ap = Apw + Apf

Apf = 0.45 × fck × (b – bw) × (Df/fp)

= 0.45 × 20 × (360 – 120) × (60/600) = 81 mm2

Apw = 160 – 81 = 79 mm2

= = 0.219

IS 1343, bonded tendons

=1 & = 0.478

fpu = 1392 N/mm2 xu = 114.72 mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 50

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

xu > Df ,

Mu = 1392 × 79 × ( 240 – 0.42 × 114.72) + 0.45 × 20 × (360 – 120) × 60 × (240 – 0.5

× 60)

= 48.31 KN-m

= (or) Vu =

= 1 N/mm2

= = 115.71 mm

y = 115.71 – 30 = 85.71 mm

I= + (360 × 60 × 85.712) + + (120 × 240 × 64.292)

= 422.43 × 106 mm4

Vu = = 27371 N = 27.37

4. A continuous prestress concrete beam ABC (AB = BC = 8m) has a uniform

rectangular section of width 100mm and deep 250mm. The cable carries a

effective prestressing force of300kN which is parallel to the axis of the beam

and located at 75mm from the soffit. Take density of concrete as 24kN/m3.

a. Determine the secondary and resultant moment at central support B

b. If the beam supports an imposed load of 1.2kN/m, calculate the

resultant stress top and bottom of the beam at B

GIVEN DATA

AB=BC=10m

B=100mm

D=300mm-

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 51

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

P=300KN

e =100mm

SOLUTION

Dead load = 24 × 0.1 × 0.3

=0.72KN/m

Applying three moment therm,

MAB + 2MBA + 2kMBC + KmCB = KBA + kKBC

MAB = MBC = 0 k=1

MBA = KBC = MB

KBA = KBC =

= [- 0.05 × 10 × 5] = 54 KNm

4MB = 2 × 54 = 108 KNm

SM @ B is, MB = 27 KNm

Total resultant moment @ B = 9 - 27.75 = -18.75

Stress at central support section B

Top fibre stress = ˗

= - 0.5 N/mm2 (ten)

Bottom fibre stress = 24.7 N/mm2(com)

Pressure line position

@ A = - 5cm

@B= = = - 52mm

Resultant moment @ centre stress

= +

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 52

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

= +

= 9.25 kNm

Shift of pressure line from the centroid axis

= = 26mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 53

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

UNIT V

MISCELLANEOUS STRUCTURES

PART A

1. How are the tanks classified based on the joint? (AU: MAY/JUNE 2016,

APRIL/MAY 2015, NOV/DEC 2013, NOV/DEC 2015)

The joint between the walls of the tank and floor slab may be of following three

types

a. Fixed base

b. Hinged base

c. Sliding base

2. Define circular prestressing(AU: MAY/JUNE 2016, APRIL/MAY 2015,

NOV/DEC 2013, NOV/DEC 2012)

The terms referred to prestressing in round members such as tanks and pipes.

Liquid retaining structures such as circular pipes, tanks and pressure vessels are

admirably suited for circular prestressing.

3. How circular prestressing is achieved? (AU: NOV/DEC 2015)

a) Overlapping tendons

b) Wrapping of HTS wires

c) Pulling through a die

4. What is circumferential prestressing?(AU: NOV/DEC 2014)

Precast members are prestressed circumferentially by wrapping the tendons

around the members. Circumferential prestress fc, is given by

Fc = (N/mm2)

5. What is the main function of longitudinal prestressing? (AU: NOV/DEC

2014)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 54

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

The main function of longitudinal prestress is to prevent cracking in

concrete during circumferential winding and cracking due to bending stresses

developed during the handling and installation of pipes.

6. Define partial prestressing(AU: MAY/JUNE 2016, NOV/DEC 2014,

MAY/JUNE 2013)

Partial prestressing can be defined by 2 condition,

a) Tensile stresses are permitted in concrete i.e tensioning the entire HTS to a

stress smaller than the maximum permissible stress.

b) Non prestressed reinforcement are employed in the member the resisting part

of working moment by prestress HTS and remaining part untensioned HTS

of intermediate grade steel or mild steel.

7. What are the merits and demerits of partial prestressing? (AU: NOV/DEC

2013, NOV/DEC 2012, MAY/JUNE 2009)

Merits:

Camber of bridge deck is better controlled.

Saving in amount of prestressing steel.

Saving in the work of tensioning and end anchorages.

Economical utilization of mild steel.

Demerits:

Earlier appearance of cracks.

Greater deflection under overloads.

Higher principle stresses.

Decrease in ultimate flexural strength in the member.

8. Differentiate prestressed cylinder and non-cylinder pipe. (AU: MAY/JUNE

2013)

Prestress concrete cylinder pipe consist of the concrete core, a thin steel

cylinder, high tensile prestressing wire and a mortar coating. The concrete core is

the main structure load bearing component with the steel cylinder acting as a

water barrier between concrete layers, the prestressing wires produced a uniform

compressive pressure in the core that offset tensile stress in the pipe, and the

mortar coating product the prestressing wires for physical damage and external

corrosion.

9. What are the stages to be considered while designing PSC pipes? (AU:

NOV/DEC 2012, MAY/JUNE 2012)

Circumferential prestressing, winding with or without longitudinal

prestressing.

Handling stresses with or without longitudinal prestressing.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 55

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Condition in which a pipe is supported by saddles at extreme point with full

water load but zero hydrostatic pressure.

Full working pressure conforming to the limit state of serviceability.

The first crack stage corresponding to the limit state of local damage.

10. Write a short note on prestressed tank floors? (AU: MAY/JUNE 2012)

The base slab forming the floor or the tank in generally made of

reinforced concrete constructed on a flat bituminous surfacing or on a thin

concrete binding with the interposition of a sliding layer such as oil paper, so that

the slab can move over the compacted soil bed. The slab should be sufficiently

flexible so that it can adapt itself to the local deformations of the precompacted

subsoil.

11. Define two stage construction for non-cylinder pipe.(AU: NOV/DEC 2011)

It was developed by Lewiston Pipe Corporation in 1930.

The first stage consists of concrete casting over the longitudinal

reinforcement.

The second stage concrete pipes are curved circumferential stressing is

provided by means of spiral wires owned around the pipe and protected by

on coat of mortar.

12. What are different shapes of prestressed concrete tanks? (AU: NOV/DEC

2011, NOV/DEC 2010)

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 56

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

13. What are advantages of PSC poles?(AU: NOV/DEC 2010)

Resistance to corrosion in humid and temperate climates and to erosion in

desert areas.

Easy handling due to less weight than other poles.

Fire resistance, particularly to grass and bush fires near the ground line.

Lighter because of reduce cross section when compared with reinforced

concrete pole

Have increased crack resistance, rigidity and can resist dynamic loads better

than reinforced concrete poles.

14. What is the stress induced in concrete due to circular prestressing? (AU:

APRIL/MAY 2010)

The circumferential hoop compression induced in concrete by prestressing

counterbalances the hoop tension developed due to internal fluid pressure.

15. What are the needs of prestressing in compression members? (AU:

MAY/JUNE 2009)

In some members, such as portal frames and masts, the sections are subjected

to compression bending. Even in axially loaded columns the external loads are

rarely concentric. As a result, the concrete section is subjected to tension at the

side farthest from the line of section of the longitudinal load. The cracking that

develops can be prevented by the prestress in the columns.

16. What is the necessity of vertical prestressing in water tanks? (AU:

MAY/JUNE 2012)

The design of tank walls to resist the hoop tension and moments developed are

based on the considerations of desirable load factor against cracking and collapse.

So, we need to go for vertical prestressing in water tank design in PSC structures.

17. What is monolyte construction of PSC pipes?

It was developed by Mr.Freyssinet in 1930.The main principle is fresh

concrete subjected to triaxial pressure. The steel is placed and the concrete is

poured with high frequency vibration. The construction consists of outer cell with

longitudinal section held together by spring and inner cell with expandable rubber

membrane. The concrete is cured by steel curing. This method is used to achieve

stressing and protection in single cycle.

PART B

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 57

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

1. A PSC circular water tank required to store 24500 million litres of water.

The permissible compressive stress in concrete at transfer should not exceed

13N/mm2 and minimum compressive stress under working pressure should

not be less than 1N/mm2. The loss ratio is 0.75. HTS wires of 7mm diameter

with initial stress of 1000N/mm2 are available for winding. Freyssinet cables

of 12 wires of 8mm diameter which are stressed to 1200N/mm 2 are available

for vertical prestressing. Assume coefficient of friction as 0.5. Use M40

concrete. Design the tank walls supported by elastometric pads.

Solution:

Volume of water tank= 24500x106liters =24500m3

IS 3370 table 12.1 D=50m(assume)

H=12.5m wall thickness @ base=400mm which gradually reduced to 200mm towards the top

WW=W H=10X12.5=125KN/m2 =0.125N/mm2

maximum ring tension(Nd)=WHR

=10X12.5X25=3125KN/m

self wt of wall=12.5+(0.4+0.2)/(0.2)X24=90KN/m

frictional force @ base=0.5X90=45KN/m

t=Nd /(ηfcd-fmin,w) =((3125)/(0.75X13)-1 )=357.14mm say 120mm

thickness of wall @ top=160mm Ring tension @0.75m from

top=WHR=10X0.75X25=188KN/m

WW=WH=0.75X10=7.5KN/m=0.0075N/mm2

f 2

c =(Nd/ηt)+(fmin,w /η) = (188/(0.75X160))+(1/0.75)=2.9N/mm

∆=(2Nd/ WW)x(fp AS/fcDt)

=((2x188)/(0.0075))X((1000x38.5)/(2.9x50x160))

=83.2mm

No of wires @ top/m=(1000/83.2)=12nos

maximum radial pressure due top prestress,

wt=(2fsAS)/(s D)=(2x1000x38.5)/(8.3x50)

2

=0.816 N/mm

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 58

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

Maximum vertical moment due to prestress

Mt = Mw (Wt/ WW)

=35.15X(0.186/0.128)=52.3KNm/m

z=1000x4002 = 26.67x106 mm2

f

c =(fmin,w/η )+(Mt/2)

=(1/0.75)+(52.3x 106mm )=3.924N/mm 2

fct= 13N/mm2

vertical prestress required=0.3x13=3.9 N/mm2

vertical prestressing force=3.9x1000x400=1560KN

spacing of vertical cables,={((12xΠx8x8)/(4)x(1200))/(1560x1000)}x(1000)

=464mm

ultimate force @ base=(120x38.5x1500)/(1000)=6930KN

load factor=(6930/3126)=2.2

cracking load=1000x400x((0.75x13)+1.7)/(1000))=4580KN

FOS=(4580/3125)=1.466

2.(a)Advantage of prestressed concrete bridge deck

High-strength concrete and high-tensile steel, besides being economical,

make for slender sections, which are aesthetically superior.

Prestressed concrete bridges can be designed as class I type structures without

any tensile stressesunderserviceloads, thusresulting in a crack-free structure.

In comparison with steel bridges, prestressed concrete bridges require

verylittlemaintenance.

Prestressed concrete is ideally suited for composite bridge construction in

which precast prestressed girders support the castin situ slab deck. This type of

construction is very popular since it involves minimum disruption of traffic.

Post-tensioned prestressed concrete finds extensive applications in long-span

continuous girder bridges of variable cross-section. Not only does it make

forsleek. structures, but it also effects considerable saving in the overall cost of

construction.

In recent years, partially prestressed concrete (type-3 structure) bas been

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 59

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

preferred for bridge construction, because it offers considerable economy in

the use of costly high-tensile steel in the girder.

2.(b) Difference between pre-tensioned and post-tensioned concrete bridges with

neat sketch?

By controlling the amount of prestress, a structural system can be made either

flexible [portal frame], or rigid [floor slab] without influencing its

strength.Prestressed, pre-tensioned, tendons are tensioned by a jack without

any concrete. Then, concrete is poured, allowed to set and bond, at which

time the ends are cut and the beam becomes instantly stressed by the tendons.

Service loads can then be applied.

Prestressed, post-tensioned, tendons are tensioned by a jack after the concrete

has already cured (but a duct is installed such that the concrete is unbonded to

the prestressing), at which time the tendons are tensioned by means of a

hydraulic jack, and the beam becomes stressed. Grout may or may not then

infill the ducts. Grouting should typically be performed, to minimize the

chance of a single tendon rupture causing catastrophic failure of the member.

Service loads can then be applied.

Post-tensioning minimizes losses in prestress that are a result of concrete

shrinkage. The only prestress loss due to shrinkage would come as a result of

duct grout shrinkage. In addition, for pre-tensioned beams, because

of concrete compressive strain at the instant that the tendons transfer the

compressive force to the concrete beam.

ARS COLLEGE OF ENGINEERING- DEPARTMENT OF CIVIL ENGINEERING Page 60

CE6702/ Prestressed Concrete

Year –IV/ Semester-VII

For post-tensioned beams, with all of the tendons jacked simultaneously, the

concrete will strain, but our value for will be equal to our , since the

tendon force is essentially (neglecting ‘anchor set’) measured after the load

is applied to the beam (after the hydraulic jacking is complete). This is in

contrast to pre-tensioning, where is measured beforethe load is applied to

the beam (before the tendons are ‘cut’).

However, post-tensioning is more prone to anchorage zone failure, as the

beam is stressed by the tendons, since large compressive forces (especially

when the tendons are un-bonded) occur only at the ends of the beam. Pre-

tensioned beams transfer the tendon force to the concrete through friction,

within a given ‘transfer length’ near the ends of the beam, rather than at a

single point. This distinct feature of pre-tensioned beams is analogous to the

development length for concrete mild-reinforced members, and should not be