Beruflich Dokumente

Kultur Dokumente

PG-500 RKC

Hochgeladen von

Thukhoadaihocla TaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PG-500 RKC

Hochgeladen von

Thukhoadaihocla TaCopyright:

Verfügbare Formate

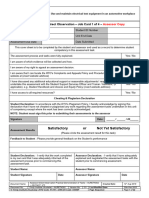

Pressure Indicator 3. TRANSFER TO EACH MODE AND PARAMETER 4.

PARAMETER LIST

PG500 Operation Manual This instrument returns to Measured value (PV) screen, if key operation within 1 minute is not performed.

Any parameter which is not used in the PG500 will not be displayed except for parameters in engineering mode.

4.1 Monitor Mode

Symbol Name Data range Description

All Rights Reserved, Copyright 2007, RKC INSTRUMENT INC. IMR02F02-E4

Thank you for purchasing this RKC product. In order to achieve maximum performance

Pressure unit Setup setting mode Measured value Pressure display low Display the Measured value (PV).

display (PV) to Pressure display

and ensure proper operation of your new instrument, carefully read all the instructions in Power Automatically high

this manual. Please place the manual in a convenient location for easy reference. ON MPA Pressure unit for display:

M PA : MPa InP Input type

dF PV digital filter

PHLD Peak hold Pressure display low Display the maximum value of

This manual describes the operation method of the PG500. (PHLd) monitor * to Pressure display Measured value (PV).

b Ar : bar SET SET high

For the installation, the parts description, the specifications and the communication Automatically K GF : Kgf/cm2 bHLd Bottom hold

At input break:

Display the minimum value of

monitor * Measured value (PV).

function (Optional), please read if necessary the following separate manuals.

PG500 Installation Manual (IMR02F01-E): Enclosed with PG500

(Approx. 4 seconds)

P SI : psi GAIn Gain setting

Pr PV ratio (bHLd) Display range limit

* The hold reset function can be executed by Hold reset (HLdr) in parameter setting mode

PG500 Communication Quick Instruction Manual (IMR02F03-E): Enclosed with PG500 * SET SET

PG500 Communication Instruction Manual (IMR02F04-E): Separate volumes and Digital input 2 (DI2, terminal Nos. 13 and 15). Reset also takes place when the power

* Only PG500 provided with the communication function. Monitor mode is turned off, or when the set value of Input type (InP), Gain setting (GAIn), Display unit

UnIT Display unit

Add Device address *

(UnIT), Input decimal point position (PGdP) or Linearizing type (LInS) is changed.

The manuals can be downloaded from the official RKC website: 4.2 Setup Setting Mode

Measured value

28

SET SET

http://www.rkcinst.com/english/manual_load.htm. (PV)

Press the MONI key Set the following parameters according the pressure sensor to be used.

SET Display the peak

MONI value.

while pressing the PGdP Input decimal

point position bPS Communication

speed * Factory

1. HANDLING PROCEDURES SET key.

Symbol Name Data range Description

set value

Peak hold

PHLd 50

SET SET

monitor InP Input type 0 to 4 Use to select the input Based on

Mounting and wiring Refer to PG500 Installation Manual

(IMR02F01-E)

SET

Display the

SET

Press and hold the MONI key

SCH Pressure display

high bIT Data bit

configuration *

(InP) Refer to Input type

and factory set value

table

type. model

code.

MONI bottom value.

SET SET

Bottom hold

monitor bHLd 0 for 2 seconds or more. GAIn Gain setting 0.500 to 4.000 mV/V

or 0.5000 to 1.9999

Use to set the gain of

pressure sensor.

Refer to

Input type

Power ON SET SET SCL Pressure display

low InT Interval time * (GAIn)

mV/V

Varies with the setting

Refer to Example and

factory set

Press and hold the SET key of the Gain setting value

SET SET

Return to Measured value (PV) for 2 seconds or more. decimal point position. table

Setting of usage condition Set the parameters for sensor’s usage condition in setup

setting mode. Press and hold the MONI

LInS Linearizing type

LCK Set lock level UnIT

(UnIT)

Display unit 0: Kgf/cm2 2: bar

1: MPa 3: psi

Use to select the

display unit for input.

1

SET SET Refer to Example

Refer to 4.2 Setup Setting Mode key for 2 seconds or more.

or Press and hold the SET

Return to Input type ( I n P )

PGdP Input decimal point 0: No decimal place Use to select the 0

Setting of operating Set the parameters for instrument's basic functions in

Press the MONI key

while pressing the

key for 2 seconds or more.

Pb PV bias (PGdP) position 1: One decimal place decimal point position

2: Two decimal places of the input display

3: Three decimal places value.

condition engineering mode. SET * This parameter is not displayed when

Press and hold

Refer to 4.4 Engineering Mode

the MONI key

SET key.

there is no communication function. SCH Pressure display

high

Pressure display low

to 19999

Use to set the high

limit of the pressure

50

for 2 seconds

Parameter setting mode (SCH)

Varies with the setting display range.

Zero/full scale point Execute the auto zero function (Zero point adjustment) or more. of the Input decimal Refer to Example

adjustment and auto calibration (Full scale point adjustment) function. point position.

Refer to 4.3 Parameter Setting Mode

or

Press the

Press the

MONI key AZEr Auto zero

ILr Interlock release 1

AL3 Alarm 3 set value 2

(AL3) SCL Pressure display

low

0 to Pressure display

high

Use to set the low limit

of the pressure display

0

Before operating the instrument for the first time (SCL)

MONI key while pressing SET SET SET Varies with the setting range.

after purchase or pressure sensor exchange, while pressing of the Input decimal Refer to Example

the SET key

always adjust the zero point and full scale point.

the SET key. for 2 seconds

or more.

ACAL Auto calibration

AL1 Alarm 1 set value 2

(AL1) AL4 Alarm 4 set value 2

(AL4) LInS Linearizing type

point position.

0 to 20 Use to set the 0

Setting of alarm Set the alarm set value. Resistance for linearizing type of our

Refer to 4.3 Parameter Setting Mode

SET SET SET (LInS)

sensitivity adjustment CZ-100P/CZ-200P.

Return to Auto zero ( A Z E r ) built-in pressure Refer to Example

HLdr Hold reset

AL2 Alarm 2 set value 2

(AL2)

1

This parameter is not displayed when the

sensor:

Use a factory set

SET SET alarm interlock is set to “0: Unused.” value of “0.”

Operation start 2

This parameter is not displayed when the

alarm type is set to “0: None.” Input type and factory set value table

Engineering mode Set Input type Factory set value

value of gain setting (mV/V)

2. CHANGING DATA SETTINGS Function Function Function Function Function Function

0 Our CZ-100P/CZ-200P (Standard) 1.500

1 Our CZ-100P/CZ-200P (Explosionproof) 1.500

block 10 block 21 block 33 block 41 block 60 block 91

Our CZ-100P/CZ-200P (Standard)

To store a new value for the parameter, always press the SET key. 2 0.650

After a new value is displayed on the display by using UP and DOWN keys, if no

To F 9 1 . F10.8 F21.8 F33.8 F41.8 F42. to F44.* F60.8 F91.8 To F 1 0 .

3

[Loose nut: 0.0 to 0.5 MPa, Fixed nut: 0 to 5 MPa]

Our CZ-100P/CZ-200P (Explosionproof) 0.650

key operation is performed within 1 minute without pressing SET key, this SET SET SET SET SET SET [Loose nut: 0.0 to 0.5 MPa, Fixed nut: 0 to 5 MPa]

instrument returns to the Measured value (PV) screen and the set value will not be 4 3.33 mV/V output type (Pressure sensor made by other companies) 3.330

changed. Shunt resistance Transmission output Communication ROM version

Display timer output value scale high Alarm 1 type protocol monitor Example: Setting of usage condition (When using our CZ-100P or CZ-200P)

Set the values and the unit engraved on the rated nameplate attached to the pressure

Example: Changing the alarm 1 set value (AL1) to 20 MPa

1. Select the Alarm 1 set value (AL1) of parameter setting mode dSPT SHnT AHS AS1 CMP C448 sensor housing to Pressure display high (SCH), Pressure display low (SCL), and Display

unit (UnIT) respectively. Set the rated output (mV/V) and the linearizing type symbol to

SET SET SET SET SET SET Gain setting (GAIn) and Linearizing setting (LInS).

Measured value Parameter setting mode Parameter setting mode

Automati- (PV) Auto zero Alarm 1 set value

Power cally * PV display Input error determi- Transmission output Return to F 6 0 . Integrated operating 0-20 MPa

ON 50 SET

AZEr SET

AL1 condition nation point (high) scale low Alarm 1 hold action time monitor Display unit (UnIT): 1 (MPa)

Pressure display high (SCH): 20

1.234 C

linearizing type symbol

* After the pressure unit is

displayed on the display

dSoP PoV ALS AHo1 WT Pressure display low (SCL): 0 Set it to Linearizing type (LInS)

by refer to the Linearizing

(Approx. 4 seconds), the display SET SET SET SET SET PRESSURE SENSOR type symbol table.

will automatically change to the 2 seconds Several times

measured value (PV) screen. or more Return to F 1 0 . Input error determi- Transmission output Return to F 9 1 . TYPE CZ-100P-HB-SNN Set the “1.”

G

nation point (low) timer Alarm 1 interlock Rated output value

2. Change the Alarm 1 set value (AL1) to 20 MPa PRESSURE RANGE 0 - 20 MPa

Pressing the MONI key displays the data display. The high-lighted digit indicates which

digit can be set.

PUn AoT ILS1 RATED OUTPUT 1.234 C

No. 97J21020

mV/V at 150 C

DATE 9710

Set it to Gain setting (GAIn).

Set the “1.234.”

SET SET

High-lighted digit High-lighted digit RKC INSTRUMENT INC. MADE IN JAPAN (Example of the rated nameplate)

Alarm 1 set value Gain setting decimal Return to F 3 3 . Alarm 1 energized/ Linearizing type symbol table

AL1 MONI

0050 MONI

0050 0020 point position

SET

Burnout direction de-energized Set Linearizing type Set Linearizing type Set Linearizing type

GdP brKS EXC1

value symbol value symbol value symbol

(Data display) High-light the Change the

0 No symbol 7 J 14 S

tens digit. number to 2.

SET SET 1 C 8 K 15 T

Three times 2 D 9 L 16 U

Return to F 2 1 . Alarm 1 differential gap 3 E 10 M 17 V

3. Store the Alarm 1 set value (AL1)

Alarm 1 set value

Parameter setting mode

Alarm 2 set value

AH1 4

5

F

G

11

12

P

Q

18

19

W

X

* Display the function block 42 to 44 (F42. to F44.). SET

0020 Store

SET

AL2 Function block 42 (F42.): Parameters of alarm 2

Function block 43 (F43.): Parameters of alarm 3 Alarm 1 delay timer

Alarm 1 action at

input error

6 H 13 R 20 Y

The rated output value (mV/V) of the CZ-100P/CZ-200P is when the cable is at a length of

The display goes to the Function block 44 (F44.): Parameters of alarm 4 5 m. When the cable is extended or a cable of a different manufacturer is used, the gain

AEo1

SET SET

next parameter. Contents will be the same as function block 41 (F41.) ALT1 Return to F 4 1 . value must be corrected and changed.

For details, refer to the CZ-100P/PCT-300 Resin Pressure Measuring System

Other data can also be set by the same procedures as described in steps 1 to 3. Instruction Manual (IM100CZ04-E) or CZ-200P Instruction Manual (IM100CZ08-E).

Symbol Name Data range Description

Factory Auto zero Symbol Name Data range Description

Factory

Symbol Name Data range Description

Factory

set value Auto zero is used to automatically set the PV bias (Pb) so that the Measured value (PV) set value set value

Pb PV bias Input span to PV bias adds bias to 0 will be 0. F21. Function block 21 This is the first parameter symbol of function block 21. WT Integrated operating 0 to 19999 hours Displays the integrated

(Pb) Input span the Measured value 1. Make sure that the pressure sensor is installed on the equipment. (F21) (WT) time monitor total operating time of

(PV). Manual zero the instrument.

Varies with the setting adjustment can be 2. Rise the temperature of the equipment installed with the pressure sensor up to the SHn T Shunt resistance 40.0 to 100.0 % It is set “What 80.0

of the Input decimal performed. temperature during operation. (SHnT) output value This parameter is valid percentage of the rated

point position. 3. Set the pressure sensor to the no-load state. when using resistance output” is output when Alarm function [Optional]

the full scale point of

dF PV digital filter 0.1 to 100.0 seconds This item is the time of

the first-order lag filter

oFF 4. Press the UP key while pressing the DOWN key displaying the Auto zero screen for sensitivity

adjustment built-in the Measured value

Action: When the Measured value (PV) reaches the alarm set value, alarm ON occurs.

(dF) oFF: Unused automatically starts auto zero operation. If this auto zero operation normally end, the (PV) is adjusted by Process high ☆: Alarm differential gap Process low ☆: Alarm differential gap

eliminate noise screen returns to the Measured value (PV) screen. pressure sensor.

against the measured auto calibration. Alarm OFF ☆ Alarm ON Alarm ON ☆ Alarm OFF

Measured Parameter setting mode Pressure display low If the Measured value PV PV

input.

value (PV) Auto zero Adjustment Measured value (PV) PoV Input error

determination point (5 % of input span) to (PV) is above the Input

53 Low

Alarm set value

High Low

Alarm set value

High

Pr PV ratio 0.500 to 1.500 PV ratio is a multiplier 1.000 execution (PoV)

(high) 1 Pressure display high error determination

(Pr) The setting value to be applied to the

Measured value (PV).

28 SET

AZEr 0 (5 % of input span) point (high), alarm Alarm hold action

varies depending on Manual full scale

using pressure sensor. adjustment can be (Adjustment end) action at input error will

be taken.

When hold action is ON, the alarm action is suppressed at start-up (Power ON) until the

measured value has entered the non-alarm range.

Refer to PV ratio. Press the key while Pressure display low If the Measured value 2 Alarm interlock

performed. 2 seconds

or more pressing the key. PUn Input error

determination point (5 % of input span) to (PV) is below the Input The alarm interlock function is used to hold the alarm state even if the Measured value

Add Device address (PUn)

(low) 1 Pressure display high error determination (PV) is out of the alarm area after its entry into the area once.

(Add) If error occur, the “ A Z E r ” and “ E r r ” are displayed alternately on the PV display (5 % of input span) point (low), alarm

unit. Press any of the keys (SET key, MONI key, DOWN key or UP key) to clear action at input error will Alarm differential gap

BPS Communication This parameter is displayed when there is the communication the error and return to the Measured value (PV) screen. be taken. It prevents chattering of alarm output due to the measured value fluctuation around the

(bPS) speed function [Optional]. The result of auto zero adjustment is also reflected to the PV bias (Pb) value. alarm set value.

brK S Burnout direction 2 0: Upscale Use to select burnout 0

BIT Data bit Refer to the PG500 Communication Quick Instruction Manual zero point adjustment can be performed by changing this PV bias value.

(brKS) 1: Downscale direction in input break. Alarm delay timer

(bIT) configuration Manual (IMR02F03-E). The auto zero can be executed by digital input 1 (DI1, terminal Nos. 13 and 14). When an alarm condition becomes ON status, the output is suppressed until the delay

Auto calibration GdP Gain setting 3: Three decimal places Use to select the 3

timer set time elapses. After the time is up, if the alarm output is still ON status, the output

InT Interval time

(GdP) decimal point 4: Four decimal places decimal point position

will be produced.

(InT) (Only resistance for sensitivity adjustment built-in pressure sensor) position of the gain setting

value.

LCK Set lock level 0: Unlock The set lock level 0000 Auto calibration is used to automatically set the PV ratio (Pr) so that the Measured value Transmission output function (AO) [Optional]

(LCK) 1: Lock restricts parameter (PV) will be the pressure of the Shunt resistance output value (SHnT). F33. Function block 33 This is the first parameter symbol of function block 33.

The transmission output function is used to output any Measured value (PV) as the

Set to “0” or “1” for setting changes by 1. Make sure that the pressure sensor (resistance for sensitivity adjustment built-in (F33)

each digit. key operation (Set pressure sensor) is installed on the equipment. voltage/current output. In addition, any range of the Measured value (PV) can be output

data lock function). 2. Rise the temperature of the equipment installed with the pressure sensor up to the AHS Transmission

output scale high 1

Transmission output

scale low to Pressure

Use to set a scale high

limit value of the

50 with the transmission output scale low and transmission output scale high set.

(AHS)

0000 Parameters

PV display temperature during operation.

3. Press the UP key while pressing the DOWN key displaying the Auto calibration screen

display high transmission output. Example: When a Measured value (PV) of 10 to 30 MPa needs to be recorded on a

recorder at an pressure range of 0 to 50 MPa.

of Setup Setting Mode and Parameter

Setting Mode other than alarm set value (AL1 to AL4) automatically starts auto calibration operation. If this auto calibration operation normally ALS Transmission

output scale low 1

Pressure display low

to Transmission output

Use to set a scale low

limit value of the

0

Output type: Current output, 4 to 20 mA DC

[except for parameters in Engineering Mode]. end, the screen returns to the Measured value (PV) screen. (ALS)

scale high transmission output. Transmission output scale high (AHS): 30 MPa

Alarm set value (AL1 to AL4) only

“0” Fixed (Do not change this one) Measured Parameter setting mode AoT Transmission 0.1 to 10.0 seconds Use to set the time 0.1 Transmission output scale low (ALS): 10 MPa

“0” Fixed (Do not change this one) value (PV) Auto zero Auto calibration Adjustment (AoT) output timer during which the

execution transmission output Current output

PV ratio 28 SET

AZEr SET ACAL value is changed.

Output

range

For the Transmission output

(AO) type (rating, output range),

[When using our CZ-100P or CZ-200P]

Explosionproof specification type

F41 .

(F41)

Function block 41

This is the first parameter symbol of function block 41 to 44.

F41: Parameters of alarm 1 F43: Parameters of alarm 3

20 mA refer to PG500 Installation

Press the key while

Manual (IMR02F01-E).

Set the desired correction factor of our safety barrier RZB-001 to the PV ratio. Thus, an 2 seconds

Function block 44 F42: Parameters of alarm 2 F44: Parameters of alarm 4

Measured value (PV) pressing the key.

indicated error caused by the use of the safety barrier is corrected. or more F44 .

The correction factor is described in the nameplate attached to the safety barrier 400 (F44)

4 mA

Measured value (MPa)

(RZB-001). (Adjustment end) 0 10 20 30 40 50

AS1 Alarm 1 type 0: None Use to select the Based on

Non-explosionproof specification type If error occur, the “ A C A L ” and “ E r r ” are displayed alternately on the PV display (AS1)

1: Process high action type of the model

As the PV ratio, use a factory set value of “1.000” with this value left intact. unit. Press any of the keys (SET key, MONI key, DOWN key or UP key) to clear

Alarm 4 type 2: Process low alarm. code 3

[When using resistance for sensitivity adjustment built-in pressure sensor] the error and return to the Measured value (PV) screen. AS4

The result obtained by auto calibration is reflected to the PV ratio. Manual full scale For this product, in order to generate the R-cal output it is not necessary to short (AS4) 5. ERROR DISPLAYS

adjustment can be performed by changing this PV ratio value. the cables (CAL and CAL) on the pressure sensor side.

The result obtained by auto calibration is reflected to the PV ratio value. AHo 1 Alarm 1 hold action 0: OFF Use to select the hold Based on

Manual full scale point adjustment can be performed by changing this PV ratio (AHo1)

1: Hold action ON action for the alarm. model Display when input error occurs

4.3 Parameter Setting Mode

Alarm 4 hold action code 3 Prior to replacing the sensor, always turn OFF the power.

value.

AHo 4

Symbol Name Data range Description

Factory

set value

4.4 Engineering Mode (AHo4) Display Description Action (Output) Solution

PV exceeds the Pressure display Output Check input type,

AZE r Auto zero * 5.0 to 5.0 mV Adjust the zero point ILS 1 Alarm 1 interlock

0: Unused (OFF) Use to select the 0

high /low. depending on the input range,

1: Used interlock function for

(AZEr) (Input conversion) of the Measured value

(PV).

! WARNING (ILS1)

Alarm 4 interlock the alarm. PV exceeds the input error alarm action at sensor and

Refer to Auto zero.

PV determination point (high/low limit). input error sensor

Parameters in the Engineering mode (F10 to F91) should be ILS 4 connection.

ACA L Auto calibration Adjust the full scale (ILS4) [Flashing] * Flashes when any of Alarms 1 to 4 Output

set according to the application before setting any parameter has occurred. (The PV and alarm

(ACAL) This parameter is valid point of the Measured depending on

when using resistance value (PV). related to operation. Once the Parameters in the Engineering EXC 1 Alarm 1 energized/ 0: Energized Use to select the 0 number are displayed alternately) the normal alarm

Refer to Auto (EXC1) de-energized 1: De-energized alarm energized or

for sensitivity

calibration.

mode are set correctly, no further changes need to be made to

de-energized. action

adjustment built-in parameters for the same application under normal conditions. If

Alarm 4 energized/

pressure sensor. EXC 4 ooo o Over-scale Output

they are changed unnecessarily, it may result in malfunction or (EXC4)

de-energized

PV is above the Pressure display depending on the

HLd r Hold reset * Peak hold/bottom hold [Flashing]

failure of the instrument. RKC will not bear any responsibility for high (5 % of input span). alarm action at

(HLdr) value is reset. AH1 Alarm 1 differential 0 to Input span Use to set a differential 2 input error

malfunction or failure as a result of improper changes in the (AH1) gap

gap of the alarm. uuu u Underscale

[Procedure] Measured value (PV) Auto zero Hold reset

Hold is reset Engineering mode.

[Flashing] PV is below the Pressure display

28 SET

AZEr SET

HLDr AH4 Alarm 4 differential low (5 % of input span)

All parameters of the engineering mode are displayed regardless of the instrument (AH4) gap

* The PV flashes depending on the PV display condition (dSoP) of engineering mode F10.

specification.

2 seconds Several times

Press the key while

pressing the key.

ALT 1 Alarm 1 delay 0.0 to 600.0 seconds Alarm delay timer is to 0.0

or more

Symbol Name Data range Description

Factory (ALT1)

timer 1

set an output delay Self-diagnostic error

set value

time for alarm outputs

ILr In an error is detected by the self-diagnostic function, the “ E r r ” and error code are

Interlock release * If the alarm state is Alarm 4 delay

(ILr) This parameter is not interlocked, interlock F10. Function block 10 This is the first parameter symbol of function block 10. ALT 4 timer 1 displayed alternately on the PV display unit. If two or more errors occur simultaneously, the

can be released. (ALT4)

displayed when the (F10) total summation of these error codes is displayed.

alarm 1 to 4 Interlock The interlock states of

all alarms are dSP T Display timer 0.1 to 10.0 seconds Use to set the time 0.1 AEo 1 Alarm 1 action at 0: Normal alarm action Alarm action at input 0

Solution: Turn off the power at once. If an error occurs after the power is turned on again,

are set to “0: Unused.” (AEo1) input error 1: Forced alarm ON error is to select the

released. (dSPT) during which the

when temperature alarm action when the please contact RKC sales office or the agent.

displayed value is Alarm 4 action at measured value Measured value (PV)

[Procedure] Measured value (PV) Auto zero Interlock release Interlock is

released. changed. AEo 4 input error exceeds the input reaches the input error

PV Description Action

28 SET

AZEr SET

ILr dSo P PV display 0 to 63 (Decimal) Sets the condition for 0

(AEo4) error determination determination point display

(dSoP) condition Bit 0: Minus display of flashing display of the point (high or low (high or low limit). 1 Adjustment data error

Display: Error display

limit).

2 seconds Several times

Press the key while

pressing the key.

PV value Measured value (PV) 2 Back-up error ( E r r and error number)

or more Bit 1: Input error * and minus display of

the Measured value

F60. Function block 60 This is the first parameter symbol of function block 60.

4 A/D conversion error Output: All the output is OFF

Bit 2: Alarm 1 occurs (F60)

AL1 Alarm 1 set value Pressure display low Use to set the set value 50 Bit 3: Alarm 2 occurs (PV). When an alarm 128 Watchdog timer error (Same as power OFF)

(AL1) to Pressure display of the alarm action. occurs and flashing is CMP Communication 0: RKC communication Use to select a protocol 0 Communication:

(AL1)

high

Bit 4: Alarm 3 occurs enabled, the (CMP) protocol 1: Modbus of communication 256 Program error (stack)

Send the error code

Signals are output Bit 5: Alarm 4 occurs

AL2 Alarm 2 set value

This parameter is not from the alarm outputs

0

Data

Measured value (PV) function. 204 8 Program error (busy)

(AL2) (AL2) and alarm number are

displayed when the (ALM1 to ALM4) Bit 0 alternately displayed. F91. Function block 91 This is the first parameter symbol of function block 91. Power supply voltage monitoring Display: All display is OFF

AL3 Alarm 3 set value alarm type is set to if exceeding the alarm 50 0: Minus display (F91) All display error

Bit data is OFF Output: All output OFF

(AL3) “0: None.” set value.

(AL3) 1: Non-minus display

000000 C44 8 ROM version 0 to 999 Displays the version of RAM check error Communication: Stop

Varies with the setting Bit 1 to Bit 5 (C448) monitor (C448-) the ROM on the

AL4 Alarm 4 set value

of the Input decimal

50

0: Non-flashing display instrument.

(AL4) (AL4) Bit 5Bit 0 Modbus is a registered trademark of Schneider Electric.

point position. 1: Flashing display 1 Company names and product names used in this manual are the trademarks or registered

Set the bit data after Varies with the setting of the Input decimal point position. trademarks of the respective companies.

* The auto zero, hold reset and interlock release functions can be executed by turning on the converting it to decimal. 2

Setting of a barn out direction select switch is necessary to select a barnout direction.

digital input. For the switch setting, refer to the PG500 Installation Manual (IMR02F01-E).

* When flashing is enabled, the Measured value (PV) flashes at the following times: ® RKC INSTRUMENT INC. The first edition: NOV. 2007 [IMQ01]

DI1 (Terminal Nos. 13 and 14): Auto zero DI2 (Terminal Nos. 13 and 15): Hold reset The fourth edition:MAR. 2016 [IMQ01]

DI3 (Terminal Nos. 13 and 16): Interlock release Measured value (PV) exceeds the pressure display high /low. 3

When not specifying: Alarm 1: Process high (without hold action) Alarm 3: No alarm

Measured value (PV) exceeds the input error determination point (high/low limit). Alarm 2: Process low (without hold action) Alarm 4: No alarm

HEADQUARTERS: 16-6, KUGAHARA 5-CHOME, OHTA-KU TOKYO 146-8515 JAPAN

PHONE: 03-3751-9799 (+81 3 3751 9799) E-mail: info@rkcinst.co.jp

For the digital input, refer to the PG500 Installation Manual (IMR02F01-E). FAX: 03-3751-8585 (+81 3 3751 8585) Website: http://www.rkcinst.com/ MAR. 2016

Das könnte Ihnen auch gefallen

- Instrumentation and Test Gear Circuits ManualVon EverandInstrumentation and Test Gear Circuits ManualBewertung: 5 von 5 Sternen5/5 (1)

- A Series Temperature Controller Instruction Sheet: SpecificationsDokument2 SeitenA Series Temperature Controller Instruction Sheet: SpecificationsGupteswara Satapathy0% (2)

- m4ns M4ys en Ma Drw160942ab 20180109 He 20180110Dokument1 Seitem4ns M4ys en Ma Drw160942ab 20180109 He 20180110serg minimeNoch keine Bewertungen

- OPTEX-FA CVS1-R ManualDokument1 SeiteOPTEX-FA CVS1-R ManualleeNoch keine Bewertungen

- Digital Temperature Controller: Fast ! Compact ! User-F Riendly !Dokument16 SeitenDigital Temperature Controller: Fast ! Compact ! User-F Riendly !Aditya Y. NovitasariNoch keine Bewertungen

- Product Appearance Product Appearance Product Appearance Menu OthersetupDokument1 SeiteProduct Appearance Product Appearance Product Appearance Menu OthersetupM. ViertelNoch keine Bewertungen

- Guia Rapida C2 ENDokument1 SeiteGuia Rapida C2 ENaquaicejuanNoch keine Bewertungen

- PSANPneumatic EN Manu DRW171185AC 20191014 WDokument1 SeitePSANPneumatic EN Manu DRW171185AC 20191014 Wsinar automationNoch keine Bewertungen

- pCO Universal Stage Controller: User ManualDokument32 SeitenpCO Universal Stage Controller: User ManualVinod LAmbadeNoch keine Bewertungen

- 9IS54376-1 EWRC 300 500 NT QuickStart EN 11141006231377Dokument14 Seiten9IS54376-1 EWRC 300 500 NT QuickStart EN 11141006231377Νικόλας ΧιονάςNoch keine Bewertungen

- Series: Intuitively Innovative!Dokument48 SeitenSeries: Intuitively Innovative!Hector Velez PizaNoch keine Bewertungen

- MR1.9TFT enDokument2 SeitenMR1.9TFT ennhnamNoch keine Bewertungen

- Pressure Sensor Evolutions To ComeDokument20 SeitenPressure Sensor Evolutions To ComeAnonymous m36V0bvzNoch keine Bewertungen

- AUTONICS Current Monitor Relay MT4Y-AA-44Dokument1 SeiteAUTONICS Current Monitor Relay MT4Y-AA-44Saimon RintoNoch keine Bewertungen

- Autonics Psan Series ManualDokument1 SeiteAutonics Psan Series ManualResaKandhyNoch keine Bewertungen

- APM VAF Datasheet-3247408Dokument3 SeitenAPM VAF Datasheet-3247408Jhonatan Lizcano ArteagaNoch keine Bewertungen

- Quick Operation Manual c62 c82Dokument2 SeitenQuick Operation Manual c62 c82dobrinp6740Noch keine Bewertungen

- Modrol DriveDokument23 SeitenModrol DriveMarcelo Lescano89% (9)

- Zenex ProDokument2 SeitenZenex Prostpltech447Noch keine Bewertungen

- FGP-180 3 .UsDokument1 SeiteFGP-180 3 .UsOzan DumanNoch keine Bewertungen

- MF PD Ver3 Data Sheet EnglishDokument2 SeitenMF PD Ver3 Data Sheet Englishfrancisca ulloa riveraNoch keine Bewertungen

- C50 1/16-Din Process Controller: Concise Product Manual - Im/C50Dokument2 SeitenC50 1/16-Din Process Controller: Concise Product Manual - Im/C50AnthonyNoch keine Bewertungen

- Setting Display Measuring Display: LR5041.LR5042.LR5043 Voltage LoggerDokument2 SeitenSetting Display Measuring Display: LR5041.LR5042.LR5043 Voltage LoggerIP LEDNoch keine Bewertungen

- Dpi 610 PDFDokument8 SeitenDpi 610 PDFJoão Pedro AlmeidaNoch keine Bewertungen

- Manual TEKNA TPRDokument68 SeitenManual TEKNA TPRfrancisco valladaresNoch keine Bewertungen

- A1000 Artificial Lift Vsa910100-DsDokument46 SeitenA1000 Artificial Lift Vsa910100-DsvictorNoch keine Bewertungen

- vr7000 Operators Guide PDFDokument2 Seitenvr7000 Operators Guide PDFvangNoch keine Bewertungen

- IV8W Manual 20171207 English Password IV8WDokument2 SeitenIV8W Manual 20171207 English Password IV8WDani-el RagaNoch keine Bewertungen

- SMC PFMB QuickguideDokument1 SeiteSMC PFMB QuickguideFRANNoch keine Bewertungen

- Chapter 4 Digital Keypad OperationDokument4 SeitenChapter 4 Digital Keypad OperationRamaNoch keine Bewertungen

- Trio 2018Dokument2 SeitenTrio 2018DZ RdNoch keine Bewertungen

- Teknaevo TPG: Installation ManualDokument95 SeitenTeknaevo TPG: Installation ManualDragisa DjukicNoch keine Bewertungen

- JVR800 2 Three Phase Voltage Monitoring Relay ManualDokument1 SeiteJVR800 2 Three Phase Voltage Monitoring Relay ManualGrosu NicolaeNoch keine Bewertungen

- Satya Catalog 2023Dokument52 SeitenSatya Catalog 2023Tashmeet SinghNoch keine Bewertungen

- Athena PR Mode EmploiDokument56 SeitenAthena PR Mode EmploiHector MendozaNoch keine Bewertungen

- DRV1 ManualDokument18 SeitenDRV1 ManualAlejandro AlvarezNoch keine Bewertungen

- Trevi Logic-Sp-Stp-Tp User Manual - enDokument2 SeitenTrevi Logic-Sp-Stp-Tp User Manual - enFrançois ClamourNoch keine Bewertungen

- Delta TemperatureController - ManualInsertDokument2 SeitenDelta TemperatureController - ManualInsertalexanderNoch keine Bewertungen

- On-Screen Keys and Their Functions: Scanned by CamscannerDokument1 SeiteOn-Screen Keys and Their Functions: Scanned by CamscannerSoluciones EspecializadasNoch keine Bewertungen

- Ninglu NMEA Simulator PDFDokument17 SeitenNinglu NMEA Simulator PDFtariktunadNoch keine Bewertungen

- External Wiring Diagram: Alarm Annunciator Microcontroller VersionDokument1 SeiteExternal Wiring Diagram: Alarm Annunciator Microcontroller VersionVinay KumarNoch keine Bewertungen

- User Manual: PWM Charge Controller Negative Grounded P2430N / P2440NDokument2 SeitenUser Manual: PWM Charge Controller Negative Grounded P2430N / P2440NHafiz Sagheer HussainNoch keine Bewertungen

- Setup: Instruction ManualDokument2 SeitenSetup: Instruction ManualnagatoNoch keine Bewertungen

- Smart IoDokument2 SeitenSmart Iotranhuutri1987quangngaiNoch keine Bewertungen

- EZRUNMAX10Dokument1 SeiteEZRUNMAX10TesterNoch keine Bewertungen

- LOGO! 8 Soft Comfort Online-Hilfe English Sides 300-303Dokument4 SeitenLOGO! 8 Soft Comfort Online-Hilfe English Sides 300-303Abdullah TalibNoch keine Bewertungen

- Eaton-IQ200X-Electronic Power Meter-User Manual-EN-USDokument2 SeitenEaton-IQ200X-Electronic Power Meter-User Manual-EN-USAlan leví TeleguarioNoch keine Bewertungen

- Maxwell-User Manual (MTB Controller)Dokument3 SeitenMaxwell-User Manual (MTB Controller)جمال ابو الفضلNoch keine Bewertungen

- AKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXDokument2 SeitenAKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXmartinNoch keine Bewertungen

- Instruction Manual en 20140610 1Dokument1 SeiteInstruction Manual en 20140610 1Zaenul AbidinNoch keine Bewertungen

- Digital Temperature Controller: Fast ! Compact ! User-F Riendly !Dokument16 SeitenDigital Temperature Controller: Fast ! Compact ! User-F Riendly !Mohamoud MuseNoch keine Bewertungen

- Quick Reference Guide Maxtesterapplication Max-800 Series English - 1082519Dokument2 SeitenQuick Reference Guide Maxtesterapplication Max-800 Series English - 1082519Abdulmoied OmarNoch keine Bewertungen

- UMQOC621C A3 VersionDokument2 SeitenUMQOC621C A3 VersionI'm AbhiNoch keine Bewertungen

- Ev 100 ManualDokument1 SeiteEv 100 Manualbugsbunny321Noch keine Bewertungen

- Eachine EV100 User ManualDokument1 SeiteEachine EV100 User ManualGuille MNoch keine Bewertungen

- Eachine EV100 User ManualDokument1 SeiteEachine EV100 User ManualMattia Terri TerrandoNoch keine Bewertungen

- 157G铜版纸⿊⽩正反印刷折页 折叠尺⼨:110*70mm 展开尺⼨:420*110mm: Product Controls Diagram Focal Length Adjustment ControlsDokument1 Seite157G铜版纸⿊⽩正反印刷折页 折叠尺⼨:110*70mm 展开尺⼨:420*110mm: Product Controls Diagram Focal Length Adjustment ControlsTiziano D'IncàNoch keine Bewertungen

- 157G铜版纸⿊⽩正反印刷折页 折叠尺⼨:110*70mm 展开尺⼨:420*110mm: Product Controls Diagram Focal Length Adjustment ControlsDokument1 Seite157G铜版纸⿊⽩正反印刷折页 折叠尺⼨:110*70mm 展开尺⼨:420*110mm: Product Controls Diagram Focal Length Adjustment ControlsDenis FaicNoch keine Bewertungen

- Tds 0005Dokument2 SeitenTds 0005computerparadise1993Noch keine Bewertungen

- PXF Digital Temperature Controller PXFDokument16 SeitenPXF Digital Temperature Controller PXFMaheshNoch keine Bewertungen

- Installation Manual: 1. Mounting !Dokument2 SeitenInstallation Manual: 1. Mounting !Thukhoadaihocla TaNoch keine Bewertungen

- PLC KoyoDokument390 SeitenPLC KoyoThukhoadaihocla TaNoch keine Bewertungen

- Temperature and Humidity CabinetDokument108 SeitenTemperature and Humidity CabinetThukhoadaihocla TaNoch keine Bewertungen

- Categories: Olive Oxygen ConcentratorDokument17 SeitenCategories: Olive Oxygen ConcentratorThukhoadaihocla TaNoch keine Bewertungen

- RTACDokument60 SeitenRTACThukhoadaihocla Ta100% (1)

- Trane-RTAC 200-Eng PDFDokument76 SeitenTrane-RTAC 200-Eng PDFThukhoadaihocla Ta100% (2)

- STR - MBRDokument6 SeitenSTR - MBRSushil Kumar SinghNoch keine Bewertungen

- MTR Document Package January 21, 2014 Trevor Wynnychuk Celtic Pride Manufacturing LTDDokument8 SeitenMTR Document Package January 21, 2014 Trevor Wynnychuk Celtic Pride Manufacturing LTDCristian BarbuceanuNoch keine Bewertungen

- Pressure Gauge Accuracy, Test Gauges - Daughtridge Sales Co, Inc - 2Dokument2 SeitenPressure Gauge Accuracy, Test Gauges - Daughtridge Sales Co, Inc - 2Edison QuimbiambaNoch keine Bewertungen

- Krautkramer MIC 20: Technical Reference and Operating ManualDokument128 SeitenKrautkramer MIC 20: Technical Reference and Operating ManualmgmqroNoch keine Bewertungen

- Flt93 Iom Flujo SwitchDokument96 SeitenFlt93 Iom Flujo SwitchQ Llanos HenryNoch keine Bewertungen

- Operations Manual Te2000psDokument13 SeitenOperations Manual Te2000pssuko winartiNoch keine Bewertungen

- Assessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 1 AURETK002 V2Dokument22 SeitenAssessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 1 AURETK002 V2Tam TranNoch keine Bewertungen

- US Army Calibration Tek 2465 TB-9-6625-2293-35Dokument36 SeitenUS Army Calibration Tek 2465 TB-9-6625-2293-35donsterthemonsterNoch keine Bewertungen

- Ansi Agma 2015-1-A01Dokument44 SeitenAnsi Agma 2015-1-A01Nilson Venancio94% (17)

- Temperature Mapping StudyDokument9 SeitenTemperature Mapping StudyJAGADISH PHARMACEUTICALSNoch keine Bewertungen

- Larson Davis CAL200 Manual: AppendixDokument15 SeitenLarson Davis CAL200 Manual: AppendixINSTRUMENTACION INGENIEROSNoch keine Bewertungen

- Annexure of Calibration CertificateDokument2 SeitenAnnexure of Calibration Certificatevizay237_430788222100% (2)

- Balatron B350.G3 User'S ManualDokument22 SeitenBalatron B350.G3 User'S ManualPedro ValdeseliasNoch keine Bewertungen

- SST e SSVDokument6 SeitenSST e SSVnandaum_laNoch keine Bewertungen

- ISO 17034 S4 Technical and Production Requirements 1Dokument29 SeitenISO 17034 S4 Technical and Production Requirements 1saotrangnguyenNoch keine Bewertungen

- BS en 10228-3-2016Dokument26 SeitenBS en 10228-3-2016Bouzid MenaaNoch keine Bewertungen

- SRM 46h Sieve 45Dokument4 SeitenSRM 46h Sieve 45Khairil HidayahNoch keine Bewertungen

- hc2-ldp-v1 - 06 Dew PointDokument29 Seitenhc2-ldp-v1 - 06 Dew Pointfelipe maciasNoch keine Bewertungen

- Roadroid User Guide - Version 2 ProDokument34 SeitenRoadroid User Guide - Version 2 ProAkila Tharanga LiyanarachchiNoch keine Bewertungen

- 1251 Weighing On An Analytical BalanceDokument6 Seiten1251 Weighing On An Analytical Balancenonick18Noch keine Bewertungen

- Dimensional Stability of Sandwich Core Materials: Standard Test Method ForDokument2 SeitenDimensional Stability of Sandwich Core Materials: Standard Test Method ForJuanNoch keine Bewertungen

- Sadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionDokument10 SeitenSadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionSuresh KumarNoch keine Bewertungen

- Casio Oceanus OCW-M700 Manual Module 4749 PDFDokument6 SeitenCasio Oceanus OCW-M700 Manual Module 4749 PDFAbdelilah Ouedghiri Saidi50% (2)

- Evlunic Ac-Wallbox Mba en Rev-C AbbDokument65 SeitenEvlunic Ac-Wallbox Mba en Rev-C AbbDiego MaldonadoNoch keine Bewertungen

- Manual Sensor Profile Probe PR2Dokument48 SeitenManual Sensor Profile Probe PR2jheisonNoch keine Bewertungen

- Steril DiskDokument3 SeitenSteril DisklukasjoNoch keine Bewertungen

- Quantity Corrections PDFDokument38 SeitenQuantity Corrections PDFVishal Garg100% (1)

- INST250 Sec1Dokument131 SeitenINST250 Sec1aricanNoch keine Bewertungen

- 02 - Primary CalibrationDokument4 Seiten02 - Primary CalibrationOmar Stalin Lucio Ron100% (2)

- Petroperu BasesDokument29 SeitenPetroperu BasesGianfrancoNoch keine Bewertungen