Beruflich Dokumente

Kultur Dokumente

HSE Alert - Dropped Object Incident During RIH With 13-58 Casing

Hochgeladen von

AAAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HSE Alert - Dropped Object Incident During RIH With 13-58 Casing

Hochgeladen von

AAACopyright:

Verfügbare Formate

HSE ALERT #20 / 2017-18

Dropped Object Incident During RIH with 13-5/8" Casing

TYPE OF INCIDENT: LOCATION DATE & TIME

Asset Damage (HIPO) Drilling Rig UPDC-180, Well # UN-0134, NK 29th December 2017; 12:10 hrs.

INCIDENT DESCRIPTION IN BRIEF

At approximately 12:10hrs, the operation was running 13 5/8’’ casing, a joint of casing number 294 measuring 46.8feet (14.2 meters)

in length and weighing 4000lbs (1814.37KG) was being picked up using the hydraulic catwalk, the single joint elevator was attached

to the casing joint. While the driller was picking up the casing joint from the power catwalk at the rig floor V door, the casing joint

snagged under the top drive beam which caused the single joint elevator wire sling shackles to part. The joint fell and landed on the

hydraulic catwalk, then rolled off and landed on the ground level on the Off Driller Side (ODS) of V-door approximately 45feet

(13.72metres) below.

There was no injury to personnel, however there was damage to the top drive beam section, casing joint, wire slings and shackles.

Potential Outcome: This incident could have resulted in severe injuries/fatality.

IMMEDIATE CAUSES RECOMMENDATIONS

Unsafe Acts/ Practices The Job Safety Analysis (JSA) for running casing to be

reviewed to include a method of signal between the rig

Lack of attention / forgetfulness. floor crew and the Driller to indicate to start lifting any

Unintentional human error. casing with the Top Drive System (TDS).

Poor communication and teamwork between driller, Contractor Management to consider installing a camera

catwalk operator and floor men. system to enable direct visual between driller and

catwalk operator console.

Unsafe Conditions Contractor Management to conduct awareness session

on Stop Work Authority (SWA).

Blind spot for driller necessitates the use of a spotter Contractor Management to consider reviewing its rig

when picking up pipe with TDS. crew Handover Policy.

Contractor Management to communicate lessons

ROOT CAUSES

learned from this incident via pre-shift meeting and

Personal factors: weekly safety meeting.

Misperception of risk.

Inadequate training/experience.

Tool Box Talk (TBT) and Job Safety Analysis (JSA)

was not properly followed.

Job Factors:

Inadequate leadership/supervision/planning.

Stop Work Authority was not utilized by the crew.

Picture showing damaged 13-5/8"

Picture showing damaged Casing Joint (Length=46.8feet;

Section of Top Drive Beam Weight = 4000lbs)

Rig floor view of the Picture showing damaged

damaged Casing Joint after Shackle and Pin

dropping from 45feet

Picture showing damaged

Wire Sling

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Uas MR1Dokument2 SeitenUas MR1IvanNoch keine Bewertungen

- CXC - Past - Paper - 2022 Solutions PDFDokument17 SeitenCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- Exercises - Fluid MechanicsDokument3 SeitenExercises - Fluid MechanicsgemnikkicNoch keine Bewertungen

- Minor Fire From Battery: Drilling & Workover OrganizationDokument2 SeitenMinor Fire From Battery: Drilling & Workover OrganizationAAANoch keine Bewertungen

- HSE Flash - Coil Tubing Unit Service Contractor LTIDokument1 SeiteHSE Flash - Coil Tubing Unit Service Contractor LTIAAANoch keine Bewertungen

- HSE Alert - Well Testing Contractor Employee Fatal MVADokument1 SeiteHSE Alert - Well Testing Contractor Employee Fatal MVAAAANoch keine Bewertungen

- Internal Safety Alert Dropped IncidentDokument2 SeitenInternal Safety Alert Dropped IncidentAAANoch keine Bewertungen

- HSE Alert - Lost The Index Finger On Right Hand During LDDokument1 SeiteHSE Alert - Lost The Index Finger On Right Hand During LDAAANoch keine Bewertungen

- Bisleri Water Industry: Project ReportDokument53 SeitenBisleri Water Industry: Project ReportJohn CarterNoch keine Bewertungen

- Brody2012 PDFDokument13 SeitenBrody2012 PDFfrancisca caceresNoch keine Bewertungen

- Fast FashionDokument9 SeitenFast FashionTeresa GonzalezNoch keine Bewertungen

- Women and ViolenceDokument8 SeitenWomen and ViolenceStyrich Nyl AbayonNoch keine Bewertungen

- Latest Low NOx Combustion TechnologyDokument7 SeitenLatest Low NOx Combustion Technology95113309Noch keine Bewertungen

- Brief RESUME EmailDokument4 SeitenBrief RESUME Emailranjit_kadalg2011Noch keine Bewertungen

- API 510 Practise Question Nov 07 Rev1Dokument200 SeitenAPI 510 Practise Question Nov 07 Rev1TRAN THONG SINH100% (3)

- Unit 8 Packet KeyDokument21 SeitenUnit 8 Packet KeyHiddenNoch keine Bewertungen

- Assignment - Lab Accidents and PrecautionsDokument6 SeitenAssignment - Lab Accidents and PrecautionsAnchu AvinashNoch keine Bewertungen

- Sustainable Development at British Petroleum: Presented by Amardeep Kulshrestha 09BS0000172 Section-EDokument20 SeitenSustainable Development at British Petroleum: Presented by Amardeep Kulshrestha 09BS0000172 Section-EAmar KulshresthaNoch keine Bewertungen

- 41403A - Guide - Rev - 12-20-17 - With Edits - 2-16-18Dokument167 Seiten41403A - Guide - Rev - 12-20-17 - With Edits - 2-16-18Ronald KahoraNoch keine Bewertungen

- Sanctuary Policy PomonaDokument3 SeitenSanctuary Policy PomonaGabriel EliasNoch keine Bewertungen

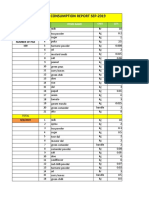

- Daily Staff Food Consumption Reports Sep-2019Dokument4 SeitenDaily Staff Food Consumption Reports Sep-2019Manjit RawatNoch keine Bewertungen

- HUM110 Gilgamesh EssayDokument4 SeitenHUM110 Gilgamesh EssaynsmeganNoch keine Bewertungen

- Transfer and Business Taxation SyllabusDokument5 SeitenTransfer and Business Taxation SyllabusamqqndeahdgeNoch keine Bewertungen

- Rooftop Rain Water Harvesting in An Educational CampusDokument9 SeitenRooftop Rain Water Harvesting in An Educational CampusAkshay BoratiNoch keine Bewertungen

- Weld Metal Overlay & CladdingDokument2 SeitenWeld Metal Overlay & CladdingbobyNoch keine Bewertungen

- Dr. Nastiti K - Manajemen Asma Pada Anak 2018 PDFDokument72 SeitenDr. Nastiti K - Manajemen Asma Pada Anak 2018 PDFagnesspratiwiNoch keine Bewertungen

- Interviewing Skill Workshop (KAU)Dokument54 SeitenInterviewing Skill Workshop (KAU)DrKomal KhalidNoch keine Bewertungen

- General Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsDokument12 SeitenGeneral Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsHazel EncarnacionNoch keine Bewertungen

- ZX110to330 ELEC E PDFDokument1 SeiteZX110to330 ELEC E PDFYadi100% (1)

- AFMAN91-201 NewDokument458 SeitenAFMAN91-201 NewbombtechNoch keine Bewertungen

- Model Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelDokument30 SeitenModel Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelVladimir Hery WijannarkoNoch keine Bewertungen

- Carboset CA-600 - CST600 - CO - enDokument3 SeitenCarboset CA-600 - CST600 - CO - enNilsNoch keine Bewertungen

- NORSOK M-630 Edition 6 Draft For HearingDokument146 SeitenNORSOK M-630 Edition 6 Draft For Hearingcaod1712100% (1)

- Characteristics of Testable HypothesesDokument30 SeitenCharacteristics of Testable HypothesesMarivic Diano67% (3)

- GEC - ReviewerDokument23 SeitenGEC - ReviewerGlycel BagabagonNoch keine Bewertungen