Beruflich Dokumente

Kultur Dokumente

Level Control With DP Do Your Level Best

Hochgeladen von

Ricardo BecOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Level Control With DP Do Your Level Best

Hochgeladen von

Ricardo BecCopyright:

Verfügbare Formate

Do Your Level Best

Level control with dP transmitters appears simple but really isn’t

By Dirk Willard, Contributing Editor

I didn’t think I could solve the problem. I had to spec- 20 in. If the total span between 100% and 0% were 450

ify the level settings for a flanged and dished tank divided in. and HH were set at 95%, then H would be at (427.5

into three compartments with a bottom head as the third – 20) /450 = 91%. Change any gap less than 3 in. to 3 in.

tank. It was a challenge but I met it. What do you know If you wanted H at 85%, the time between H and HH

— integral calculus is actually good for something! would be 4.4 min.

In a typical level problem, you must set high-high With other shapes such as cones and vessels where

(HH), high (H), low (L) and low-low (LL), based on most of the volume is in the head, the calculation is

percent, for a standard two-element (wet, dry) differential more difficult. I’ve found it best to use the actual volume

pressure (dP) transmitter. Don’t forget about full (100%) rather than the column change. In one vessel only 30%

and empty (0%). All measurements normally are to cen- of the volume was in the cone. I’ve set LL based on liquid

terline unless otherwise noted. holdup and recirculation rate for such tanks. Also, you

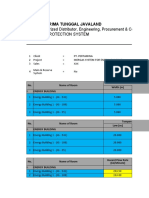

For a dP level transmitter, the upper range value may want to confirm LL against Cameron’s submergence

(URV) and lower range value (LRV) are defined as: recommendation.

URV = liquid specific gravity (SG) × the distance Calibration introduces new problems. The density

between 100% and 0% (h100%) + LRV; and of ambient water used in testing probably won’t match

LRV = capillary fill SG × distance between the ele- that of your process liquid. There’s a simple correction. If

ments or pancakes × -1. The LRV distance should com- water temperature during testing is 75°F, SG is 0.997. If

fortably exceed the URV span. process fluid at process temperature has an SG of 0.880,

The HH setting usually is at the lip of the overflow correct via a ratio. For example, if an H of 90% were

but sometimes is lower if process constraints dictate. desirable, then during calibration, the setting should be:

Equating that with 100% full can cause problems. You 90% × 0.997/0.880 = 102%. The total inches of water

may want to measure above HH in case the overflow column is the same but the height of the liquid is less for

fails. “Cameron Hydraulic Data” recommends a mini- the heavier test water.

mum spacing between settings of 3 in. or 2 min. While geometry makes life difficult, SG causes real

Establishing LL is simple for a cylindrical shape. problems in dP level measurement. Sometimes a vessel

Cameron suggests 1-ft submergence for every ft/sec veloc- contains more than one liquid, sometimes it changes

ity for the pump suction. So, for a 2-ft/sec velocity and a during the process. Usually, it’s best to set HH and H

6-in. nozzle, LL should be: 6/2 + 2×12 = 27 in. above the using the lighter liquid but not if the density ratio is

pump suction nozzle centerline. For saturated (boiling) more than about 1.2:1. Otherwise, your HH and LL

liquids, use a safety factor or company standard. alarms would be separated by only 20–40%, which is

The setting for H depends on the maximum fill unworkable.

rate. The material balance may be helpful. The L setting When this occurs, it’s still possible to use a dP — but

depends on the maximum withdrawal rate. It may make not alone. Consider a density measurement; a nuclear or

sense to set HH and H for the light liquid and LL and L dP cell in a still well may work. Calculate a new URV

for the dense liquid. However, here’s where the calcula- from the density: URVnew = SGnew × h100% + LRV. Now,

tion gets complicated. determine the true level: % level = (dPnew - LRV)/(URVnew

To calculate a setting for a cylinder, first calculate the - LRV). In this way, URV and span are variables.

volume per inch. For a 10-ft-dia. tank this is 4.9 gal/in.

If the fill rate were 50 gal/min, then for 2-min. minimum dirk willard, Contributing Editor

spacing the gap between HH and H would be 50×2/4.9 = dwillard@putman.net

15

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- How To Know If Cogeneration Is The Right Choice For YouDokument4 SeitenHow To Know If Cogeneration Is The Right Choice For YouRicardo BecNoch keine Bewertungen

- Cases and Tools in Biotechnology Management 1555630271. PrintDokument790 SeitenCases and Tools in Biotechnology Management 1555630271. PrintRicardo BecNoch keine Bewertungen

- Line Sizing GuidelinesDokument30 SeitenLine Sizing GuidelinesSanjay Parmar100% (1)

- Gunbarrel Sizing NomographDokument1 SeiteGunbarrel Sizing NomographRicardo BecNoch keine Bewertungen

- Design - and - Development Tank DehydrationDokument16 SeitenDesign - and - Development Tank DehydrationRicardo BecNoch keine Bewertungen

- Gas Flare Design Debottlenecking Using Pinch AnalysisDokument25 SeitenGas Flare Design Debottlenecking Using Pinch AnalysisRicardo BecNoch keine Bewertungen

- Separator Design GuideDokument37 SeitenSeparator Design GuideSanjay ParmarNoch keine Bewertungen

- Gun Barrel Sizing For Crude Oil DehydrationDokument3 SeitenGun Barrel Sizing For Crude Oil DehydrationRicardo BecNoch keine Bewertungen

- Five Things You Didn't Know About Rotary PD PumpsDokument2 SeitenFive Things You Didn't Know About Rotary PD PumpsRicardo BecNoch keine Bewertungen

- Simulation Results Should You Relay On ThemDokument5 SeitenSimulation Results Should You Relay On ThemRicardo BecNoch keine Bewertungen

- Role of Natural GasDokument3 SeitenRole of Natural GasRicardo BecNoch keine Bewertungen

- Psvs Detecting Leaking Helps Avoid Potential Emissions Fines and PenaltiesDokument2 SeitenPsvs Detecting Leaking Helps Avoid Potential Emissions Fines and PenaltiesRicardo BecNoch keine Bewertungen

- The Basis of Rotary Positive PD Pump TechnologyDokument1 SeiteThe Basis of Rotary Positive PD Pump TechnologyRicardo BecNoch keine Bewertungen

- Rotary Pumps On Pipeline ServicesDokument6 SeitenRotary Pumps On Pipeline ServicesRicardo BecNoch keine Bewertungen

- Process Design Considerations Compressor Dry Gas Seal System InterfaceDokument5 SeitenProcess Design Considerations Compressor Dry Gas Seal System InterfaceRicardo BecNoch keine Bewertungen

- CHE - Facts - 1221 - CAKE FILTRATION BASICSDokument1 SeiteCHE - Facts - 1221 - CAKE FILTRATION BASICSRicardo BecNoch keine Bewertungen

- Design Operation of Renewable Diesel UnitDokument4 SeitenDesign Operation of Renewable Diesel UnitRicardo BecNoch keine Bewertungen

- Rotary PD Pump Inlet Pressure RequirementsDokument4 SeitenRotary PD Pump Inlet Pressure RequirementsRicardo BecNoch keine Bewertungen

- 5.5 Thing Power Plant Need To Know About PumpsDokument4 Seiten5.5 Thing Power Plant Need To Know About Pumpsfirdausshukri14Noch keine Bewertungen

- Business Transformation Real Time Data ManagementDokument6 SeitenBusiness Transformation Real Time Data ManagementRicardo BecNoch keine Bewertungen

- Distillation Tower Trays Downcomers and WeirsDokument9 SeitenDistillation Tower Trays Downcomers and WeirsRicardo BecNoch keine Bewertungen

- Flare Gas Compliance EpaDokument6 SeitenFlare Gas Compliance EpaRicardo BecNoch keine Bewertungen

- The Need For Capital BudgetingDokument5 SeitenThe Need For Capital BudgetingRicardo BecNoch keine Bewertungen

- Compressor Myth - Bearing Temperature Must Be Below 200FDokument2 SeitenCompressor Myth - Bearing Temperature Must Be Below 200FRicardo BecNoch keine Bewertungen

- Steam VS Electric Heating (The Basics)Dokument5 SeitenSteam VS Electric Heating (The Basics)Ricardo BecNoch keine Bewertungen

- Pump and System Magazine PapersDokument76 SeitenPump and System Magazine PapersRicardo BecNoch keine Bewertungen

- CHE - Facts - 0321 - THERMAL OXIDIZER SELECTIONDokument1 SeiteCHE - Facts - 0321 - THERMAL OXIDIZER SELECTIONRicardo BecNoch keine Bewertungen

- Fired Heaters Operation Troubleshooting 1589699753 PDFDokument80 SeitenFired Heaters Operation Troubleshooting 1589699753 PDFAliNoch keine Bewertungen

- How To Calculate HeatDokument6 SeitenHow To Calculate HeatRicardo BecNoch keine Bewertungen

- Water Hammer Understand and MitigateDokument5 SeitenWater Hammer Understand and MitigateRicardo BecNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Mass, Volume and Density Without NumbersDokument4 SeitenMass, Volume and Density Without NumbersKeith Josephs100% (3)

- CBSE Question Paper 2018 Class 12 Computer Science: Material Downloaded From - 1 / 40Dokument40 SeitenCBSE Question Paper 2018 Class 12 Computer Science: Material Downloaded From - 1 / 40Usha GuptaNoch keine Bewertungen

- CH 5 Earthwork and QuantificationDokument43 SeitenCH 5 Earthwork and QuantificationZeleke Taimu0% (1)

- METSIM Value FunctionsDokument23 SeitenMETSIM Value Functionssunnysmile81950% (2)

- CNQ#1 PDFDokument32 SeitenCNQ#1 PDFareejaNoch keine Bewertungen

- Dimensional Analysis Worksheet 2Dokument4 SeitenDimensional Analysis Worksheet 2German ToledoNoch keine Bewertungen

- Math Eog 2015 Prep - Spiral ReviewDokument89 SeitenMath Eog 2015 Prep - Spiral Reviewapi-297696505Noch keine Bewertungen

- Slickline TallybookDokument29 SeitenSlickline Tallybookpitia100% (3)

- MATH G4 IDEALEQ4 W3 MELC56-58 Lesson ExemplarDokument6 SeitenMATH G4 IDEALEQ4 W3 MELC56-58 Lesson ExemplarJEFFREY SORIANONoch keine Bewertungen

- Agitator Power Requirement and Mixing Intensity CalculationDokument26 SeitenAgitator Power Requirement and Mixing Intensity CalculationNitin KurupNoch keine Bewertungen

- Empaques 4Dokument131 SeitenEmpaques 4MARIA ALEJANDRA LOPEZ REVELONoch keine Bewertungen

- Math3 Unit 1 Test 2 Sample - Inverse Functions 1819Dokument4 SeitenMath3 Unit 1 Test 2 Sample - Inverse Functions 1819api-368121935Noch keine Bewertungen

- Math4 5 2017 PDFDokument164 SeitenMath4 5 2017 PDFNat WeeNoch keine Bewertungen

- Bulk DensityDokument4 SeitenBulk DensitycatalinNoch keine Bewertungen

- MeasurementDokument27 SeitenMeasurementanon_259712034Noch keine Bewertungen

- Dimensions and Tolerances For Plastic BottlesDokument17 SeitenDimensions and Tolerances For Plastic BottlesAshokNoch keine Bewertungen

- Operating Instructions Mettler Toledo LC-P45 PrinterDokument36 SeitenOperating Instructions Mettler Toledo LC-P45 PrinterTrongtai PhamNoch keine Bewertungen

- Vessel Volume CalculationDokument2 SeitenVessel Volume CalculationDhia Slama100% (1)

- Math9 Q2 Week1 - Variation 1Dokument26 SeitenMath9 Q2 Week1 - Variation 1Ryan Acosta100% (1)

- Detail Cal. & Boq Inergas Ig - 541 - Project Juno - 140 LDokument41 SeitenDetail Cal. & Boq Inergas Ig - 541 - Project Juno - 140 LBagus PrambudiNoch keine Bewertungen

- Cambridge International General Certificate of Secondary EducationDokument12 SeitenCambridge International General Certificate of Secondary EducationPrince YugNoch keine Bewertungen

- MB Day 3 ECQ VersionDokument4 SeitenMB Day 3 ECQ VersionAileen MayaNoch keine Bewertungen

- Primary 3Dokument6 SeitenPrimary 3Ian LimNoch keine Bewertungen

- Sizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONDokument31 SeitenSizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONHai PhanNoch keine Bewertungen

- 2.1.5 Redesign A Protective Case: Emma Filipovits and Josiah LiebDokument31 Seiten2.1.5 Redesign A Protective Case: Emma Filipovits and Josiah Liebapi-551027316Noch keine Bewertungen

- GeometryDokument22 SeitenGeometrycharles gueta100% (1)

- International Mining January 2018Dokument80 SeitenInternational Mining January 2018GordNoch keine Bewertungen

- Selected Physical Properties of PeanutsDokument15 SeitenSelected Physical Properties of PeanutsElton TngNoch keine Bewertungen

- Water Mist System Design GuideDokument6 SeitenWater Mist System Design Guidejun005100% (1)

- Formula SheetDokument6 SeitenFormula Sheetsangeethk1021Noch keine Bewertungen