Beruflich Dokumente

Kultur Dokumente

T400, T700 Temp. Switch Installation and Maintenance Manual

Hochgeladen von

Huan Trinh VanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T400, T700 Temp. Switch Installation and Maintenance Manual

Hochgeladen von

Huan Trinh VanCopyright:

Verfügbare Formate

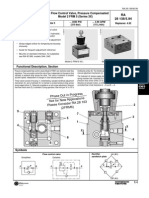

Installation and Maintenance Instructions for

T400 & T700 ASHCROFT® Snap Action

Switches for Temperature Control

T400 REMOTE MOUNT T400 DIRECT MOUNT

G G

B B

H Ø 0.28 H

Ø 0.28 (3 Holes)

(3 Holes)

C I C I

A A

3/4 NPT 3/4 NPT

7/8 Hex E

E “L” 1/2 NPT Male

3.5 lbs. 2.5 lbs. F

F D

D 2-5/16

2.31 “S”

Active

Active J Bulb

Bulb Length

Length

Ø 3/8 Ø 3/8

T700 REMOTE MOUNT T700 DIRECT MOUNT

B E

0.28 THRU F B E

(3 PLACES) 0.28 THRU F

(3 PLACES)

IGNITION O

EN T F

EV SPHERE TUR N IG N I T I O N O

P R MO OPENING. C OFF ENT F

AT RE RE O PER L OS EV SPHERE TURN

PO WE DO TO

AT P R M O O P E N I N G. C OFF

FO EF O

TI GH R B S

IN AT RE RE OPER LOS

P O W D O TO

U

HAZAR ON

E

TL E

B AT

H FO E F O

TI G H R B S

G

IN

Y

U

ION

E

.

I

TL E

B

CAUT

G

Y

.

HAZ AR

CA UT

E

D

M E T RI R

D’OU ION

C AU T

M E T RI R

A

D’OU I O N

C A UT

TR . C

V

A

E BI

TR . C

V

E

E B

E SE

E

O N RVICE D E NT

N

UP F E . IE SE

E R RMER AVANT AVA O N RV I C E

LE COUR ANT UP FE . DE NT

ER RMER AVANT AVA

LE C O R A N T

U

3/4 NPT

(2 PLACES) G 3/4 NPT

(2 PLACES) G

I 7/8 HEX

J L 1/2 NPT I

J MALE

C

4.5 lbs. 3.7 lbs. C

2.31 (59) 2.31 (59) S

ACTIVE 3.00 (76) ACTIVE

BULB BULB

LENGTH LENGTH

0.379 (9)

0.379 (9)

A B C D E F G H I J STEM LENGTH – INCHES

T400 4.6 4.0 3.31 3.25 1.30 2.31 2.27 1.19 2.75 – S 2.75 4.0 6.0 9.0 12.0

T700 5.23 5.20 4.38 3.88 3.58 1.22 2.31 .312 1.30 2.44 LINE LENGTH – FEET

L 5.0 10.0 15.0 20.0 25.0

INTRODUCTION requires the use of a thermowell for installation where pressure

The Ashcroft® temperature switch is a precision built U.L. and may be applied to the thermal system. The thermowell provides

C.S.A. approved control device which features a mechanical protection against physical damage as well as corrosive effects

snap action switch. Controllers are available for operation on of media flow. Use of a thermowell also facilitates removal of the

temperature with fixed or variable differential. Also, manual reset bulb from the process line without disturbing the process.

types are available for operation on increasing or decreasing Standard thermowell materials include brass, steel and stainless

temperature. The manual reset types remain tripped until reset steel; other materials are available upon request. Selection

by pressing a button on the top of the enclosure. The standard should be based on corrosion resistance requirements and

electrical switch is SPDT and is available with various electrical process pressure.

characteristics. Two SPDT switch elements mounted together

are available except on variable deadband and manual reset MOUNTING T400 AND T700 SERIES

types. Bulb materials are either stainless steel or copper. There are three holes external to the enclosure for surface

The Ashcroft snap action temperature switch is furnished in the mounting. Location of these holes is shown on the general

standard NEMA 4/4X and explosion proof NEMA 7 and 9 enclo- dimension drawing.

sure styles. Both enclosures are epoxy coated aluminum castings.

A. Direct - Mounted Controls

INSTALLATION These controls have a 1⁄2 NPT threaded adapter and may be

These controls are precision instruments and should never be attached directly or indirectly by means of a thermowell to

left with internal components exposed. During installation insure equipment to be controlled. When installing or removing con-

that covers are in place and conduit openings are closed except trol always use the wrench flats or hex above the threads.

when actually working on the control. Good piping practice Do not twist the housing.

© Dresser, Inc., Dresser Instrument, 250 East Main Street, Stratford, CT 06614, Tel: 203-378-8281, Fax: 203-385-0402, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M009-10006-10/00 (250-2230G)

Installation and Maintenance Instructions for

T400 & T700 ASHCROFT® Snap Action

Switches for Temperature Control

B. Remote Mounted Controls ADJUSTMENT OF SETPOINT

Two types of union bushings are available to install a remote T400 & T700 Series – A single setpoint adjustment nut (7⁄8˝) is

mounted bulb into a thermowell or other 1⁄2 NPT threaded hole. located centrally at the bottom on the inside of the enclosure.

A non-pressure tight type consists of a bushing, split grommet The bulb of the control should be immersed in a bath at the

and compression nut. To use this, the bulb is inserted through desired setpoint temperature. Optimum performance will be

the nut and the split grommet is slipped into the capillary obtained if the bulb is fully immersed. Allow five minutes for

between the compression nut and the bushing. After positioning initial stabilization.

the bulb as desired tighten the nut to the bushing. This will lock As received, the temperature switch will normally be set to

the capillary at the desired location. The pressure tight type is approximately 90% of the indicated range. After stabilization,

clamped to the bulb after insertion by tightening the compres-

sion nut. To use this, the union bushing is screwed into the 1⁄2 TERMINAL BLOCK

FRONT SWITCH

NPT threaded hole. The compression nut and sleeve are slipped

onto the bulb which is then inserted into the union bushing.

The bulb is then positioned and the compression nut is hand TERMINAL BLOCK

tightened pus 21⁄4 turns. This will lock the capillary at the NC REAR SWITCH

desired location. NO

C

ELECTRICAL CONNECTIONS

NC

Remove cover

NO

T400 Series – two screws hold cover to enclosure

C

T700 Series – cover unscrews

turn the adjustment nut until switch changes mode. Direction of

CONDUIT CONNECTIONS turning is indicated on a label affixed to the inside of the control

Note – It is recommended that Teflon® tape or other sealant be enclosure. When setpoint has been achieved raise and lower

used on conduit, bushing or plug threads to ensure integrity of temperature to insure that the setpoint is correct.

the enclosure. After installation of the control replace cover to insure electrical

T400 Series standard – one 3⁄4 NPT conduit hole right side. safety and to protect internal parts from the environment.

T700 Series standard – two 3⁄4 NPT conduit holes with one per-

manent plug. NEMA 7 & 9 enclosures require proper conduit T450 and T750 VARIABLE DEADBAND SWITCHES

seals and breathers as per the National Electrical Code. Deadband is varied by rotating the wheel on the precision

T400 & WT700 series – XJL variation – 3⁄4 to 1⁄2 NPT reducing switch. When viewed from the front of the enclosure, rotation to

bushing supplied. the left increases deadband – rotation to the right decreased

T400 Series – XJK variation – two 3⁄4 NPT conduit holes. deadband. Letters on the wheel may be used as a reference.

Deadbands obtainable will vary from 0.5% to 9% of pressure

T400 SERIES range depending on range segment and type of diaphragm.

SPDT – Wire directly to the switch according to circuit require-

ments. On controls with pilot lights wire lights according to circuit ADJUSTMENT OF SETPOINT

diagram on inside of cover. See special wiring instruction tag for As received, the temperature switch will normally be set to

single switches with two pilot lights and dual switches with one approximately 90% of range. Rotate the wheel on the MICRO

or more lights. SWITCH all the way to the right; this will provide smallest dead-

band. Increase bath temperature to the required setpoint and

2-SPDT – Dual switching elements consist of two SPDT switches turn the adjustment nut until the switch changes mode. Lower

mounted together in a bracket. Switches are calibrated to have the bath temperature to reset the switch. Rotate the wheel on

simultaneous operation within 1% of range either on increasing the MICRO SWITCH until the desired deadband is obtained.

or decreasing pressure but not in both directions. Wire directly to The upper setpoint will be changing upward with this adjust-

the front and rear switch according to circuit requirements. ment. Lower the bath temperature to reset the switch. Raise the

Leads are provided on rear switch color coded as follows: bath temperature to the desired setpoint and turn the adjusting

Common – White nut until the switch changes mode. Lower the bath temperature

Normally Closed – Red and check reset point and deadband.

Normally Open – Blue

T428 & T429 MANUAL RESET SWITCHES

When hermetically sealed switch element (s) are supplied, the Dress wire leads from switch terminals so as not to interfere

lead color coding is as follows: with or touch reset button.

Common – White Note – As indicated above, adjustment of setpoint is made by

Normally Closed – Red use of 7⁄8˝ nut. Precision switch element mounting screws and

Normally Open – Blue bracket ad-justing screw are factory sealed and should not be

tampered with.

T700 SERIES

SPDT – Wire directly to the switch according to circuit

requirements.

2-SPDT – Wire to front switch terminal block (left) and rear

switch terminal block (right) as marked. Strip insulation 5⁄16˝,

insert in proper terminal connector and tighten clamping screw

to secure.

© Dresser, Inc., Dresser Instrument, 250 East Main Street, Stratford, CT 06614, Tel: 203-378-8281, Fax: 203-385-0402, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M009-10006-10/00 (250-2230G)

Das könnte Ihnen auch gefallen

- 4844 803 +superDokument2 Seiten4844 803 +superBudi WaskitoNoch keine Bewertungen

- ASC Q14!5!075 R001 V1R3 Redundant Solenoid SIL Verificaiton ReportDokument57 SeitenASC Q14!5!075 R001 V1R3 Redundant Solenoid SIL Verificaiton ReportHuan Trinh VanNoch keine Bewertungen

- Doorking 1834 ManualDokument66 SeitenDoorking 1834 ManualclspropleaseNoch keine Bewertungen

- 1282094111153Dokument9 Seiten1282094111153PaperCraft VNNoch keine Bewertungen

- Diagrama Electrico 4runner 2007 1gr-FeDokument8 SeitenDiagrama Electrico 4runner 2007 1gr-FeRonald100% (2)

- InsulationDokument63 SeitenInsulationSH1961Noch keine Bewertungen

- Welding TechnologyDokument26 SeitenWelding TechnologyHiren Kumar100% (1)

- "Yo Quisiera": I TromboneDokument2 Seiten"Yo Quisiera": I TromboneSantiago Guerra0% (1)

- The Rough Guide to Beijing (Travel Guide eBook)Von EverandThe Rough Guide to Beijing (Travel Guide eBook)Bewertung: 2 von 5 Sternen2/5 (1)

- Cathelco ICCP Hull Protection SystemsDokument8 SeitenCathelco ICCP Hull Protection SystemsdalianbouriNoch keine Bewertungen

- ONNE IPP Layout Land Use + MV Distribution Layout-Layout2Dokument1 SeiteONNE IPP Layout Land Use + MV Distribution Layout-Layout2peekateNoch keine Bewertungen

- 66 LS 600h L / LS 600h (From Nov. 2009 Production) : Sliding RoofDokument1 Seite66 LS 600h L / LS 600h (From Nov. 2009 Production) : Sliding RoofWaleed AlshgaaaNoch keine Bewertungen

- Slewing Up Extg 10° Curve at MVGDokument1 SeiteSlewing Up Extg 10° Curve at MVGKD Rao ConstructionNoch keine Bewertungen

- Detalle Embarcadero Propuesta FDokument1 SeiteDetalle Embarcadero Propuesta FFrancisco Javier Rodriguez FlorezNoch keine Bewertungen

- Notes:: Expansion Joint Butt Construction Joint Butt Construction JointDokument4 SeitenNotes:: Expansion Joint Butt Construction Joint Butt Construction JointbillNoch keine Bewertungen

- Asarama Town Water Front Sand Field Shore Protection and Reclamation Schematic DiagramDokument1 SeiteAsarama Town Water Front Sand Field Shore Protection and Reclamation Schematic DiagramEddyNoch keine Bewertungen

- 9xr 06 1 SchematicsDokument1 Seite9xr 06 1 SchematicsĐức PhánNoch keine Bewertungen

- Needle Valve SUS-NSS14 PDFDokument1 SeiteNeedle Valve SUS-NSS14 PDFhungNoch keine Bewertungen

- ASM - A330 - IBE - Rev. Num - 48 - 01-Jan-2024 - Figure 34-12-02 SCH 02 P 0013 (SHEET 1) - NAVIGATIONDokument1 SeiteASM - A330 - IBE - Rev. Num - 48 - 01-Jan-2024 - Figure 34-12-02 SCH 02 P 0013 (SHEET 1) - NAVIGATIONEl Tortugo HD/appsNoch keine Bewertungen

- 5f2a ReferenceDokument1 Seite5f2a ReferenceJuhani KokkonenNoch keine Bewertungen

- Diagrama UnifilarDokument1 SeiteDiagrama UnifilarJose Alfredo Gonzalez CNoch keine Bewertungen

- Tray Filler WiringDiagramPg1Dokument1 SeiteTray Filler WiringDiagramPg1Alexandre Werneck SilvaNoch keine Bewertungen

- F127 76-10526-Detail Design: Fire Protection Services - Level 3 Plan - Part 1Dokument1 SeiteF127 76-10526-Detail Design: Fire Protection Services - Level 3 Plan - Part 1Mazen IsmailNoch keine Bewertungen

- Plano VELARIA R15Dokument1 SeitePlano VELARIA R15carina jannetNoch keine Bewertungen

- Project: Demos Job: Sample Guyed Tower Client: C-Concepts, Inc. LC:3 Dead+Wind 90 Deg - No Ice+Guy Max. Disp.11.595 in at 180.000 FT Scaling 10Dokument52 SeitenProject: Demos Job: Sample Guyed Tower Client: C-Concepts, Inc. LC:3 Dead+Wind 90 Deg - No Ice+Guy Max. Disp.11.595 in at 180.000 FT Scaling 10Syed Ehtesham aliNoch keine Bewertungen

- ZX400R ZX400LCH Hydrauliccircuit Diagram: Attach To Part No.: TT1JK-E-00Dokument9 SeitenZX400R ZX400LCH Hydrauliccircuit Diagram: Attach To Part No.: TT1JK-E-00Anonymous PBe2tL4i100% (1)

- En Barranquilla - 004 Trumpet IDokument2 SeitenEn Barranquilla - 004 Trumpet IJohn Jairo Briceño CristanchoNoch keine Bewertungen

- ABUTEC 20 MTF 0.7 GADesquema - QuemadorDokument1 SeiteABUTEC 20 MTF 0.7 GADesquema - QuemadorAndrea Ninia RebelNoch keine Bewertungen

- ASDokument1 SeiteASDkorniNoch keine Bewertungen

- Site B LatestDokument1 SeiteSite B Latestarkitek pppntNoch keine Bewertungen

- Engr. Ramon A. Orbita Engineering Utilities 2 Tan, Maria Francheska ZDokument1 SeiteEngr. Ramon A. Orbita Engineering Utilities 2 Tan, Maria Francheska ZBalte, Richard F.Noch keine Bewertungen

- Height of Cross-Over Platforms - Summary SheetDokument1 SeiteHeight of Cross-Over Platforms - Summary Sheetjamshaid_abidNoch keine Bewertungen

- Ceiling Ground FloorModelDokument1 SeiteCeiling Ground FloorModelhumaira fabihaNoch keine Bewertungen

- Typical Culvert Plan: Manhole Detail Typ. Concrete Curb and Approach Driveway DetailsDokument1 SeiteTypical Culvert Plan: Manhole Detail Typ. Concrete Curb and Approach Driveway DetailsCasmir TayagNoch keine Bewertungen

- A0 Khloe DressDokument1 SeiteA0 Khloe Dressguzmandarcy7Noch keine Bewertungen

- m0043 003 1 PDFDokument1 Seitem0043 003 1 PDFajarekarga ajarekarNoch keine Bewertungen

- PV 14at - PV 14BTDokument20 SeitenPV 14at - PV 14BTVictor Rodriguez MariNoch keine Bewertungen

- ElevacionesDokument1 SeiteElevacionesRickyFrancoCoaguilaNoch keine Bewertungen

- 6) List of DrawingDokument20 Seiten6) List of DrawingJinSoon TanNoch keine Bewertungen

- 200 - 250 Kva Can-Model1Dokument1 Seite200 - 250 Kva Can-Model1Osanebi Chukwudi LuckyNoch keine Bewertungen

- Stainless Steel Bevel Gears: Spur Gears Spur GearsDokument1 SeiteStainless Steel Bevel Gears: Spur Gears Spur Gearsdenizbademci31Noch keine Bewertungen

- Dilermando Reis Noite de Lua1Dokument7 SeitenDilermando Reis Noite de Lua1daniel nogaraNoch keine Bewertungen

- 07 0149 Ikea Tempe Appg Contamination Assessment RPT Pt6Dokument8 Seiten07 0149 Ikea Tempe Appg Contamination Assessment RPT Pt6Leonardus SijabatNoch keine Bewertungen

- Coventry University Campus MapDokument2 SeitenCoventry University Campus MapIrina StanicaNoch keine Bewertungen

- Ar 02Dokument1 SeiteAr 02Anggi AndriyansahNoch keine Bewertungen

- '86-'88 Suzuki Samurai - Us Model, Ecu Deleted: Wire Color ChartDokument1 Seite'86-'88 Suzuki Samurai - Us Model, Ecu Deleted: Wire Color ChartChuck LNoch keine Bewertungen

- I I I I: Peroxid.Q!Dokument2 SeitenI I I I: Peroxid.Q!Diego PradelNoch keine Bewertungen

- 40 MLD SBR Air Blower Break Tank - R1, Sheet-2Dokument1 Seite40 MLD SBR Air Blower Break Tank - R1, Sheet-2pratikNoch keine Bewertungen

- Plano PuertaDokument1 SeitePlano PuertaHarry Fran Rojas RNoch keine Bewertungen

- AJA Converter MatrixDokument1 SeiteAJA Converter Matrixnokia9600Noch keine Bewertungen

- UmedaDokument1 SeiteUmedaRuby Jean RosalNoch keine Bewertungen

- Edward Grieg - Vaaren - 6Dokument4 SeitenEdward Grieg - Vaaren - 6Giovanni SDNoch keine Bewertungen

- Yucuk Thut:: Pbl2:Thitk CCC Cutrong NGC Tnhtonthitk NG C (DF8-022)Dokument4 SeitenYucuk Thut:: Pbl2:Thitk CCC Cutrong NGC Tnhtonthitk NG C (DF8-022)Trần Duy CảnhNoch keine Bewertungen

- Denah Basement Denah Ac Lantai Basement: Nama Tugas Utilitas BangunanDokument1 SeiteDenah Basement Denah Ac Lantai Basement: Nama Tugas Utilitas BangunanAlif Dio Riskiansyah100% (1)

- Women Casual Short GreenDokument5 SeitenWomen Casual Short GreentulipclothingNoch keine Bewertungen

- STRUC MergedDokument11 SeitenSTRUC MergedMuhammad AfrasiyabNoch keine Bewertungen

- Dse 7220Dokument1 SeiteDse 7220Muhammad IkhsanNoch keine Bewertungen

- Dse 5220Dokument1 SeiteDse 5220Muhammad IkhsanNoch keine Bewertungen

- Dse 7510Dokument1 SeiteDse 7510Muhammad IkhsanNoch keine Bewertungen

- NETZSCH GAD NTZ 400-090ST50-THT-P - Number 4738722Dokument1 SeiteNETZSCH GAD NTZ 400-090ST50-THT-P - Number 4738722Indira briceñoNoch keine Bewertungen

- 7061 0-17840 Rev0 Assembly Drawing HTASreview NoCommentsDokument1 Seite7061 0-17840 Rev0 Assembly Drawing HTASreview NoCommentsgabriel augusto arteaga loaizaNoch keine Bewertungen

- European Catalog Pressure Motorised Operated Valves Complete Asco en 4982200Dokument88 SeitenEuropean Catalog Pressure Motorised Operated Valves Complete Asco en 4982200Harja PandanaNoch keine Bewertungen

- BLIND FLANGE 28 IN 150 RF - SERIES A Rev.01 PDFDokument1 SeiteBLIND FLANGE 28 IN 150 RF - SERIES A Rev.01 PDFdhani projectoNoch keine Bewertungen

- Universitatea "Lucian Blaga" Sibiu: Number Number NR - desen/STAS Buc. Material Observatii Masa NetaDokument1 SeiteUniversitatea "Lucian Blaga" Sibiu: Number Number NR - desen/STAS Buc. Material Observatii Masa NetaBogdan NicolaeNoch keine Bewertungen

- Tính toán & Lựa chọn SILDokument4 SeitenTính toán & Lựa chọn SILHuan Trinh VanNoch keine Bewertungen

- Phân Tích Mối Nguy Và Khả Năng Vận Hành HAZOPDokument5 SeitenPhân Tích Mối Nguy Và Khả Năng Vận Hành HAZOPHuan Trinh VanNoch keine Bewertungen

- Thực hiện Fire and Gas MappingDokument4 SeitenThực hiện Fire and Gas MappingHuan Trinh VanNoch keine Bewertungen

- User Manual Hazcalc: Version: Final 1.0Dokument10 SeitenUser Manual Hazcalc: Version: Final 1.0Huan Trinh VanNoch keine Bewertungen

- Content: 2 User Manual Hazcalc 1.0Dokument38 SeitenContent: 2 User Manual Hazcalc 1.0Huan Trinh VanNoch keine Bewertungen

- Fundamentals of Area ClassificationDokument8 SeitenFundamentals of Area ClassificationHuan Trinh VanNoch keine Bewertungen

- Fundamentals of Area Classification 1Dokument3 SeitenFundamentals of Area Classification 1Huan Trinh VanNoch keine Bewertungen

- Fundamentals of Area ClassificationDokument10 SeitenFundamentals of Area ClassificationHuan Trinh VanNoch keine Bewertungen

- Appendix 9D: SPU Electrical Design ChecklistDokument9 SeitenAppendix 9D: SPU Electrical Design ChecklistHuan Trinh VanNoch keine Bewertungen

- Ashcomstd DialDokument23 SeitenAshcomstd DialHuan Trinh VanNoch keine Bewertungen

- F 03 01 09 Brosur Welding Inspector Rev.22-14Dokument1 SeiteF 03 01 09 Brosur Welding Inspector Rev.22-14Garry MorhanNoch keine Bewertungen

- 2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dokument4 Seiten2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dias EliNoch keine Bewertungen

- Ansys Tutorial 3Dokument4 SeitenAnsys Tutorial 3deathesNoch keine Bewertungen

- Dynapac - PL500TDokument370 SeitenDynapac - PL500TFRNoch keine Bewertungen

- D A42 1362 0001J 17 Isometric ExtractedDokument3 SeitenD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoNoch keine Bewertungen

- Ansi CodesDokument3 SeitenAnsi CodesMunavwar ProfessNoch keine Bewertungen

- Experiment 1Dokument4 SeitenExperiment 1Kathrine E. BautistaNoch keine Bewertungen

- EE Lab Viva QuestionsDokument3 SeitenEE Lab Viva QuestionsRamaswamy Koodalloor Parasuraman67% (3)

- Master enDokument40 SeitenMaster enKosta KockovNoch keine Bewertungen

- Sae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsDokument3 SeitenSae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsAnonymous 7ZTcBn100% (1)

- Conceptual Design: Thulhiriya Textile City Comprehensive Design ProjectDokument14 SeitenConceptual Design: Thulhiriya Textile City Comprehensive Design ProjectAmila DayarathnaNoch keine Bewertungen

- NS2 De00 P0uhn 170012Dokument13 SeitenNS2 De00 P0uhn 170012ĐỨC ĐOÀN NGỌCNoch keine Bewertungen

- Simpolo Integrity Price List 20-11-018Dokument1 SeiteSimpolo Integrity Price List 20-11-018shashirajNoch keine Bewertungen

- Troubleshooting-Overhauling of A Centrifugal PumpDokument3 SeitenTroubleshooting-Overhauling of A Centrifugal PumpSrini VasanNoch keine Bewertungen

- Camapana de Humo Sin DuctosDokument4 SeitenCamapana de Humo Sin DuctosBRIAN JULIAN GARCIA ALFONSONoch keine Bewertungen

- Isolated Phase Busduct Ipb EnerbusDokument2 SeitenIsolated Phase Busduct Ipb EnerbuszulryNoch keine Bewertungen

- Transmission Towers & Lines: Download Brochure PDFDokument2 SeitenTransmission Towers & Lines: Download Brochure PDFGhayas Ud-din DarNoch keine Bewertungen

- Mil DTL 17849FDokument23 SeitenMil DTL 17849FOm Parkash SharmaNoch keine Bewertungen

- Clear Burn - E - BrochureDokument21 SeitenClear Burn - E - BrochureRamandeep SinghNoch keine Bewertungen

- ST014 Sod - MetasilicateDokument1 SeiteST014 Sod - MetasilicateAreIf Cron BmxStreetNoch keine Bewertungen

- Analisis Sikap Good Faith Non-Compliance Indonesia Dalam Upaya Implementasi Konvensi Basel Nehru AnggitaDokument9 SeitenAnalisis Sikap Good Faith Non-Compliance Indonesia Dalam Upaya Implementasi Konvensi Basel Nehru AnggitaMuhammad IqbalNoch keine Bewertungen

- Sheetmetal Design GuidelinesDokument5 SeitenSheetmetal Design GuidelinesVikram Borkhediya0% (1)

- XLIGHT Revestimientos InterioresDokument4 SeitenXLIGHT Revestimientos InterioresdandragutescuNoch keine Bewertungen

- Randhol - Ensuring Well Integrity in Connection With CO2 InjectionDokument59 SeitenRandhol - Ensuring Well Integrity in Connection With CO2 InjectionLauren AndersonNoch keine Bewertungen

- Gym Area Boq For Nri Club HouseDokument5 SeitenGym Area Boq For Nri Club HouseRamesh Arjun TNoch keine Bewertungen

- HANDSET - Poster Idioma InglesDokument3 SeitenHANDSET - Poster Idioma InglesJuan Francisco Mora ZeladaNoch keine Bewertungen