Beruflich Dokumente

Kultur Dokumente

Normas Chavetas

Hochgeladen von

jofeluOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Normas Chavetas

Hochgeladen von

jofeluCopyright:

Verfügbare Formate

Orttech

4405 Glenbrook Road North American Representative for

Willoughby, Ohio 44094 Ortlinghaus Products

(440) 951 5533 Fax (440) 951 0869

Hydraulic Installation Guidelines

Appendix A

Keyway Guidelines

When using keys and keyways to mount a clutch/brake, clutch, or brake on a shaft, the

dimensions of the keyways and keys should be made in accordance with an accepted

standard. Currently the most common standards are the ANSI B17.1 which is used for inch

series shafts, and the DIN 6885 for millimeter series shafts. Either of these standards may

be used for inch or millimeter shafts by a simple conversion of units (inch to mm or mm to

inch). The DIN 6885 generally gives a more compact rectangular key/keyway combination.

In either standard, a tight side to side fit between the key and the hub and shaft keyways

is required. In the ANSI B17.1 this is a class 3 fit. For tolerances on key and keyway

widths Orttech recommends the following:

• Keyways per ANSI B17.1 be +0 / -.002 inch (+0 / -.05 mm) and keyways per DIN

6885 be to the P9 tolerance range.

• Keys per ANSI B17.1 be +.002 / -0 inch (+.05 / -0 mm) and keys per DIN 6885 be

+.05 / -0 mm (+.002 / -0 inch)

This will require that the keys be fitted to the keyways at assembly. A loose fit key will

result on a poor connection will allow the hub to move slightly on the shaft, which will

cause wear and premature failure. A tight side to side fit will prevent this movement and

provide a good connection.

For the hydraulic clutch/brakes, clutches, and brakes the rectangular keys are

recommended, particularly for the larger bores, as they are more compact than square keys

and allow the maximum bore to be used.

When designing a keyed connection, the strength of the key and that of the hub and shaft

materials must be considered. The shear strength of the key(s) must be sufficient to

transmit the torque. Also, the bearing stresses in the faces of the key and keyways that

contact each other must not exceed the allowable limits for the materials. For the material

used in the hub of the Ortlinghaus hydraulic clutch/brakes, clutches, and brakes a reasonable

maximum bearing stress is 21,755 psi (15,000 N/cm2). To calculate the shear stress in the

key, the formula S = (T/R) / (w*l) can be used. To calculate the bearing stress in a keyway

the formula B = (T/R) / (b*l) can be used. S is shear stress in psi, B is bearing stress in psi,

T is torque to be transmitted in lb-in, R is shaft radius in inches, w is width of key in

inches, l is length of key in contact with keyway in the hub, and b is the height of the

keyway in contact with the key.

If two keys are used, which is recommended in most cases (180° apart), allowances must be

made for the keys having an unequal load distribution due to machining and fitting

variances. Tapered keys and keys with a tight top and bottom fit are not recommended.

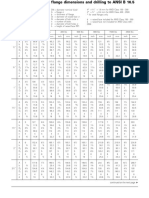

See Figure A1 and Table A1 for hub keyway limits. See Table A2 for shaft diameter/key

combinations per ANSI B17.1. See Tables A3 and A4 for shaft diameter/key combinations

per DIN 6885 Part 1.

If you have any questions please contact Orttech or your local Orttech representative.

ighyd appA Page A1 Issue date Aug 03

Orttech Hydraulic Installation Guidelines, Appendix A

Table A1

Hub Keyway Depth and Width Limits

C/B Size Max. Bore (D) Max. (T) in Hub Bore Max. Key Width (W)

mm inches mm inches mm inches

63 75 2.95 79.9 3.15 20 0.79

75 95 3.74 100.4 3.95 25 0.98

80 130 5.12 137.4 5.41 32 1.26

86 160 6.30 169.4 6.67 40 1.57

90 200 7.87 210.4 8.28 45 1.77

94 250 9.84 262.4 10.34 56 2.20

96 310 12.20 324.4 12.77 70 2.76

98 375 14.76 390.4 15.37 80 3.15

C – Chordal Height T – Dim.to top of Hub keyway

D – Nominal Diameter W – Nominal width of keyway

S – Dim.to bottom of Shaft Keyway X – Depth of Shaft Keyway

Y – Depth of Hub Keyway

Figure A1

ighyd appA Page A2 Issue date Aug 03

Orttech Hydraulic Installation Guidelines, Appendix A

Table A2

Shaft Diameter / Key Combinations Per ANSI B17.1

Dimensions in inches

Nom. Shaft Dia. Rectangular Key Square Key

over to (width x height) (width & height)

5/16 7/16 --- 3/32

7/16 9/16 1/8 x 3/32 1/8

9/16 7/8 3/16 x 1/8 3/16

7/8 1-1/4 1/4 x 3/16 1/4

1-1/4 1-3/8 5/16 x 1/4 5/16

1-3/8 1-3/4 3/8 x 1/4 3/8

1-3/4 2-1/4 1/2 x 3/8 1/2

2-1/4 2-3/4 5/8 x 7/16 5/8

2-3/4 3-1/4 3/4 x 1/2 3/4

3-1/4 3-3/4 7/8 x 5/8 7/8

3-3/4 4-1/2 1 x 3/4 1

4-1/2 5-1/2 1-1/4 x 7/8 1-1/4

5-1/2 6-1/2 1-1/2 x 1 1-1/2

6-1/2 7-1/2 1-3/4 x 1-1/2 1-3/4

7-1/2 9 2 x 1-1/2 2

9 11 2-1/2 x 1-3/4 2-1/2

11 13 3x2 3

13 15 3-1/2 x 2-1/2 3-1/2

15 18 4x3 4

Please Note:

1. For depth of keyways in the hub and shaft refer to “Depth Control Formulas” or

Table 3 in the ANSI B17.1 Standard.

2. A minimum headroom clearance of .005 inch is recommended.

3. Recommended tolerance on keyway width is +0 / -.002 inch.

4. Recommended tolerance on key width is +.002 / -0 inch.

5. A tight side to side fit is required between the keys and the shaft and hub keyways.

Hand fitting at assembly is usually required.

6. Key sizes listed in this table are per the ANSI B17.1 standard, maximum allowable

key size for the hub is per Table A1.

ighyd appA Page A3 Issue date Aug 03

Orttech Hydraulic Installation Guidelines, Appendix A

Table A3

Shaft Diameter / Key Combinations per DIN 6885 Part 1

Nom. Shaft dia. Key Key "X" "Y"

mm inches Width Height For Shaft For Hub

over to over to mm mm mm mm

6 8 0.24 0.31 2 2 1.1 / 1.3 1.0 / 1.1

8 10 0.31 0.39 3 3 1.8 / 1.9 1.4 / 1.5

10 12 0.39 0.47 4 4 2.5 / 2.6 1.8 / 1.9

12 17 0.47 0.67 5 5 3.0 / 3.1 2.3 / 2.4

17 22 0.67 0.87 6 6 3.5 / 3.6 2.8 / 2.9

22 30 0.87 1.18 8 7 4.0 / 4.2 3.3 / 3.5

30 38 1.18 1.50 10 8 5.0 / 5.2 3.3 / 3.5

38 44 1.50 1.73 12 8 5.0 / 5.2 3.3 / 3.5

44 50 1.73 1.97 14 9 5.5 / 5.7 3.8 / 4.0

50 58 1.97 2.28 16 10 6.0 / 6.2 4.3 / 4.5

58 65 2.28 2.56 18 11 7.0 / 7.2 4.4 / 4.6

65 75 2.56 2.95 20 12 7.5 / 7.7 4.9 / 5.1

75 85 2.95 3.35 22 14 9.0 / 9.2 5.4 / 5.6

85 95 3.35 3.74 25 14 9.0 / 9.2 5.4 / 5.6

95 110 3.74 4.33 28 16 10.0 / 10.2 6.4 / 6.6

110 130 4.33 5.12 32 18 11.0 / 11.2 7.4 / 7.6

130 150 5.12 5.91 36 20 12.0 / 12.3 8.4 / 8.7

150 170 5.91 6.69 40 22 13.0 / 13.3 9.4 / 9.7

170 200 6.69 7.87 45 25 15.0 / 15.3 10.4 / 10.7

200 230 7.87 9.06 50 28 17.0 / 17.3 11.4 / 11.7

230 260 9.06 10.24 56 32 20.0 / 20.3 12.4 / 12.7

260 290 10.24 11.42 63 32 20.0 / 20.3 12.4 / 12.7

290 330 11.42 12.99 70 36 22.0 / 22.3 14.4 / 14.7

330 380 12.99 14.96 80 40 25.0 / 25.3 15.4 / 15.7

Please Note:

1. See table A4 for recommended keyway widths.

2. Recommended tolerance on key width is +.05 / -0 mm (+.002 / - 0 inch).

3. Using the “X” and “Y” dimensions given will allow proper headroom clearance.

4. A tight side to side fit is required between the keys and the shaft and hub keyways.

Hand fitting at assembly is usually required.

ighyd appA Page A4 Issue date Aug 03

Orttech Hydraulic Installation Guidelines, Appendix A

Table A4

Recommended Widths of Keyways made to DIN 6885 Part 1

Tolerance Class is P9

Nominal Keyway Width Limits

Width (mm) mm inches

2 1.994 / 1.969 0.0785 / 0.0775

3 2.994 / 2.969 0.1179 / 0.1169

4 3.988 / 3.958 0.1570 / 0.1558

5 4.988 / 4.958 0.1964 / 0.1952

6 5.988 / 5.958 0.2357 / 0.2345

8 7.985 / 7.949 0.3144 / 0.3130

10 9.985 / 9.949 0.3931 / 0.3917

12 11.982 / 11.939 0.4717 / 0.4701

14 13.982 / 13.939 0.5505 / 0.5489

16 15.982 / 15.939 0.6292 / 0.6276

18 17.982 / 17.939 0.7080 / 0.7064

20 19.978 / 19.926 0.7865 / 0.7845

22 21.978 / 21.926 0.8653 / 0.8633

25 24.978 / 24.926 0.9835 / 0.9815

28 27.978 / 27.926 1.1016 / 1.0996

32 31.974 / 31.912 1.2588 / 1.2563

36 35.974 / 35.912 1.4163 / 1.4138

40 39.974 / 39.912 1.5738 / 1.5713

45 44.974 / 44.912 1.7707 / 1.7682

50 49.974 / 49.912 1.9675 / 1.9650

56 55.968 / 55.894 2.2035 / 2.2006

63 62.968 / 62.894 2.4791 / 2.4761

70 69.968 / 69.894 2.7546 / 2.7517

80 79.968 / 79.894 3.1483 / 3.1454

ighyd appA Page A5 Issue date Aug 03

Das könnte Ihnen auch gefallen

- l19146 Xa02uen E1 CombinedDokument41 Seitenl19146 Xa02uen E1 CombinedErik HansonNoch keine Bewertungen

- Hand Bender InstructionsDokument27 SeitenHand Bender InstructionsenkntadoNoch keine Bewertungen

- Daniel Senior Orifice Fitting: Fastener Torque GuideDokument20 SeitenDaniel Senior Orifice Fitting: Fastener Torque GuideDianaMartínezNoch keine Bewertungen

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Von EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Noch keine Bewertungen

- Keystone Betterfly Valves AR1 y AR2 KEYMC-0025-USDokument4 SeitenKeystone Betterfly Valves AR1 y AR2 KEYMC-0025-USpca97Noch keine Bewertungen

- Bolt and Nut TableDokument6 SeitenBolt and Nut TableSteve John PolandNoch keine Bewertungen

- Drill StemDokument28 SeitenDrill Stemchonubobby100% (1)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsVon EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsBewertung: 5 von 5 Sternen5/5 (1)

- Grooved Pins Technical SpecsDokument8 SeitenGrooved Pins Technical Specsjagan_san10Noch keine Bewertungen

- Catalog Keystone Butterfly ValveDokument4 SeitenCatalog Keystone Butterfly ValvePawrij Suriyaaroonroj100% (2)

- Divisor Rotary TablesDokument4 SeitenDivisor Rotary TablesDeysi CardenasNoch keine Bewertungen

- Orifice PDFDokument11 SeitenOrifice PDFb_wooNoch keine Bewertungen

- Square KeywayDokument1 SeiteSquare KeywayDan JeremyNoch keine Bewertungen

- Kit Installation Instruction: Siemens Industry, IncDokument12 SeitenKit Installation Instruction: Siemens Industry, IncKiaraNoch keine Bewertungen

- Chap EDokument44 SeitenChap ERANJITH K PNoch keine Bewertungen

- Tchart PDFDokument3 SeitenTchart PDFferdyak1Noch keine Bewertungen

- Graseras AlemitesDokument37 SeitenGraseras Alemitesjoroma58Noch keine Bewertungen

- Socket Pressure PlugsDokument3 SeitenSocket Pressure Plugs황철Noch keine Bewertungen

- SocketPressurePlugs PDFDokument3 SeitenSocketPressurePlugs PDFJoram MHNoch keine Bewertungen

- E-Hydro Trip Sub Technical DatasheetDokument4 SeitenE-Hydro Trip Sub Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- API Flange Bolt Wrenches, Hammer Wrenches For Wellheads and BOPs, Size Chart, SDokument2 SeitenAPI Flange Bolt Wrenches, Hammer Wrenches For Wellheads and BOPs, Size Chart, Samir aminuddin100% (4)

- Rotorseal Tech Specs PDFDokument19 SeitenRotorseal Tech Specs PDFMykola TitovNoch keine Bewertungen

- Stainless Steel Weld Neck Flange Technical Data Sheet: TypeDokument5 SeitenStainless Steel Weld Neck Flange Technical Data Sheet: TypeÁngela GarzónNoch keine Bewertungen

- API 650 Tank Nozzle Stand OutDokument5 SeitenAPI 650 Tank Nozzle Stand Outgplese0Noch keine Bewertungen

- 3-Piece Stainless Steel Ball Valve: Series We02Dokument4 Seiten3-Piece Stainless Steel Ball Valve: Series We02Alvaro Muñoz BNoch keine Bewertungen

- Pernos Huck C50LDokument4 SeitenPernos Huck C50LAngelina Santiago JimenezNoch keine Bewertungen

- How To Identify and Specify Hydraulic Pumps: Replacing An Existing PumpDokument1 SeiteHow To Identify and Specify Hydraulic Pumps: Replacing An Existing PumpYuriPasenkoNoch keine Bewertungen

- Tech Tips: Fitting Torque ChartDokument7 SeitenTech Tips: Fitting Torque ChartAnthony David Martínez VallejoNoch keine Bewertungen

- Torquimetros de ManoDokument6 SeitenTorquimetros de ManoPablo PasqualiniNoch keine Bewertungen

- Baby Lock Symphony BLSY AddendumDokument56 SeitenBaby Lock Symphony BLSY AddendumiliiexpugnansNoch keine Bewertungen

- AMICO - Grating Stair Tread SectionDokument12 SeitenAMICO - Grating Stair Tread SectionwijayanataNoch keine Bewertungen

- Parabody GS4 ManualDokument27 SeitenParabody GS4 ManualmokuskaNoch keine Bewertungen

- Hex Cap Screw Grade 8 May 4 2009Dokument5 SeitenHex Cap Screw Grade 8 May 4 2009Chris MedeirosNoch keine Bewertungen

- Bolts FastenerDokument20 SeitenBolts FastenerUpadrasta HarishNoch keine Bewertungen

- Cabina de Ducha CurvaDokument52 SeitenCabina de Ducha CurvaEdSoloNoch keine Bewertungen

- B16.5 Size ListDokument3 SeitenB16.5 Size ListSue EpicNoch keine Bewertungen

- Mason Ind - ANSI-BS-DIN-JIS-KS PDFDokument4 SeitenMason Ind - ANSI-BS-DIN-JIS-KS PDFMeleti Meleti MeletiouNoch keine Bewertungen

- Burst Plug Tubing Drain - Technical DatasheetDokument8 SeitenBurst Plug Tubing Drain - Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- Keyway and Key Size DimensionsDokument1 SeiteKeyway and Key Size DimensionsShashank Saxena100% (1)

- Ulfm Butterfly ValveDokument7 SeitenUlfm Butterfly ValveFranklin Esteban CárdenasNoch keine Bewertungen

- SRTDokument3 SeitenSRTDaniel SamokovliaNoch keine Bewertungen

- TABLE 3-7 Dimensions For 36 - Inch Shell Manhole (Inches) Shell Nozzles Api 650Dokument1 SeiteTABLE 3-7 Dimensions For 36 - Inch Shell Manhole (Inches) Shell Nozzles Api 650Pradeep DahiyaNoch keine Bewertungen

- Clamps SectionDokument32 SeitenClamps Sectionxuanphuong2710Noch keine Bewertungen

- AppendicesDokument69 SeitenAppendicesIvan CanoNoch keine Bewertungen

- Appendices V2Dokument76 SeitenAppendices V2Nikola AngjelkovskiNoch keine Bewertungen

- PDT Standard Hole Opener Rev2Dokument2 SeitenPDT Standard Hole Opener Rev2Aboozar FathinejadNoch keine Bewertungen

- GIW Technical Series: Pipe Flange BoltsDokument4 SeitenGIW Technical Series: Pipe Flange BoltsTravis SkinnerNoch keine Bewertungen

- Bronze Flanges - ASME/ANSI 150 LB: (Inches)Dokument6 SeitenBronze Flanges - ASME/ANSI 150 LB: (Inches)Karim ShamsNoch keine Bewertungen

- Resistance To Plastic Flow of Bituminous Mixtures Using Marshall ApparatusDokument10 SeitenResistance To Plastic Flow of Bituminous Mixtures Using Marshall ApparatusRichar DiegoNoch keine Bewertungen

- Section - B - Fittings 1Dokument40 SeitenSection - B - Fittings 1mhaznNoch keine Bewertungen

- Draftguard Anti-Rotation Device Installation and Maintenance InstructionsDokument7 SeitenDraftguard Anti-Rotation Device Installation and Maintenance InstructionsFarzadNoch keine Bewertungen

- Grating AceroGrillDokument9 SeitenGrating AceroGrillRafaelNoch keine Bewertungen

- Sch80ctech SDL80C TDokument9 SeitenSch80ctech SDL80C Thumberto.aranguiz2715Noch keine Bewertungen

- TubesDokument78 SeitenTubeschonubobbyNoch keine Bewertungen

- Air Handler Unit - Ahb SeriesDokument2 SeitenAir Handler Unit - Ahb SeriesLuis VargasNoch keine Bewertungen

- 2017 Chevrolet Colorado 2.5L, L4, Gas, ASP N, VIN A, Des LCV, 16V, USACanadaDokument1 Seite2017 Chevrolet Colorado 2.5L, L4, Gas, ASP N, VIN A, Des LCV, 16V, USACanadaMisa GamezNoch keine Bewertungen

- Automatic Bar Feeding Mechanism For Hack Saw MachineDokument12 SeitenAutomatic Bar Feeding Mechanism For Hack Saw MachineAnonymous j0aO95fgNoch keine Bewertungen

- 08P70-MKA-D80 - Installation InstructionDokument3 Seiten08P70-MKA-D80 - Installation Instructionroma100% (1)

- of Eddy Current Braking System NNNNDokument17 Seitenof Eddy Current Braking System NNNNKaramjeet Singh MalhotraNoch keine Bewertungen

- Merine 1Dokument14 SeitenMerine 1MaheswarrjyNoch keine Bewertungen

- Problem Sheet-07 ME201 Power CyclesDokument1 SeiteProblem Sheet-07 ME201 Power CyclesKavitha KandulaNoch keine Bewertungen

- Untitled DocumentDokument5 SeitenUntitled DocumentEsther KoltermanNoch keine Bewertungen

- An Introduction To Pumping Equipment: Principle, Operation & MaintenanceDokument18 SeitenAn Introduction To Pumping Equipment: Principle, Operation & Maintenancegowrisankar32Noch keine Bewertungen

- Kuhl Tek Catalog 2013Dokument8 SeitenKuhl Tek Catalog 2013Ivansk8Noch keine Bewertungen

- enDokument70 SeitenenRegistr Registr93% (14)

- 3408 Con Rod Specification PDFDokument3 Seiten3408 Con Rod Specification PDFmanu luvungaNoch keine Bewertungen

- Trimmer: Not For ReproductionDokument36 SeitenTrimmer: Not For Reproductionkelvin felix garciaNoch keine Bewertungen

- 10ME56 Turobo MachinesDokument3 Seiten10ME56 Turobo MachinesHemanth KumarNoch keine Bewertungen

- Geared MachinesDokument2 SeitenGeared Machinespete-walkerhotmail.co.ukNoch keine Bewertungen

- Maintenance Challenges of Wankel Rotary Engines and Utility in Aviation ApplicationsDokument12 SeitenMaintenance Challenges of Wankel Rotary Engines and Utility in Aviation Applications임학진Noch keine Bewertungen

- ISO Starline Pump Curves and DataDokument99 SeitenISO Starline Pump Curves and DataJohn SmithNoch keine Bewertungen

- FirePumps Scopes ULFMDokument36 SeitenFirePumps Scopes ULFMZeh Garcia JuniorNoch keine Bewertungen

- Sotufip BSF-1200 TKL207021-0Dokument3 SeitenSotufip BSF-1200 TKL207021-0Mohamed ZakiNoch keine Bewertungen

- Chapter 3 DC MOTORDokument28 SeitenChapter 3 DC MOTORBawan AramNoch keine Bewertungen

- PC350 350LC-7Dokument7 SeitenPC350 350LC-7bellatobingNoch keine Bewertungen

- Oldsmobile Shop ManualDokument458 SeitenOldsmobile Shop ManualDiego Hernan PiñeiroNoch keine Bewertungen

- Cummins QSK T3 Fault LISTA DE CODIGOS PDFDokument31 SeitenCummins QSK T3 Fault LISTA DE CODIGOS PDFWalid Aouini100% (1)

- McENG 6221-Advanced Fluid Power System (Mechatronics)Dokument4 SeitenMcENG 6221-Advanced Fluid Power System (Mechatronics)duraiprakash83Noch keine Bewertungen

- Hasnain Saleheen (1411066046)Dokument7 SeitenHasnain Saleheen (1411066046)hasnainNoch keine Bewertungen

- Suzuki RatiosDokument4 SeitenSuzuki RatiosNuph NotschaeleNoch keine Bewertungen

- Manual Piaggio Hexagon ELECTRICODokument25 SeitenManual Piaggio Hexagon ELECTRICOLuis Kike50% (2)

- 2011 GN125 PDFDokument74 Seiten2011 GN125 PDFWalter SaguiNoch keine Bewertungen

- Mueller W300 Installation Guide: Do Not Cut Bands or Wrapping Until InstructedDokument14 SeitenMueller W300 Installation Guide: Do Not Cut Bands or Wrapping Until InstructedAbu AlAnda Gate for metal industries and Equipment.Noch keine Bewertungen

- 2450 Series: Features Base ModelsDokument3 Seiten2450 Series: Features Base Modelsمحمود رشوان السيدNoch keine Bewertungen

- MSG11 3500UK OfflineDokument854 SeitenMSG11 3500UK Offlinemanuel sebastian avendanoNoch keine Bewertungen

- University of Chicago Press Fall 2009 CatalogueVon EverandUniversity of Chicago Press Fall 2009 CatalogueBewertung: 5 von 5 Sternen5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesVon EverandUniversity of Chicago Press Fall 2009 Distributed TitlesBewertung: 1 von 5 Sternen1/5 (1)