Beruflich Dokumente

Kultur Dokumente

Invasion of Saturated Vapor Coconut Shell The Transition Obat Merah To Liquid Smoke Coconut Shell As Solutions in The Treatment of Wound Outside

Hochgeladen von

Global Research and Development ServicesOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Invasion of Saturated Vapor Coconut Shell The Transition Obat Merah To Liquid Smoke Coconut Shell As Solutions in The Treatment of Wound Outside

Hochgeladen von

Global Research and Development ServicesCopyright:

Verfügbare Formate

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Kistriyani et al., 2018

Volume 4 Issue 3, pp. 01-10

Date of Publication: 15th November, 2018

DOI-https://dx.doi.org/10.20319/mijst.2018.43.0110

This paper can be cited as: Kistriyani, L., Ghifari, M. A. D., Mawaddah, M., & Sari, Y. D. (2018).

Invasıon of Saturated Vapor Coconut Shell the Transıtıon Obat Merah to Lıquıd Smoke Coconut Shell as

Solutıons in the Treatment of Wound Outsıde. MATTER: International Journal of Science and

Technology, 4(3), 01-10.

This work is licensed under the Creative Commons Attribution-Non Commercial 4.0 International

License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc/4.0/ or send a

letter to Creative Commons, PO Box 1866, Mountain View, CA 94042, USA.

INVASION OF SATURATED VAPOR COCONUT SHELL

THE TRANSITION OBAT MERAH TO LIQUID SMOKE

COCONUT SHELL AS SOLUTIONS IN THE TREATMENT OF

WOUND OUTSIDE

Lilis Kistriyani

Department of Chemical Engineering, Islamic University of Indonesia, Yogyakarta, Indonesia

lilis.kistriyani@gmail.com

Muhammad Abu Dzar Al Ghifari

Department of Chemical Engineering, Islamic University of Indonesia, Yogyakarta, Indonesia

m.abudzar@gmail.com

Miftahil Mawaddah

Department of Chemical Engineering, Islamic University of Indonesia, Yogyakarta, Indonesia

miftahilm2@gmail.com

Yolla Dwita Sari

Department of Chemistry, Islamic University of Indonesia, Yogyakarta, Indonesia

yolladwitasari@gmail.com

Abstract

Coconut shell is a waste generated from the use of coconut itself. Utilization of liquid smoke

coconut shell that is not widely known by the public is the content of phenols that can inhibit the

growth of bacteria / fungi and can be used in the treatment of external injury. Liquid Smoke is

Available Online at: http://grdspublishing.org/ 1

MATTER: International Journal of Science and Technology

ISSN 2454-5880

obtained from pyrolysis of coconut shell after heating at temperature variation 300oC, 400oC

and 500oC. The result of liquid smoke from pyrolysis is then purified by distillation method with

temperature variation 80-100 and 100-110oC for each pyrolysis temperature. After obtaining

pure liquid smoke was tested using GC-MS, antibacterial test between liquid smoke and red

medicine using Staphylococcus aureus bacteria by diffusion method. It is known from the

optimum GC-MS phenol results at 400oC pyrolysis temperature with distillation temperature

100-110 and its content of 13.55%. In antibacterial tests known antibiotic efficacy associated

with growth inhibition zone, the larger the diameter, the greater the potential of the antibiotic

sample. The widest diameter of 15.6 mm contained at 400oC pyrolysis temperature with

distillation temperature 100-110oC while on the red diameter of smaller diameter of 10.0 mm.

The results showed that the content of phenol in liquid smoke from coconut shells acts as a

substitute for the use of red medication, because of its high antimicrobial potential associated

with the treatment of infectious diseases such as blisters and ulcers. This is an alternative

solution that is easy to manufacture and does not cost a lot.

Keywords

Antibiotic, External Injury, Infection, Liquid Smoke, Red Medicine, Staphylococcus Aureus

1. Introduction

As agrarian country Indonesia potantial have a lot of varietis. Coconut trees are no

exception. Coconut (Cocos nucifera) is the sole family of Cocos or aren arenan or Arecaceae.

The area of coconut plantations in Indonesia reaches 3.6 million ha and total coconut production

in Indonesia reaches ± 2.9 tons / year (DG 2016). This plant can be used almost all parts by

humans so it is considered as versatile plant. The origin of this plant is estimated from the coast

of the Indian Ocean, Asian side, but now spread throughout all the tropical beaches across the

world. Ripe coconut fruit has weight of coir (35%), shell (12%), endosperm (28%) and water

(25%) (Setyamidjaja, 1995).

In addition can be used as hand craft and made charcoal as fuel, coconut shell can also used as

a healing remedy. However, general public has not much information about it. Smoke from

burning coconut shells contains vapors it can be used as external drugs wound antibiotics, such

as acidic compounds, phenols and alcohols (Luditama, 2006). Currently, there are many people

still using first iad wound cleanser as wound medicine. First aid wound cleanser was very

Available Online at: http://grdspublishing.org/ 2

MATTER: International Journal of Science and Technology

ISSN 2454-5880

popular before independets of indonesia (corpsman using the medicine for wound care of

national armed force ) until 1980s. The first aid wound cleanser was discovered by Doctor Hugh

Young in 1919. In 1998 US Food and Drug Administration was banned this medicine because it

has contained mercurochrome (mercury and chromium). Mercury and chrome make the wet

wound dry. But in wet conditions, can make microbes like bacteria and fungi to growth.

So it’s forbidden to used. Compounds act as antioxidants and antibacterials are phenols, acids

and alcohols (Karseno, 2002). Therefore, this liquid smoke has same act role with first aid

wound cleanser because it has antibacterial content to process inhibiting and killing bacterial

growth (Yulistiani et al, 1997 in Ferayanti research, 2007). Based on this case, we have an idea

to use liquid smoke from coconut shell as external drug. This low cost alternative solusition

may inprofe the benevit and econimical value.

2. Details Experimental

2.1 Materials and Methods

2.1.1 Materials

The materials used on this research is coconut shell. For analisys materials are used

staphylococcus aureus bacterial with life contain tryptose soya agar (TSA). Instrument used in

this research are furnance (pyrolysis), Distillation, and instrumantion Gas Cromatografy Mass

Spectrometry (GC-MS).

2.1.2. Methods

2.1.2.1 Liquid Smoke Making

The coconut shell have to cleaned up first before burning. Making liquid smoke can we

done with kiln machine made by stainless steel equipped with an electrical heater machine 3

condenser and 2 distilled containers. The temperature used are 300 ° C - 500 ° C through Liquid

flow to the bottom of cooler, after that distilled containers accomodated in 2 squares with 2 liters

of volume. The top of the distillate solution are pyroligneous liquor while the bottom is ter

(setteled ter).

2.1.2.2 Liquid Smoke Purification

The Purification of liquid smoke done by distillation. Liquid smoke put into a distillation

flask, heated by using electric heater. This distillation process takes about 2 - 2.5 hours or until

maximum distillation temperature are reached. Temperature of liquid smoke in the distillation

Available Online at: http://grdspublishing.org/ 3

MATTER: International Journal of Science and Technology

ISSN 2454-5880

flask. The steam that forms and then enters refrigerant pipe (condenser) and the distillate is

accommodated in a container or flask.

2.1.2.3 Analyst of GC-MS

The liquid smoke dissolved in ether, then separation of the phase of dissolved in ether

and polar phase. Then 5 μl of the ether phase was taken and injected into GC-MS using standard

acetate and phenol. The compound mix that passed gas chromatography will be separated into

individual components. Some of the dominant components were further analyzed with a mass

spectrophotometer. By computer determinable any types of compounds after consultation with

known standard.

2.1.2.4. Analyst of Antibacterial Activity

Antibacterial activity test was done by using paper disk/disc diffusion method. The filter

paper disc contains a certain amount of drug placed on a solid medium previously inoculated by

test bacteria on its surface. After incubation, the inhibitory zone diameter around the disc used

measures the strength of drug resistance to the test organism. This method is influenced by

several physical and chemical factors, in addition to factors between drugs and organisms (eg

medium properties and diffusion abilities, molecular size and drug stability). As well as the use

of antibiotics Ampicilin as a positive control. The media was incubated for 24 hours at a

temperature (35-37)0C.

3. Result and Discussion

3.1 Pyrolysis and Distillation

Pyrolysis process involves a variety of processes, namely the reaction of decomposition,

oxidation, polymerization, and condensation. Reactions occurring during wood pyrolysis are:

removal of water from wood at a temperature of 120-150° C, hemicellulose pyrolysis at a

temperature of 200-250° C, cellulosic pyrolysis at a temperature of 280-320° C and lignin

pyrolysis at 400° C (Maga, 1988, Girrard, 1995).

Available Online at: http://grdspublishing.org/ 4

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Figure 1: Result of Pyrolysis at Temperature 3000C, 4000C, and 5000C

It can be seen by the figure 1 that the higher the temperature, the more liquid smoke is

obtained. This is in accordance with the Arhenius equation states that the higher the temperature

the greater the thermal decomposition constant value, resulting in the pyrolysis rate increases and

the conversion rises. The pyrolysis rate of coconut shell can be proved by the Arhenius equation

( ) in the table. 1 and figure. 2 by converting the Arhenius equation to a linear

equation.

So that the activation energy values obtained by the equation:

Then the value of the pre-exponential factor (A) can be obtained based on the graph

cut the y-axis or (1/Twall)

-10.4000

-10.4200 0.00129 0.00149 0.00174

-10.4400

-10.4600 -10.4638 y = -0.05154x - 10.40836

-10.4800 R² = 0.98317

-10.5000 -10.5037

-10.5200

-10.5400

-10.5600

-10.5669

-10.5800

Figure 2: Cureve Relation ln(dy/dt) with 1/Twall

Available Online at: http://grdspublishing.org/ 5

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Table 1: Activation Energy Value and Pre-Exponential Factor on Pyrolysis Process and Rate of

Coconut Pyrolysis

Y T wall

t (second) dy/dt ln (dy/dt) 1 / Twall E A Rate of Reaction

(mass fraction) (K)

11100 0,31692 2,855,E-05 -10,4638 773,15 1,29341,E-03 3,01771,E-05

12000 0,32923 2,744,E-05 -10,5037 673,15 1,48555,E-03 0,4283 3,018E-05 3,01768,E-05

13500 0,34769 2,575,E-05 -10,5669 573,15 1,74474,E-03 3,01764,E-05

3.01772.E-05

3.01771.E-05

3.01770.E-05

𝑅𝑇𝑤𝑎𝑙𝑙

3.01768.E-05 3.01768.E-05

𝐸

3.01766.E-05

𝐴𝑒

3.01764.E-05 3.01764.E-05

𝑑𝑦

𝑑𝑡

3.01762.E-05

3.01760.E-05

573.15 673.15 773.15

Temperature (Twall)

Figure 3: Rate of Coconut Shell Pyrolysis at Temperature 3000C, 4000C and 5000C

Liquid smoke obtained from pyrolysis of coconut shell after heating at temperature variation

3000C, 4000C, and 5000C. Then, it is distilled by distillation method with temperature variation

(80-100)0C, (100-110)0C for each pyrolysis temperature.

3.2 Result of GC-MS

Liquid smoke has been purified by distillation method, then tested by using GC-MS. The

results show that some of the main components contain in liquid smoke. The main components

show in table 2.

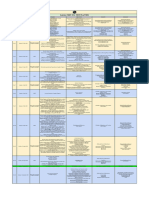

Table 2: Result of GC-MS Test Analysis at Temperature Distillation

Temperature of Tempareture of

Component Percentage (%)

Pyrolysis (C) Distillation (C)

Phenol 11,80

300°C 80-100

Acetic Acid 0,00

Available Online at: http://grdspublishing.org/ 6

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Phenol 12,78

100-110

Acetic Acid 60,43

Phenol 21,00

Cairan Hitam

Acetic Acid 24,32

Phenol 7,27

80-100

Acetic Acid 42,26

Phenol 13,55

400°C 100-110

Acetic Acid 54,09

Phenol 20,34

Cairan Hitam

Acetic Acid 17,69

Phenol 6,98

80-100

Acetic Acid 44,87

Phenol 12,84

500°C 100-110

Acetic Acid 50,69

Phenol 22,20

Cairan Hitam

Acetic Acid 20,34

Based on table 2, the distillation of liquid smoke reaches optimum condition at 4000C.

The pyrolysis process involved in various reaction processes, that is decomposition, oxidation,

polymerization, and condensation, lignin pyrolysis occurs on temperature 4000C, which more

phenols and other acidic compounds will produce. Those compounds use to be anti microbial in

the process of wound healing using liquid smoke. The acidity is one of chemical properties that

determining the quality of produced liquid smoke. Acetic acid is an organic compound that has

important role in liquid smoke.

The high level of acidity and phenols are useful as anti-microbial. The role of phenol and

acetic acid is increased when those compounds are present together (Darmadji, 1995). In

additional, Fenol could be use to antioxidant. (Pszczola, 1995).

Available Online at: http://grdspublishing.org/ 7

MATTER: International Journal of Science and Technology

ISSN 2454-5880

3.3 Antibacterial Test

Determination of sensitivity bacteria pathogens to antimicrobials could be doing with one

of two method principal, that is dilution or diffusion. It is important to use standard method for

controlling all of factor that affect in antimicrobial activity (Jawetz et al., 2005).

The method which is often used is method diffusion of gels (agar). Paperdisc contain any

number of certain drug that placed on the solid medium that was bacteria inoculation test on the

surface . After that, diameter resistor zone around discs used measure power resistant drug to

organism test. Method this affected some facors physical and chemistry, besides factor between

drug and organism ( eg. the nature of the medium and ability diffusion, size molecular and

stability medicine ). Nevertheless, standardization factors are allowed to do sensitivity test

properly (Jawetz et al., 2005)

Diffusion Process

1) The diffusion that occurs is the removal antibiotic solution from backup through a

microbial gel (agar) test.

2) Diffusion can occur in two ways: linear diffusion and radial diffusion.

3) When incubation occurs, the microbe undergoes a phase of adaptation (lag), then breeds

to a level where many cells absorb antibiotics.

4) Diffusion solution from antibiotic will prevented, so, there are area obstacles growth.

Linear Diffusion and Radial

Diffusion linear occurs when backup relative great (center line > 8)

Radial diffusion occurs on backup small (like paperdisk which is 1.5 mm in diameter)

Figure 4: Effectiveness of Antibiotics

Result

Antibiotics diffuse in to the agar.

Concentration of antibiotics decreased when depart from the disk.

After incubation, look on clear area on the gel (agar) surface and called as inhibition

zone.

Available Online at: http://grdspublishing.org/ 8

MATTER: International Journal of Science and Technology

ISSN 2454-5880

The effectivity of antibiotics is related to the zone growth of inhibition. The larger the

diameter, the better antibiotic sample potential. Here the catagories if inhibition of bacteria,

according to David and Stout (1971) in Ambarwati (2007), if rate the inhibition of bacterial

growth is 5 mm or less, categorized as weak, 5-10 mm are categorized medium, 10-19 mm

categorized strong, and 20 mm or more categorized very strong.

Table 3 show that the results of bacteria test using difussion method with Tryptose Soya

Agar (TSA) with incubation for 24 hours dan temperature range between 35-37 0C and using

positive control of ampicillin antibiotic.

Table 3: Result of Bacterial Test

No. Sample Result of Observation (mm)

1 300 (80-100) 10,4

2 300 (100-110) 13,3

3 400 (80-100) 12,6

4 400 (100-110) 15,6

5 500 (80-100) 11,5

6 500 (100-110) 12,2

7 Obat Merah 10,0

8 Kontrol + 25,9

9 Kontrol - 0

Based on Table 3, show that at temperature 400 0C with distillation result at 100-110 0C the

result of bacteria test with including strong category in bacterial inhibition level, ie 15.6 mm.

4. Conclusion

The Liquid smoke are natural ingredients, that made from burning of hemicellulose,

cellulose, and lignin from hardwoods to produce antimicrobial, antibacterial, and antioxidant

effects, including phenols, carbonyls, acids, furans, alcohols, esters compounds, and so on.

Liquid smoke is widely used in the food industry, health, insecticides and pesticides, and plants.

From the result of many experiment, the higher pyrolysis temperature the greater smoke

that produced. However, optimum temperature of pyrolysis in coconut shell is only about 400

0

C. This is also as evidenced by the result of bacteria test in pyrolysa temperature 400 0C and

Available Online at: http://grdspublishing.org/ 9

MATTER: International Journal of Science and Technology

ISSN 2454-5880

distillation temperature at 100-110 0C show that rate of bacterial inhibition is 15.6 mm, which is

included in the strong category in inhibiting bacterial growth.

References

Balai Pengkajian Teknologi Pertanian Aceh. 2017. Pemanfaatn Asap Cair dari Tempurung

Kelapa. BPTP Banda Aceh, Badan Litbang – Kementerian Pertanian. 7 hal.

Balai Pengkajian Teknologi Pertanian Riau. 2015. Laporan Perkembangan Pengkajian

Bioindustri Kelapa Kabupaten Indragiri Hilir. BPTP Riau, Badan Litbang – Kementerian

Pertanian. 23 hal.

Darmadji, P. 2002. Optimasi Pemurnian Asap Cair dengan Metoda Redistilasi. J Teknologi dan

Industri Pangan 13(3): 267-271.

Djatmiko, B., S. Ketaren dan Setyakartini. 1985. Arang Pengolahan dan Kegunaannya.

Departemen Teknologi Hasil Pertanian, Fakultas Teknologi Pertanian, Institut Pertanian

Bogor.

Girrard, J.P. 1992. Smoking in Technology of Meat Products. Clermont Ferran, Ellis

Horwood, New York pp: 165:205.

Karseno, P. Darmadji and Rahayu. 2002. Daya hambat asap cair kayu karet terhadap bakteri

pengkontaminan lateks dan ribbed smoke sheet. Agritech 21(1): 10-15.

Kollman, F. P. and Cote, W. A. 1984. Principles of Wood Science and Technology.New York,

USA: Sprenger Verlag.

Maga, J.A. 1988. Smoke in Food Processing. Florida: CRC Press Inc.

Pszczola, D. E. 1995. Tour Higlights Production and Uses of Smoke Base Flavors. J Food Tech

(49): 70-74.

Solcihin, M. 2007. Penggunaan Asap Cair Deorub dalam Pengolahan RSS. J Penelitian Karet

25(1) : 1-12.

Suhendi, Endang dan Jayanudin. 2012. Identifikasi Komponen Kimia Asap Cair Tempurung

Kelapa dari Wilayah Anyer Banten. Jur. Agroekotek 4(1): 39-46.

Tranggono, dkk. 1996. Identifikasi Asap cair dari berbagai jenis kayu dan tempurung kelapa. J

Ilmu dan Teknologi Pangan 1(2): 15-24.

Available Online at: http://grdspublishing.org/ 10

Das könnte Ihnen auch gefallen

- Resolving A Realistic Middle Ground Towards The Sustainability Transition in The Global Political and Economic Landscape: A Comprehensive Review On Green CapitalismDokument29 SeitenResolving A Realistic Middle Ground Towards The Sustainability Transition in The Global Political and Economic Landscape: A Comprehensive Review On Green CapitalismGlobal Research and Development ServicesNoch keine Bewertungen

- The Ethical Perception On Utang Na Loob As Basis of Voter's ChoiceDokument18 SeitenThe Ethical Perception On Utang Na Loob As Basis of Voter's ChoiceGlobal Research and Development Services100% (1)

- Analyzing The Relationship Between Industrial Policy and Entrepreneurial EcosystemDokument13 SeitenAnalyzing The Relationship Between Industrial Policy and Entrepreneurial EcosystemGlobal Research and Development ServicesNoch keine Bewertungen

- Examine The Effects of Goods and Services Tax (GST) and Its Compliance: Reference To Sierra LeoneDokument18 SeitenExamine The Effects of Goods and Services Tax (GST) and Its Compliance: Reference To Sierra LeoneGlobal Research and Development ServicesNoch keine Bewertungen

- Interpretation and Justification of Rules For Managers in Business Organizations: A Professional Ethics PerspectiveDokument10 SeitenInterpretation and Justification of Rules For Managers in Business Organizations: A Professional Ethics PerspectiveGlobal Research and Development ServicesNoch keine Bewertungen

- Teacher Educators' Perceptions of Utilizing Mobile Apps For English Learning in Secondary EducationDokument28 SeitenTeacher Educators' Perceptions of Utilizing Mobile Apps For English Learning in Secondary EducationGlobal Research and Development ServicesNoch keine Bewertungen

- Perceived Self-Efficacy and Academic Performance of Stem Senior High School StudentsDokument13 SeitenPerceived Self-Efficacy and Academic Performance of Stem Senior High School StudentsGlobal Research and Development ServicesNoch keine Bewertungen

- Implementation of Biorhythm Graph With Trigonometric Functions Using PythonDokument8 SeitenImplementation of Biorhythm Graph With Trigonometric Functions Using PythonGlobal Research and Development ServicesNoch keine Bewertungen

- Potential Factors Influence Failure of The Village-Owned Business: The Entity Village Autonomy of Indonesian Government's ProgramDokument12 SeitenPotential Factors Influence Failure of The Village-Owned Business: The Entity Village Autonomy of Indonesian Government's ProgramGlobal Research and Development ServicesNoch keine Bewertungen

- Challenges in The Implementation of Schoolbased Management of Developing Schools: Basis For A Compliance FrameworkDokument14 SeitenChallenges in The Implementation of Schoolbased Management of Developing Schools: Basis For A Compliance FrameworkGlobal Research and Development ServicesNoch keine Bewertungen

- Effect of Metacognitive Intervention Strategies in Enhancing Resilience Among Pre-Service TeachersDokument12 SeitenEffect of Metacognitive Intervention Strategies in Enhancing Resilience Among Pre-Service TeachersGlobal Research and Development ServicesNoch keine Bewertungen

- Design and Implementation of An Arabic Braille Self-Learning WebsiteDokument17 SeitenDesign and Implementation of An Arabic Braille Self-Learning WebsiteGlobal Research and Development ServicesNoch keine Bewertungen

- Loss Analysis in Bread Production Process Using Material Flow Cost Accounting TechniqueDokument16 SeitenLoss Analysis in Bread Production Process Using Material Flow Cost Accounting TechniqueGlobal Research and Development ServicesNoch keine Bewertungen

- Influence of Iot On Smart LogisticsDokument12 SeitenInfluence of Iot On Smart LogisticsGlobal Research and Development ServicesNoch keine Bewertungen

- Using Collaborative Web-Based Maps To Promote Geography Teaching and LearningDokument13 SeitenUsing Collaborative Web-Based Maps To Promote Geography Teaching and LearningGlobal Research and Development ServicesNoch keine Bewertungen

- Refining The English Syntax Course For Undergraduate English Language Students With Digital TechnologiesDokument19 SeitenRefining The English Syntax Course For Undergraduate English Language Students With Digital TechnologiesGlobal Research and Development ServicesNoch keine Bewertungen

- Bank-Specific and Macroeconomic Determinants of Banks Liquidity in Southeast AsiaDokument18 SeitenBank-Specific and Macroeconomic Determinants of Banks Liquidity in Southeast AsiaGlobal Research and Development ServicesNoch keine Bewertungen

- The Development of Nursing Care Model in Patients With Total Knee Replacement Reconstructive SurgeryDokument17 SeitenThe Development of Nursing Care Model in Patients With Total Knee Replacement Reconstructive SurgeryGlobal Research and Development ServicesNoch keine Bewertungen

- How Bi-Lingual Fathers Support Their Children To Learn Languages at HomeDokument35 SeitenHow Bi-Lingual Fathers Support Their Children To Learn Languages at HomeGlobal Research and Development ServicesNoch keine Bewertungen

- Study of Urban Heat Island in Yogyakarta City Using Local Climate Zone ApproachDokument17 SeitenStudy of Urban Heat Island in Yogyakarta City Using Local Climate Zone ApproachGlobal Research and Development ServicesNoch keine Bewertungen

- Development of A Topical Gel Containing A Dipeptidyl Peptidase-4 Inhibitor For Wound Healing ApplicationsDokument15 SeitenDevelopment of A Topical Gel Containing A Dipeptidyl Peptidase-4 Inhibitor For Wound Healing ApplicationsGlobal Research and Development ServicesNoch keine Bewertungen

- "Higher, Faster, Stronger": Championing Classroom TeachingDokument13 Seiten"Higher, Faster, Stronger": Championing Classroom TeachingGlobal Research and Development ServicesNoch keine Bewertungen

- Work-Related Problems and Performance Level of Senior High School TeachersDokument22 SeitenWork-Related Problems and Performance Level of Senior High School TeachersGlobal Research and Development ServicesNoch keine Bewertungen

- Global E-Learning and Experiential Opportunities For Programs and StudentsDokument12 SeitenGlobal E-Learning and Experiential Opportunities For Programs and StudentsGlobal Research and Development ServicesNoch keine Bewertungen

- Investigating The Effects of Social Media On The Well-Being of TeenagersDokument18 SeitenInvestigating The Effects of Social Media On The Well-Being of TeenagersGlobal Research and Development ServicesNoch keine Bewertungen

- The Relationship of Teaching Clarity and Student Academic Motivation in Online ClassesDokument9 SeitenThe Relationship of Teaching Clarity and Student Academic Motivation in Online ClassesGlobal Research and Development ServicesNoch keine Bewertungen

- The Hijiri Calendar and Its Conformance With The Gregorain Calendar by Mathematical CalculationsDokument19 SeitenThe Hijiri Calendar and Its Conformance With The Gregorain Calendar by Mathematical CalculationsGlobal Research and Development ServicesNoch keine Bewertungen

- Thai and Non-Thai Instructors' Perspectives On Peer Feedback Activities in English Oral PresentationsDokument22 SeitenThai and Non-Thai Instructors' Perspectives On Peer Feedback Activities in English Oral PresentationsGlobal Research and Development ServicesNoch keine Bewertungen

- Review of Vibration-Based Surface & Terrain Classification For Wheel-Based Robot in Palm Oil PlantationDokument14 SeitenReview of Vibration-Based Surface & Terrain Classification For Wheel-Based Robot in Palm Oil PlantationGlobal Research and Development ServicesNoch keine Bewertungen

- Building A Scale of Competence To Apply Interdisciplinary Integrated Knowledge Into Practice For StudentDokument10 SeitenBuilding A Scale of Competence To Apply Interdisciplinary Integrated Knowledge Into Practice For StudentGlobal Research and Development ServicesNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Modelling Colour and ChlorophyllDokument9 SeitenModelling Colour and ChlorophyllAri ArfandiNoch keine Bewertungen

- Lec 3Dokument116 SeitenLec 3Cheng Chao HanNoch keine Bewertungen

- Raw Board Battle Round 1Dokument13 SeitenRaw Board Battle Round 1Maridil Joy IsidroNoch keine Bewertungen

- How To Extract The Maximum Information From Dma TestsDokument13 SeitenHow To Extract The Maximum Information From Dma TestsGyörgy BánhegyiNoch keine Bewertungen

- Chemical Kinetic Data Base For Combustion Chemistry. Part I. Methane and ReDokument192 SeitenChemical Kinetic Data Base For Combustion Chemistry. Part I. Methane and ReMuhammad AtharNoch keine Bewertungen

- Chap 1 CREDokument24 SeitenChap 1 CREtuansyafiqNoch keine Bewertungen

- CHEM311 211 Major2 SolvedDokument9 SeitenCHEM311 211 Major2 SolvedhussainNoch keine Bewertungen

- Chemical Kinetics: Medical ChemistryDokument46 SeitenChemical Kinetics: Medical ChemistryВиталий НечипорукNoch keine Bewertungen

- Test Planner - Lakshya NEET 2024 - (Only PDFDokument2 SeitenTest Planner - Lakshya NEET 2024 - (Only PDFdakshahirwar0708Noch keine Bewertungen

- Welcome To:: Materials Science NMC 113 (2022)Dokument20 SeitenWelcome To:: Materials Science NMC 113 (2022)Lizzsel FranchesNoch keine Bewertungen

- Investigation of The Stability of The Corey-Kim IntermediateDokument5 SeitenInvestigation of The Stability of The Corey-Kim IntermediateAndrew ShiaoNoch keine Bewertungen

- Adiabatic Reactors Final Lab Group 1-ADokument22 SeitenAdiabatic Reactors Final Lab Group 1-AHaris SheikhNoch keine Bewertungen

- Paracetamol DegradationDokument9 SeitenParacetamol DegradationTruyền Phạm MinhNoch keine Bewertungen

- MODELLING OF A PACKED BED REACTOR Equipo Suri 7 y Equipo Dana 5Dokument9 SeitenMODELLING OF A PACKED BED REACTOR Equipo Suri 7 y Equipo Dana 5Reyna MariaNoch keine Bewertungen

- No. 1 Cinetica QuimicaDokument60 SeitenNo. 1 Cinetica QuimicaAngəl Javiər Pinilla BulaNoch keine Bewertungen

- Práctica A Reacción SN1Dokument3 SeitenPráctica A Reacción SN1Freddy Alexander Vija SochaNoch keine Bewertungen

- Janzer2021 Article GreenPropellantsAsAHydrazineSuDokument9 SeitenJanzer2021 Article GreenPropellantsAsAHydrazineSuAIEIMANoch keine Bewertungen

- CSTRDokument25 SeitenCSTRAinul Mardhiah Abdul Rahim100% (1)

- Kinetics of GraphitizationDokument6 SeitenKinetics of GraphitizationJaq Plin PlinNoch keine Bewertungen

- Chemical Kinetics Classnotes-374 PDFDokument41 SeitenChemical Kinetics Classnotes-374 PDFAshok ChoudharyNoch keine Bewertungen

- Intro Cre1Dokument3 SeitenIntro Cre1Kai ChernNoch keine Bewertungen

- Chemical Kinetics FRDokument6 SeitenChemical Kinetics FRJo FernandezNoch keine Bewertungen

- 10.1016@S0950 42309900061 3 PDFDokument11 Seiten10.1016@S0950 42309900061 3 PDFsameer sahaanNoch keine Bewertungen

- Chapter 3 SummaryDokument4 SeitenChapter 3 SummaryKTINE08Noch keine Bewertungen

- Activation EnergyDokument9 SeitenActivation Energyشكير قصطيNoch keine Bewertungen

- V.B. Vikram - 2004Dokument10 SeitenV.B. Vikram - 2004Anonymous w1pZcsNNoch keine Bewertungen

- Experiment 10: Iodine Clock ReactionDokument11 SeitenExperiment 10: Iodine Clock ReactionJohn NdambukiNoch keine Bewertungen

- Chemical Kinetics (M) PDFDokument41 SeitenChemical Kinetics (M) PDFNalla Umapathi Reddy75% (4)

- Reaction Mechanisms of Inorganic and Organometallic Systems by Robert B. JordanDokument532 SeitenReaction Mechanisms of Inorganic and Organometallic Systems by Robert B. JordanSreedevi Krishnakumar100% (1)

- Determination of Product Shelf Life and Activation Energy For Five Drugs of Abuse PDFDokument5 SeitenDetermination of Product Shelf Life and Activation Energy For Five Drugs of Abuse PDFMiguelArceMonroyNoch keine Bewertungen