Beruflich Dokumente

Kultur Dokumente

Chemical Bolt Catalogue-01

Hochgeladen von

antony_michaelCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chemical Bolt Catalogue-01

Hochgeladen von

antony_michaelCopyright:

Verfügbare Formate

Injection System for non-cracked concrete and brickwork

Injection System VMU

Threaded Stud VMU-A

for concrete and brickwork

Internally Threaded Sleeve

VMU-IG

for concrete and brickwork

Threaded Stud VM-A

1 meter length, to be cut to

the required length

Threaded Stud VMU-AH

for perforated brick with perfo

sleeve

Internally Threaded Sleeve

VMU-IGH

for perforated brick with perfo

sleeve

Perfo Sleeve VMU-SH

for perforated brick

www.mkt-duebel.de MKT Software 3.40

MKT Metall-Kunststoff-Technik

GmbH & Co. KG

Auf dem Immel 2

F30-F120

D-67685 Weilerbach

Cartridge VMU 150 Range of loading: 0,3 kN - 105,2 kN

suitable for silicone guns Concrete quality: C20/25 - C50/60

Content: 150ml

Brickwork: Solid and perforated brick

Material: Steel zinc plated, hot dip galvanized,

Stainless steel A4/316

On request: Stainless steel HCR

Cartridge VMU 280 Description

suitable for silicone guns

Content: 280ml, including 2

The Injection System VMU (ETA option 7) is a chemical fastening

mixers, attached to the system for non-cracked concrete. It consists of a styrene-free vinyl

cartridge ester resin plus an attached hardening agent contained in a cartridge

to be used with a threaded stud VMU-A, an internally threaded sleeve

VMU-IG, a threaded stud V-A (see pages 119) or threaded studs VM-A

(see page 82). By means of the dispenser gun VM-P the components

are injected through the mixer nozzle into the drill hole. The threaded

Cartridge VMU 300 stud is inserted manually into the drill hole. The hardened injection

suitable for silicone guns

Content: 300ml adhesive gives a secure fastening to the base material.

Advantages:

- approved in non-cracked concrete, sizes M8 to M30.

- approved for solid and perforated brickwork (M8 to M12)

- threaded Studs V-A (pages 119) and VM-A (see page 82) are also

covered by the approval.

Cartridge VMU 345 - approved with standard threaded studs (strength test required)

Side-by-side cartridge

Content: 345ml - with fire test report (loads see page 139).

- no load reduction for wet concrete

- opened cartridges can be re-used with a new mixer nozzle

- VMU express with shorter curing time during the cold season

- styrene-free

Cartridge VMU 420 Applications

Coaxial cartridge Fastenings in non-cracked concrete:

Content: 420ml

Baseplates, fastenings to walls and columns, joint tapes

Fastenings in masonry:

Canopies, door and window frames, facade substructures, battens

... a solid connection 90 2016 PR MKT

Chemical Anchors

Cartridge VMU 280

express

suitable for silicone guns

Content: 280ml

Cartridge VMU 345

express

Side-by-side cartridge

Content: 345ml

Cartridge VMU 420

express

Coaxial cartridge

Content: 420ml

Stock-Box In stackable multi-purpose container

Stock-Box, the container for various items

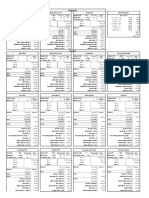

Injection Cartridge VMU Description Ref. No. Contents Quantity Weight per

Chemical Anchors

Two component cartridge, styrene-free Box

pcs. kg

Approved for non-cracked concrete and

brickwork Stock-Box VMU 300 28999166 Cartridge VMU 300 20 12,45

Static mixer VM-X 40

Description Ref. No. Content Content Weight per Weight per Stock-Box VMU 345 28999157 Cartridge VMU 345 20 15,3

of master master box piece

Static mixer VM-X 40

box kg

ml pcs kg Stock-Box VMU 420 28999195 Cartridge VMU 420 20 18,0

Cartridge VMU 150 28255261 150 12 4,20 0,34 Static mixer VM-XP 40

Cartridge VMU 2801) 28252501 280 12 6,70 0,56

Cartridge VMU 280 express 28252502 280 12 6,70 0,56 Dimensions Stock-Box

Cartridge VMU 300 28255140 300 12 6,40 0,53 Description Height Width Depth

mm mm mm

Cartridge VMU 345 28255371 345 12 8,00 0,65

Stock-Box 220 400 300

Cartridge VMU 345 express 28255380 345 12 8,00 0,65

Cartridge VMU 420 28257001 420 12 10,1 0,83

Cartridge VMU 420 express 28257020 420 12 10,1 0,83

Curing Time

Cartridge temperature when installing min. +5°C

Injection Adhesive VMU

Static mixer VM-X (for all cartridges) 28305111 - 12 0,12 0,01

Mixer extension VM-XE 10/200 (200mm) 28306011 - 12 - 0,01 Temperature (°C) of Gel time Curing time

the base materia

Mixer extension VM-XE 10/500 (500mm) 85951101 - 10 - 0,02 dry base material wet base material

One static mixer VM-X as well as one screw-on cap comes with each cartridge. -5°C 1:30 h 5:30 h 11:00 h1)

Usable length of static mixer see page 85. -4°C to -1°C 45 min 5:30 h 11:00 h1)

1)

Cartridge VMU 280 (not VMU 280 express) comes with 2 mixers.

0°C to +4°C 20 min 3:00 h 6:00 h

+5°C to +9°C 12 min 2:00 h 4:00 h

+10°C to +19°C 6 min 1:20 h 2:40 h

+20°C to +29°C 4 min 45 min 1:30 h

+30°C to +34°C 2 min 25 min 50 min

+35°C to +39°C 1,4 min 20 min 40 min

+40°C 1,4 min 15 min 30 min

1)

It must be ensured that icing does not occur in the drill hole. The hole must be drilled and cleaned

directly prior to the installation of the anchor.

Curing Time Injection

Cartridge temperature when installing min. +5°C

Adhesive VMU express

Temperature (°C) of the Gel time Curing time

base material

dry base material wet base material

-5°C 40 min 4:00 h 8:00 h1)

-4°C to -1°C 20 min 4:00 h 8:00 h1)

0°C to +4°C 10 min 2:00 h 4:00 h

+5°C to +9°C 6 min 1:00 h 2:00 h

+10°C to +19°C 3 min 40 min 80 min

+20°C to +29°C 1 min 20 min 40 min

+30°C 1 min 10 min 20 min

1)

It must be ensured that icing does not occur in the drill hole. The hole must be drilled and cleaned

directly prior to the installation of the anchor.

2016 PR MKT 91 ... a solid connection

Chemical Anchors

Threaded Studs for applications in solid and hollow base material

Threaded Stud VMU-A Threaded stud VMU-A recommended for solid base material and hollow base material with perfo sleeve

Threaded Stud VMU-AH

Steel, zinc plated 5.8 Threaded stud VMU-AH recommended for solid- and hollow base material with perfo sleeve

Stainless steel A4 / 316

Steel hot dip galvanized and stainless steel HCR (1.4529) on demand

VMU-A VMU-AH

F30-F90

Description Steel, zinc Stainless steel Maximum Solid base material Solid and hollow base material Pkg. Weight

plated 5.8 A4 / 316 Fixture without SH with SH cont. per

thickness pkg.

tfix Drill hole Ø x depth perfo sleeve Drill hole Ø x depth pcs. kg

Ref. No. Ref. No. mm mm mm

VMU-A 8-10/100 31510101 31510501 10 10 x 85 VMU-SH 14x100 14 x 105 10 0,42

VMU-A 8-20/110 31515101 31515501 20 10 x 85 VMU-SH 14x100 14 x 105 10 0,46

VMU-A 8-40/130 31525101 31525501 40 10 x 85 VMU-SH 14x100 14 x 105 10 0,52

VMU-A 8-55/145 31528101 31528501 55 10 x 85 VMU-SH 14x100 14 x 105 10 0,55

VMU-A 8-70/160 31530101 31530501 70 10 x 85 VMU-SH 14x100 14 x 105 10 0,60

VMU-A 8-115/205 31550101 31550501 115 10 x 85 VMU-SH 14x100 14 x 105 10 0,74

VMU-A 10-10/110 31605101 31605501 10 12 x 95 VMU-SH 16x100 16 x 105 10 0,75

VMU-A 10-30/130 31625101 31625501 30 12 x 95 VMU-SH 16x100 16 x 105 10 0,85

VMU-A 10-50/150 31630101 31630501 50 12 x 95 VMU-SH 16x100 16 x 105 10 0,95

VMU-A 10-65/165 31635101 31635501 65 12 x 95 VMU-SH 16x100 16 x 105 10 1,02

VMU-A 10-90/190 31645101 31645501 90 12 x 95 VMU-SH 16x100 16 x 105 10 1,15

VMU-A 10-160/260 31655101 31655501 160 12 x 95 VMU-SH 16x100 16 x 105 10 1,50

Chemical Anchors

VMU-A 12-15/120 31717101 31717501 15 14 x 98 - 10 1,14

VMU-A 12-25/130 31718101 31718501 25 14 x 98 - 10 1,21

VMU-A 12-50/155 31732101 31732501 50 14 x 98 - 10 1,42

VMU-A 12-80/185 31734101 31734501 80 14 x 98 - 10 1,63

VMU-A 12-120/225 31748101 31748501 120 14 x 98 - 10 1,89

VMU-A 12-160/265 31757101 31757501 160 14 x 98 - 10 2,18

VMU-AH 12-15/120 31302181 31302581 15 - VMU-SH 16x100 16 x 105 10 0,92

VMU-AH 12-25/130 31304181 31304581 25 - VMU-SH 16x100 16 x 105 10 0,99

VMU-AH 12-50/155 31306181 31306581 50 - VMU-SH 16x100 16 x 105 10 1,18

VMU-AH 12-80/185 31310181 31310581 80 - VMU-SH 16x100 16 x 105 10 1,38

VMU-AH 12-120/225 31312181 31312581 120 - VMU-SH 16x100 16 x 105 10 1,68

VMU-AH 12-160/265 31315181 31315581 160 - VMU-SH 16x100 16 x 105 10 1,97

Internally Threaded Sleeve Internally Threaded Sleeve

With internal thread With internal thread

VMU-IG VMU-IGH

Steel, zinc plated 5.8 Recommended for solid base material without Steel, zinc plated 5.8 Recommended for solid and hollow base

perfo sleeve material with perfo sleeve

Stainless steel A4 / 316 Stainless steel A4 / 316

Description Steel, zinc Stainless Drill hole Outer-Ø x Thread depth Package Weight per Description Steel, zinc Stainless Drill hole Outer-Ø x Thread depth Package Weight per

plated 5.8 steel Ø x depth anchor min s / max s content pkg. plated 5.8 steel Ø x depth anchor min s / max s content pkg.

A4 / 316 length A4 / 316 length kg

Ref. No. Ref. No. mm mm mm pcs. kg Ref. No. Ref. No. mm mm mm pcs.

VMU-IG M6 31500101 31500501 12 x 98 10 x 93 8 / 20 10 0,50 VMU-IGH M 6 31060111 31060511 16x105 12 x 93 8 / 20 10 0,50

VMU-IG M8 31560101 31560501 14 x 98 12 x 93 8 / 20 10 0,60 VMU-IGH M 8 31160111 31160511 16x105 12 x 93 8 / 20 10 0,50

Perfo SleeveVMU-SH

Polypropylene

Recommended for solid and hollow base

material

Description Ref. No. Drill hole suitable for Package Weight per

Ø x depth content pkg.

threaded internally

mm pcs kg

studs threaded sleeves

VMU-SH 14x100 28171301 14x105 M8 10 0,03

VMU-SH 16x100 28171501 16x105 M10-M121) IGH M6-M8 10 0,04

1)

M12 only as VMU-AMH

2016 PR MKT 93 ... a solid connection

Cleaning Brush RB M6

With connection thread M6 – extension for large depths of drill hole and/or for through-setting installation

For drilling machines with keyed chuck or with SDS adaptor for SDS plus drills

RB M6, with connection thread M6

Description Ref. No. Suitable for Total length Base Suitable for Pkg. Weight

drill hole Ø of brush material cont. per piece

mm mm Threaded stud Internally threaded sleeve pcs kg

RB 10 M6 33510101 10 130 concrete VMU-A M8 - 1 0,05

RBL M6, with internal and external thread M6 RB 12 M6 33512101 12 140 concrete VMU-A M10 VMU-IG M6 1 0,05

RB 14 M6 33514101 14 180 concrete VMU-A M12 VMU-IG M8 1 0,05

RB 18 M6 33518101 18 200 concrete VMU-A M16 - 1 0,05

RB 22 M6 33522101 22 220 concrete VMU-A M20 - 1 0,05

RBL M6 SDS, with internal thread M6

RB 26 M6 33526101 26 290 concrete VMU-A M24 - 1 0,06

RB 32 M6 33532101 32 350 concrete VMU-A M30 - 1 0,06

RBL M6 33968101 Brush extention 150mm with connection thread M6 1 0,09

RBL M6 SDS 33350101 SDS Plus adapter with internal thread M6 1 0,06

Drill hole cleaning in solid and hollow base material

Description Ref. No. Suitable for lenght of Base Suitable for Pkg. Weight

drill hole Ø brush material cont. per piece

mm Threaded stud Int. threaded sleeve pcs kg

RB-H 18 Nylon, with handle RB-H 18/280 29918501 10-16 250 brickwork all all 1 0,04

RB-H 18/400 33618101 10-16 400 brickwork all all 1 0,05

Blow-out pump VM-AP Drill hole cleaning for VMU-A / VMU-AH M8-M16 and VMU-IG / VMU-IGH M6-M8

Description Ref. No. Suitable for maximum Pkg. Weight

depth of drill hole cont. per piece

mm pcs kg

VM-AP 360, blow-out pump 33200101 330 1 0,27

Air gun VM-ABP Drill hole cleaning with compressed air for VMU-A M20-M30

Description Ref. No. Nozzle Ø Suitable for maximum For drill Pkg. Weight

depth of drill hole hole Ø cont. per piece

mm mm mm pcs kg

VM-ABP 250 33100101 16 240 18-40 1 1,00

VM-ABP 500 33106101 16 480 18-40 1 1,30

Dispenser VM-P Profi Professional dispenser with an ideal center of gravity for more comfortable working

Automatic pressure release for minimum mortar overrun

Description Ref. No. Suitable for cartridge Pkg. cont. Weight per piece

pcs. kg

VM-P 345 Profi 28350511 150ml, 280ml, 300ml, 345ml also suitable for silicone cartridges 1 1,00

VM-P 380 Profi 28351001 380ml, 410ml, 420ml 1 1,10

Dispenser VM-P Standard

For occasional use, metal version

Piston rod with adjusting screw

Description Ref. No. Suitable for cartridge Pkg. cont. Weight per piece

pcs. kg

VM-P 345 Standard 28350505 150ml, 280ml, 300ml, 345ml also suitable for silicone cartridges 1 1,00

VM-P 380 Standard 28353005 380ml, 410ml, 420ml 1 1,15

Dispenser VM-P Pneumatic Professional air tool with an optimum center of gravity and quick cartridge exchange

Automatic pressure release system reduces mortar overrun to a minimum

Single-hand pressure regulation to adjust the piston speed

Description Ref. No. Suitable for cartridge Pkg. cont. Weight per piece

pcs. kg

VM-P 345 Pneumatic 28350601 345ml max. working pressure 8bar, 40l/min 1 2,41

VM-P 380 Pneumatic 28352002 380ml, 410ml, 420ml max. working pressure 8bar, 40l/min 1 2,00

... a solid connection 94 2016 PR MKT

Chemical Anchors

Recommended loads for single anchor without influence of spacing and edge distance.

Total safety factor as per ETAG 001 included (γM and γF). 5)

Loads and per- Injection System VMU with threaded stud VMU-A/AH/IG/IGH VMU-A VMU-AH VMU-IG/VMU-IGH

formance data steel z.p. / s.s. A4 /316 / s.s. HCR in masonry

M8 M 10 M 12 M 12 M6 M8

Recommended bending moments (Steel, zinc plated 5.8) appr. M [Nm] 11,0 21,0 37,0 37,0 4,4 11,0

Recommended bending moments (Stainless steel A4/316) appr. M [Nm] 12,0 24,0 42,0 42,0 4,9 12,0

Recommended bending moments (Stainless steel HCR 1.4529) appr. M [Nm] 9,4 19,0 33,0 33,0 4,9 9,4

Spacing and edge distance

Effective anchorage depth hef [mm] 80 90 93 93 93 93

Spacing (Anchor group) a> [mm] 100 (200)1)

Minimum spacing min a [mm] 502)

Spacing (single anchor) az [mm] 250

Edge distance ar > [mm] 200 (250)3)

Edge distance for special applications ar [mm] 50 (60)3)

Minimum thickness of base material (masonry) hmin [mm] 110

Installation parameters

Thread length of screw/threaded stud min s [mm] - - - - 8 8

max s [mm] - - - - 20 20

Diameter of drill hole with perfo sleeve do [mm] 14 16 - 16 16 16

Dia. of drill hole without perfo sleeve (solid base material) do [mm] 10 12 14 - 12 14

Clearance hole in the fixture df [mm] 9 12 14 14 7 9

Depth of drill hole with perfo sleeve h0 [mm] 105 105 - 105 105 105

Depth of drill hole without perfo sleeve h0 [mm] 85 95 98 - 98 98

Installation torque < Tinst [Nm] 84) 84) 84) 84) 84) 84)

Diameter cleaning brush RB-H 18 dB [mm] 18 18 18 18 18 18

Amount of mortar per drill hole with perfo sleeve [ml] 15,0 21,0 - 21,0 21,0 21,0

Chemical Anchors

Amount of mortar per drill hole without perfo sleeve [ml] 5,2 7,3 9,8 - 7,3 9,8

Drill holes per cartridge with perfo sleeve VMU 150 / 280 / 300 [Quan.] 7 / 16 / 17 5 / 11 / 12 - 5 / 11 / 12 5 / 11 / 12 5 / 11 / 12

Drill holes per cartridge with perfo sleeve VMU 345 / 420 [Quan.] 20 / 25 14 / 18 - 14 / 18 14 / 18 14 / 18

Drill holes per cart. without perfo sleeve VMU 150 / 280 / 300 [Quan.] 21 / 46 / 50 15 / 32 / 35 11 / 24 / 26 - 15 / 32 / 35 11 / 24 / 26

Drill holes per cart. without perfo sleeve VMU 345 / 420 [Quan.] 58 / 73 41 / 52 31 / 38 - 41 / 52 31 / 38

1)

Value in brackets for Hbl (Hollow block concrete, according to DIN 18151) and 3)

Value in brackets valid for solid brick.

Hbn (Hollow block concrete, DIN 18153). 4)

2 Nm if anchor plate is not seated solidly on surface of base material.

2)

min a not valid for Hbl and Hbn brickwork. 5)

max. long term temperature +50°C / max. short term temperature +80°C.

Recommended loads in masonry Solid brick Solid sand- Vertical Sand-lime Hollow block Hollow block

for all load directions lime perforated brick perforated brick lightw. concrete concrete

Mz 12 KS 12 HLz 4 HLz 6 HLz 12 KSL 4 KSL 6 KSL 12 Hbl 2 Hbl 4 Hbn 4

Drilling with rotation only [kN] 1,7 1,7 0,6 0,8 1,0 0,61) 0,81) 1,41) 0,5 0,8 0,8

Drilling with hammer action [kN] 1,7 1,7 0,3 0,4 0,8 0,4 0,6 0,8 0,3 0,6 0,6

1)

Outer web > 30mm

Maximum load for single brick < 3 DF1) 4 to 10 DF1) > 10 DF1)

Unburdened masonry max. F [kN] 1,0 1,4 2,0

Burdened masonry max. F [kN] 1,4 1,7 2,5

1)

Dimension of brick acc. to DIN-Standard

ho

Tinst

hef

h m hmin tfix

Installation

+20 °C

Tinst

Nm

45 min.

2016 PR MKT 97 ... a solid connection

Das könnte Ihnen auch gefallen

- PWD Schedule of Rates For Civil Works 2014 PDFDokument146 SeitenPWD Schedule of Rates For Civil Works 2014 PDFSanjoy Roy83% (58)

- 350 - Tray Installation Manual - EngDokument36 Seiten350 - Tray Installation Manual - EngRashid MadathilNoch keine Bewertungen

- Estimating & CostingDokument10 SeitenEstimating & CostingJohn G JoseNoch keine Bewertungen

- DPR Format of Civil Engineers in Excel FormatDokument14 SeitenDPR Format of Civil Engineers in Excel Formatanilkumar1811197664% (28)

- Technical Data Sheet For HIT-HY 270 Injectable Anchor For Masonry Technical Information ASSET DOC 4098527Dokument22 SeitenTechnical Data Sheet For HIT-HY 270 Injectable Anchor For Masonry Technical Information ASSET DOC 4098527Johneal MatiasNoch keine Bewertungen

- Aac Blocks PDFDokument8 SeitenAac Blocks PDFTulika GalaniNoch keine Bewertungen

- Engg - Ref - Book (Steel Weight Cal.)Dokument246 SeitenEngg - Ref - Book (Steel Weight Cal.)Anonymous Iev5ggSRNoch keine Bewertungen

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleVon EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleBewertung: 5 von 5 Sternen5/5 (1)

- Al Naboodah - Compliance StatementDokument5 SeitenAl Naboodah - Compliance StatementrexNoch keine Bewertungen

- Hilti Hit-Re-500 PDFDokument68 SeitenHilti Hit-Re-500 PDFSumanta BhayaNoch keine Bewertungen

- Alumina Bricks PDFDokument64 SeitenAlumina Bricks PDFpurohit_manishNoch keine Bewertungen

- 041125FehnEssayFinal PDFDokument26 Seiten041125FehnEssayFinal PDFHerminio PagnoncelliNoch keine Bewertungen

- MYSORE URBAN DEVELOPMENT AUTHORITY PROJECT ESTIMATEDokument5 SeitenMYSORE URBAN DEVELOPMENT AUTHORITY PROJECT ESTIMATESunilkumar CeNoch keine Bewertungen

- TARA Machines markets green building solutionsDokument8 SeitenTARA Machines markets green building solutionsBaba Jee Shiva ShankarNoch keine Bewertungen

- Hilti Hit Hy 170Dokument37 SeitenHilti Hit Hy 170Adhil RamsurupNoch keine Bewertungen

- Allweiler NTTDokument12 SeitenAllweiler NTTSalsa Amorir50% (2)

- Volute Casing Centrifugal Pumps for Heat Transfer Oils up to 350°CDokument12 SeitenVolute Casing Centrifugal Pumps for Heat Transfer Oils up to 350°CjambukuningNoch keine Bewertungen

- Model Estimate For Hume Pipe Culvert Dia - 600 MMDokument6 SeitenModel Estimate For Hume Pipe Culvert Dia - 600 MMNirmal Singh AdhikariNoch keine Bewertungen

- Injection System VMUplusDokument15 SeitenInjection System VMUplusmohamed rafiNoch keine Bewertungen

- Injection System VMHDokument14 SeitenInjection System VMHcodrutNoch keine Bewertungen

- MKT KatalogDokument193 SeitenMKT KatalogÜstün Onur BaktırNoch keine Bewertungen

- Kat VME Rebar EngDokument3 SeitenKat VME Rebar EngArghaNoch keine Bewertungen

- DESIGN GUIDANCE - Sustainable Masonry LintelsDokument3 SeitenDESIGN GUIDANCE - Sustainable Masonry LintelsSyamil DzulfidaNoch keine Bewertungen

- LMVMC 0107 UsDokument4 SeitenLMVMC 0107 UsRioga RiogaNoch keine Bewertungen

- Schletter-Product_Sheets-Roof_Systems-Beaver_Tail_Roof_HooksDokument6 SeitenSchletter-Product_Sheets-Roof_Systems-Beaver_Tail_Roof_Hooksf789sgacanonNoch keine Bewertungen

- Hilti HIT-HY 270 mortar for high-performance masonry fasteningDokument26 SeitenHilti HIT-HY 270 mortar for high-performance masonry fasteningH (Chief11)Noch keine Bewertungen

- Series FV: Cantilever Sump PumpsDokument4 SeitenSeries FV: Cantilever Sump PumpsFranciscoNoch keine Bewertungen

- FTM Hit-Re 500 v3 Hit-VDokument12 SeitenFTM Hit-Re 500 v3 Hit-VfdfazfzNoch keine Bewertungen

- Technical Data Sheet For HIT-HY 270 Injectable Anchor For Masonry Technical Information ASSET DOC 4098527Dokument29 SeitenTechnical Data Sheet For HIT-HY 270 Injectable Anchor For Masonry Technical Information ASSET DOC 4098527Rui Gavina100% (1)

- HILTI Chemical Injection AnchoringDokument6 SeitenHILTI Chemical Injection AnchoringBaden Lim-bonautNoch keine Bewertungen

- Hilti HIT-RE 500-SD With HIT-V Rod Hilti HIT-RE 500-SD With HIT-V RodDokument26 SeitenHilti HIT-RE 500-SD With HIT-V Rod Hilti HIT-RE 500-SD With HIT-V RodAktif FA Konsult Sdn BhdNoch keine Bewertungen

- Anchor Fastening Technology Manual: Hilti HIT-HY 270 Mortar For MasonryDokument29 SeitenAnchor Fastening Technology Manual: Hilti HIT-HY 270 Mortar For MasonryFrancisco RojasNoch keine Bewertungen

- Technical Data Sheet For HIT HY 270 Injectable Anchor Mortar For Masonry Technical Information ASSET DOC 4098527Dokument33 SeitenTechnical Data Sheet For HIT HY 270 Injectable Anchor Mortar For Masonry Technical Information ASSET DOC 4098527NGUYENNoch keine Bewertungen

- HY 270 With HAS-U A (Yr 2021)Dokument10 SeitenHY 270 With HAS-U A (Yr 2021)Stephen WongNoch keine Bewertungen

- Fischer Frame Fixings: The Complete Product Range For All RequirementsDokument22 SeitenFischer Frame Fixings: The Complete Product Range For All RequirementsARYANoch keine Bewertungen

- Push-In/threaded L-Fitting QSL-G1/8-6: Catalogue PageDokument4 SeitenPush-In/threaded L-Fitting QSL-G1/8-6: Catalogue Pageabrap_dNoch keine Bewertungen

- TDS Hy 170Dokument14 SeitenTDS Hy 170Vengatesh HariNoch keine Bewertungen

- Push-in fittings catalogueDokument4 SeitenPush-in fittings catalogueRamon rodenciaNoch keine Bewertungen

- PSI Casing End Seals For Carrier Pipe End SealDokument10 SeitenPSI Casing End Seals For Carrier Pipe End SealvenkateshwaranNoch keine Bewertungen

- Multiple Distributor QSQ-6-4: Catalogue PageDokument4 SeitenMultiple Distributor QSQ-6-4: Catalogue PagepauloNoch keine Bewertungen

- Kat V EngDokument4 SeitenKat V EngmiliNoch keine Bewertungen

- Technical Data Sheet For HVU2 Adhesive Capsule With Rods Technical Information ASSET DOC 8000652Dokument17 SeitenTechnical Data Sheet For HVU2 Adhesive Capsule With Rods Technical Information ASSET DOC 8000652Ramesh TiruttaniNoch keine Bewertungen

- Kingspan - Trapezoidal Wall KS1000 RW - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENDokument12 SeitenKingspan - Trapezoidal Wall KS1000 RW - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENlames1Noch keine Bewertungen

- Pulleys and Sheaves 1060Dokument84 SeitenPulleys and Sheaves 1060m s sankar raoNoch keine Bewertungen

- MBT CouplersDokument10 SeitenMBT Couplersboris1516Noch keine Bewertungen

- HY 200 - RebarDokument19 SeitenHY 200 - RebarPrasad ThambadNoch keine Bewertungen

- 4 - Compakt Seals Special - GB - 2012Dokument5 Seiten4 - Compakt Seals Special - GB - 2012Akshay PoddarNoch keine Bewertungen

- L&M Model 145Dokument4 SeitenL&M Model 145Capacitacion TodocatNoch keine Bewertungen

- Technical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Dokument42 SeitenTechnical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Kovacs Zsolt-Istvan100% (1)

- 940 601 Ball Transfer For Air CargoDokument2 Seiten940 601 Ball Transfer For Air CargoHyundianto AgNoch keine Bewertungen

- ISO-Certified Extruder Gearbox SolutionsDokument4 SeitenISO-Certified Extruder Gearbox SolutionsMGCS Servicios IndustrialesNoch keine Bewertungen

- Push-In Bulkhead Connector QSS-4: Catalogue PageDokument4 SeitenPush-In Bulkhead Connector QSS-4: Catalogue PagepauloNoch keine Bewertungen

- Technical Data Sheet For HVU2 Adhesive Capsule With Rods Technical Information ASSET DOC 8000652Dokument17 SeitenTechnical Data Sheet For HVU2 Adhesive Capsule With Rods Technical Information ASSET DOC 8000652Kovacs Zsolt-IstvanNoch keine Bewertungen

- Frame Fixing - Nylon and Metal Anchors For FramesDokument22 SeitenFrame Fixing - Nylon and Metal Anchors For FramesjulianNoch keine Bewertungen

- RB425 4 InchDokument2 SeitenRB425 4 Inchmustafa.e.ahmed2017Noch keine Bewertungen

- Topdek PIR Installation Guide A5 Sept 2020Dokument12 SeitenTopdek PIR Installation Guide A5 Sept 2020fahim007Noch keine Bewertungen

- SF HY270 (Brickwork) + HAS-U (Dec 2019) CompactDokument11 SeitenSF HY270 (Brickwork) + HAS-U (Dec 2019) CompactStephen WongNoch keine Bewertungen

- WCC Colmonoy 200 Series - TDSDokument3 SeitenWCC Colmonoy 200 Series - TDSedipson100% (2)

- 02 Standard Pipe Press Seal HSD-SSG PDFDokument4 Seiten02 Standard Pipe Press Seal HSD-SSG PDFVlad NistorNoch keine Bewertungen

- SXRL Data SheetDokument5 SeitenSXRL Data SheetARYANoch keine Bewertungen

- Chezy PP Chamber CatalogueDokument6 SeitenChezy PP Chamber CatalogueYong QingNoch keine Bewertungen

- RE100 With HAS RodsDokument8 SeitenRE100 With HAS RodssahanNoch keine Bewertungen

- Knauf Hammer Fixing ScrewDokument2 SeitenKnauf Hammer Fixing ScrewAmir SohailNoch keine Bewertungen

- Push-In/threaded L-Fitting QSML-M5-4: Catalogue PageDokument4 SeitenPush-In/threaded L-Fitting QSML-M5-4: Catalogue Pageabrap_dNoch keine Bewertungen

- Ancon 25-14 Restraint SystemDokument2 SeitenAncon 25-14 Restraint SystemabudabeejajaNoch keine Bewertungen

- Hilti Hit Re 500 SD Hit VDokument26 SeitenHilti Hit Re 500 SD Hit Vhector saavedraNoch keine Bewertungen

- VSL - BarrasDokument10 SeitenVSL - BarrasJoão VenturaNoch keine Bewertungen

- HY-200 With HIT-V or HAS-EDokument8 SeitenHY-200 With HIT-V or HAS-EUmer NaeemNoch keine Bewertungen

- Hilti HIT-RE 500 Injection Mortar System Design GuideDokument24 SeitenHilti HIT-RE 500 Injection Mortar System Design Guidemukim0201004Noch keine Bewertungen

- Kat LP EngDokument143 SeitenKat LP Engqsdpfyb2c5Noch keine Bewertungen

- EagleBurgmann - AP4-BKTE - E4 - API 682 4th Edition Piping Plans - EN - 30.05.2017Dokument68 SeitenEagleBurgmann - AP4-BKTE - E4 - API 682 4th Edition Piping Plans - EN - 30.05.2017Saqib AminNoch keine Bewertungen

- NPT Threaded and Socket Welding Fittings ANSI Standard 3000lbsDokument10 SeitenNPT Threaded and Socket Welding Fittings ANSI Standard 3000lbsdandan29Noch keine Bewertungen

- Sr. No. Description Unit Total Qty Unit Rate Amount 1 PipeDokument1 SeiteSr. No. Description Unit Total Qty Unit Rate Amount 1 Pipeantony_michaelNoch keine Bewertungen

- B o MDokument14 SeitenB o Mantony_michaelNoch keine Bewertungen

- Coping and CappingDokument15 SeitenCoping and CappingWawaChumelNoch keine Bewertungen

- RVS SCREENING OF MASONRY BUILDINGSDokument14 SeitenRVS SCREENING OF MASONRY BUILDINGSTpa ZadengNoch keine Bewertungen

- PWD Project ReportDokument20 SeitenPWD Project ReportSandeep PatelNoch keine Bewertungen

- Earthwork excavation and concrete work documentDokument12 SeitenEarthwork excavation and concrete work documentMd Mukarram RezaNoch keine Bewertungen

- PWD Schedule of Rates 2014Dokument269 SeitenPWD Schedule of Rates 2014Md. Ibrahim KhalilNoch keine Bewertungen

- Principles of Geotechnical Engi - Braja M. Das Khaled SobhanDokument11 SeitenPrinciples of Geotechnical Engi - Braja M. Das Khaled SobhanshivaNoch keine Bewertungen

- Baguma Abel 07/U/4744/EXTDokument48 SeitenBaguma Abel 07/U/4744/EXTEng-Mukhtaar CatooshNoch keine Bewertungen

- Design and Evaluation of Biomass FurnaceDokument18 SeitenDesign and Evaluation of Biomass FurnaceChie ChieNoch keine Bewertungen

- GreenScan Lightweight Panel Provides Complete Building SolutionDokument65 SeitenGreenScan Lightweight Panel Provides Complete Building Solutiondeanz_75Noch keine Bewertungen

- Quatation - 05.12.09Dokument8 SeitenQuatation - 05.12.09Jason Fisher100% (1)

- Itemwise Detailed Technical SpecificationDokument3 SeitenItemwise Detailed Technical Specificationanku4frenzNoch keine Bewertungen

- SOR GandhinagarDokument212 SeitenSOR GandhinagarRakesh7770Noch keine Bewertungen

- Writing Task 1 - DiagramDokument7 SeitenWriting Task 1 - DiagramMeggie NguyenNoch keine Bewertungen

- Vol. 3 - BOQDokument22 SeitenVol. 3 - BOQpravassNoch keine Bewertungen

- Environmental Regulations and The Indian Brick Industry: Sameermaithel R.UmaDokument2 SeitenEnvironmental Regulations and The Indian Brick Industry: Sameermaithel R.UmaAnonymous DH7sVjaZONoch keine Bewertungen

- Novel redesign of autoclaves improves platinum refiningDokument5 SeitenNovel redesign of autoclaves improves platinum refiningHabram Miranda AlcantaraNoch keine Bewertungen

- 40+ Construction Tools List With Images For Building ConstructionDokument31 Seiten40+ Construction Tools List With Images For Building ConstructionJohn NjunwaNoch keine Bewertungen

- How The Diamond Works - The Italian Ceramic Tile IndustryDokument5 SeitenHow The Diamond Works - The Italian Ceramic Tile IndustrySatYam VaRmaNoch keine Bewertungen

- Ties - Hr+sbaDokument3 SeitenTies - Hr+sbatkarrardohaNoch keine Bewertungen

- PGH Brick-Commons-Paint Grade Common (BR)Dokument1 SeitePGH Brick-Commons-Paint Grade Common (BR)amewypm730Noch keine Bewertungen

- LONTTO Block Machine CatalogueDokument18 SeitenLONTTO Block Machine Cataloguemichael2Noch keine Bewertungen