Beruflich Dokumente

Kultur Dokumente

Ma 1C7-C03 U

Hochgeladen von

richintukOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ma 1C7-C03 U

Hochgeladen von

richintukCopyright:

Verfügbare Formate

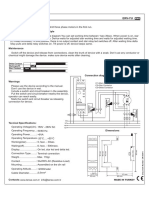

Installation Instruction

for ½” annular corrugation cable MA_1C7-C03_U

60S1C7-C03 60K1C7-C03 53S1C7-C03 53K1C7-C03 64S1C7-C03 64K1C7-C03

Dieses Dokument ist urheberrechtlich geschützt ● This document is protected by copyright ● Rosenberger Hochfrequenztechnik GmbH & Co. KG

A)

SLZ0002-000 SLT001-C03

Torque Wrench SLZ0009-000 • Cut your cable with tool of picture A)

acc. to series SLZ0009-001 • Straighten the first 200mm of the cable.

SLZ0009-003

1) Insert the cable into the jacket stripping 2) Insert the cable into the jacket cutter, 3) Remove cable jacket until the mark

tool and remove about 20 mm of the annular nose in cable groove and cut done by the jacket blade.

cable jacket. the jacket and cable outer conductor.

4) Control the cut surfaces 5) Remove the cable outer conductor and 6) If needed, clean the cable inner

dielectric. Tool: 99W057-000 conductor with stripper, avoid any

-001 damages, scratches on the inner

-002 contact. Tool: SLT004-000

7) mark inner conductor by means of 8) cut the inner conductor at the marked 9) Sharpen the inner conductor of the

gauge : SLT009-000 position. Tool: 99W057-003 cable with the striping tool.

RF_35/06.10/1.0

Rosenberger Hochfrequenztechnik GmbH & Co. KG Page

Tel. : +49 8684 18-0

P.O.Box 1260 D-84526 Tittmoning Germany

Email : info@rosenberger.de

www.rosenberger.de 1/2

Installation Instruction

for ½” annular corrugation cable MA_1C7-C03_U

Dieses Dokument ist urheberrechtlich geschützt ● This document is protected by copyright ● Rosenberger Hochfrequenztechnik GmbH & Co. KG

10) Deburr the inner conductor with brush 11) Check the dimensions 12) Slide back nut onto the cable until it is

and control the roundness of outer Serie X completely seated. Please loose sealing

conductor N and 7-16 7 nut slightly (not complete) in order to

4.3-10 4 easily install the back nut.

13) Press clamp ring on outer conductor. 14) Expanding outer conductor on one 15) Insert center conductor into flaring tool´s

point with a screwdriver. hole marked with ½”, start in expanded

point then press and spin the tool to

flare outer conductor.

16) Proper shape after flaring operation. 18) Put connector head by hand onto the

Please don´t hurt inner contact. Push 17) clean the cable end with brush, cable and fix it with the back nut by

back nut until clamp ring slides into alcohol and compressed air. hand.Only turn the back nut, not the

the back nut. connector head.

19) Tighten connector head and back nut 20) Tighten sealing nut with wrenches

with wrenches until stop. (Recommended torque: 5-8Nm;

(Recommended torque: 18-22Nm; Proof torque: 15Nm)

Proof torque 25Nm)

Link for Video: https://www.youtube.com/watch?v=yMMhysZPvB0

Draft Date Approved Date Rev. Engineering change number Name Date

RF_35/06.10/1.0

J. Gramsamer 13.08.2017 M. Wimmer 01.12.2017 b00 17-0003 S. Krautenb. 01.12.2017

Rosenberger Hochfrequenztechnik GmbH & Co. KG Page

Tel. : +49 8684 18-0

P.O.Box 1260 D-84526 Tittmoning Germany

Email : info@rosenberger.de

www.rosenberger.de 2/2

Das könnte Ihnen auch gefallen

- Ma 1C7-CX5 UDokument2 SeitenMa 1C7-CX5 Urichintuk100% (1)

- 315Wp - 72 Cell - 35mm FrameDokument2 Seiten315Wp - 72 Cell - 35mm FrameIshan ShahadeNoch keine Bewertungen

- Euromold k200lrDokument9 SeitenEuromold k200lrElecmor06 Elecmor06Noch keine Bewertungen

- Quick Guide: Replacement of The SUN2000 - (8KTL-12KTL) andDokument25 SeitenQuick Guide: Replacement of The SUN2000 - (8KTL-12KTL) andWagner FerreiraNoch keine Bewertungen

- WEG Molded Case Circuit Breakers: User's ManualDokument12 SeitenWEG Molded Case Circuit Breakers: User's ManualfelipeNoch keine Bewertungen

- Service Manual: Gr-Pd1Ek, Gr-Pd1Ex, Gr-Pd1Ey, Gr-Pd1EzDokument24 SeitenService Manual: Gr-Pd1Ek, Gr-Pd1Ex, Gr-Pd1Ey, Gr-Pd1EzchimcamNoch keine Bewertungen

- 31043898MMIK000103 Installation GuideV02Dokument6 Seiten31043898MMIK000103 Installation GuideV02Himanshu GondNoch keine Bewertungen

- Mps & Itt - Spiral SteelDokument23 SeitenMps & Itt - Spiral SteelSiswo YuwonoNoch keine Bewertungen

- Fine Adjust Crimp ApplicatorDokument5 SeitenFine Adjust Crimp ApplicatorAmine MaaouiNoch keine Bewertungen

- Denon DN-S3500Dokument60 SeitenDenon DN-S3500Tevel ComNoch keine Bewertungen

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionDokument10 SeitenEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidNoch keine Bewertungen

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionDokument10 SeitenEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidNoch keine Bewertungen

- Manual Instalación Radar Furuno 1622iDokument24 SeitenManual Instalación Radar Furuno 1622ipevalpevalNoch keine Bewertungen

- High voltage discharge rod EST for damped discharge and earthingDokument2 SeitenHigh voltage discharge rod EST for damped discharge and earthingAchira DasanayakeNoch keine Bewertungen

- Product: Torsional Vibration Meter - Type 2523Dokument4 SeitenProduct: Torsional Vibration Meter - Type 2523jhon vargas100% (1)

- Acl 079 ProvisoryDokument8 SeitenAcl 079 ProvisoryRuben KammingaNoch keine Bewertungen

- DJ Mixer Service Manual GuideDokument43 SeitenDJ Mixer Service Manual Guidesava kovskNoch keine Bewertungen

- ABC Construction StandardsDokument16 SeitenABC Construction StandardswolverinepNoch keine Bewertungen

- IM&OM - PC-AR - enDokument12 SeitenIM&OM - PC-AR - enzodenapeNoch keine Bewertungen

- Cdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFDokument87 SeitenCdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFMilciades MurilloNoch keine Bewertungen

- Service Manual: GR-D93US, GR-D94USDokument22 SeitenService Manual: GR-D93US, GR-D94USsilictronicNoch keine Bewertungen

- M22520 2 01 HarwinDokument5 SeitenM22520 2 01 Harwin이용일Noch keine Bewertungen

- DX-40, DX-60, DX-40 PLUS, DX-60 PLUS: FeaturesDokument4 SeitenDX-40, DX-60, DX-40 PLUS, DX-60 PLUS: FeaturesIulia GvrNoch keine Bewertungen

- T-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Dokument23 SeitenT-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Abdulhanan Shaukat AliNoch keine Bewertungen

- Pentax Me Super Service ManualDokument33 SeitenPentax Me Super Service Manualopenid_NBsrljQi0% (1)

- JLN 550 eDokument10 SeitenJLN 550 eCostas PeppasNoch keine Bewertungen

- Electronic Traffic Avoidance System D1RW3-W-0-FDokument21 SeitenElectronic Traffic Avoidance System D1RW3-W-0-FGui233Noch keine Bewertungen

- C 304 PDFDokument2 SeitenC 304 PDFWilliam DiasNoch keine Bewertungen

- Features: P-9903 Loop Relay ModuleDokument2 SeitenFeatures: P-9903 Loop Relay ModuleHiteshgangeleNoch keine Bewertungen

- 11kvcableterminationheatshrinkkits3core16-25sqmmsps3tis-12x-a-170810144849Dokument7 Seiten11kvcableterminationheatshrinkkits3core16-25sqmmsps3tis-12x-a-170810144849Talha BurnyNoch keine Bewertungen

- Sunlord Wire Wound Chip Balun Transformer SpecsDokument3 SeitenSunlord Wire Wound Chip Balun Transformer SpecskishordaNoch keine Bewertungen

- TV-F2400 Service ManualDokument37 SeitenTV-F2400 Service ManualAndré LeftNoch keine Bewertungen

- Videocon - Chassis Nano3 CST - Nano4 CSTDokument29 SeitenVideocon - Chassis Nano3 CST - Nano4 CSTchanchaldatta0% (1)

- Hollow Silica Waveguide Usage Guide and Test Process OverviewDokument3 SeitenHollow Silica Waveguide Usage Guide and Test Process OverviewAnonymous cgKtuWzNoch keine Bewertungen

- Retrofit cable guard plate sensor instructions JSK 37 CDokument1 SeiteRetrofit cable guard plate sensor instructions JSK 37 Ctito del pinoNoch keine Bewertungen

- XST-3535-UV Surface Mount Uvc LedDokument12 SeitenXST-3535-UV Surface Mount Uvc LeddezdeepblueNoch keine Bewertungen

- HifiDokument50 SeitenHifigolddigger19890% (1)

- Service Manual: Color TelevisionDokument21 SeitenService Manual: Color TelevisionLuis MorenoNoch keine Bewertungen

- Miniature Carbon Potentiometers Spec SheetDokument1 SeiteMiniature Carbon Potentiometers Spec SheetGonzalo MachadoNoch keine Bewertungen

- Nvent RAYCHEM NGC 30 Flex Series System Panel - DA VEDEREDokument2 SeitenNvent RAYCHEM NGC 30 Flex Series System Panel - DA VEDERECataloghi TecniciNoch keine Bewertungen

- PS2 Plug Kit: Manual For InstallationDokument2 SeitenPS2 Plug Kit: Manual For InstallationLuis RolaNoch keine Bewertungen

- Connector: Board-In Crimp Style ConnectorsDokument3 SeitenConnector: Board-In Crimp Style ConnectorsTrần Long VũNoch keine Bewertungen

- Fil Control: ApplicationDokument2 SeitenFil Control: ApplicationLolo BoaNoch keine Bewertungen

- Erv-Yu Star Delta Relay: GeneralDokument1 SeiteErv-Yu Star Delta Relay: GeneralMai Văn BáchNoch keine Bewertungen

- INSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVDokument7 SeitenINSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanNoch keine Bewertungen

- Hong Kong Lightning Protection System and CodeDokument26 SeitenHong Kong Lightning Protection System and CodeChan Li LiNoch keine Bewertungen

- SI10 Simulation Indicator Production ManualDokument5 SeitenSI10 Simulation Indicator Production ManualDANIEL BURILLO HOMBRIA0% (1)

- Foto Ce LulaDokument1 SeiteFoto Ce LulaIoan PascuNoch keine Bewertungen

- Det 222 2Dokument3 SeitenDet 222 2edgardelgado87Noch keine Bewertungen

- MX gc5jDokument35 SeitenMX gc5jdavidNoch keine Bewertungen

- Videocon Nano1-Cst Vcn14mbf-CnaDokument24 SeitenVideocon Nano1-Cst Vcn14mbf-CnaRamesh Singh100% (1)

- HMS-2000-4T Quick Installation Guide: 1. AccessoriesDokument2 SeitenHMS-2000-4T Quick Installation Guide: 1. AccessoriesOscar Fernando Roque PardoNoch keine Bewertungen

- E 70910041Dokument5 SeitenE 70910041Dimitra NakitNoch keine Bewertungen

- Operating Instructions: Coring Stripping ToolDokument2 SeitenOperating Instructions: Coring Stripping ToolCarlos CastilloNoch keine Bewertungen

- Disney Dt1350c - Oec7108a, m61250bfp, La78040ne - TV SMDokument31 SeitenDisney Dt1350c - Oec7108a, m61250bfp, La78040ne - TV SMFlorin Bila-NicolaNoch keine Bewertungen

- Pub145 002 00 - 0218Dokument4 SeitenPub145 002 00 - 0218engkos koswaraNoch keine Bewertungen

- TV-CN202 Service ManualDokument33 SeitenTV-CN202 Service Manualjama35Noch keine Bewertungen

- Linear IC Applications: A Designer's HandbookVon EverandLinear IC Applications: A Designer's HandbookBewertung: 4 von 5 Sternen4/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- RPM 517 551 - 01 XPIC Cable DescriptionDokument4 SeitenRPM 517 551 - 01 XPIC Cable DescriptionEniverseNoch keine Bewertungen

- Limites Trigonometricos ResolvidosDokument7 SeitenLimites Trigonometricos Resolvidosjp_natarioNoch keine Bewertungen

- SauDokument2 SeitenSaurichintukNoch keine Bewertungen

- Satmotion Pocket PC User GuideDokument27 SeitenSatmotion Pocket PC User GuiderichintukNoch keine Bewertungen

- Installation Guide for 1/2Dokument2 SeitenInstallation Guide for 1/2richintukNoch keine Bewertungen

- Installation Guide for 1/2Dokument2 SeitenInstallation Guide for 1/2richintukNoch keine Bewertungen

- Formulario de Integrales PDFDokument1 SeiteFormulario de Integrales PDFrichintukNoch keine Bewertungen

- Remote Electrical Downtilt System Handbook: Installation Overview and Troubleshooting GuideDokument82 SeitenRemote Electrical Downtilt System Handbook: Installation Overview and Troubleshooting GuiderichintukNoch keine Bewertungen

- Instruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsDokument2 SeitenInstruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsrichintukNoch keine Bewertungen

- Ma 60W110-C08 PDFDokument2 SeitenMa 60W110-C08 PDFrichintukNoch keine Bewertungen

- Omniaccess User: Admin Password: Xipantu Tarjeta Will 3 (Administrador) Password: ImhotepDokument1 SeiteOmniaccess User: Admin Password: Xipantu Tarjeta Will 3 (Administrador) Password: ImhoteprichintukNoch keine Bewertungen

- 1-1/4Dokument2 Seiten1-1/4richintukNoch keine Bewertungen

- Script TCU ZB163 - TerrenoDokument2 SeitenScript TCU ZB163 - TerrenorichintukNoch keine Bewertungen

- FXL 780Dokument4 SeitenFXL 780richintukNoch keine Bewertungen

- Patient Medication Management: DRUG STUDY University of Cebu Medical CenterDokument1 SeitePatient Medication Management: DRUG STUDY University of Cebu Medical CenterMemcom SolutionNoch keine Bewertungen

- Tripac Technical Data - Bolt - Wrench Sizes ChartDokument19 SeitenTripac Technical Data - Bolt - Wrench Sizes Chartcmms88100% (2)

- Individual and Family Health Insurance ApplicationDokument7 SeitenIndividual and Family Health Insurance Applicationahmad abu sharkhNoch keine Bewertungen

- zxr400 H 04 PDFDokument23 Seitenzxr400 H 04 PDFPierre LemaireNoch keine Bewertungen

- Install RU PC-TOOLDokument1 SeiteInstall RU PC-TOOLsegurahNoch keine Bewertungen

- OppositionDokument2 SeitenOppositionbrancronNoch keine Bewertungen

- Latihan Soal IDokument6 SeitenLatihan Soal IMas GigihNoch keine Bewertungen

- Corporate Lifting Expert Leads SafetyDokument3 SeitenCorporate Lifting Expert Leads Safetyanthony jamesNoch keine Bewertungen

- Tendernotice 1Dokument1 SeiteTendernotice 1Vijaykumar JaganiaNoch keine Bewertungen

- Active AntennasDokument5 SeitenActive AntennasGöestaf ZarNoch keine Bewertungen

- Sri Venkateshwara College of EngineeringDokument3 SeitenSri Venkateshwara College of EngineeringpavanNoch keine Bewertungen

- Mr. Subhas Chandra Nath Assistant Professor Department of Computer ApplicationDokument13 SeitenMr. Subhas Chandra Nath Assistant Professor Department of Computer Application01ABHIGYAN MAJINoch keine Bewertungen

- Acer-Aspire - 5738 - 5738z - ENGl 12Dokument1 SeiteAcer-Aspire - 5738 - 5738z - ENGl 12Juan PabloNoch keine Bewertungen

- Radiation Protection Qualification StandardDokument33 SeitenRadiation Protection Qualification StandardRamakrishnan AmbiSubbiahNoch keine Bewertungen

- Surface Preparation StandardsDokument5 SeitenSurface Preparation Standardsayub82Noch keine Bewertungen

- Major Project ReportDokument33 SeitenMajor Project ReportSuraj mouryaNoch keine Bewertungen

- Topic 3 - Flexible Pavement Stress Analysis HandoutsDokument17 SeitenTopic 3 - Flexible Pavement Stress Analysis HandoutsjulspdNoch keine Bewertungen

- Lux Level Test Certificate FormDokument1 SeiteLux Level Test Certificate FormSandhyaRamakrishna100% (1)

- Urn Uvci 01 Ro 1g267oxmr4ln080w3loz8vyekd095p#nDokument2 SeitenUrn Uvci 01 Ro 1g267oxmr4ln080w3loz8vyekd095p#nionpopescuNoch keine Bewertungen

- Brushless and Brushed DC MotorsDokument27 SeitenBrushless and Brushed DC MotorsMarc Jairro GajudoNoch keine Bewertungen

- Aerodynamic stability derivatives for aircraft roll and yawDokument3 SeitenAerodynamic stability derivatives for aircraft roll and yawGurunath AeroNoch keine Bewertungen

- Private Company Issues and Opportunities 2020 - Family Business EditionDokument58 SeitenPrivate Company Issues and Opportunities 2020 - Family Business EditionBusiness Families FoundationNoch keine Bewertungen

- Vertical Shaft Flocculator - BrochureDokument8 SeitenVertical Shaft Flocculator - BrochureLTE002Noch keine Bewertungen

- Babcock Cover Letter Grad SchemeDokument1 SeiteBabcock Cover Letter Grad SchemeJames Tomy100% (1)

- Overview of The Applications of Thermodynamic Databases To Steelmaking ProcessesDokument31 SeitenOverview of The Applications of Thermodynamic Databases To Steelmaking ProcessesakshukNoch keine Bewertungen

- Cambios Radiculares en Pacientes Tratados OrtodoncicamenteDokument11 SeitenCambios Radiculares en Pacientes Tratados OrtodoncicamenteJUAN FONSECANoch keine Bewertungen

- 2015 TTT Loading Master Program Oil Gas ChemicalsDokument6 Seiten2015 TTT Loading Master Program Oil Gas ChemicalstenggarayNoch keine Bewertungen

- ACCOUNTING & FINANCE FOR BANKERSDokument41 SeitenACCOUNTING & FINANCE FOR BANKERSNidhi RanjanNoch keine Bewertungen

- Level 4Dokument7 SeitenLevel 4Tudor PricopNoch keine Bewertungen

- TERRAZO - Specifications and Design GuideDokument50 SeitenTERRAZO - Specifications and Design GuidejuanNoch keine Bewertungen