Beruflich Dokumente

Kultur Dokumente

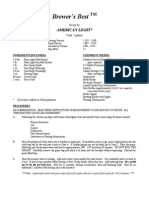

Brewmaker Instructions

Hochgeladen von

David SanzOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Brewmaker Instructions

Hochgeladen von

David SanzCopyright:

Verfügbare Formate

Brewmaker

Equipment required

A food grade plastic or polythene container with a loose fitting lid large enough to hold 40

pints (23 litres). A 25 litre fermenting bin is ideal.

A length of plastic syphon tubing to syphon the fermented beer into bottles or a barrel.

A pressure barrel or bottles sufficient for 40 pints (23 litres) PET (plastic) fizzy drink bottles

are suitable or brown beer bottles with crown corks are ideal. Note – do not use glass bottles

with cracks or chips in them or non-returnable glass bottles.

A kilo of white granulated sugar or 1kg brewing sugar. See notes on ‘experience’.

A proprietary cleaning agent such as Muntons Bruclens to sterilise your equipment.

Optional items

A hydrometer and trial jar is useful to check the progress of fermentation and final

gravity.

A thermometer and a heat tray or brew belt (for optimum temperature control).

Cleanliness

All equipment, bottles etc. must be cleaned and sterilised with a proprietary sterilising agent.

Rinse with clean cold water after sterilising. Do not use household detergents and cleaners.

Brewing

Empty the contents of the can into your sterilised container and add 1kg of sugar. Boil

2.25 litres (4 pints) of water. Allow to cool slightly and stir into the mix until the

sugar has dissolved.

Add the balance of cold water to make up the total of 23 litres (40 pints). Stir

thoroughly. The final temperature of the mixture should be 18° – 24°C.

Sprinkle the contents of the sachet of yeast onto the brew, stir, and replace the lid.

Stand the container in a warm place 18°-24°C (we recommend the use of a heater belt

or tray for optimum temperature control) and leave to ferment for between 4 and 8

days.

Check the fermentation has completely finished before proceeding. This can be

confirmed when no bubbles are rising to the surface and the brew begins to clear. A

hydrometer reading of below 1006 on two consecutive days will confirm that

fermentation is complete.

It is important to make sure that fermentation is complete before boiling; otherwise

there is a danger of the bottles bursting.

Bottling the beer

This ‘priming’ process will carbonate your beer, which adds the life and sparkle to the beer.

Put a maximum of 1 level teaspoon of sugar or dried malt extract into each of your 1

pint or ½ litre (sterilised) bottles. Do not exceed this amount or the beer will be too

lively to serve. Syphon the beer from the container into the bottles (taking care not to

disturb the sediment at the bottom) leaving a head space of 5cm (2 inches) between

the top of the liquid and the rim.

Seal or cap your bottles with crown caps and transfer to a warm place at room

temperature (about 20°C) and leave for about 4 days to allow secondary fermentation

to take place. Do not store in direct sunlight.

Now move the bottles to a cool place to allow the beer to clear. Clearing will take

about one week. Once the beer is perfectly clear it is ready to drink, but will improve

if left to mature for at least a further two weeks.

When serving the beer be careful not to disturb the yeast sediment that will have

collected at the bottom of the bottle. You may find it preferable to pour the beer into a

jug first. Serve cool.

Rinsing the bottles out with water immediately after emptying will make them easier

to clean and sterilise the next time.

Using a pressure barrel

Follow the brewing instructions given earlier until fermentation is complete.

Now refer to the detailed instructions supplied with your barrel. As a guide, the steps will be:

Syphon the beer from the container into your sterilised barrel leaving the sediment

behind.

Dissolve 60grams (1/4 cup / 2oz) of ‘priming’ sugar in a cupful of hot water, add this

solution to the barrel, and stir well.

Cap the barrel tightly and move to a warm place (20°) for 4 days, then leave to clear

in a cool place. Note that beer takes longer to clear in a barrel than in bottles and

should be left for 3 or 4 weeks to clarify and mature. Beer finings may be added to

reduce clearing time.

If the cup of your barrel is fitted with a CO2 valve, you can inject further gas when

the naturally produced CO2 has been used up.

Experience

Experienced brewers may find that the slight variations to the instructions given

above will produce a beer more to their individual taste. For example, substituting

some of the additional sugar with canned malt extract or dried malt extract will

produce a beer with a correspondingly fuller body.

Das könnte Ihnen auch gefallen

- Home Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsVon EverandHome Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsNoch keine Bewertungen

- The Ultimate Hot Cocktail Directory: 360 New and Classic Coffee, Tea, and Hot Toddy RecipesVon EverandThe Ultimate Hot Cocktail Directory: 360 New and Classic Coffee, Tea, and Hot Toddy RecipesNoch keine Bewertungen

- Beer Instruction ManualDokument4 SeitenBeer Instruction ManualShaheer MuhammadNoch keine Bewertungen

- Extract Brewing Instructions: Necessary Equipment and SuppliesDokument2 SeitenExtract Brewing Instructions: Necessary Equipment and SuppliesHenry Clark TravagliniNoch keine Bewertungen

- Killians RED Beer Reciepe 03638Dokument2 SeitenKillians RED Beer Reciepe 03638Joe MoldovanNoch keine Bewertungen

- Bulldog Brews InstructionsDokument4 SeitenBulldog Brews InstructionsrciobanasuNoch keine Bewertungen

- Rice BeerDokument8 SeitenRice BeerPied7PiperNoch keine Bewertungen

- The Key IngredientsDokument4 SeitenThe Key Ingredientsk_168911826Noch keine Bewertungen

- Beer Brewing For BeginnersDokument5 SeitenBeer Brewing For BeginnerspauloadrianoNoch keine Bewertungen

- How To Brew Beer at HomeDokument5 SeitenHow To Brew Beer at Homelucas.siqueiraNoch keine Bewertungen

- Brewing: A Brief Guide To Get You Started Making Your Own Home BrewDokument1 SeiteBrewing: A Brief Guide To Get You Started Making Your Own Home Brewbathtub2025Noch keine Bewertungen

- 25L Pot Still: ManualDokument8 Seiten25L Pot Still: ManualrectechNoch keine Bewertungen

- 25 L SUPER Reflux Still Ins With Z FilterDokument16 Seiten25 L SUPER Reflux Still Ins With Z FiltertoffeloffeNoch keine Bewertungen

- Mangrove Jack's Brewer's Series Kit InstructionsDokument2 SeitenMangrove Jack's Brewer's Series Kit InstructionsEsteban Iturra CerónNoch keine Bewertungen

- 1018 American LightDokument2 Seiten1018 American LightAhmet MetinNoch keine Bewertungen

- Mangrove Jack's Craft Series Beer Pouch InstructionsDokument2 SeitenMangrove Jack's Craft Series Beer Pouch InstructionsJoao MoreiraNoch keine Bewertungen

- Brooklyn Brew Shop Punk IPA InstructionsDokument3 SeitenBrooklyn Brew Shop Punk IPA InstructionsRamón Farré GómezNoch keine Bewertungen

- Brew Buddy StarterDokument2 SeitenBrew Buddy StarterJuk ArmstrongNoch keine Bewertungen

- Midwest Honeybee AleDokument2 SeitenMidwest Honeybee AleJesso GeorgeNoch keine Bewertungen

- How To Brew - by John PalmerDokument4 SeitenHow To Brew - by John Palmerzaratustra210% (1)

- Brooklyn Brew Shop - Everyday IPA InstructionsDokument3 SeitenBrooklyn Brew Shop - Everyday IPA Instructionstecleador10% (1)

- Morebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemDokument2 SeitenMorebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemTeddy Riaño AlarconNoch keine Bewertungen

- A Water Tublng Capper: OftubingDokument1 SeiteA Water Tublng Capper: OftubingAhmet MetinNoch keine Bewertungen

- Brewers Friend Checklist ExtractDokument2 SeitenBrewers Friend Checklist ExtractGanges LimNoch keine Bewertungen

- 1 US Gallon Water PurifierDokument16 Seiten1 US Gallon Water Purifieremily turnerNoch keine Bewertungen

- Oatmeal StoutDokument3 SeitenOatmeal Stoutriffs_ahoyNoch keine Bewertungen

- Still Spirits 25L Super Reflux Still 55719 WEB June08Dokument4 SeitenStill Spirits 25L Super Reflux Still 55719 WEB June08AndréRochaNoch keine Bewertungen

- Austin Homebrew Supply: 15112 N IH-35, Austin TX 78728 (512) 300-BREW or (800) 890-BREWDokument2 SeitenAustin Homebrew Supply: 15112 N IH-35, Austin TX 78728 (512) 300-BREW or (800) 890-BREWEric SteenNoch keine Bewertungen

- JB's Best India AleDokument2 SeitenJB's Best India AleJesso GeorgeNoch keine Bewertungen

- American Pale AleDokument2 SeitenAmerican Pale AleJustin GarciaNoch keine Bewertungen

- Mangrove Jack's Craft Series Cider Pouch InstructionsDokument2 SeitenMangrove Jack's Craft Series Cider Pouch InstructionsCsillag DávidNoch keine Bewertungen

- Fantome Saison-Style Ale (16C) - All GrainDokument2 SeitenFantome Saison-Style Ale (16C) - All GrainMonitoreo SPERNoch keine Bewertungen

- QL BaldrgaxDokument1 SeiteQL BaldrgaxwackorobieNoch keine Bewertungen

- Air Still Full ManualDokument8 SeitenAir Still Full Manualfrasers1Noch keine Bewertungen

- Cask CleaningDokument4 SeitenCask Cleaningde_klusNoch keine Bewertungen

- Serving Draught Beer: Glassware CleaningDokument4 SeitenServing Draught Beer: Glassware CleaningDeven SolankiNoch keine Bewertungen

- How To Make Your Own Red Dragon Fruit WineDokument8 SeitenHow To Make Your Own Red Dragon Fruit WineShakura Ahseyia0% (1)

- Apple Cider InstructDokument2 SeitenApple Cider InstructlegionsixNoch keine Bewertungen

- 5L Super Reflux Still InstructionsDokument16 Seiten5L Super Reflux Still InstructionsAndréRochaNoch keine Bewertungen

- 1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiDokument5 Seiten1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiRyanNoch keine Bewertungen

- HowtobrewDokument2 SeitenHowtobrewJohan RiosNoch keine Bewertungen

- Basic Mead Making: University of Minnesota Instructional Poster #158, Gary S. Reuter, Department of EntomologyDokument1 SeiteBasic Mead Making: University of Minnesota Instructional Poster #158, Gary S. Reuter, Department of EntomologysanjosewhoreNoch keine Bewertungen

- Instructions On How To Make Hard CiderDokument3 SeitenInstructions On How To Make Hard CiderkarnizsdjuroNoch keine Bewertungen

- Beer Making ClassDokument5 SeitenBeer Making ClassMichael BernierNoch keine Bewertungen

- BrewingDokument3 SeitenBrewingChris IsmutyantoNoch keine Bewertungen

- KK Beer Guide Booklet 091522 Print Ready - Small-MinDokument12 SeitenKK Beer Guide Booklet 091522 Print Ready - Small-MinClifton SutherlandNoch keine Bewertungen

- A Short Overview of Distilling: - Plus 2 Bonus RecipesDokument4 SeitenA Short Overview of Distilling: - Plus 2 Bonus RecipesMatheus Jeronimo MarianNoch keine Bewertungen

- Coopers Yeast CulturingDokument4 SeitenCoopers Yeast Culturingmatthendry100% (1)

- Food in BiotechnologyDokument18 SeitenFood in BiotechnologyEndah Permata SariNoch keine Bewertungen

- Beer Instructions CanDokument1 SeiteBeer Instructions CanEric SteenNoch keine Bewertungen

- Negra Modelo All Grain RecipeDokument2 SeitenNegra Modelo All Grain RecipeKevin van HollandNoch keine Bewertungen

- 1 Gallon of BeerDokument1 Seite1 Gallon of Beergo1iathNoch keine Bewertungen

- Spirit of Wine and Spirit of VinegarDokument3 SeitenSpirit of Wine and Spirit of VinegarDonna KennedyNoch keine Bewertungen

- How To Make Homemade WineDokument3 SeitenHow To Make Homemade WineKriszara MandanasNoch keine Bewertungen

- Ginger Beer: (Using Double Fermentation Based Loosely On La MéthodeDokument2 SeitenGinger Beer: (Using Double Fermentation Based Loosely On La MéthodevelivolantNoch keine Bewertungen

- Classy as Fuck Cocktails: 60+ Damn Good Recipes for All OccasionsVon EverandClassy as Fuck Cocktails: 60+ Damn Good Recipes for All OccasionsBewertung: 1 von 5 Sternen1/5 (1)

- 100 Taka Bangla FeaturesDokument1 Seite100 Taka Bangla FeaturesDavid SanzNoch keine Bewertungen

- Security Features of 200 Taka Denomination Commemorative Bank NoteDokument2 SeitenSecurity Features of 200 Taka Denomination Commemorative Bank NoteDavid SanzNoch keine Bewertungen

- 100 Taka Bangla FeaturesDokument1 Seite100 Taka Bangla FeaturesDavid SanzNoch keine Bewertungen

- Footprints of The Invisible Enemy PDFDokument1 SeiteFootprints of The Invisible Enemy PDFDavid SanzNoch keine Bewertungen

- Covid-19 and Life ExpectancyDokument1 SeiteCovid-19 and Life ExpectancyDavid SanzNoch keine Bewertungen

- Tubos Acero Al Carbono ASTMDokument6 SeitenTubos Acero Al Carbono ASTMDavid SanzNoch keine Bewertungen

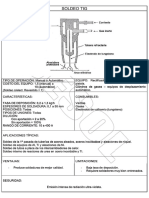

- Soldeo TIGDokument1 SeiteSoldeo TIGDavid SanzNoch keine Bewertungen

- Caso PlazaDokument1 SeiteCaso PlazaDavid SanzNoch keine Bewertungen

- Factor Density Light Transmission F-Stop: C D Logc T 1/C F Logc/Log2Dokument1 SeiteFactor Density Light Transmission F-Stop: C D Logc T 1/C F Logc/Log2David SanzNoch keine Bewertungen

- Trade Wars (The Economist, 2019-04-27)Dokument1 SeiteTrade Wars (The Economist, 2019-04-27)David SanzNoch keine Bewertungen

- Macao (Bnu) 50 Patacas 2009Dokument1 SeiteMacao (Bnu) 50 Patacas 2009David SanzNoch keine Bewertungen

- FIJI 2007 BanknotesDokument2 SeitenFIJI 2007 BanknotesDavid SanzNoch keine Bewertungen

- Cable-Stayed Bridge in MoroccoDokument1 SeiteCable-Stayed Bridge in MoroccoDavid SanzNoch keine Bewertungen

- Fluid Mechanics and SimulationDokument1 SeiteFluid Mechanics and SimulationDavid SanzNoch keine Bewertungen

- Marketing ResourcesDokument1 SeiteMarketing ResourcesDavid SanzNoch keine Bewertungen

- Risk AnalysisDokument1 SeiteRisk AnalysisDavid SanzNoch keine Bewertungen

- Specimen Issue 1Dokument11 SeitenSpecimen Issue 1David SanzNoch keine Bewertungen

- Infosecura73 PDFDokument20 SeitenInfosecura73 PDFDavid SanzNoch keine Bewertungen

- How Wings WorkDokument7 SeitenHow Wings WorkMatteo MiglioriniNoch keine Bewertungen

- Indesit WIXL 105Dokument72 SeitenIndesit WIXL 105David SanzNoch keine Bewertungen

- 4 Verifying FalsifyingDokument16 Seiten4 Verifying FalsifyingRazvan IulianNoch keine Bewertungen

- PSP Press KitDokument42 SeitenPSP Press KitDavid SanzNoch keine Bewertungen

- 4 Verifying FalsifyingDokument16 Seiten4 Verifying FalsifyingRazvan IulianNoch keine Bewertungen

- Formulation and Evaluation of Probiotic Breadfriut (Artocarpus) BeverageDokument16 SeitenFormulation and Evaluation of Probiotic Breadfriut (Artocarpus) BeverageCBSUANoch keine Bewertungen

- 2206 SUBMISSION ManuscriptFile - PDF - .Docx 9327 1 10 20230711Dokument13 Seiten2206 SUBMISSION ManuscriptFile - PDF - .Docx 9327 1 10 20230711Meryouma LarbNoch keine Bewertungen

- Holiday Homework Class 12 MathematicsDokument2 SeitenHoliday Homework Class 12 MathematicsKartik SharmaNoch keine Bewertungen

- Fisher 9500 Butterfly Control ValveDokument12 SeitenFisher 9500 Butterfly Control ValveOscarNoch keine Bewertungen

- Calculation of The Size of The Mooring SystemDokument7 SeitenCalculation of The Size of The Mooring SystemKyle RubricoNoch keine Bewertungen

- 3 Types of Emergency Shutdown and Emergency Isolation ValvesDokument4 Seiten3 Types of Emergency Shutdown and Emergency Isolation ValvesMateusz KonopnickiNoch keine Bewertungen

- Python GUI Programming With Tkinter Deve-31-118 Job 1Dokument88 SeitenPython GUI Programming With Tkinter Deve-31-118 Job 1Shafira LuthfiyahNoch keine Bewertungen

- Alternator E1S13S A/4: Three-Phase Synchronous Alternator With Brushes and Compound - 4 PolesDokument7 SeitenAlternator E1S13S A/4: Three-Phase Synchronous Alternator With Brushes and Compound - 4 PolesmasanmartinfNoch keine Bewertungen

- Siddartha Institute of Science and Technoloy, Puttur: Seminar On Audio SpotlightingDokument19 SeitenSiddartha Institute of Science and Technoloy, Puttur: Seminar On Audio SpotlightingRasiNoch keine Bewertungen

- EE223 - Signals & Systems Assignment #3 (CLO#3)Dokument3 SeitenEE223 - Signals & Systems Assignment #3 (CLO#3)haider aliNoch keine Bewertungen

- Fiber Series CTCDokument31 SeitenFiber Series CTCJorge GaitanNoch keine Bewertungen

- 5 - Cut Method To Square: PrinciplesDokument4 Seiten5 - Cut Method To Square: Principleso______oNoch keine Bewertungen

- Lipid TestDokument4 SeitenLipid TestHak KubNoch keine Bewertungen

- DDR3 and LPDDR3 Measurement and Analysis: 6 Series MSO Opt. 6-CMDDR3 and Opt. 6-DBDDR3 Application DatasheetDokument14 SeitenDDR3 and LPDDR3 Measurement and Analysis: 6 Series MSO Opt. 6-CMDDR3 and Opt. 6-DBDDR3 Application DatasheetNaveenNoch keine Bewertungen

- Bone Specific Alkaline PhophataseDokument6 SeitenBone Specific Alkaline PhophataseMohan DesaiNoch keine Bewertungen

- Periodicity in 3D Lab Report FormDokument2 SeitenPeriodicity in 3D Lab Report FormZIX326100% (1)

- C100-F Installation ManualDokument55 SeitenC100-F Installation ManualpvfcqrtqcrNoch keine Bewertungen

- CCNA 4 - Chapter 2 QuzDokument1 SeiteCCNA 4 - Chapter 2 Quzchobiipiggy26Noch keine Bewertungen

- Users Manual ACS 501 PDFDokument94 SeitenUsers Manual ACS 501 PDFmodelador3dNoch keine Bewertungen

- STS Cat-1Dokument490 SeitenSTS Cat-1Sri AdityaNoch keine Bewertungen

- Bearing FitsDokument9 SeitenBearing Fitsm2110Noch keine Bewertungen

- Physics: FiitjeeDokument1.319 SeitenPhysics: FiitjeeBISWAJEET100% (2)

- Aphing Systemsof Linear Inequalities PR5Dokument3 SeitenAphing Systemsof Linear Inequalities PR5Panagiotis SotiropoulosNoch keine Bewertungen

- Configure and Verify Device ManagementDokument24 SeitenConfigure and Verify Device ManagementJose L. RodriguezNoch keine Bewertungen

- Irhlf77214 250V Radhard N MosfetDokument9 SeitenIrhlf77214 250V Radhard N MosfetarsebiscuitsNoch keine Bewertungen

- Comparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistanDokument10 SeitenComparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistannithyaNoch keine Bewertungen

- Sen2022 Software Engineering Analysis and DesignDokument84 SeitenSen2022 Software Engineering Analysis and DesignElif KaraatlıNoch keine Bewertungen

- Airplane Wing Geometry and ConfigurationsDokument7 SeitenAirplane Wing Geometry and Configurationsh_mahdiNoch keine Bewertungen

- W 9540Dokument6 SeitenW 9540imharveNoch keine Bewertungen

- SP485Dokument10 SeitenSP485DmitriyNoch keine Bewertungen