Beruflich Dokumente

Kultur Dokumente

Timber

Hochgeladen von

Liseth StylesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Timber

Hochgeladen von

Liseth StylesCopyright:

Verfügbare Formate

Timber trees is useful in some limited engineering

purposes.

Wood is one of the most used natural building

materials in the world. A number of valuable properties Examples: bamboo, palm, cane etc.

such as low heat conductivity, small bulk density,

relatively high strength, amenability to mechanical Structure of a Tree

working etc. makes wood as famous building material.

The structure of tree can be divided in to two

Timber can be used in most economical way categories as follows.

without wasting any of the derivatives of it. Even the

1. Macrostructure

saw dust obtained during wood sawing can also be

used to make fiber boards, paper etc. The structure of a tree which is visible

to the naked eye is called macro structure of

Types of Trees for Timber Production

tree. Macrostructure of tree contains following

The trees are classified into following types components

based on their mode of growth.

1. Exogenous

Exogenous trees are outward growing

trees. Horizontal section of such tree contains

several rings which are nothing but annual

rings. These rings can be used to predict the

age of tree. Most of the exogenous trees are

useful for many engineering purposes.

Exogenous trees are sub classified

into following types.

a. Pith

a. Conifers

The core part or innermost

Conifers are nothing but soft part of the tree is called as pith. It

wood producing trees which are also contains cellulose tissues which are

called as ever green trees. The timber helpful for the growth of plant during

of these trees is light colored, light in its young age.

weight, low dense and poor against

fire. b. Heart wood

Examples: Pine, Fir, redwood, Heart wood is the portion

spruce, deodar, cedar etc. around the pith which is dark in color

and contain some annual rings in it. It

b. Deciduous is very hard and provides rigidity to the

tree. Heart wood is used for several

Deciduous trees are hard

engineering purposes because of its

wood producing trees. The leaves of

strength and durability.

this type of trees are generally broad

in size and they fall in autumn and c. Sap wood

grow in spring. Deciduous trees are

most suitable for constructional Sap wood contain outer

purposes. Timber of deciduous trees annual rings. This indicates the recent

is dark colored, dense, heaviest and growth of tree and is light in color. It

good against fire. contains sap which helps in the growth

of tress.

Examples: Maple, Mahogany,

Oak, teak, walnut, babul etc. d. Cambium Layer

2. Endogenous Cambium layer contains sap

which will turn into sap wood after

Endogenous trees are inward growing some time. It should not exposed to

trees which contains fibrous mass in their

longitudinal section. The timber from these

atmosphere otherwise the tree may chopped off, bark is removed and is cut into

dead. required sizes.

e. Inner bark 2. Seasoning of Timber

The protecting layer of cambium Seasoning of timber means removal of

layer is known as inner bark. moisture content from timber. A newly fell tree

contains water up to 50% of its dry weight. The

f. Outer bark timber contains free moisture and bound

moisture.

The outermost layer of the

tree section is called outer bark or Free moisture is present in timber as

cortex. It contains cells of wood fiber. water vapor while bound moisture is present in

cell walls. When it is allowed to seasoning,

g. Medullary rays

free moisture evaporated first and this point is

The rays extending from pith called as fiber saturation point.

to cambium layer are known as

After Fiber saturation point, the timber

medullary rays. These rays hold the

will shrink on drying which is nothing but

annual rings of sap wood and heart

evaporation of bound moisture.

wood together.

There are two methods of seasoning

2. Microstructure

are there namely:

Micro structure of a tree can only be

Natural seasoning

visible with great magnifications. It contains

Artificial Seasoning

cells of different shapes and sizes. These cells

are responsible for many actions like nutrients

3. Conversion of Timber

transport to branches from stem, strength of

tree etc. Conversion of timber is the process of

cutting of timber into required sections. This

Processing of Timber

can be done by using power machines. Skilled

Processing of Timber contains following steps persons should be required for economic

conversion of timber. The conversion can be

1. Felling of Trees done by four types as follows

Felling of trees is nothing but cutting of a. Ordinary sawing

trees which are suitable for engineering

purposes. Felling should be done when the It is the most used and easy

tree is matured. Then only it contains more method of sawing. The cutting is done

amount of heart wood than sap wood. The through the section of timber piece at

perfect age of trees for felling varies from 50 to perpendicular to the annual rings.

100 years. The best season for felling of trees Wastage of timber is minimum in this

is Mid-winter for plain areas and mid-summer case.

for hilly areas.

The obtained planks are not of

Firstly a cut is made at the lower most equal strength. The outer planks

part of the trunk on a side where tree is contain sap wood and shrinks more

expected to fell. The cut should be beyond while the inner portion planks contain

center of gravity of tree. Then provide parallel heart wood which shrinks less.

cut which is exactly opposite to the first cut.

Then tie up the tree top with 4 ropes on 4

sides.

Now pull the rope of first cut side and

loosen the rope on the opposite side. Using

other two ropes swing the tree slowly. Then

the tree starts breaking along the cuts and

gently fall on the ground. The branches are

b. Tangential sawing 4. Preservation of Timber

In this type of sawing the cuts The final stage of timber processing is

are tangential to annual rings and they preservation which is carried out to increase

meet each other at right angles. This the durability of timber and also to resist the

method is suitable when the annual attacks of fungi, insects etc. on timber. In

rings are very distinct with each other. general ASCU, Coal tar, Oil paints, Solignum

paints etc. are used as preservatives.

c. Quarter sawing

In quarter sawing, the cuts are

made right angles to each other. This

is suitable when the timber have no

distinct medullary rays.

d. Radial sawing

In this type of sawing, the cuts

are made parallel to the medullary

rays radially. In this method wastage

of timber is maximum.

Asphalt nature and it is used for flooring, roofing, water

proofing material etc.

The asphalt is a mixture which consists

alumina, lime, silica and asphaltic bitumen. At low 4. Mastic Asphalt

temperatures, it is in solid state and at high

temperatures it is in liquid state. Mastic asphalt is obtained by heating

natural asphalt with sand and mineral fillers. It

Asphalt is produced in two different ways as is impermeable matter does not contain any

follows. voids.

1. Natural Asphalt Hardness and melting point of mastic

asphalt can be managed during the process of

Natural asphalt is obtained directly heating. It is in solid state and by heating it can

from the nature especially from the two be brought to liquid state. It is used for damp

resources lakes and rocks. proofing course.

The lake asphalt contains 40 to 70 %

of pure bitumen which is boiled in tank and

water content evaporates and impurities are

separated. The final product is called as

asphalt which a=can be used for laying roads

etc.

Rock asphalt contains 10 to 15% of

pure bitumen and calcareous matter. These

rocks are crushed and heated and

consolidates by sudden cooling. This asphalt

is used for paving tiles etc.

2. Residual Asphalt

Residual asphalt is obtained artificially

by the distillation of crude petroleum oil with

asphaltic base.

Forms of Asphalt

The available forms of asphalt are:

1. Cutback Asphalt

Cutback asphalt is in liquid state.

Asphalt is dissolved in a volatile solvent to get

this cutback asphalt. It is used for

manufacturing bituminous paint, repairing

roofs etc.

2. Asphalt Emulsion

Asphaltic emulsion is obtained by

adding 50 to 60% water to the asphalt in

presence of 1% emulsifying agent. The

emulsifying agent forms water proof film when

water evaporates. So, it can be used in cold

conditions.

3. Asphalt Cement

Natural asphalt is subjected to high

pressure air under high temperature to get

asphalt cement. Asphalt cement is plastic in

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- BMP Project-Implementation-Manual (V 1 1) PDFDokument131 SeitenBMP Project-Implementation-Manual (V 1 1) PDFLiseth StylesNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Forestry Code: Assignment No. 3Dokument16 SeitenForestry Code: Assignment No. 3Liseth StylesNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Forestry Code: Assignment No. 3Dokument6 SeitenForestry Code: Assignment No. 3Liseth StylesNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Draft 1Dokument2 SeitenDraft 1Liseth StylesNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

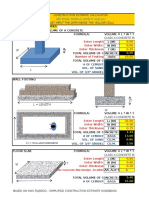

- Const-Estimate-Made-Easy, by Engr. Ronald John R. CajillaDokument54 SeitenConst-Estimate-Made-Easy, by Engr. Ronald John R. CajillaAr John Bernard Abad100% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Scalextric Arc One GuideDokument46 SeitenScalextric Arc One GuidenotifyatpriNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Aci 522R-06 PDFDokument25 SeitenAci 522R-06 PDFaldi raimon100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Battery Installation ProcedureDokument5 SeitenBattery Installation ProceduresantoshkumarNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- FP Lecture Midterm Exam Sec - Sem.2020Dokument4 SeitenFP Lecture Midterm Exam Sec - Sem.2020SAEEDA ALMUQAHWINoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Akshaya Vanam: Indian SandalwoodDokument52 SeitenAkshaya Vanam: Indian Sandalwoodprasadgss100% (4)

- Syllabi: The Institution of Engineers, Sri LankaDokument107 SeitenSyllabi: The Institution of Engineers, Sri LankaAmal Priyashantha Perera100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- مستر رمضان عوضDokument24 Seitenمستر رمضان عوضSamuel SaadNoch keine Bewertungen

- Lecture 8Dokument22 SeitenLecture 8Ramil Jr. EntanaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Effect of Vino Gano Ginger and Herbal Liquor On The Heamatological Parameters of The Wistar RatsDokument5 SeitenEffect of Vino Gano Ginger and Herbal Liquor On The Heamatological Parameters of The Wistar RatsInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Ah 1000Dokument1 SeiteAh 1000Zafir SihabuddinNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Lec22 Mod 5-1 Copper New TechniquesDokument24 SeitenLec22 Mod 5-1 Copper New TechniquesAaila AkhterNoch keine Bewertungen

- Foundation Design LectureDokument59 SeitenFoundation Design LectureJamaica MarambaNoch keine Bewertungen

- 3TRIGODokument5 Seiten3TRIGOCielo Pabilan ObemioNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Gingerbread Man-1 EnglishareDokument40 SeitenThe Gingerbread Man-1 EnglishareamayalibelulaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- EndressHauser HART CommunicatorDokument1 SeiteEndressHauser HART CommunicatorGhafur AgusNoch keine Bewertungen

- AeonDokument4 SeitenAeonsancsa_74Noch keine Bewertungen

- Unit-1 Infancy: S.Dharaneeshwari. 1MSC - Home Science-Food &nutritionDokument16 SeitenUnit-1 Infancy: S.Dharaneeshwari. 1MSC - Home Science-Food &nutritionDharaneeshwari Siva-F&NNoch keine Bewertungen

- Mechanism Design: A SeriesDokument3 SeitenMechanism Design: A Seriesamirmasood kholojiniNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 11 - Morphology AlgorithmsDokument60 Seiten11 - Morphology AlgorithmsFahad MattooNoch keine Bewertungen

- Ae 2 PerformanceDokument4 SeitenAe 2 PerformanceankitNoch keine Bewertungen

- Dwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFDokument13 SeitenDwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFcomfortdehm1350100% (7)

- Setting Times of ConcreteDokument3 SeitenSetting Times of ConcreteP DhanunjayaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Mono 108Dokument438 SeitenMono 108pasaricaNoch keine Bewertungen

- Chemistry Jun 2010 Mark Scheme Unit 3Dokument15 SeitenChemistry Jun 2010 Mark Scheme Unit 3dylandonNoch keine Bewertungen

- E Numbers Are Number Codes ForDokument3 SeitenE Numbers Are Number Codes ForaradhyaNoch keine Bewertungen

- Pantalla Anterior Bienvenido: Cr080vbesDokument3 SeitenPantalla Anterior Bienvenido: Cr080vbesJuan Pablo Virreyra TriguerosNoch keine Bewertungen

- Company Profile Pt. KPT PDFDokument23 SeitenCompany Profile Pt. KPT PDFfery buyaNoch keine Bewertungen

- Pelton2014 Para-Equilibrium Phase DiagramsDokument7 SeitenPelton2014 Para-Equilibrium Phase DiagramsAbraham Becerra AranedaNoch keine Bewertungen

- Diabetes in Pregnancy: Supervisor: DR Rathimalar By: DR Ashwini Arumugam & DR Laily MokhtarDokument21 SeitenDiabetes in Pregnancy: Supervisor: DR Rathimalar By: DR Ashwini Arumugam & DR Laily MokhtarHarleyquinn96 DrNoch keine Bewertungen

- American Pile Driving Equipment Equipment CatalogDokument25 SeitenAmerican Pile Driving Equipment Equipment CatalogW Morales100% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)