Beruflich Dokumente

Kultur Dokumente

Ovation Steam Turbine Control Technical

Hochgeladen von

Rhadityo Shakti BudimanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ovation Steam Turbine Control Technical

Hochgeladen von

Rhadityo Shakti BudimanCopyright:

Verfügbare Formate

Steam Turbine Control Solutions

Data Sheet

Features

Maximizes turbine life

Vast experience with various turbine types from

a variety of turbine manufacturers

Centered on reliability, safety, and efficient

operation

Clear, concise view of key turbine parameters

Various protection schemes

Fully coordinated turbine and boiler control

Innovative Steam Turbine Control turbines. Our experience extends across the

Solutions board with various turbine types including:

Utilities worldwide are increasingly focused on

Straight flow and two section condensing

maintaining reliable power generation in order

Single and double reheat

to meet the growing demand for electricity. A

key factor in maximizing plant availability is Triple and four flow low pressure

efficient turbine operation. Accurate control and Tandem and cross compound

monitoring of turbine processes extends life

cycles and protects plant generation to meet Ovation digital controls offer you many

power demands. advantages including a clear, concise view of

key turbine parameters, various protection

For more than 50 years, Emerson Process schemes and seamless, full coordinated turbine

Management (Emerson) has been an industry and boiler control. By working above the normal

leader in controlling every aspect of a power standards of turbine control, we have created a

plant, including the steam turbine. Today, as system that maximizes the life of today's

older turbines operate beyond their original life turbines

expectancy, better control is a necessity. Controlling Your Steam Turbines

Emerson’s Steam Turbine solutions use state-

of-the-art Ovation technology to give today's Our vast experience in the power generation

utilities the most flexible, powerful control industry has given us many opportunities to

system available. work with turbine control systems from various

manufacturers. Our control philosophy for each

Since 1963, steam turbine control has been a solution centers on efficient operation, reliability,

mainstay of our business. From over 130 AEH and safety. Steam turbine functions included

units installed in the 1960’s to over 175 DEH within our solution include:

Mod I, II, II, and Ovation systems to date, we

have developed a proven solution combining all Speed feedback loop

the design and operational knowledge of Megawatt feedback loop

previous systems. Our long history of retrofitting Operator adjustable speed or MW demand

turbines from leading manufacturers, including and rate selection

Westinghouse, ABB, and General Electric Initial load pickup at breaker closure

improves the reliability and availability of your Flow feedback loop

© Emerson Process Management Power & Water Solutions. -1-

PWS_002715 [2]

Steam Turbine Control Solutions

Data Sheet

Load limiting Throttle pressure compensation on breaker

Initial pressure limiting closure

Critical speed detection Operator adjustable speed demand, speed

Valve test capability rate, valve position limit, load demand, and

Valve calibration load rate

Individual valve curves Remote control interface for automatic

Valve position indication dispatch, boiler control, etc.

Synchronizer interface Open/close graphic indication for all non-

Remote control interface modulating steam valves

Throttle pressure limiter – operator

adjustable and remote

Our Solutions for Westinghouse Operator adjustable high and low load limits

Steam Turbines

Our Solutions for GE Steam Turbines

The Emerson steam turbine package performs

all of the original Westinghouse AEH or DEH

Overspeed protection and operator automatic The Emerson steam turbine package performs

control functions. Protection and testing all of the original GE control and protection

functions normally include: functions. Normally included with this solution is:

103% electrical overspeed protection Backup over speed protection

Load drop anticipator Power load unbalance

Fast valving Trip anticipator

Valve test capability Oil trip testing

Mechanical/electrical overspeed testing Turbine speed regulation

Pre-programmed blade resonance ranges Trip trap

for improved turbine protection Turbine valve testing

Pre-programmed turbine runbacks Mechanical/electrical over speed testing

Preprogrammed blade resonance ranges for

Control functions normally included for improved turbine protection

Westinghouse turbines are: Pre-programmed turbine runbacks

Remote latching of the turbine

Throttle valve speed control Control functions normally included for GE

TV/GV transfer and graphical position turbines are:

indication Turbine pre-warming

GV speed and load control Remote latching of the turbine

Automatic synchronizer interface SV speed and load control

Speed, megawatt, and first stage pressure FA/PA transfer

feedback loops CV speed and load control

Minimum load pickup on breaker closure Automatic synchronizer interface

Stage pressure feedback loop

© Emerson Process Management Power & Water Solutions. -2-

PWS_002715 [2]

Steam Turbine Control Solutions

Data Sheet

Speed feedback loop Minimum load pickup on breaker closure

Megawatt feedback loop Throttle pressure compensation on breaker

Minimum load pickup and initial breaker closure

compensation on breaker closure Operator adjustable speed demand, speed

Operator adjustable speed demand, speed rate, valve position limit, load demand, and

rate, load demand, load rate load rate

Remote control interface for automatic Remote control interface for automatic

dispatch, boiler control, etc. dispatch, boiler control, etc.

SV,CV, and IV graphical position indication Graphic position indication for all modulating

Open and close indication for all non- steam valves

modulating steam valves Throttle pressure limiter – operator

Initial pressure flow limiter adjustable and remote

Operator adjustable high load limits

Our Solutions for BBC

Steam Turbines Built on a Solid Foundation

Revolutionary Ovation technology is the basis

for Emerson’s Steam Turbine Control solution.

Compatible Ovation building blocks allow for

flexible combination of various components and

subsystems to match specific plant

configurations. Ovations built in redundancy

and self-diagnostics increases reliability,

reducing expensive system downtime.

A broad range of subsystems, each designed

for specific applications, are used to create our

steam turbine controls. Applications include

process control, data retrieval, general-purpose

computation and man-machine interface. All

subsystems are linked together by the powerful

Ovation Network. An Operator/Engineer

The Emerson steam turbine package performs workstation provides a high-resolution window

all of the original BBC control and protection to the process for control graphics, diagnostics,

functions. Normally included with this solution is: trending, alarms, and plant status displays.

Electrical overspeed protection Engineering functions are performed through

Fast valving powerful tools to configure and maintain the

Valve test capability Ovation control system. Combining functions

Mechanical/electrical overspeed testing within a single workstation reduces equipment

Start probe protection costs, spare parts, and space requirements.

Pre-programmed blade resonance ranges

The Ovation Controller executes simple or

for improved turbine protection

complex modulating and sequential steam

Turbine runbacks turbine control strategies, as well as performs

Acceleration limiter data acquisition functions. Standard I/O such as

the sequence of events and link controller

Control functions normally included for BBC modules provide 1 msec. resolution of turbine

turbines are: operations and interfaces to OEM systems

Remote latching of the turbine using standard protocols respectively.

CV speed and load control Specialized I/O modules for speed detection

Automatic synchronizer interface and valve position provide additional protection

Speed, starting probe, and throttle pressure against turbine failures.

feedback loops

© Emerson Process Management Power & Water Solutions. -3-

PWS_002715 [2]

Steam Turbine Control Solutions

Data Sheet

The Speed Detector Module determines the Connecting To Your Controls –

speed of the equipment by measuring the Protecting Your Investments

frequency of the tachometer output signal.

Converted to 16 and 32 bit binary numbers the Typically new plants will purchase the turbine

output signal is then used to detect and controls directly from the turbine OEM. Our

regulate equipment over speed steam turbine control solution recognizes your

investment in these products and includes

The Valve Positioner Module provides closed connectivity packages so we can interface state-

loop position control of the steam turbine valve. of-the-art Emerson controls with your pre-

Valve styles controlled by this module include purchased turbine control system. Our vast

throttle, governor, interceptor, extraction, and turbine experience has connected turbine

bypass. controls from GE, Toshiba, Mitsubishi, and

Siemens to our control systems.

© Emerson Process Management Power & Water Solutions. -4-

PWS_002715 [2]

Das könnte Ihnen auch gefallen

- Steam Turbine Control Solutions: FeaturesDokument4 SeitenSteam Turbine Control Solutions: Featuresmsw123Noch keine Bewertungen

- REF - 1100 Ovation Algorithms Reference ManualDokument838 SeitenREF - 1100 Ovation Algorithms Reference Manualracareanudanut100% (9)

- Process Control System A Complete Guide - 2020 EditionVon EverandProcess Control System A Complete Guide - 2020 EditionNoch keine Bewertungen

- OW360 - R1100 - Ovation Algorithms Reference ManualDokument692 SeitenOW360 - R1100 - Ovation Algorithms Reference ManualRicardas Kragnys50% (2)

- 0704 MCS System Logic Design Instruction PDFDokument28 Seiten0704 MCS System Logic Design Instruction PDFrahul100% (1)

- Core Ovation Training Reference Manual For Ovation 3.5Dokument743 SeitenCore Ovation Training Reference Manual For Ovation 3.5Hải Đăng Nguyễn80% (5)

- Control Builder User Guide For Ovation 3.5 - OW350 - 80 PDFDokument441 SeitenControl Builder User Guide For Ovation 3.5 - OW350 - 80 PDFEvbaru100% (2)

- Ovation GE LM6000 Control System Retrofit: FeaturesDokument5 SeitenOvation GE LM6000 Control System Retrofit: FeaturesErik Van GroningenNoch keine Bewertungen

- OW360 - 20 - Operator Station User GuideDokument764 SeitenOW360 - 20 - Operator Station User GuideRicardas KragnysNoch keine Bewertungen

- Ovation ProfibusDokument128 SeitenOvation ProfibusthienNoch keine Bewertungen

- OvationDokument36 SeitenOvationanandtvr100% (2)

- Ovation-OW352 R1100 PDFDokument597 SeitenOvation-OW352 R1100 PDFHakan Bozkurt100% (2)

- Ovation Ethernet Link Controller ModuleDokument5 SeitenOvation Ethernet Link Controller Modulekaicyem100% (1)

- OW331 - 47-SIS User GuideDokument337 SeitenOW331 - 47-SIS User GuideSelva ManianNoch keine Bewertungen

- Ow351 60 PDFDokument390 SeitenOw351 60 PDFHashim BukhariNoch keine Bewertungen

- RSLOGIX5000 Programming A Clear and Concise ReferenceVon EverandRSLOGIX5000 Programming A Clear and Concise ReferenceNoch keine Bewertungen

- DCS MannualDokument242 SeitenDCS Mannualashmirxa50% (4)

- GEK-114903 OC6000e Hardware Manual - V2.0Dokument204 SeitenGEK-114903 OC6000e Hardware Manual - V2.0Magoroku D. Yudho50% (2)

- Ovation NetworkDokument9 SeitenOvation NetworkDavid Berry100% (1)

- Pws 010189Dokument17 SeitenPws 010189Ishit DhadaNoch keine Bewertungen

- Basic Overview of Foxboro IA SeriesDokument8 SeitenBasic Overview of Foxboro IA SeriesvelusunilNoch keine Bewertungen

- Ovation Q LineDokument678 SeitenOvation Q LineCyrix.One100% (1)

- Docslide - Us - 41 Ovation Dcs 2007 PDFDokument52 SeitenDocslide - Us - 41 Ovation Dcs 2007 PDFtriplbingazi100% (1)

- Ge Mark VieDokument43 SeitenGe Mark VieKevin Ngo100% (1)

- GE MARK VI CONTROL INTERFACE OPTIONSDokument8 SeitenGE MARK VI CONTROL INTERFACE OPTIONStriplbingaziNoch keine Bewertungen

- OVATION (Pws - 002856-2) PDFDokument12 SeitenOVATION (Pws - 002856-2) PDFMaxmilianNoch keine Bewertungen

- Fieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Von EverandFieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Miguel Leon ChavezNoch keine Bewertungen

- Cimplicity HMI PDFDokument36 SeitenCimplicity HMI PDFazizi reNoch keine Bewertungen

- Distributed Process Control ReportVon EverandDistributed Process Control ReportNoch keine Bewertungen

- Control two tanks using Foxboro systemDokument6 SeitenControl two tanks using Foxboro systemluriah100% (1)

- Steam Turbine ControlDokument13 SeitenSteam Turbine Controlnirbhay111100% (4)

- TDC 3000 Advanced Process Manager Specification and Technical DataDokument28 SeitenTDC 3000 Advanced Process Manager Specification and Technical DataJosephus RavaneraNoch keine Bewertungen

- maxTOOLS4E PDFDokument111 SeitenmaxTOOLS4E PDFAPURBANoch keine Bewertungen

- Boiler-Tuning Basics, Part II PDFDokument12 SeitenBoiler-Tuning Basics, Part II PDFIain NeillNoch keine Bewertungen

- Controls & InstrumentationDokument23 SeitenControls & Instrumentationसचिन उरुणकर100% (1)

- Ovation Controller User Guide WIN55 00Dokument228 SeitenOvation Controller User Guide WIN55 00Hải Đăng Nguyễn100% (1)

- Gei 100620 PDFDokument121 SeitenGei 100620 PDFHung NgoNoch keine Bewertungen

- Wireless Control Foundation: Continuous and Discrete Control for the Process IndustryVon EverandWireless Control Foundation: Continuous and Discrete Control for the Process IndustryNoch keine Bewertungen

- OV150 WIN Ovation Maintenance CourseDokument102 SeitenOV150 WIN Ovation Maintenance CourseVasiljevic Zeljko100% (1)

- Operator Training WoodwardDokument19 SeitenOperator Training WoodwardLuis Anzola100% (1)

- Ovation IntroductionDokument8 SeitenOvation IntroductionMagoroku D. YudhoNoch keine Bewertungen

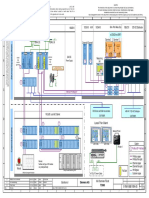

- I&C bus connections diagramDokument3 SeitenI&C bus connections diagramDiego Armando Vanegas Rodriguez100% (3)

- Max DnaDokument17 SeitenMax DnaAdil ButtNoch keine Bewertungen

- IO Reference Manual OW351 - R1150 PDFDokument654 SeitenIO Reference Manual OW351 - R1150 PDFraul salinas100% (1)

- 3300 20 Operation Manual 80178-01 Rev FDokument24 Seiten3300 20 Operation Manual 80178-01 Rev FAhmad Saad Gahwagi100% (1)

- Compact Controller (OCC100) User Guide For Ovation 3.6.0 and Feature Pack 4 OW360 - 50Dokument195 SeitenCompact Controller (OCC100) User Guide For Ovation 3.6.0 and Feature Pack 4 OW360 - 50Adrian ReyesNoch keine Bewertungen

- Trip Oil SystemDokument6 SeitenTrip Oil Systemsmart_eng2009100% (3)

- Developer Studio User Guide For Ovation 3.5 OW350 - 60: January 2013Dokument297 SeitenDeveloper Studio User Guide For Ovation 3.5 OW350 - 60: January 2013Ahmad100% (3)

- Control Builder Components ReferenceDokument368 SeitenControl Builder Components ReferenceBouazza100% (1)

- Geh 6700Dokument292 SeitenGeh 6700nabil160874100% (2)

- 02 OperatorStationDokument168 Seiten02 OperatorStationbmw316100% (1)

- GEH-6721 Vol IDokument202 SeitenGEH-6721 Vol Ivishnu ramkaran100% (1)

- Adani Power Mundra Unit 3 DCS Maintenance ManualDokument33 SeitenAdani Power Mundra Unit 3 DCS Maintenance ManualrahulNoch keine Bewertungen

- B0750ap - D System ManagerDokument328 SeitenB0750ap - D System ManagerSreedhar Avula100% (1)

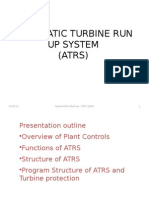

- Automatic Turbine Run Up SystemDokument47 SeitenAutomatic Turbine Run Up SystemNikhil Dhingra100% (1)

- DPU4F Address Configuration Sardar Sarovar Canal Head Power HouseDokument6 SeitenDPU4F Address Configuration Sardar Sarovar Canal Head Power HouseKrishna DNoch keine Bewertungen

- GEH-6721 Vol II PDFDokument908 SeitenGEH-6721 Vol II PDFMARIO OLIVIERINoch keine Bewertungen

- Sppa D3000Dokument20 SeitenSppa D3000Shahab AhmadaniNoch keine Bewertungen

- Electrical Inspection and Test PlanDokument19 SeitenElectrical Inspection and Test PlanRhadityo Shakti BudimanNoch keine Bewertungen

- Modbus Embedded Controller: Ndustrial Omputer Roducts Ata Cquisition YstemDokument34 SeitenModbus Embedded Controller: Ndustrial Omputer Roducts Ata Cquisition Ystemramesh_br85100% (1)

- ILF VacancyDokument2 SeitenILF VacancyRhadityo Shakti BudimanNoch keine Bewertungen

- DCR - Lge001-Csa-Str-101-10 150KV SS Steel Structure Disconnecting Switch W Earth (La) Section & Detail R1 SubmitDokument4 SeitenDCR - Lge001-Csa-Str-101-10 150KV SS Steel Structure Disconnecting Switch W Earth (La) Section & Detail R1 SubmitRhadityo Shakti BudimanNoch keine Bewertungen

- 1914 Apollo Series 65 Product GuideDokument21 Seiten1914 Apollo Series 65 Product GuideRhadityo Shakti Budiman0% (1)

- Technical Note Guided Wave Radar Interface Measurement Rosemount en 78542 PDFDokument20 SeitenTechnical Note Guided Wave Radar Interface Measurement Rosemount en 78542 PDFRhadityo Shakti BudimanNoch keine Bewertungen

- DCR - LGE001-CSA-CAL-103 150 KV Switchyard Structure Calculation - Lightning Arrester (LA) Rev 1Dokument7 SeitenDCR - LGE001-CSA-CAL-103 150 KV Switchyard Structure Calculation - Lightning Arrester (LA) Rev 1Rhadityo Shakti BudimanNoch keine Bewertungen

- PT PLN Design Change Request for Steel Structure Lightning ArrestersDokument1 SeitePT PLN Design Change Request for Steel Structure Lightning ArrestersRhadityo Shakti BudimanNoch keine Bewertungen

- Lge001-Csa-Str-101-10 150KV SS Steel Structure Disconnecting Switch W Earth (La) Section & Detail R1 SubmitDokument3 SeitenLge001-Csa-Str-101-10 150KV SS Steel Structure Disconnecting Switch W Earth (La) Section & Detail R1 SubmitRhadityo Shakti BudimanNoch keine Bewertungen

- DatasheetDokument71 SeitenDatasheetRhadityo Shakti BudimanNoch keine Bewertungen

- The Calibration of Flow Meters PDFDokument35 SeitenThe Calibration of Flow Meters PDFRené Mora-CasalNoch keine Bewertungen

- Processcontrol PDFDokument13 SeitenProcesscontrol PDFSIVANoch keine Bewertungen

- TNU SPC 60 002 A4 - Rev.0 - Specification For Instrument CableDokument17 SeitenTNU SPC 60 002 A4 - Rev.0 - Specification For Instrument CableRhadityo Shakti BudimanNoch keine Bewertungen

- 29psheet Design Master HVACDokument3 Seiten29psheet Design Master HVACRhadityo Shakti Budiman100% (2)

- PSV SelectionDokument12 SeitenPSV Selectionmetal_dung2Noch keine Bewertungen

- Control of Boiler Operation Using PLC - SCADADokument6 SeitenControl of Boiler Operation Using PLC - SCADAvikyarifNoch keine Bewertungen

- What An Instrument Engineer Should KnowDokument2 SeitenWhat An Instrument Engineer Should KnowHutama Putra Wibawa75% (4)

- Tomas Del Rosario College: Department: EDUCATIONDokument12 SeitenTomas Del Rosario College: Department: EDUCATIONveehneeNoch keine Bewertungen

- Display TFT SPI ST7735Dokument6 SeitenDisplay TFT SPI ST7735Adlene DenniNoch keine Bewertungen

- A Hirshfeld Surface Analysis and Crystal StructureDokument8 SeitenA Hirshfeld Surface Analysis and Crystal StructureLidiane MicheliniNoch keine Bewertungen

- Empowerment Technology - Week 2Dokument3 SeitenEmpowerment Technology - Week 2yahgieNoch keine Bewertungen

- Exhaust Brake PDFDokument2 SeitenExhaust Brake PDFFeliciaNoch keine Bewertungen

- Internal Controls and Risk Management: Learning ObjectivesDokument24 SeitenInternal Controls and Risk Management: Learning ObjectivesRamil SagubanNoch keine Bewertungen

- Republic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityDokument3 SeitenRepublic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityErika Joy EscobarNoch keine Bewertungen

- Face To Face Pre-Intermediate B1Dokument162 SeitenFace To Face Pre-Intermediate B1Andra OlariNoch keine Bewertungen

- Kavanaugh On Philosophical EnterpriseDokument9 SeitenKavanaugh On Philosophical EnterprisePauline Zoi RabagoNoch keine Bewertungen

- Lab Report 1Dokument8 SeitenLab Report 1Hammad SattiNoch keine Bewertungen

- Math 101Dokument3 SeitenMath 101Nitish ShahNoch keine Bewertungen

- Be3000 Manual 2016Dokument77 SeitenBe3000 Manual 2016Itzel JuárezNoch keine Bewertungen

- wt-and-fds-practical-slipsDokument32 Seitenwt-and-fds-practical-slipsRohidas SapkalNoch keine Bewertungen

- AWS D1.5 PQR TitleDokument1 SeiteAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamNoch keine Bewertungen

- Brake System PDFDokument9 SeitenBrake System PDFdiego diaz100% (1)

- Mil B 49430BDokument36 SeitenMil B 49430Bparam.vennelaNoch keine Bewertungen

- IPA Assignment Analyzes New Public AdministrationDokument8 SeitenIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNoch keine Bewertungen

- Design and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABDokument5 SeitenDesign and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABJeannot MpianaNoch keine Bewertungen

- Spectro Xepos Brochure 2016Dokument8 SeitenSpectro Xepos Brochure 2016Mary100% (1)

- Proejcr ManduaDokument552 SeitenProejcr ManduaDanny NguyenNoch keine Bewertungen

- Margin Philosophy For Science Assessment Studies: EstecDokument11 SeitenMargin Philosophy For Science Assessment Studies: EstecFeyippNoch keine Bewertungen

- Lec08 (Topic 4 Define Classes)Dokument33 SeitenLec08 (Topic 4 Define Classes)huaiencheengNoch keine Bewertungen

- HR MasterlistDokument6 SeitenHR MasterlistLeychelle AnnNoch keine Bewertungen

- Develop Network Monitoring System IP Subnet CalculatorDokument23 SeitenDevelop Network Monitoring System IP Subnet CalculatorabiramanNoch keine Bewertungen

- Individual Moving Range (I-MR) Charts ExplainedDokument18 SeitenIndividual Moving Range (I-MR) Charts ExplainedRam Ramanathan0% (1)

- Abiding LonelinessDokument9 SeitenAbiding Lonelinessgrupodelectura04Noch keine Bewertungen

- Maths Note P1 and P3Dokument188 SeitenMaths Note P1 and P3Afeefa SaadatNoch keine Bewertungen

- Managerial Performance Evaluation ProceduresDokument3 SeitenManagerial Performance Evaluation Procedures1robcortesNoch keine Bewertungen

- U1L2 - Definitions of 21st Century LiteraciesDokument19 SeitenU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloNoch keine Bewertungen

- Saes H 201Dokument9 SeitenSaes H 201heartbreakkid132Noch keine Bewertungen