Beruflich Dokumente

Kultur Dokumente

Dimension Scope Help

Hochgeladen von

Eby JoyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dimension Scope Help

Hochgeladen von

Eby JoyCopyright:

Verfügbare Formate

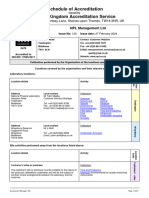

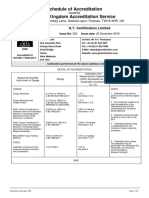

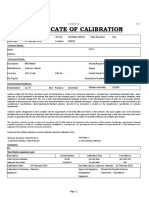

Schedule of Accreditation

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

Lambda Calibration Ltd

Issue No: 049 Issue date: 25 May 2018

Units 11-13 Contact: Brenda Seeds

Chorley Central Business Park Tel: +44 (0)845 241 1533

Stump Lane Fax: +44 (0)845 241 1544

0495 Chorley E-Mail: mail@lambda-cal.co.uk

Lancashire Website: www.lambda-cal.co.uk

Accredited to

PR6 0BL

ISO/IEC 17025:2005

Calibration performed by the Organisations at the locations specified below

Locations covered by the organisation and their relevant activities

Laboratory locations:

Location details Activity Location

code

Address Local contact Dimensional A

Lambda Calibration Ltd Brenda Seeds Electrical

Units 11-13 Pressure

Chorley Central Business Park Torque

Stump Lane Temperature

Chorley

Lancashire

PR6 0BL

Site activities performed away from the locations listed above:

Location details Activity Location

code

At customers premises Brenda Seeds Dimensional B

Electrical

Assessment Manager: AT Page 1 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

DETAIL OF ACCREDITATION

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

LENGTH NOTES

Gauge blocks Class (See Notes) Class C uncertainties A

apply to the measurement

Inch (Steel and Carbide) BS 4311-1:2007 C of length of gauges by

0.010 to 0.4 in 3.0 comparison with grade K

0.4 in to 1 in 4.0 standards of length of a

Size 2 in 5.0 inches similar material. Class C

Size 3 in 6.0 uncertainties apply to new

Size 4 in 7.0 and used grade 0, 1 and 2

gauges to BS 4311-

Millimetre (Steel and Carbide) BS EN ISO 3650:1999 C 1:2007 and BS EN ISO A

0.5 to 10 0.080 3650:1999.

10 to 25 0.10

Sizes 30, 40, 50 0.12 1. The uncertainty

60, 70, 75 0.15 quoted is for the departure

80, 90, 100 0.18 from flatness,

straightness, parallelism

Gauge block accessories As BS 4311-2:2009 0.30 or squareness, i.e. the A

0.1 to 12.5 distance separating the

two parallel planes which

just enclose the surface

Length gauges, flat and 0 to 1000 1.0 + (5.0 x length m) A

under consideration

spherical ended (excluding

Length Bars)

2. Single start,

symmetrical thread forms

Plain plug gauges parallel, 1 to 50 diameter 0.80 only. A

cylindrical setting standards 50 to 100 1.0

and rollers. 100 to 300 1.5 3. Functional test of size

using setting plugs

Plain ring gauges 0.7 to 10 diameter 1.0 calibrated with a CMC of A

(parallel) 10 to 50 0.80 3.0 µm

50 to 100 1.0

100 to 300 2.5 4. Features and

associated parts of these

Plain plug gauges (taper) gauges can be measured A

to the uncertainties given

Parallel to 1 in 3 on diameter 3 to 200 diameter 3.0 for equivalent items listed

in this schedule.

Plain ring gauges (taper) A

5. The uncertainty

Parallel to 1 in 3 on diameter 3 to 100 diameter 3.0 quoted is for the

100 to 200 diameter 5.0 application of the

calibration torque and

does not take into account

Precision balls 1 to 70 diameter 0.80 the characteristics of the

(steel, carbide, ceramic) device being calibrated.

Feeler Gauges BS 957:20080.025 to 1 1.0 6. Calibrations may also A

be given in lbf.in and lbf.ft

Assessment Manager: AT Page 2 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

LENGTH (cont’d) 7. Simple height gauges

- vernier, dial and digital

Gap gauges (Plain parallel) 2 to 100 3.0 instruments designed only A

100 to 200 5.0 for measuring distances

200 to 300 8.0 parallel to the beam.

Paint thickness setting foils 0 to 8 1.0 8. Conformance A

statements cannot be

Rule - steel BS 4372:1968 made against A

0 to 1000 5.0 + (10 x length in m) specifications whose

magnitudes are smaller

than the specified CMC

SCREW THREAD GAUGES

values

Screw plug gauges (parallel) 1 to 100 diameter 3.0 on pitch A

including check and setting 100 to 150 diameter 5.0 diameter

plugs. See Note 2

Screw plug gauges (taper) 5 to 100 diameter 5.0 on pitch

See Note 4 100 to 150 diameter 8.0 diameter

Screw ring gauges (parallel) 1 to 75 diameter 5.0 on pitch

See Note 2 75 to 150 diameter 7.0 diameter

Screw ring gauges (taper) 5 to 100 diameter 7.0 on pitch

See Note 2 100 to 150 diameter 10.0 diameter

Screw pitch 0.2 to 8 1.5

Screw flank angle 0° to 52° 5.0 minutes of arc

Screw thread adjustable 1 to 150 See note 3 A

caliper gauges (parallel) See

Note 2

Thread measuring cylinders BS 5590:1978 and specials A

0.1 to 5 0.50

Parallels BS 906:1972 A

5 to 50 x 100 x 400 1.5 to 5.0

Vee blocks BS 3731:1987 A

20 to 200 2.5 to 5.0

Receiver and position gauges, 0 to 600 x 600 x 600 See note 4 A

jigs, fixtures

0 to 700 x 450 x 250 (Using a 17µm + 8µm/m

coordinate measuring

machine)

Thread vee groove jaw blades 0.6 (40 T.P.I.) to 6.0 (4.5 3.0 A

T.P.I)

Assessment Manager: AT Page 3 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

ANGLE

Squares A

Blade type BS 939:2007 A

50 to 300 3.0

300 to 600 5.0

Cylindrical 75 to 300 2.0 A

300 up to 600 4.0 On squareness

see Note 1

Block 50 to 300 3.0 A

300 to 600 5.0

Right angle and box angle BS 5535:1878 Squareness: A

plates 50 to 600 3.0 + 1.0 per 100 mm

Parallelism:

1.0 + 1.0 per 100 mm

See Note 1

Sine bars and tables BS 3064:1978 Linear dimensions A

0 to 500 length 1.0 + (10 x length in m)

Overall performance 3.0

seconds of arc

Clinometers 0 to 360 10 seconds of arc A

Electronic indicating levels 0 minutes of arc to 8 minutes 1.0 % of range A

of arc Minimum 0.40 seconds

of arc

Spirit levels BS 3509:1962 and BS Mean sensitivity A

958:1968 10% of nominal

5 seconds of arc to 60 minutes Minimum 0.50 seconds

of arc nominal sensitivity of arc

MEASURING INSTRUMENTS

Micrometers

Micrometers A

External BS 870:2008 Heads: 2.0

0 to 600

Internal BS 959:2008 Setting and

0 to 900 extension rods

Depth BS 6468:2008 1.0 + (5.0 x length in m)

0 to 300

Micrometer, 3 point bore 6 to 250 3.0 + (12 x length in m) A

Assessment Manager: AT Page 4 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

MEASURING INSTRUMENTS

(cont’d)

Micrometer Heads BS 1734:1951 1.0 A

0 to 50

Height setting micrometer 0 to 300 Heads 1.5 between any A

two points

Stepped column 2.5

Overall performance 3.0

Riser blocks for above 150 2.5 A

300 5.0

MEASURING INSTRUMENTS

Vernier A

Caliper, Height and Depth BS 887:2008

gauges 0 to 1200 Overall performance

BS 1643:2008 10 + (30 x length in m)

0 to 1200

BS 6365:2008

0 to 600

Height gauges - (Simple) As BS EN ISO 13225:2012 Length measurement

including vernier, dial and 0 to 1200 error (E):

digital types (See notes 7 and 1 + (5 x length in metres)

8)

Bevel protractors As BS 1685:2008 6.0 minutes of arc A

0 to 360

Dial gauges and BS 907:2008 and BS A

dial test indicators 2795:1981 1.0

0 to 50

Displacement transducers 0 to 100 0.60 to 1.6 A

(linear)

Height gauges 0 to 1000 1.0 + (5 x length in m) A

(digital and electronic)

FORM

Surface plates

Granite and Cast Iron BS 817:2008 A, B

160 x 100 to 1600 x 1000 1.5 + (1.0 x diagonal in

m)

Assessment Manager: AT Page 5 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

MEASURING INSTRUMENTS

(cont’d)

Straightedges

Cast iron, Steel and Granite BS 5204:Part 1:1975 4.0 A

BS 5204:Part 2:1977 See note 1

0 to 2000

Tool makers flats 63 to 150 0.15 A

See note 1

Cube moulds for cement and BS EN 12390-1 2012 17µm + 8µm/m A

concrete 100 to 150 × 150 × 150

BS EN 196-1 2005

160 × 40 × 40

ELECTRICAL Note

MEASUREMENT Published uncertainties

apply for an environment

of 18C to 28C.

Measurements can take

place outside these limits

but at increased

uncertainties.

A, B

RESISTANCE 0 to 2 20 ppm + 15

2 to 20 11 ppm + 20

20 to 200 9.5 ppm + 110

200 to 2 k 9.5 ppm + 600

2 k to 20 k 9.5 ppm + 6.4 m

20 k to 200 k 9.7 ppm + 66 m

200 k to 2 M 12 ppm + 1.5

2 M to 20 M 24 ppm + 16

20 M to 200 M 87 ppm + 2.2 k

200 M to 2 G 240 ppm + 100 k

2 G to 20 G 0.16 % + 10 M

AC RESISTANCE 0.5 to 2 k A, B

50 Hz 0.65 %

DC VOLTS 0 mV to 200 mV 7.1 ppm + 600 nV A, B

200 mV to 2 V 4.1 ppm + 800 nV

2 V to 20 V 4.1 ppm + 4.8 V

20 V to 200 V 6.3 ppm + 47 V

200 V to 1050 V 6.5 ppm + 720 V

1 kV to 10 kV 0.050 %

Assessment Manager: AT Page 6 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

ELECTRICAL

MEASUREMENT (cont’d)

DC CURRENT 0 μA to 200 A 15 ppm + 500 pA A, B

200 A to 2 mA 16 ppm + 4.8 nA

2 mA to 20 mA 17 ppm + 48 nA

20 mA to 200 mA 54 ppm + 900 nA

200 mA to 2 A 200 ppm + 17 A

2 A to 10 A 170 ppm + 61 A

10 A to 20 A 440 ppm + 410 A

20 A to 100 A 640 ppm + 1.3 mA

100 A to 1 kA 300 ppm + 6.1 mA Measure only above 350

A

DC CURRENT Suitable for Clamp Meters A, B

Generation only 3.2 A to 105 A 0.24 % + 10 mA Using 10 turn coil

105 A to 200 A 0.24 % + 46 mA Using 10 turn coil

16 A to 160 A 0.24 % + 6.4 mA Using 50 turn coil

160 A to 525 A 0.24 % + 52 mA Using 50 turn coil

525 A to 1 kA 0.24 % + 230 mA Using 50 turn coil

AC VOLTAGE 1 μV to 200 mV A, B

20 Hz to 40 Hz 170 ppm + 4.2 V

40 Hz to 10 kHz 170 ppm + 4.4 V

10 kHz to 30 kHz 360 ppm + 5.0 V

30 kHz to 100 kHz 720 ppm + 20 V

200 mV to 2 V A, B

20 Hz to 40 Hz 130 ppm + 23 V

40 Hz to 10 kHz 130 ppm + 24 V

10 kHz to 30 kHz 240 ppm + 30 V

30 kHz to 100 kHz 500 ppm + 100 V

2 V to 20 V A, B

20 Hz to 40 Hz 130 ppm + 230 V

40 Hz to 10 kHz 130 ppm + 230 V

10 kHz to 30 kHz 240 ppm + 300 V

30 kHz to 100 kHz 500 ppm + 1.0 mV

20 V to 200 V

20 Hz to 40 Hz 140 ppm + 2.3 mV

40 Hz to 10 kHz 130 ppm + 2.4 mV

10 kHz to 30 kHz 240 ppm + 4.0 mV

30 kHz to 100 kHz 530 ppm + 11 mV

200 V to 300 V

20 Hz to 40 Hz 210 ppm + 71 mV

40 Hz to 10 kHz 140 ppm + 25 mV

10 kHz to 30 kHz 270 ppm + 44 mV

300 V to 1050 V

20 Hz to 40 Hz 210 ppm + 71 mV

40 Hz to 10 kHz 170 ppm + 51 mV

10 kHz to 30 kHz 340 ppm + 150 mV

Assessment Manager: AT Page 7 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

ELECTRICAL A, B

MEASUREMENT (cont’d)

AC VOLTAGE (cont’d) 1 kV to 10 kV @ 50 Hz 2.2 %

AC CURRENT 1 nA to 200 A

10 Hz to 1 kHz 380 ppm + 21 nA

1 kHz to 5 kHz 600 ppm + 21 nA

200 A to 2 mA

10 Hz to 1 kHz 380 ppm + 210 nA

1 kHz to 10 kHz 360 ppm + 200 nA

2 mA to 20 mA

10 Hz to 1 kHz 360 ppm + 2.1 A

1 kHz to 10 kHz 350 ppm + 2.0 A

20 mA to 200 mA

10 Hz to 1 kHz 380 ppm + 21 A

1 kHz to 10 kHz 330 ppm + 20 A

200 mA to 500 mA

40 Hz to 3 kHz 0.12 %

3 kHz to 5 kHz 0.15 %

200 mA to 2 A

10 Hz to 1 kHz 670 ppm + 230 A

1 kHz to 10 kHz 870 ppm + 210 A

2 A to 4 A

40 Hz to 3 kHz 0.16 %

3 kHz to 5 kHz 0.27 %

2 A to 20 A

10 Hz to 1 kHz 920 ppm + 2.4 mA

1 kHz to 10 kHz 0.26 % + 2.1 mA

20A to 50A

50 Hz 0.37%

AC CURRENT Suitable for Clamp Meters A, B

Generation only 3.2 A to 32 A (10 to 100 Hz) 0.33 % + 6.0 mA Using 10 turn coil

32 A to 200 A (10 to 100 Hz) 0.33 % + 100 mA Using 10 turn coil

3.2 A to 32 A (100 to 440 0.93 % + 31 mA Using 10 turn coil

Hz) 0.81 % + 290 mA Using 10 turn coil

32 A to 200 A (100 to 440 0.33 % + 320 mA Using 50 turn coil

Hz) 0.33 % + 520 mA Using 50 turn coil

16 A to 160 A (10 to 100 Hz)

160 A to 1 kA (10 to 100 Hz)

10 A to 50 A @ 50 Hz 0.38 %

Assessment Manager: AT Page 8 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

ELECTRICAL A, B

MEASUREMENT (cont’d)

DISTORTION

Distortion Factor

0.01 % to 0.1 %

0.2 V to 300 V The capabilities for

20 Hz to 20 kHz 0.015 % distortion factor distortion factor relate to

20 kHz to 100 kHz 0.029 % distortion factor fundamental components

in the frequency range 20

Hz to 100 kHz.

0.1 % to 1 %

0.2 V to 300 V

20 Hz to 20 kHz 0.15 % distortion factor

20 kHz to 100 kHz 0.29 % distortion factor

1 % to 30 %

0.2 V to 300 V

20 Hz to 20 kHz 15 % of reading

20 kHz to 100 kHz 30 % of reading

Spot frequency 1 kHz and 100 mV to 300 V

0.01 % to 0.1 % A

0.1 % to 3 % 0.0028 % distortion factor Calibration of distortion

3 % to 30 % 3.1 % of reading Analyzers

0.41 % of reading

Phase angle O o to 360 o 1.0 o

Assessment Manager: AT Page 9 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

ELECTRICAL SIMULTION OF

THERMOCOUPLES

UUT with RJC

Type: A, B

B +500 ºC to +1820 ºC 0.56 ºC

C 0 ºC to +2320 ºC 0.42 ºC

E -250 ºC to +1000 ºC 0.46 ºC

J -210 ºC to +1200 ºC 0.27 ºC

K -250 ºC to –200 ºC 0.58 ºC

K -200 ºC to +1372 ºC 0.29 ºC

L -200 ºC to +900 ºC 0.28 ºC

N -200 ºC to +1300 ºC 0.34 ºC

R 0 ºC to +1767 ºC 0.53 ºC

S 0 ºC to +1767 ºC 0.50 ºC

T -250 ºC to –200 ºC 0.60 ºC

T -200 ºC to +400 ºC 0.29 ºC

UUT without RJC A, B

Type:

B 250 ºC to +500 ºC 0.520 ºC

B +500 ºC to +1820 ºC 0.260 ºC

E -200 ºC to +1000 ºC 0.021 ºC

J -200 ºC to –80 ºC 0.059 ºC

J -80 ºC to +1200 ºC 0.030 ºC

K -200 ºC to –80 ºC 0.082 ºC

K -80 ºC to +1372 ºC 0.039 ºC

N -200 ºC to –80 ºC 0.130 ºC

N -80 ºC to +1300 ºC 0.056 ºC

R 0 ºC to +20 ºC 0.260 ºC

R +20 ºC to +1767 ºC 0.220 ºC

S 0 ºC to +20 ºC 0.260 ºC

S +20 ºC to +1767 ºC 0.220 ºC

T -200 ºC to –80 ºC 0.082 ºC

T -80 ºC to +400 ºC 0.043 ºC

Assessment Manager: AT Page 10 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

PRT Simulation A, B

At 1 mA

Spot Values - nominal

5Ω 120 µΩ

25.4 Ω 210 µΩ

100 Ω 520 µΩ

188 Ω 890 µΩ

254 Ω 1.2 mΩ

333 Ω 1.5 mΩ

400 Ω 1.8 mΩ

Pt100 (temperature

equivalents)

BS EN 60751:2008 -184 ºC 0.00050 ºC

0 ºC 0.0013 ºC

232 ºC 0.0025 ºC

420 ºC 0.0034 ºC

660 ºC 0.0047 ºC

Intermediate Values 0 Ω to 400 Ω 12 ppm + 0.75 mΩ Simulate between nominal A, B

– 200 ºC and 900 ºC

ELECTRICAL

MEASUREMENT

Thermistor Simulation The uncertainties are

-50 ºC 0.00047 ºC appropriate for a typical

-20 ºC 0.00039 ºC 10,000 Ohm NTC

0 ºC 0.00043 ºC thermistor simulation, and

+20 ºC 0.00043 ºC will vary for other types.

+40 ºC 0.00049 ºC Calibrations can also be

+60 ºC 0.00054 ºC carried out at other

+80 ºC 0.00059 ºC simulated temperatures in

+100 ºC 0.00065 ºC the range –50 ºC to +125

+120 ºC 0.00072 ºC ºC. The uncertainties will

+125 ºC 0.00073 ºC lie between the adjacent

points.

Thermometer Readout Ambient (nominally 20°C) 0.060 °C

(Ref Junction Compensation)

Optical Tachometers 0 RPM to 1000 RPM 0.020 RPM

1000 RPM to 10000 RPM 0.20 RPM

10000 RPM to 100000 RPM 2.0 RPM

Assessment Manager: AT Page 11 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

CAPACITANCE

Generation only 0 to 350 Hz

0.5 nF to 4 nF 0.35 % + 18 pF Suitable for the testing of A, B

4 nF to 40 nF 0.35 % + 35 pF capacitance measuring

40 nF to 400 nF 0.35 % + 190 pF devices

400 nF to 4 F 0.47 % + 2.0 nF

4 F to 40 F 0.57 % + 19 nF

40 F to 400 F 0.58 % + 190 nF

400 F to 4 mF 0.58 % + 2.0 F

4 mF to 40 mF 1.2 % + 69 F

350 Hz to 1.5 kHz

0.5 nF to 4 nF 0.70 % +35 pF

4 nF to 40 nF 0.70 % + 69 pF

40 nF to 400 nF 0.70 % + 370 pF

400 nF to 4 F 0.93 % + 3.0 nF

4 F to 40 F 1.2 % + 37 nF

40 F to 400 F 1.2 % + 370 nF

400 F to 4 mF 1.2 % + 4.0 F

4 mF to 40 mF 2.3 % +140 F

BANDWIDTH

3 dB point with respect to set Appropriate for calibration A, B

point of oscilloscopes

10 Hz to 50 kHz 0.60 %

50 kHz to 100 MHz 2.4 %

100 MHz to 250 MHz 5.2 %

FREQUENCY

10 MHz reference 1.0 in 109 Stable oscillators

2 Hz to 200 Hz 1.5 mHz May be expressed as time A

200 Hz to 1.3 GHz 2.0 in 109 (1/f) for repetitive

1.3 GHz to 20.1 GHz 5.0 in 109 measurements

Generation only 0.5 Hz to 250 MHz 0.29 ppm May be expressed as time A, B

(1/f ) for repetitive

measurements

Rise time Nominal 1 ns 100 mV to 500 90 ps In to 50 Ω

mV pulse rise and fall

Nominal 100 ns 5 V to 50 V 9 ns In to 1 M Ω

pulse rise and fall

TIME Electronically Triggered

Interval/Period Average 25 ns to 10 s 2.0 in 109 + (100 ns/No Actual uncertainties A, B

of periods) quoted on certificate will

include an allowance for

the characteristics of the

measured signal

Assessment Manager: AT Page 12 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

FREQUENCY (cont’d)

Time Interval (A-A Event) 100 ns to 109 s 2.0 in 109 + 100 ns A, B

Time Interval (A-B Event) 100 ns to 109 s 2.0 in 109 + 100 ns

Time Interval 0.1 ms to 10 s 1.8 % Appropriate for the A, B

calibration of RCD testers

TIME Mechanically Triggered over 1 second 50 ms A, B

POWER

At unity power factor ± 1 10 μW to 10.5 kW

@ 40 Hz to 1 kHz 0.20 %

4 kW to 21 kW

@ 50 Hz 0.47 %

AC Power Factor 0 to unity capacitive or 0.034 A, B

Inductive

DC power 10 μW to 10.5 kW 0.060 %

TORQUE

Hand torque tools To BS EN ISO 6789:2003 1.5 % See Notes 5 & 6 A

(including drivers) (withdrawn)

0.2 N·m to 1500 N·m

PRESSURE

Hydraulic pressure (gauge)

Calibration of pressure 500 kPa to 7 MPa 0.010 % Calibration of devices with A

indicating instruments and 7 MPa to 110 MPa 0.010 % an electrical output may

gauges 110 MPa to 400 MPa 0.013 % + 0.12 ppm/MPa be undertaken

Calibration of Piezoelectric 500 kPa to 7 MPa 0.36 % Calibration of devices with A

pressure transducers at quasi- 7 MPa to 400 MPa 0.36 % a charge output may be

static pressures undertaken

Pressure equivalent 500 kPa to 7 MPa 0.010 % + 90 Pa

calibration of Dead Weight 7 MPa to 70 MPa 0.010 % + 850 Pa

Testers (pressure balance 70 MPa to 110 MPa 0.010 % + 8.5 kPa

supplied with an associated 110 MPa to 400 MPa 0.013 % + 8.5 kPa + 0.12

mass set) ppm/MPa

Pressure relief valves and 0 Pa to 7 MPa 0.011 % + 1.2 kPa

switches 7 MPa to 70 MPa 0.011 % + 7 kPa

70 MPa to 110 MPa 0.011 % + 18 kPa

110 MPa to 140 MPa 0.015 % + 20 kPa

140 MPa to 400 MPa 0.013 % + 500 kPa

Assessment Manager: AT Page 13 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

PRESSURE (cont’d)

Gas pressure (gauge)

Calibration of pressure -95 kPa to -1.5 kPa 0.010 % Absolute pressure A

indicating instruments and -1.5 kPa to -125 Pa 0.010 % + 0.45 Pa calibrations can be

gauges -125 Pa to -24 Pa 0.35 % + 0.090 Pa undertaken using

-24 Pa to 24 Pa 0.35 % + 0.045 Pa associated barometric

Pressure equivalent 24 Pa to 125 Pa 0.35 % + 0.090 Pa pressure measurement

calibration of Dead Weight 125 Pa to 1.5 kPa 0.010 % + 0.45 Pa correction. The

Testers (pressure balance 1.5 kPa to 3.5 kPa 0.010 % uncertainties quoted will

supplied with an associated 3.5 kPa to 7 MPa 0.0090 % be increased by 8 Pa.

mass set) 7 MPa to 25 MPa 0.011 % + 4.0 kPa

25 MPa to 45 MPa 0.011 % + 7.0 kPa

Pressure relief valves and -95 kPa to –20 kPa 12 Pa

switches -20 kPa to –7 kPa 0.010 % + 3.70 Pa

-7 kPa to –3 kPa 0.011 % + 0.90 Pa

-3 kPa to –1.5 kPa 0.011 % + 0.60 Pa

-1.5 kPa to –160 Pa 0.025 % + 0.35 Pa

-160 Pa to –24 Pa 0.35 % + 0.090 Pa

-24 Pa to +24 Pa 0.35 % + 0.045 Pa

24 Pa to 160 Pa 0.35 % + 0.090 Pa

160 Pa to 1.5 kPa 0.025 % + 0.35 Pa

1.5 kPa to 3 kPa 0.011 % + 0.60 Pa

3 kPa to 7 kPa 0.011 % + 0.90 Pa

7 kPa to 20 kPa 0.010 % + 3.70 Pa

20 kPa to 200 kPa 40 Pa

200 kPa to 2 MPa 270 Pa

2 MPa to 6 MPa 0.011 % + 1.20 kPa

6 MPa to 25 MPa 0.011 % + 4.00 kPa

Gas pressure (absolute)

Calibration of pressure 1 Pa to 10 Pa 0.12 Pa A

indicating instruments and 10 Pa to 100 Pa 0.50 % + 0.40 Pa

gauges 100 Pa to 1 kPa 6.0 Pa

1 kPa to 3.5 kPa 7.0 Pa

3.5 kPa to 131 kPa 8.0 Pa

Assessment Manager: AT Page 14 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

TEMPERATURE

Radiation thermometers 20 C to 100 C 0.80 C A

(pyrometers) 100 C to 200 C 1.2 C

200 C to 300 C 1.9 C

300 C to 400 C 2.1 C

400 C to 500 C 2.6 C

Resistance Thermometers - 80 C to - 50 C 0.013 C 3 and 2 wire PRT can also A

(4 Wire) -50 C to 5 C 0.011 C be calibrated but will have

0 C (Ice Point) 0.007 C an increased uncertainty

0.01 C (Triple Point of Water) 0.003 C

20 C (Ambient) 0.010 C

5 C to 80 C 0.013 C

80 C to 160 C 0.015 C

160 C to 260 C 0.016 C

260 C to 425 C 0.032 C

425 C to 660 C 0.055 C

Temperature Indicators and/or - 80 C to- 50 C 0.012 C A

recorders with temperature - 50 C to 5 C 0.010 C

sensors 0 C (Ice Point) 0.006 C

0.01 C (Triple Point of Water) 0.003 C

20 C (Ambient) 0.010 C

5 C to 80 C 0.012 C

80 C to 160 C 0.014 C

160 C to 260 C 0.015 C

260 C to 425 C 0.031 C

425 C to 660 C 0.054 C

Block Calibrators - 80 C to 0 C 0.035 C A

0 C to 150 C 0.032 C

150 C to 250 C 0.040 C

250 C to 425 C 0.060 C

425 C to 660 C 0.090 C

660 C to 1100 C 1.1 C

1100 C to 1200 C 2.0 C

Noble Metal Thermocouples 0 C (Ice Point) 0.12 C Thermocouples without a A

(Thermocouples with cold 20 C (Ambient) 0.11 C cold junction will have an

junctions) 20 C to 260 C 0.11 C increased uncertainty

260 C to 660 C 0.35 C

660 C to 1100 C 1.2 C

1100 C to 1200 C 2.1 C

Assessment Manager: AT Page 15 of 16

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

0495 Lambda Calibration Ltd

Accredited to

Issue No: 049 Issue date: 25 May 2018

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability (CMC)

Expressed as an

Expanded

Uncertainty (k=2)

TEMPERATURE (cont’d)

Base metal Thermocouples 0 C (Ice Point) 0.062 C A

20 C (Ambient) 0.069 C

-80 C to 260 C 0.070 C

260 C to 425 C 0.15 C

425 C to 660 C 0.15 C

660 C to 1200 C 2.1 C

Extension or compensating A

cable

Base Metal 0 C (Ice Point) 0.026 C

20 C (Ambient) 0.040 C

-25 C to 200 C 0.040 C

Noble Metal 0 C (Ice Point) 0.11 C

20 C (Ambient) 0.10 C

20 C to 200 C 0.10 C

Thermistors 0°C (Ice Point) 0.007°C A

0.01ºC (Triple Point of Water) 0.003°C

Ambient (nominally 20°C) 0.010°C

-50°C to 5°C 0.010°C

5°C to 125°C 0.013°C

END

Assessment Manager: AT Page 16 of 16

Das könnte Ihnen auch gefallen

- Method Statement-Thickness GaugeDokument1 SeiteMethod Statement-Thickness GaugeEby JoyNoch keine Bewertungen

- Alien Legacy-Manual PDFDokument93 SeitenAlien Legacy-Manual PDFMark BallingerNoch keine Bewertungen

- 0103calibration SingleDokument1 Seite0103calibration Singledanielbo2220Noch keine Bewertungen

- Accreditation Certificate-0269calibration MultipleDokument6 SeitenAccreditation Certificate-0269calibration MultipleebbasinghNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument5 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceNoor N000rNoch keine Bewertungen

- Avery Weigh Tronix 054Dokument2 SeitenAvery Weigh Tronix 054huidhyiuodghNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument3 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceashishtrueNoch keine Bewertungen

- 0478calibration MultipleDokument67 Seiten0478calibration MultipleJose ramon cornelio torresNoch keine Bewertungen

- UKAS Hydrometer Calibration CertificateDokument2 SeitenUKAS Hydrometer Calibration Certificatejepri purwanto50% (2)

- L19-456-2 Com FinalDokument7 SeitenL19-456-2 Com FinalVERONICANoch keine Bewertungen

- 0809 UKAS Calibration ScheduleDokument17 Seiten0809 UKAS Calibration ScheduleEdwin Osogo100% (1)

- Acred 019 CDMXDokument7 SeitenAcred 019 CDMXVERONICANoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument4 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceEngwarwickNoch keine Bewertungen

- Alpha A2LA CertificateDokument5 SeitenAlpha A2LA CertificateNg Wei LihNoch keine Bewertungen

- KapDokument29 SeitenKapRajesh KumarNoch keine Bewertungen

- Diplomate ServivveDokument1 SeiteDiplomate ServivveSunil Kumar GoudaNoch keine Bewertungen

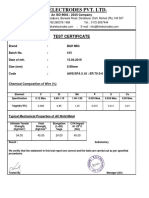

- B&H Electrodes Pvt. LTD.: Test CertificateDokument1 SeiteB&H Electrodes Pvt. LTD.: Test CertificatebrijeshNoch keine Bewertungen

- Anton Paar USA ISO 17025 Updated May 2020Dokument3 SeitenAnton Paar USA ISO 17025 Updated May 2020nabilaNoch keine Bewertungen

- 20807testing SingleDokument1 Seite20807testing SingleHayderr HassNoch keine Bewertungen

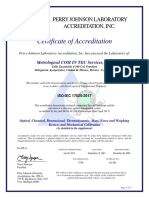

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument11 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncJoel MelendezNoch keine Bewertungen

- Wedge Anchor M10x150 CERTDokument1 SeiteWedge Anchor M10x150 CERTAlina DimaNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument4 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceRangaNoch keine Bewertungen

- Sae 1035Dokument2 SeitenSae 1035Maintenance Plant 1 & 2Noch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument32 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncOSCAR YOBANY VEGA HERNANDEZNoch keine Bewertungen

- RTD CertificateDokument2 SeitenRTD CertificateraghuNoch keine Bewertungen

- Raw Material Incoming Inspection Report: 0.23 - 0.28 0.30 Max 0.90 - 1.30 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Dokument2 SeitenRaw Material Incoming Inspection Report: 0.23 - 0.28 0.30 Max 0.90 - 1.30 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Maintenance Plant 1 & 2Noch keine Bewertungen

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDokument2 SeitenErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNoch keine Bewertungen

- Certificación Gammadensimetro. Oct. 2021Dokument3 SeitenCertificación Gammadensimetro. Oct. 2021Vladimir DovalNoch keine Bewertungen

- Sample MTC - C276-69.85mmDokument2 SeitenSample MTC - C276-69.85mmsachin.meshramNoch keine Bewertungen

- 3486 01Dokument3 Seiten3486 01Anonymous y3tPCbVrNoch keine Bewertungen

- Crs 000007Dokument2 SeitenCrs 000007ahetesham marufNoch keine Bewertungen

- Ground Bound Tester. Phoenix Calibration.Dokument3 SeitenGround Bound Tester. Phoenix Calibration.Vladimir DovalNoch keine Bewertungen

- SS420, 12mm-RamDokument1 SeiteSS420, 12mm-RamganeshNoch keine Bewertungen

- A2LA 1101 01 Valid To February 28 2017Dokument4 SeitenA2LA 1101 01 Valid To February 28 2017QA LAB ISMNoch keine Bewertungen

- KC EntDokument12 SeitenKC Entsai associatesNoch keine Bewertungen

- 0205testing MultipleDokument3 Seiten0205testing MultipleAazam KhanNoch keine Bewertungen

- Testi: OrationDokument1 SeiteTesti: OrationSusil Kumar SahooNoch keine Bewertungen

- Digital Inclinometer - 2022-15-FM1Dokument1 SeiteDigital Inclinometer - 2022-15-FM1Chethan Nagaraju KumbarNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument2 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceebbasinghNoch keine Bewertungen

- Specification Aa10109 1440410164 PDFDokument5 SeitenSpecification Aa10109 1440410164 PDFParthi NatarajNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument20 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncIsela ArrietaNoch keine Bewertungen

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDokument6 SeitenInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185Noch keine Bewertungen

- AccreditationDokument40 SeitenAccreditationWalid BdeirNoch keine Bewertungen

- 92a Astm B148 C95800Dokument2 Seiten92a Astm B148 C95800Qualitysm MicrotechprecisionengineeringNoch keine Bewertungen

- Tag No TL0010730Dokument4 SeitenTag No TL0010730Arvin AmiriNoch keine Bewertungen

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDokument1 Seite30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNoch keine Bewertungen

- Arc 2Dokument2 SeitenArc 2chandrabhushan kushwahaNoch keine Bewertungen

- 0080calibration MultipleDokument10 Seiten0080calibration MultiplePanneer SelvamNoch keine Bewertungen

- 1111-1179 Tata Steel BSL Limited ETM-2000-1153Dokument1 Seite1111-1179 Tata Steel BSL Limited ETM-2000-1153VikasNoch keine Bewertungen

- CAIRN-TSG-L-TN-0006-B1-Technical Notes For Flanges, Spectacle Blinds and Drip RingsDokument7 SeitenCAIRN-TSG-L-TN-0006-B1-Technical Notes For Flanges, Spectacle Blinds and Drip RingsGOPINATH KRISHNAN NAIRNoch keine Bewertungen

- Test Certificate: D & H Secheron Electrodes Pvt. LTDDokument1 SeiteTest Certificate: D & H Secheron Electrodes Pvt. LTDSagar KumarNoch keine Bewertungen

- 195 EL8 3.15mm Feb 20Dokument1 Seite195 EL8 3.15mm Feb 20harikrishnanNoch keine Bewertungen

- FF - 01 - Vernier CaliperDokument2 SeitenFF - 01 - Vernier CaliperMechtek LabNoch keine Bewertungen

- BYK Gardner USA Cert and Scope File 07 25 2022 - 1658779904Dokument17 SeitenBYK Gardner USA Cert and Scope File 07 25 2022 - 1658779904Raghunath DashNoch keine Bewertungen

- Certificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inDokument1 SeiteCertificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inharikrishnanNoch keine Bewertungen

- 1347 01Dokument3 Seiten1347 01Anonymous y3tPCbVrNoch keine Bewertungen

- Arc 1Dokument2 SeitenArc 1chandrabhushan kushwahaNoch keine Bewertungen

- Alcoa Ultralloy® 6020-T8 Aluminum: Metal, Nonferrous Metal, Aluminum Alloy, 6000 Series Aluminum AlloyDokument2 SeitenAlcoa Ultralloy® 6020-T8 Aluminum: Metal, Nonferrous Metal, Aluminum Alloy, 6000 Series Aluminum AlloyChristina Christina ChristinaNoch keine Bewertungen

- 10MMDokument1 Seite10MMStructures ProductionNoch keine Bewertungen

- UMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentVon EverandUMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentNoch keine Bewertungen

- 4700 Precision High Voltage MeterDokument4 Seiten4700 Precision High Voltage MeterEby JoyNoch keine Bewertungen

- Refer Electrical Dimension 0361calibration SingleDokument12 SeitenRefer Electrical Dimension 0361calibration SingleEby JoyNoch keine Bewertungen

- Certificate of Calibration: 08-Oc31356 - Revno:0Dokument1 SeiteCertificate of Calibration: 08-Oc31356 - Revno:0Eby JoyNoch keine Bewertungen

- GTC 1Dokument183 SeitenGTC 1Eby JoyNoch keine Bewertungen

- EUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Dokument23 SeitenEUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Eby Joy0% (2)

- Calibration ISO IEC 17025 Annex Temperature MetrologyDokument12 SeitenCalibration ISO IEC 17025 Annex Temperature MetrologyEby JoyNoch keine Bewertungen

- Review On Application of Drone in Agriculture Field: XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEEDokument6 SeitenReview On Application of Drone in Agriculture Field: XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEESagar PatilNoch keine Bewertungen

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFDokument240 SeitenLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- CVision AVR Man3 PDFDokument513 SeitenCVision AVR Man3 PDFsigiloNoch keine Bewertungen

- Assessment of Rotational Capacity Test Procedure FINALDokument21 SeitenAssessment of Rotational Capacity Test Procedure FINALzaheerahmed77Noch keine Bewertungen

- Common Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Dokument4 SeitenCommon Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Yashi SrivastavaNoch keine Bewertungen

- Case HardeningDokument38 SeitenCase HardeningsatyaNoch keine Bewertungen

- Zener DiodeDokument3 SeitenZener DiodeAde MurtalaNoch keine Bewertungen

- PreponlineDokument8 SeitenPreponlineGeeth SagarNoch keine Bewertungen

- Jovan Marjanovic Theory of Gravity MachinesDokument10 SeitenJovan Marjanovic Theory of Gravity MachinesWilhelm HartmanNoch keine Bewertungen

- Bcgroup GeniusDokument9 SeitenBcgroup GeniusNenad JovanovicNoch keine Bewertungen

- The Oredigger Issue 24 - April 26, 2010Dokument12 SeitenThe Oredigger Issue 24 - April 26, 2010The OrediggerNoch keine Bewertungen

- Garrita National High SchoolDokument5 SeitenGarrita National High SchoolAxle Rose CastroNoch keine Bewertungen

- BioStrength ServiceExcite Loader Manual - 8.0Dokument10 SeitenBioStrength ServiceExcite Loader Manual - 8.0powerliftermiloNoch keine Bewertungen

- Land Rover Popular PartsDokument25 SeitenLand Rover Popular Partseleanor shelbyNoch keine Bewertungen

- Contoh Form JsaDokument3 SeitenContoh Form JsaWahyu FebriantoNoch keine Bewertungen

- Numerical Modeling of MHD Convective Heat and Mass Transfer in Presence of First-Order Chemical Reaction and Thermal RadiationDokument20 SeitenNumerical Modeling of MHD Convective Heat and Mass Transfer in Presence of First-Order Chemical Reaction and Thermal Radiationmanasdutta3495Noch keine Bewertungen

- HQ Accessoriescatalogue 20142015 LRDokument28 SeitenHQ Accessoriescatalogue 20142015 LRapi-36492444Noch keine Bewertungen

- Lab 11.4.1: Using The Scandisk and Defrag Utilities: Estimated Time: 30 Minutes ObjectiveDokument2 SeitenLab 11.4.1: Using The Scandisk and Defrag Utilities: Estimated Time: 30 Minutes ObjectiveHamzaSpahijaNoch keine Bewertungen

- CilindarDokument44 SeitenCilindardjoko123Noch keine Bewertungen

- LiliaGutnik Resume 2013Dokument2 SeitenLiliaGutnik Resume 2013Lilia GutnikNoch keine Bewertungen

- DC Coding and Decoding With Convolutional CodesDokument28 SeitenDC Coding and Decoding With Convolutional CodesARAVINDNoch keine Bewertungen

- Ahlborn Hymnus IV - Manual de UsuarioDokument94 SeitenAhlborn Hymnus IV - Manual de Usuariogonbaa0% (1)

- Crystal StructuresDokument54 SeitenCrystal StructuresyashvantNoch keine Bewertungen

- ADPlaylistEditor3 (Network Version)Dokument42 SeitenADPlaylistEditor3 (Network Version)Dramane BonkoungouNoch keine Bewertungen

- H 012200 Barame Sho Man 2Dokument2 SeitenH 012200 Barame Sho Man 2Obande OrinyaNoch keine Bewertungen

- s7 1500 Compare Table en MnemoDokument88 Seitens7 1500 Compare Table en MnemoPeli JorroNoch keine Bewertungen

- Arc Welding ReadingDokument16 SeitenArc Welding ReadingJessica S. MellNoch keine Bewertungen

- ABB Contactor Wear GuidelinesDokument12 SeitenABB Contactor Wear GuidelinesPhuc PhamNoch keine Bewertungen

- Concrete Making MaterialsDokument55 SeitenConcrete Making Materialsjaffna100% (1)