Beruflich Dokumente

Kultur Dokumente

6 - Welding of Stainless Steel & Aluminium

Hochgeladen von

Aziful Aieman0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

46 Ansichten24 Seitenc

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenc

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

46 Ansichten24 Seiten6 - Welding of Stainless Steel & Aluminium

Hochgeladen von

Aziful Aiemanc

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 24

WELDING OF

STAINLESS STEEL &

ALUMINIUM

WHAT MAKES STEEL BECOMES

STAINLESS STEEL?

► Presence of Cr > 12% & Ni

► Formation of stable layer of protective chromium-

chromium-

rich oxide on surface (important on WM too) – for

stainless characteristic

► Fe, C, Cr & Ni - primary elements

► Cr retards rust → increase corrosion resistance

Problem when welding SS !

► Localised corrosive attack (on HAZ

longitudinally)

► WM & HAZ cracking

► Ductile to Brittle Fracture Transition

(Embrittlement)

CLASSIFICATION OF STAINLESS

STEEL

► Ferritic

SS (10-

(10-28%Cr, no Ni, no Mo) e.g.

400 series, 407, 430

► Martensitic SS (12Cr-

(12Cr-0.1C wt%, no Ni, +

Mo) e.g. 400 series, 410

► Austenitic SS (18Cr-

(18Cr-8Ni wt%) e.g. 200, 300

series

► Duplex SS (Austenitic + Ferritic) e.g. 329

ELEMENT STABILISER

► Elements which like Cr (Ferrite Stabilisers)

→ Promote Ferrite → Ferritic SS

► Elements which like Ni(AuteniteStabilisers)

→ Promote Austenite → Austenitic SS

CHARACTERISTIC OF FERRITIC SS

► Good resistance to chloride SCC

► Poor toughness

► Non Hardenable, Magnetic

► Coeff of Thermal Exp < Austenitic (about same as

Mild Steel)

► Higher yield strength, lower ductility than

austenitic SS

► Exhibit ductile-

ductile-to-

to-brittle fracture behaviour as CS

WELDABILITY OF FERRITIC SS

► Generally Weldable, Fusion Welded

► DO NOT weld using Oxy fuel gas Process, Carbon Arc Process

and CO2 W (not recommended) – Carbon pickup (formation of

CrC)

► Course grained HAZ – poor toughness → cracks

► Lower Cr → harden, martensites at GB

► Thick section require preheat ~ 200 oC and solution annealed

at 760 – 820 oC, water or air quench to improve Q & restore

full CorRes (due to dissociation of CrC).

► For better impact resistance – use austenitic SS filler metal

► For normal application match with the base metal

► Weld embrittlement possible when prolong used at high

temperature

► < 6 mm thickness – no special precaution necessary

► Thick section – needs low heat input to control grain

coursening

CHARACTERISTICS OF

MARTENSITIC SS

► Higher C (hard) → cracks

► ~ 11.5 – 18% Cr, C as high as 1.2%

► Good tensile, creep, fatigue strength (can be used

for high temperature environment)

► BCC alloy of Cr & C

► In hardened condition(martensitic) – BCT (Body-

(Body-

centred tetragonal)

► Ferromagnetic & hardenable

► CorRes < other SS (due to higher C content, CrC)

WELDABILITY OF MARTENSITIC SS

► Mostdifficult to weld

► Need special welding procedure

► Need tempering between 600 -750 oC (to

balance hardness & toughness)

CHARACTERISTICS OF AUSTENITIC SS

► 16-26%Cr, 8

16- 8--22%Ni

► 300 series, 316 (marine application)

► Type 304 18%Cr, 10%Ni (Basic) – commonly used for

welded fabrication

► Non Magnetic

► 50% of SS production

► Solidification & liquation cracking common

► Thermal expansion > other SS → distortion, residual

stresses

WELDABILITY OF AUSTENITIC SS

► Possible welding processes s.a. GTAW, GMAW, SMAW,

SAW

► Weld pool viscous →slow metal flow, low wettability →

lack of fusion

► Need relatively high travel speed, lower current – reduce

heat input, prevent carbide precipitation → minimise

distortion

► Control interpass temp (CrC formed bet. 500 – 850o C)

► To weld 304 SS, 308L filler metal is recommended. (L=Low

C content less than 0.03% to prevent weld decay)

► Good fabrication weldability, low temp toughness

► Poor Chloride SCC resistance, intolerant to contaminants

s.a. S, P & Boron.

► Suitable for Cryogenic application

CHARACTERISTICS OF DUPLEX SS

► Two phase alloy of Fe-

Fe-Cr

Cr--Ni system

► Approx. equal proportions of BCC Ferrite & FCC

Austenite phases & low C

► 20--30Cr, 5

20 5--10Ni

► Good strength, Chloride Stress-

Stress-Corrosion Cracking (SCC)

resistance, pitting corrosion resistance.

► Use in temperature range of ambient to several hundred

deg. F

► Acid & aqueous chloride resistance

► In high Ferritic content – poor low temp toughness

► In high Austenitic content – low strength, low resistance

to chloride SCC

► Suitable for offshore application

WELDABILITY OF DUPLEX SS

► Better than Ferritic SS, not as good as Austenitic

SS

► Solidification & Hydrogen cracking

► Avoid low heat input welding

► Preheat normally not required

► Control interpass temp

► Filler metal overalloyed with Nitrogen

► Shielding gas may contain Nitrogen

WELDING OF

ALUMINIUM

CHARACTERISTICS OF

ALUMINIUM

► Light weight, high thermal conductivity, low

melting point

► Easy burnthrough, warpage

► Alloying element Cu,Mn,Si,Mg,Zn

► Al

Al--Mn alloy (1.0-

(1.0-1.2%Mn), Al-

Al-Mg alloy (up to

5%Mg), Al-Al-Mg-

Mg-Mn alloy

► 3 types of Aluminium:

► PureAluminium – 99.7, 99.5, 99.0% Al, non hardenable

► Non heat treatable Al Alloy – Al & Mn

► Strengthincreased thru cold working or strain hardening

by mechanical deformation

► Heat treatable Al Alloy (hardenable)–

(hardenable)–(Cu), (Mg+Si), (Zn+Mg)

► Can be heated after welding to regain strength

ALUMINIUM SERIES

► 1000 Series - Pure Aluminium

► 2000 - Al & Cu (high strength, aerospace

industry) –limited weldability

► 3000 - Al & Mn (low/medium strength,

beverage cans) – non heat treatable

► 4000 - Al & Si (for welding/brazing filler wire).

Si to lower melting temp hence can be

used for brazing material.

► 5000 - Al & Mg (structural application in sheet

or plate, weldable)

► 6000 - Al, Mg & Si (heat treatable, for

extrusion, sheet & plate, weldable,

crack sensitive, welding must use filler

metal)

► 7000 - Al & Zn (high strength aerospace alloy)

► 8000 - Others

Aluminium & Aluminium Alloy Designation

Al

Al Cu Mn Si Mg Mg/Si Zn Other

1xxx 2xxx 3xxx 4xxx 5xxx 6xxx 7xxx 8xxx

Electrical, Strength Formability Brazing Strength Strength Strength

Thermal Welding After Extrusionability

Conductivity Filler Welding

Non Heat Treatable

Heat Treatable

WELDABILITY OF ALUMINIUM &

ALLOY

► Hardenable alloy – difficult to weld, hot cracking

► Cast Al with high Cu or Mg content–

content– unsuitable for welding

► Aluminium Oxide easily formed on welding, needs good shielding (Ar + He)

► Aluminium Oxide melting point high

► Al Oxide can cause welding defects

► Scrap or brush using SS wire prior to welding, brush in one direction.

► Other contaminants s.a. grease, paint cause pores in weld

► Recommended welding methods are GTAW & GMAW

► Use AC with GTAW, Zirconiated tungsten electrode

► Less distortion with GMAW, use push-

push-pull type of welding equipment, DCRP

► Pulse--Arc welding gives less distortion, low defects

Pulse

► Root backing by Cu or steel

► Inert Gas Backing or Purging

► Al & NHT Alloy – filler wire same with BM

► Hardenable Alloy – use high Si or Mg in filler wire to avoid hot cracking, preheating

► 5000 series – shielding by Ar + He, good penetration, minimise MgO

E

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Introduction To Mechanical Engineering DesignDokument16 SeitenIntroduction To Mechanical Engineering DesignAziful AiemanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Chapter 5 - Org & HRMDokument50 SeitenChapter 5 - Org & HRMAziful AiemanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- 5a - Welding Metallurgy of Carbon SteelDokument16 Seiten5a - Welding Metallurgy of Carbon SteelAziful AiemanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 7.1 Environmental Quality ActDokument20 Seiten7.1 Environmental Quality ActAziful AiemanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Topic T1: Mass, Momentum and Energy AUTUMN 2013Dokument32 SeitenTopic T1: Mass, Momentum and Energy AUTUMN 2013Aziful AiemanNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Etr - Siti Zubaidah Azizan M at 14 - 5Dokument5 SeitenEtr - Siti Zubaidah Azizan M at 14 - 5Aziful AiemanNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Misrun Defects 2. Cut and Washes Defects: Results Type of DefectDokument2 SeitenMisrun Defects 2. Cut and Washes Defects: Results Type of DefectAziful AiemanNoch keine Bewertungen

- 7.4 Employment Act and RegulationDokument63 Seiten7.4 Employment Act and RegulationAziful AiemanNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Chapter 2 MEC600Dokument50 SeitenChapter 2 MEC600Aziful AiemanNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

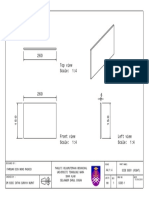

- 2 6 0 Top View Scale: 1:4 Isometric View Scale: 1:4Dokument1 Seite2 6 0 Top View Scale: 1:4 Isometric View Scale: 1:4Aziful AiemanNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- (BLADE) Inner BladeDokument1 Seite(BLADE) Inner BladeAziful AiemanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Top View Scale: 1:1 4 8 - 2 5 Isometric View Scale: 1:1Dokument1 SeiteTop View Scale: 1:1 4 8 - 2 5 Isometric View Scale: 1:1Aziful AiemanNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- FunnelDokument1 SeiteFunnelAziful AiemanNoch keine Bewertungen

- Top View Scale: 1:3 Isometric View Scale: 1:3Dokument1 SeiteTop View Scale: 1:3 Isometric View Scale: 1:3Aziful AiemanNoch keine Bewertungen

- (BLADE) New Shredder BladeDokument1 Seite(BLADE) New Shredder BladeAziful AiemanNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shredder HousingDokument1 SeiteShredder HousingAziful AiemanNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 2nd Presentation ReportDokument14 Seiten2nd Presentation ReportAziful AiemanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- (BOX) Rear BodyDokument1 Seite(BOX) Rear BodyAziful AiemanNoch keine Bewertungen

- "The Alpha Truck" Progress Report: Em220: Bachelor of Mechanical EngineeringDokument2 Seiten"The Alpha Truck" Progress Report: Em220: Bachelor of Mechanical EngineeringAziful AiemanNoch keine Bewertungen

- New CO5b - MEC532 Progress Assessment Form 2Dokument1 SeiteNew CO5b - MEC532 Progress Assessment Form 2Aziful AiemanNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Expectorant SDokument5 SeitenExpectorant SBob Villa Fisher CaplanNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Cambridge International General Certificate of Secondary EducationDokument16 SeitenCambridge International General Certificate of Secondary EducationAdam GhaliNoch keine Bewertungen

- IodometryDokument4 SeitenIodometryRenol ArnevNoch keine Bewertungen

- Analysis Presentation 1Dokument12 SeitenAnalysis Presentation 1Muhammad Hussain KhalilNoch keine Bewertungen

- Chapter 13 Multiple-Choice QuestionsDokument16 SeitenChapter 13 Multiple-Choice Questionsteresa tsoiNoch keine Bewertungen

- 05 - Periodic ClassificationDokument29 Seiten05 - Periodic ClassificationSamveg ClassesNoch keine Bewertungen

- Ionic Bonding Dot and Cross WorksheetDokument2 SeitenIonic Bonding Dot and Cross WorksheetBasra AbdillahiNoch keine Bewertungen

- Chemistry SparknotesDokument12 SeitenChemistry Sparknotesapi-287852328Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Engineering Metallurgy Chapter 5Dokument28 SeitenEngineering Metallurgy Chapter 5Mayur SatputeNoch keine Bewertungen

- ENG2223 PAM Tutorial 2 SolutionDokument5 SeitenENG2223 PAM Tutorial 2 SolutionCovyn YongNoch keine Bewertungen

- Periodic Table of ElementsDokument1 SeitePeriodic Table of Elementsteknologipangan bthNoch keine Bewertungen

- Ductile IronDokument2 SeitenDuctile Ironpraval84Noch keine Bewertungen

- EAPCETDokument2 SeitenEAPCETP. Phani prasadNoch keine Bewertungen

- What Is Periodic TableDokument19 SeitenWhat Is Periodic TableAli AkbarNoch keine Bewertungen

- Science 8 3RD Quater Exam ReviewerDokument6 SeitenScience 8 3RD Quater Exam ReviewerCrafter CaptsNoch keine Bewertungen

- Law of Definite Proportions Lab ReportDokument3 SeitenLaw of Definite Proportions Lab Reportrinkeanmark50% (2)

- Class 10 Mid Exam 2019Dokument12 SeitenClass 10 Mid Exam 2019Khalid HassanNoch keine Bewertungen

- Metals and Non Metals ExcDokument3 SeitenMetals and Non Metals ExcGaurav BatraNoch keine Bewertungen

- LME Zinc FactsheetDokument6 SeitenLME Zinc FactsheetOscar Zuñiga SolariNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- AnaChem ProblemsDokument4 SeitenAnaChem ProblemsGarcia RaphNoch keine Bewertungen

- Manganese Price Jan MarDokument2 SeitenManganese Price Jan Marsharath_medishettyNoch keine Bewertungen

- Price List: Fans Home Appliances Lighting SwitchgearDokument10 SeitenPrice List: Fans Home Appliances Lighting SwitchgearYashwanth KrishnanNoch keine Bewertungen

- Ionic vs. Covalent Bonding Lab InvestigationDokument3 SeitenIonic vs. Covalent Bonding Lab InvestigationLeslieNoch keine Bewertungen

- Unit 2 The Components of MatterDokument106 SeitenUnit 2 The Components of MatterlmaohelloxdNoch keine Bewertungen

- CopperDokument6 SeitenCoppershubhangi garg100% (1)

- Natural Science 3: MatterDokument7 SeitenNatural Science 3: MatterEchuserang FrogletNoch keine Bewertungen

- BKB Ha0402Dokument203 SeitenBKB Ha0402Rashedul IslamNoch keine Bewertungen

- Code of Scheduled WasteDokument6 SeitenCode of Scheduled WasteBazlaa HasmanNoch keine Bewertungen

- Astm G1 - 03 - Evaluating Corrossion PDFDokument9 SeitenAstm G1 - 03 - Evaluating Corrossion PDFVasu RajaNoch keine Bewertungen

- Chapter 2, 3Dokument35 SeitenChapter 2, 3silvanyangelliong2Noch keine Bewertungen