Beruflich Dokumente

Kultur Dokumente

Running Tubing

Hochgeladen von

Abdul Hameed OmarOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Running Tubing

Hochgeladen von

Abdul Hameed OmarCopyright:

Verfügbare Formate

1.

TOOLS AND EQUIPMENT

TWO SPANNERS (BULLDOG GRIP REMOVAL)

TIMBER (FOR SEPARATING ROWS)

HIGH PRESSURE WASH GUN

PAINT & BRUSH / WOOD CHOCKS

DERRICK TAPE

SLINGS

2. SAFETY INFORMATION AND PRECAUTIONS

HOLD A PRE-TOUR OR PRE-JOB SAFETY MEETING.

THOROUGHLY CHECK ALL HIGHLINE WIRES, SNATCH BLOCK SHEAVES,

SHACKLES AND SLINGS ARE IN GOOD CONDITION.

ENSURE TAG LINES ARE USED ON THE ENDS OF EACH CRANE LOAD.

TENDER AND RIG FLOOR WINCHMEN TEST INTERCOMS AND ENSURE GOOD

COMMUNICATION IS ESTABLISHED. INFORM EACH OTHER OF ANY SAFETY

HAZARDS. DO NOT ASSUME THE OTHER OPERATOR IS AWARE OF THEM.

PIN PROTECTORS ARE SNUGGED UP.

DO NOT OPERATE HIGHLINE WHILE CRANE BOOM IS OVER LINE.

SHOULD ANY PROBLEMS ARISE DURING THE RUNNING OF TUBING, INFORM

YOUR SUPERVISOR AND RECTIFY THE PROBLEM IMMEDIATELY.

CATWALK AND DROP ZONES MUST REMAIN CLEAR OF PERSONNEL DURING

LOAD TRANSFER.

CLEAR PRECISE INSTRUCTIONS VIA THE INTERCOM, ARE ESSENTIAL.

ALL ASSEMBLIES MUST BE PROPERLY PROTECTED AND TRANSFERRED

CAREFULLY. PUP JOINTS OF MODERATE LENGTH ARE TO BE TRANSFERRED BY

BASKET.

3. PROCEDURES

3.1. PREPARING

1. LAY OUT FIRST ROW OF TUBING, KEEPING PIN ENDS LEVEL. LONG STRING

AND SHORT STRING JOINTS WILL BE IN A DIVIDED BAY.

2. REMOVE AND CLEAN ALL THREAD PROTECTORS.

3. DRIFT EACH JOINT WITH THE CORRECT SIZED TEFLON DRIFT,

EXERCISING CARE NOT TO DAMAGE THREAD AND SEAL AREAS. (DRIFT

TUBING SAME AS CASING)

(A) CONNECT A CABLE TO EACH END OF THE CORRECT SIZED DRIFT.

(B) FEED THE CABLE THROUGH THE FIRST JOINT AND INSTALL THE

DRIFT.

(C) MAN AT THE OTHER END PULLS THE DRIFT THROUGH AND FEEDS

THE CABLE INTO NEXT JOINT.

WARNING: WHEN THE DRIFT REACHES THE END OF THE

TUBING, CARE MUST BE EXERCISED TO ENSURE THAT THE

DRIFT DOES NOT DROP OUT AND CAUSE PERSONAL INJURY.

4. PROPERLY CLEAN ALL THREADS WITH HIGH PRESSURE WASH GUN AND

THOROUGHLY INSPECT ALL THREADS AND SEAL AREAS REPORT ANY

SUSPECT THREAD OR SEAL FACE AND REPLACE WITH NEW JOINT.

5. NUMBERS ARE THEN PAINTED ON THE JOINTS 2 FT FROM THE BOX AND

PIN TOOL JOINTS. A SINGLE BAND IS PAINTED NEAR EACH BOX AND PIN

TOOL JOINT TO IDENTIFY THE STRING. THE SHORT STRING IS PAINTED IN

WHITE AND WILL HAVE ODD NUMBERS. THE LONG STRING AND SHORT

STRING ARE SEQUENTIAL.

6. NOTIFY WSDE OR PERSON RESPONSIBLE FOR TUBING MEASUREMENT.

DECK MANDORE TO RECORD MEASUREMENTS ON SEPARATE SHEET.

MEASUREMENTS ARE COMPARED AND ANY JOINT THAT DIFFERS WILL BE

RE-MEASURED.

7. REPLACE ALL THREAD PROTECTORS AND ENSURE THEY ARE SNUG.

8. LAY 2" X 4" WOOD STRIPPING ON TOP OF ROW AND REPEAT AS THE FIRST

LAYER UNTIL ALL JOINTS ARE LAID OUT.

9. ALL PUP JOINTS WILL BE SERVICED AS PER STEPS 2-4 AND 6-7.

10. PUP JOINTS OF THE SAME LENGTHS TO BE KEPT TOGETHER AND

NUMBERED IN SEQUENCE WITH WHITE PAINT E.G. P1, P2, P3, ETC.

11. LAY OUT ASSEMBLIES FOR ADS TO NUMBER AND MEASURE.

3.2. RUNNING TUBING

1. PLACE TUBING ON CATWALK. REMOVE BOX PROTECTORS AND INSTALL

LIFTING CAPS.

2. THREAD ½” TUBING SLINGS THROUGH LIFTING CAPS (4 JTS PER SLING)

DOUBLE WRAP PIN END. IF USING CHROME TUBING, USE RUBBER COATED

SLINGS SUPPLIED BY B.S.P.

3. WHEN READY TENDER AND RIGFLOOR WINCHMEN RAISE THE BASKET TO

THE V-DOOR.

4. REMOVE SLINGS AND RETURN HIGHLINE WITH LIFTING CAPS TO

TENDER FOR NEXT LOAD.

5. ATTACH THE HIGHLINE TO THE TUBING. WHEN READY TENDER AND RIG

FLOOR WINCHMEN RAISE THE TUBING TO THE V-DOOR.

6. REMOVE THE SLINGS AND ATTACH TO THE LIFTING CAPS READY TO BE

RETURNED TO THE BARGE.

Das könnte Ihnen auch gefallen

- Hazard And Risk Analysis A Complete Guide - 2020 EditionVon EverandHazard And Risk Analysis A Complete Guide - 2020 EditionNoch keine Bewertungen

- HSE-RA-067 Threading Machine - Rev 0Dokument14 SeitenHSE-RA-067 Threading Machine - Rev 0عمروNoch keine Bewertungen

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- Tools and Equipment: 2-08 Changing Suction ModuleDokument2 SeitenTools and Equipment: 2-08 Changing Suction ModuleAbdul Hameed OmarNoch keine Bewertungen

- BOP Nipple Down 17-May-2010Dokument1 SeiteBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- Senior Pump Operator: Passbooks Study GuideVon EverandSenior Pump Operator: Passbooks Study GuideNoch keine Bewertungen

- SLP STD 28 CHIKSANDokument20 SeitenSLP STD 28 CHIKSANmashanghNoch keine Bewertungen

- Change Out Rig Tong DiesDokument1 SeiteChange Out Rig Tong DiesAbdul Hameed OmarNoch keine Bewertungen

- 2-07 1. Tools and Equipment: Changing LinersDokument2 Seiten2-07 1. Tools and Equipment: Changing LinersAbdul Hameed OmarNoch keine Bewertungen

- Safe Work Procedure A Complete Guide - 2020 EditionVon EverandSafe Work Procedure A Complete Guide - 2020 EditionNoch keine Bewertungen

- BOP-08 - (Koomey Unit, Bleed Off Pressure) - RV (1) Jan. '05Dokument1 SeiteBOP-08 - (Koomey Unit, Bleed Off Pressure) - RV (1) Jan. '05Abdul Hameed OmarNoch keine Bewertungen

- Precision Drilling International Task Risk Assessment WorksheetDokument1 SeitePrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNoch keine Bewertungen

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDokument6 SeitenArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusNoch keine Bewertungen

- Land RigDokument2 SeitenLand RigRoger AddyNoch keine Bewertungen

- Rig Skill ScrewDokument73 SeitenRig Skill Screwylaala8010Noch keine Bewertungen

- DOP 206 - Rev 4Dokument12 SeitenDOP 206 - Rev 4Fernando AybarNoch keine Bewertungen

- Safety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonsDokument4 SeitenSafety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonskhaledNoch keine Bewertungen

- Floorman-Tasks & ProjDokument9 SeitenFloorman-Tasks & ProjAmeerNoch keine Bewertungen

- PackerDokument9 SeitenPackerMahesh sinhaNoch keine Bewertungen

- Caught Between - Spooling Cable Results in An InjuryDokument2 SeitenCaught Between - Spooling Cable Results in An InjuryAbdul Hameed OmarNoch keine Bewertungen

- Adjust Brake On Draw WorksDokument1 SeiteAdjust Brake On Draw WorksDQE040 HSSENoch keine Bewertungen

- Drilling and Well ConstructionDokument36 SeitenDrilling and Well ConstructionMarcio Nascimento BezerraNoch keine Bewertungen

- Basic of Rig SafetyDokument90 SeitenBasic of Rig SafetyAli MessaoudiNoch keine Bewertungen

- JSA HEMP Well Services Pg25-30Dokument5 SeitenJSA HEMP Well Services Pg25-30Ashok SureshNoch keine Bewertungen

- Rig Building ReportDokument22 SeitenRig Building ReportAditya SumanNoch keine Bewertungen

- Rig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: InitialsDokument1 SeiteRig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: Initialssaeed ghafooriNoch keine Bewertungen

- #12 Rig Up and Run CasingDokument1 Seite#12 Rig Up and Run Casingkhurram100% (1)

- Responsibilities of Rig Superintendent StudyDokument7 SeitenResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavNoch keine Bewertungen

- Safety Communications Log Sheet 2008Dokument1 SeiteSafety Communications Log Sheet 2008Abdul Hameed OmarNoch keine Bewertungen

- #101 - Oilfield HSE Inspection HandbookDokument30 Seiten#101 - Oilfield HSE Inspection HandbookEagle EyeNoch keine Bewertungen

- OIl Rig Safety ChecklistDokument10 SeitenOIl Rig Safety ChecklistTom TaoNoch keine Bewertungen

- MaxiRider ManualDokument36 SeitenMaxiRider ManualSalam Elec fsuptNoch keine Bewertungen

- Tennin HAZOPDokument4 SeitenTennin HAZOPMohamed SamirNoch keine Bewertungen

- Rig Safety PresentationDokument20 SeitenRig Safety PresentationMohamed MostafaNoch keine Bewertungen

- #15 Laying Down PipeDokument1 Seite#15 Laying Down PipekhurramNoch keine Bewertungen

- Viking H Se ManualDokument168 SeitenViking H Se ManualAF Dowell MirinNoch keine Bewertungen

- Safety Lines 75Dokument7 SeitenSafety Lines 75Ben FriskneyNoch keine Bewertungen

- Bairstow RiggingDokument168 SeitenBairstow Riggingswhite336Noch keine Bewertungen

- 1 PDFDokument39 Seiten1 PDFAmirHossein SaberBaghabnNoch keine Bewertungen

- Golden RulesDokument10 SeitenGolden RulesSrđan NjegićNoch keine Bewertungen

- Saudi Aramco: Installation of Telecommunication Equipment On High Structures, Including Radio TowersDokument5 SeitenSaudi Aramco: Installation of Telecommunication Equipment On High Structures, Including Radio TowersaymenmoatazNoch keine Bewertungen

- Drilling TerminologyDokument75 SeitenDrilling TerminologyAshish Kumar JhaNoch keine Bewertungen

- Well Control Equipment Course (Wcec) For Floating RigsDokument3 SeitenWell Control Equipment Course (Wcec) For Floating RigsrickyngsNoch keine Bewertungen

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationDokument5 SeitenArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusNoch keine Bewertungen

- Drill StringDokument27 SeitenDrill StringAboZaidNoch keine Bewertungen

- Milling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURDokument5 SeitenMilling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURAshok SureshNoch keine Bewertungen

- Emergency PreparednessDokument10 SeitenEmergency Preparednessnitin_kulkarni_2Noch keine Bewertungen

- Derrick Escape Descender - Instruction ManualDokument12 SeitenDerrick Escape Descender - Instruction ManualSteve WatsonNoch keine Bewertungen

- Predator Flow ChartDokument1 SeitePredator Flow ChartJuan DelgadoNoch keine Bewertungen

- Sec6 Subsea Blowout Preventers PDFDokument22 SeitenSec6 Subsea Blowout Preventers PDFMaría MarquinaNoch keine Bewertungen

- Equipment Register - Pat Testing Original CertificateDokument3 SeitenEquipment Register - Pat Testing Original CertificateSayed AbbasNoch keine Bewertungen

- Operation and Maintenance Manual: Triplex Mud Pump - Skid MountedDokument118 SeitenOperation and Maintenance Manual: Triplex Mud Pump - Skid MountedrolandNoch keine Bewertungen

- Oil Rig Inspection ChecklistDokument17 SeitenOil Rig Inspection ChecklistAhmedNoch keine Bewertungen

- Workover Operations PDFDokument13 SeitenWorkover Operations PDFterusunduhNoch keine Bewertungen

- Pre-Spud Checklist # 4Dokument2 SeitenPre-Spud Checklist # 4Yougchu LuanNoch keine Bewertungen

- Pick Up Drill PipeDokument5 SeitenPick Up Drill PipeinfonexusNoch keine Bewertungen

- 091 Preventing Crown CollisionsDokument5 Seiten091 Preventing Crown CollisionsalduwaikiNoch keine Bewertungen

- 39 - Buckling & Wellhead Load After CementingDokument2 Seiten39 - Buckling & Wellhead Load After CementingAbdul Hameed OmarNoch keine Bewertungen

- 10 - Simple Mud Engineerv1.22Dokument22 Seiten10 - Simple Mud Engineerv1.22Abdul Hameed OmarNoch keine Bewertungen

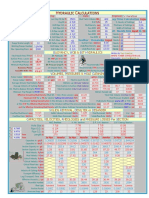

- Hydraulic Calculations MudpumpDokument1 SeiteHydraulic Calculations MudpumpSudish BhatNoch keine Bewertungen

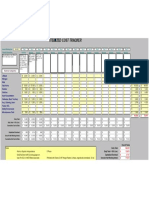

- Wo Cost TrackerDokument1 SeiteWo Cost TrackerAbdul Hameed OmarNoch keine Bewertungen

- Data Input Sheet: A Worksheet From Well Control TOOLKIT - .Dokument4 SeitenData Input Sheet: A Worksheet From Well Control TOOLKIT - .Abdul Hameed OmarNoch keine Bewertungen

- Drilling Application: Name of Company: Well Name & Number: DateDokument1 SeiteDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNoch keine Bewertungen

- Subsea AccumulatorsDokument4 SeitenSubsea AccumulatorsAbdul Hameed OmarNoch keine Bewertungen

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDokument3 SeitenMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarNoch keine Bewertungen

- Drilling Application: Name of Company: Well Name & Number: DateDokument1 SeiteDrilling Application: Name of Company: Well Name & Number: DateAbdul Hameed OmarNoch keine Bewertungen

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Dokument1 SeiteDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNoch keine Bewertungen

- Allowable Drilling Torque: Calculations 30,577 4.855 21.733 4.154 0.362 0.2Dokument1 SeiteAllowable Drilling Torque: Calculations 30,577 4.855 21.733 4.154 0.362 0.2Abdul Hameed OmarNoch keine Bewertungen

- Ideal Kick Removal: Drill Hole DataDokument2 SeitenIdeal Kick Removal: Drill Hole DataAbdul Hameed OmarNoch keine Bewertungen

- 1260707780BOP Equipment Failure ReportDokument1 Seite1260707780BOP Equipment Failure ReportAbdul Hameed OmarNoch keine Bewertungen

- 1260709146e - Hydraulics PDFDokument9 Seiten1260709146e - Hydraulics PDFAbdul Hameed OmarNoch keine Bewertungen

- 1260707829bop Test FormDokument4 Seiten1260707829bop Test FormAbdul Hameed Omar100% (1)

- Assortment of Mini ApplicationsDokument1 SeiteAssortment of Mini ApplicationsAbdul Hameed OmarNoch keine Bewertungen

- TDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTDokument1 SeiteTDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTAbdul Hameed OmarNoch keine Bewertungen

- New TDS 11 CourseDokument171 SeitenNew TDS 11 CourseAbdul Hameed Omar100% (3)

- Asset RegisterDokument101 SeitenAsset RegistertothemNoch keine Bewertungen

- B 0000188Dokument20 SeitenB 0000188jose antonioNoch keine Bewertungen

- Cilindro AssemblyDokument3 SeitenCilindro AssemblyCK ChioNoch keine Bewertungen

- Alibration Escription: - F-1100 Single Turbine - Insertion Flow Meter Frequency OutputDokument2 SeitenAlibration Escription: - F-1100 Single Turbine - Insertion Flow Meter Frequency OutputrameshNoch keine Bewertungen

- 150.12-AD1 (922) - MCHX Fluid-To-Air Heat Exchangers in Stationary HVAC ApplicationsDokument20 Seiten150.12-AD1 (922) - MCHX Fluid-To-Air Heat Exchangers in Stationary HVAC ApplicationsSachin SiwachNoch keine Bewertungen

- The in Uence of The Bourdon Effect On Pipe Elbow: September 2016Dokument11 SeitenThe in Uence of The Bourdon Effect On Pipe Elbow: September 2016araz_1985Noch keine Bewertungen

- JDM A24 Spec For Electric-Resistance Welded Steel Mechanical TubingDokument5 SeitenJDM A24 Spec For Electric-Resistance Welded Steel Mechanical TubingJoe ScopeliteNoch keine Bewertungen

- Installation Guideline For AGRUSAFE Sure Grip Concrete Protective Double Sealing SystemDokument22 SeitenInstallation Guideline For AGRUSAFE Sure Grip Concrete Protective Double Sealing SystemManriquez Andres100% (1)

- Mueller: B-101 and B-100 Drilling and Tapping MachineDokument16 SeitenMueller: B-101 and B-100 Drilling and Tapping MachineaurabloodNoch keine Bewertungen

- MothballingDokument130 SeitenMothballingrajeshpillai83Noch keine Bewertungen

- G Cem4000 Ops BDokument106 SeitenG Cem4000 Ops BSebastian Torres100% (1)

- IOM Manual ICV USDokument2 SeitenIOM Manual ICV USJhon GuerreroNoch keine Bewertungen

- Operation Manual 2 in 1 Filling Capping Full UpdatedDokument103 SeitenOperation Manual 2 in 1 Filling Capping Full UpdatedRiyoko Fillex100% (2)

- Itp Ec14epDokument1 SeiteItp Ec14epRavi ShankarNoch keine Bewertungen

- Blue Gas Supply and Installation Company Profile Portfolio and CertificationsDokument23 SeitenBlue Gas Supply and Installation Company Profile Portfolio and Certificationslito77Noch keine Bewertungen

- Robin Engine EH650 EH650DC7091Dokument29 SeitenRobin Engine EH650 EH650DC7091yewlimNoch keine Bewertungen

- Diy PVC Grow Light StandDokument7 SeitenDiy PVC Grow Light StandRichard MussioNoch keine Bewertungen

- High Head Small HydroDokument17 SeitenHigh Head Small HydroCortney JohnsonNoch keine Bewertungen

- Ficha Tecnica Tuberias Viega Pureflow - TDPF - 0120 - Pureflow - Pex - TubingDokument4 SeitenFicha Tecnica Tuberias Viega Pureflow - TDPF - 0120 - Pureflow - Pex - TubingDaniella GarciaNoch keine Bewertungen

- Fata Livelihood Project (FLP) : Tehsil JamrudDokument19 SeitenFata Livelihood Project (FLP) : Tehsil JamrudSyedShahHasnainNoch keine Bewertungen

- 2.875 N80 6.51ppf EUEDokument1 Seite2.875 N80 6.51ppf EUEHanyNoch keine Bewertungen

- Recovery Boiler Floor Inspection Experience TAPPI2004Dokument31 SeitenRecovery Boiler Floor Inspection Experience TAPPI2004delta_scopeNoch keine Bewertungen

- Notice Soac M25nss52er0Dokument227 SeitenNotice Soac M25nss52er0Hassan YoussefNoch keine Bewertungen

- CPI Part 3&4 (Chemical Processing & Process Flow Diagrams) PDFDokument54 SeitenCPI Part 3&4 (Chemical Processing & Process Flow Diagrams) PDFBench GuecoNoch keine Bewertungen

- Automatic Programming For Industrial Robot To WeldDokument9 SeitenAutomatic Programming For Industrial Robot To WeldAgus WidyiantoNoch keine Bewertungen

- Data Rates Gate Works 13Dokument15 SeitenData Rates Gate Works 13vpmohammedNoch keine Bewertungen

- Format Punchlist PDFDokument27 SeitenFormat Punchlist PDFDuan Tokcer100% (2)

- Ingersolrand Portable Diesel Compressor PartsDokument163 SeitenIngersolrand Portable Diesel Compressor PartsTeo Deustch100% (6)

- Astm - A761 A761m 04 (2009)Dokument8 SeitenAstm - A761 A761m 04 (2009)nugroho teguhNoch keine Bewertungen

- DetDisp ECM Barrelmaking v2.0 Shopping ListDokument8 SeitenDetDisp ECM Barrelmaking v2.0 Shopping ListDiegoMartinezCastrillonNoch keine Bewertungen

- EQ VA20 Volumetric Valve: Operating ManualDokument17 SeitenEQ VA20 Volumetric Valve: Operating ManualChristian RobertoNoch keine Bewertungen

- House Rules: How to Decorate for Every Home, Style, and BudgetVon EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNoch keine Bewertungen

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiVon EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiBewertung: 4 von 5 Sternen4/5 (3)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsVon EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsVon EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNoch keine Bewertungen

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiVon Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiBewertung: 5 von 5 Sternen5/5 (2)

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- Edward's Menagerie: Dogs: 50 canine crochet patternsVon EverandEdward's Menagerie: Dogs: 50 canine crochet patternsBewertung: 3 von 5 Sternen3/5 (5)

- Modern Embroidery: A Book of Stitches to Unleash CreativityVon EverandModern Embroidery: A Book of Stitches to Unleash CreativityNoch keine Bewertungen

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsVon EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsNoch keine Bewertungen

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesVon EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesBewertung: 5 von 5 Sternen5/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!Von EverandCrochet Impkins: Over a million possible combinations! Yes, really!Bewertung: 4.5 von 5 Sternen4.5/5 (10)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersVon EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreVon EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreBewertung: 4 von 5 Sternen4/5 (6)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Von EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Noch keine Bewertungen

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsVon EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsBewertung: 4 von 5 Sternen4/5 (5)

- Modern Crochet Sweaters: 20 Chic Designs for Everyday WearVon EverandModern Crochet Sweaters: 20 Chic Designs for Everyday WearBewertung: 5 von 5 Sternen5/5 (1)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeVon EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeBewertung: 5 von 5 Sternen5/5 (1)

- Funny Amigurumi: 16 Creatures & Their Accessories to CrochetVon EverandFunny Amigurumi: 16 Creatures & Their Accessories to CrochetBewertung: 5 von 5 Sternen5/5 (1)

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsVon EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsBewertung: 5 von 5 Sternen5/5 (3)

- Little Happy Circus: 12 Amigurumi Crochet Toy Patterns for Your Favourite Circus PerformersVon EverandLittle Happy Circus: 12 Amigurumi Crochet Toy Patterns for Your Favourite Circus PerformersBewertung: 5 von 5 Sternen5/5 (3)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesVon Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNoch keine Bewertungen

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsVon EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsNoch keine Bewertungen

- How to Embroider Almost Everything: A Sourcebook of 500+ Modern Motifs & Easy Stitch TutorialsVon EverandHow to Embroider Almost Everything: A Sourcebook of 500+ Modern Motifs & Easy Stitch TutorialsBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldVon EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldBewertung: 4.5 von 5 Sternen4.5/5 (30)

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtVon EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtNoch keine Bewertungen

- Art Journals & Creative Healing: Restoring the Spirit through Self-ExpressionVon EverandArt Journals & Creative Healing: Restoring the Spirit through Self-ExpressionBewertung: 3 von 5 Sternen3/5 (7)

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookVon EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Textiles Transformed: Thread and thrift with reclaimed textilesVon EverandTextiles Transformed: Thread and thrift with reclaimed textilesNoch keine Bewertungen

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreVon EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreBewertung: 5 von 5 Sternen5/5 (5)