Beruflich Dokumente

Kultur Dokumente

5S - Levels of Excellence

Hochgeladen von

Hartoyo SwiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5S - Levels of Excellence

Hochgeladen von

Hartoyo SwiCopyright:

Verfügbare Formate

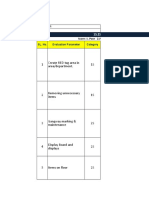

5S Levels of Excellence

SORTING SIMPLIFYING SWEEPING STANDARDIZING SUSTAINING

Employees are A dependable, Area employees Everyone is continually There is a general appearance

continually seeking documented method has have devised a seeking the elimination of of a confident understanding

LEVEL improvement been developed to dependable, waste with changes of, and adherence to, the 5S

5 opportunities. provide continual documented method documented and principles.

evaluation, and a of preventive cleaning information shared.

Focus on

process is in place to and maintenance.

Prevention implement improvements.

A dependable, A dependable, 5S agreements are Substantial process Follow-through with 5S

documented documented method has understood and documentation is available agreements and safety

LEVEL method has been been established to practiced continually. and followed. practices is evident.

4 established to keep recognize in a visual

the work area free sweep if items are out of

Focus on

of unnecessary place or exceed quantity

Consistency items. limits.

Unnecessary items Designated locations are Work/break areas Working environment 5S agreements and safety

have been marked to make and machinery are changes are being practices have been

LEVEL documented. Visual control

removed from the Organization more cleaned on a daily developed and are utilized.

3 workplace. visible. basis. Visual controls agreements for labeling and

have been quantity levels established.

Make it visual

established and

marked.

Necessary and A designated location Work/breaks areas Methods are being A recognizable effort has been

unnecessary items has been established for are cleaned on a improved but changes made to improve the condition

LEVEL are separated. items. regular scheduled haven' been documented. of the workplace.

2 basis. Key Items to

check have been

Focus on

identified.

Basics

Needed and not Items are randomly Work place areas are Work place methods are Work place checks are

needed items are located throughout the dirty, disorganized not consistently followed randomly performed and there

LEVEL mixed throughout work place. and key items not and are undocumented. is no visual measurement of 5S

1 the work place. marked or identified. performance.

Just

Beginning

Performed by: Area: Date:

Scoring Criteria Item

# Description Rating Scale: 0-5 (poor = 0, excellent = 5) Score Notes for next level improvement

General Office has a well organized, clean, neat professional look. Items

1 not required for performing work are removed from the workplace.

Appearance Personal items are stored in one drawer.

Cleaning All cleaning equipment is stored in a neat manner; handy & easily

2

Equipment available when needed. (Papertowels, duster, Lysol, glass cleaner)

3 Floor Cleaning All floors are clean & free of debris & dirt.

No outdated, torn, or soiled announcements are displayed.

4 Bulletin Boards Bulletin Boards are arranged in a straight, neat manner, & properly

mounted.

Emergency

Emergency evacuation plans are in place & personnel knows

5 Access &

where located .

Evacuation Plan

Large items such as storage boxes are not routinely stored on the

6 Storage on Floor

floor. Extension cords are properly organized and stored.

Desk/Computer Nothing is stored under desk. Computer files (e-mail deleted &

7

Storage recycle bin) are kept neat, cleaned out, and organized.

Coat racks are available and coats are stored there, not on the

8 Coat Racks

backs of chairs.

9 Labeling Drawers & file folders are clearly labeled preferably typed.

Equipment All machines & equipment are kept clean (free of extra paper) by

10 (Computers, routine daily care. Computer screens & key boards are clean,

printers, faxes) windows & desktops are clean - no dust bunnies.

11 Binders All binders are labeled and clearly identified.

12 Badges Badges are worn by all employees.

Equipment - Nothing is stored on top of computers, cabinets, or equipment;

13

Storage nothing leans against the walls or columns.

Only documents necessary to the work are stored at desks; such

Documents - documents & binders are stored in a neat & orderly manner & a

14 visual management system for these items are in place. No

Storage/Control unlabeled binders/documents are present. Obsolete or unused

documents are removed.

15 Filing Filing system is visible and easy to understand.

Desktop Work Detailed instructions put together with the intent to make sure if a

16 Instructions/ person is absent from their job, a person could step in & find their

Binder Available way around the work area, important for critical operations.

Shelves, File Shelves, file cabinets & desks are arranged, divided & clearly

Cabinets, & Desks - labeled to make it obvious where things are stored. They are kept

17

Arrangement & free of unused objects. Items are returned to proper location after

Maintenance each use.

There is a disciplined system of control & maintenance to assure

5S Control & that each of the above items is maintained at the highest possible

18 level. It is the responsibility of the team to maintain this system.

Maintenance The 5S poster is displayed in a prominent place, & everyone

understands it.

Total Score: Divided by 18 = Avg. Score:

Das könnte Ihnen auch gefallen

- 5S - Excellence Assessment PDFDokument2 Seiten5S - Excellence Assessment PDFAshokNoch keine Bewertungen

- 5S Audit MudaMastersDokument1 Seite5S Audit MudaMastersManoj ShahNoch keine Bewertungen

- Guide 5SDokument33 SeitenGuide 5SGUILLERMO VAZQUEZNoch keine Bewertungen

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsVon Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsBewertung: 5 von 5 Sternen5/5 (1)

- Systems Drive BehaviourDokument15 SeitenSystems Drive BehaviourchrysobergiNoch keine Bewertungen

- 6s Evaluation FormDokument3 Seiten6s Evaluation FormDhananjay PatilNoch keine Bewertungen

- 5S Audit ProcessDokument5 Seiten5S Audit ProcessChatnoir NoirNoch keine Bewertungen

- LEAN STRATEGY: Why people in great companies cannot wait for MondaysVon EverandLEAN STRATEGY: Why people in great companies cannot wait for MondaysNoch keine Bewertungen

- SMED single minute exchange of die A Complete Guide - 2019 EditionVon EverandSMED single minute exchange of die A Complete Guide - 2019 EditionNoch keine Bewertungen

- Elementary Quality Assurance ToolsDokument19 SeitenElementary Quality Assurance ToolsignaunaqNoch keine Bewertungen

- Basic Concepts On 5s Kaizen TQMDokument19 SeitenBasic Concepts On 5s Kaizen TQMRodj Eli Mikael Viernes-IncognitoNoch keine Bewertungen

- 5s CSRDokument69 Seiten5s CSRFadzilahMohamadNoch keine Bewertungen

- 5S Audit Scorecard: Alumina Refinery Mechanical DepartmentDokument1 Seite5S Audit Scorecard: Alumina Refinery Mechanical DepartmentMohammad Abubakar SiddiqNoch keine Bewertungen

- Compensation Management Assignment: Shingo ModelDokument3 SeitenCompensation Management Assignment: Shingo ModelHarsheen KaurNoch keine Bewertungen

- BF Area - 5S Check ListDokument30 SeitenBF Area - 5S Check ListVi KraNoch keine Bewertungen

- 5S (Methodology) - WikipediaDokument4 Seiten5S (Methodology) - WikipediaBORRELNoch keine Bewertungen

- 1S2S3S - Check SheetDokument1 Seite1S2S3S - Check SheetManoj KaushikNoch keine Bewertungen

- 6S in HealthcareDokument13 Seiten6S in HealthcareChannel MedicalNoch keine Bewertungen

- 5S Map Structure Handout 20160108Dokument2 Seiten5S Map Structure Handout 20160108Ramesh Babu100% (1)

- 6S Levels of Achievement Matrix Self AssessmentDokument3 Seiten6S Levels of Achievement Matrix Self AssessmentAnbalagan Ravichandran100% (1)

- Implement 5 "S" System: Visual FactoryDokument47 SeitenImplement 5 "S" System: Visual FactoryAnil Maurya100% (1)

- Ciencia Y Virtud: The 7SDokument11 SeitenCiencia Y Virtud: The 7SElle DyNoch keine Bewertungen

- 5S Training OfficeDokument21 Seiten5S Training OfficeDhiraj Pradhan100% (1)

- Introduction To 5SDokument98 SeitenIntroduction To 5SnahomNoch keine Bewertungen

- Five S Implementation: SORT (Clearing Up Space) OrganizationDokument8 SeitenFive S Implementation: SORT (Clearing Up Space) OrganizationDONNoch keine Bewertungen

- 6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1Dokument5 Seiten6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1stylish eagleNoch keine Bewertungen

- 5s Step by Step GuideDokument10 Seiten5s Step by Step GuideKalkidan MekuriyaNoch keine Bewertungen

- Office 5S ChecklistDokument15 SeitenOffice 5S ChecklistAkhilesh Yadav100% (1)

- 5S TrainingDokument30 Seiten5S Trainingamaresh nkNoch keine Bewertungen

- Kaizen Structure Rev0Dokument86 SeitenKaizen Structure Rev0hiattolaNoch keine Bewertungen

- Direction For The Kata WayDokument30 SeitenDirection For The Kata WayhydrasearchNoch keine Bewertungen

- 6S - 5S - Evaluation and Implementation Tool - LeanDokument8 Seiten6S - 5S - Evaluation and Implementation Tool - LeanShekhar RaviNoch keine Bewertungen

- 5S Concept Tool For Operation and Quality Excellence 1564423751Dokument2 Seiten5S Concept Tool For Operation and Quality Excellence 1564423751Parag Mane100% (1)

- Presentation On House Keeping TechniquesDokument82 SeitenPresentation On House Keeping TechniquesJanak DoshiNoch keine Bewertungen

- The Lean Stack - Part 1Dokument15 SeitenThe Lean Stack - Part 1iNFuT™ - Institute for Future TechnologyNoch keine Bewertungen

- 5S Implementation Manual Part 2Dokument63 Seiten5S Implementation Manual Part 2jgprasadNoch keine Bewertungen

- Presentation 6 S STARTER TrainingDokument96 SeitenPresentation 6 S STARTER Trainingm_ramas2001Noch keine Bewertungen

- Operational Excellence A Complete Guide - 2019 EditionVon EverandOperational Excellence A Complete Guide - 2019 EditionBewertung: 1 von 5 Sternen1/5 (1)

- The 5S Shapes Game - What's Missing?Dokument2 SeitenThe 5S Shapes Game - What's Missing?Asrizal asrizalNoch keine Bewertungen

- 5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsDokument21 Seiten5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsAtul SharmaNoch keine Bewertungen

- Value Stream Mapping Software A Complete Guide - 2020 EditionVon EverandValue Stream Mapping Software A Complete Guide - 2020 EditionNoch keine Bewertungen

- 5S Audit Checklist and Report 1663039107Dokument2 Seiten5S Audit Checklist and Report 1663039107Ashish R. SinghNoch keine Bewertungen

- Visual ControlDokument29 SeitenVisual ControlDeepak NayakNoch keine Bewertungen

- 5S Thoughts - AllDokument12 Seiten5S Thoughts - Allssk3712Noch keine Bewertungen

- 5S Audit FormDokument1 Seite5S Audit FormViorel IosubNoch keine Bewertungen

- 5 S Information and Training OutlineDokument5 Seiten5 S Information and Training Outlinekprasad_mlNoch keine Bewertungen

- Css-5s Audit ScorecardDokument4 SeitenCss-5s Audit ScorecardTarunaiNoch keine Bewertungen

- 5s Audit Check SheetDokument1 Seite5s Audit Check SheetDevendra Singh100% (1)

- SMED single minute exchange of die Complete Self-Assessment GuideVon EverandSMED single minute exchange of die Complete Self-Assessment GuideNoch keine Bewertungen

- 5S Is A Defined Visual Simple Method For Maintaining The Workplace in The Optimum Condition and Eliminate WasteDokument1 Seite5S Is A Defined Visual Simple Method For Maintaining The Workplace in The Optimum Condition and Eliminate WastejplaraziNoch keine Bewertungen

- International Business Centre (Ibc) : One Day Training Programme OnDokument35 SeitenInternational Business Centre (Ibc) : One Day Training Programme Onanpuselvi125Noch keine Bewertungen

- NAME OF COMPANY - 5S Audit ChecklistDokument2 SeitenNAME OF COMPANY - 5S Audit ChecklistDũng Tây NinhNoch keine Bewertungen

- Office 5s ChecklistDokument109 SeitenOffice 5s ChecklistSercan SülünNoch keine Bewertungen

- Quiz Answers Standard WorkDokument4 SeitenQuiz Answers Standard WorkJose OrtegaNoch keine Bewertungen

- Lean Assessment2Dokument18 SeitenLean Assessment2Yenaro CortesNoch keine Bewertungen

- Understanding The Self Midterm Exam - PasigDokument1 SeiteUnderstanding The Self Midterm Exam - PasigEarl Tyrone P. Blanco100% (1)

- Stage 1 Handwriting Program Term 2Dokument4 SeitenStage 1 Handwriting Program Term 2api-206221838Noch keine Bewertungen

- Status Report Cbms 2020Dokument20 SeitenStatus Report Cbms 2020Lilian Belen Dela CruzNoch keine Bewertungen

- Solutions To Mathematics 17 Exercises On Systems of Equations PDFDokument6 SeitenSolutions To Mathematics 17 Exercises On Systems of Equations PDFMichael Christian BaysauliNoch keine Bewertungen

- Chapter 2 - Consumer Behavior - Market SegmentationDokument26 SeitenChapter 2 - Consumer Behavior - Market SegmentationAhmed RaufNoch keine Bewertungen

- Mac CyrillicDokument6 SeitenMac CyrillicRazvan DiezNoch keine Bewertungen

- VBH - Pull Handle - FramelessDokument10 SeitenVBH - Pull Handle - FramelessgoreechongNoch keine Bewertungen

- SCITECH - OBE SyllabusDokument12 SeitenSCITECH - OBE SyllabusMary Athena100% (1)

- 3406 Discrete MathematicsDokument3 Seiten3406 Discrete MathematicsFaiza ShafiqNoch keine Bewertungen

- Lecture 1 EntrepreneurshipDokument35 SeitenLecture 1 EntrepreneurshipNipul BafnaNoch keine Bewertungen

- The Universe ALWAYS Says YES - Brad JensenDokument15 SeitenThe Universe ALWAYS Says YES - Brad JensenNicole Weatherley100% (3)

- Lab Report Physics FinalDokument5 SeitenLab Report Physics FinalJahrel DaneNoch keine Bewertungen

- Market Technician No 44Dokument16 SeitenMarket Technician No 44ppfahdNoch keine Bewertungen

- Insurance Regulatory & Development Authority Act: Module - 5Dokument12 SeitenInsurance Regulatory & Development Authority Act: Module - 5RKNoch keine Bewertungen

- GRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridayDokument4 SeitenGRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridayAILEEN GALIDONoch keine Bewertungen

- Chapter Three SpeechDokument12 SeitenChapter Three SpeechAlex GetachewNoch keine Bewertungen

- New Maths Frameworking: Matches The Revised KS3 FrameworkDokument232 SeitenNew Maths Frameworking: Matches The Revised KS3 FrameworkMerihane Naguib100% (2)

- Listening FIB SpellingDokument6 SeitenListening FIB SpellingAtif JavedNoch keine Bewertungen

- Ieee-Pc57 12 80-2002Dokument4 SeitenIeee-Pc57 12 80-2002Dioven A. CadungogNoch keine Bewertungen

- An Effective Cover LetterDokument4 SeitenAn Effective Cover LetterbernmamNoch keine Bewertungen

- Guide To GENEX Assistant Drive Test (20101031)Dokument28 SeitenGuide To GENEX Assistant Drive Test (20101031)Aruna FermadiNoch keine Bewertungen

- Lesson Plan 6 ReflectionDokument4 SeitenLesson Plan 6 Reflectionapi-295690946Noch keine Bewertungen

- Full HRM Notes by Ram Chad Ran SirDokument122 SeitenFull HRM Notes by Ram Chad Ran SirKrupa PatilNoch keine Bewertungen

- VTU 7 Sem B.E (CSE/ISE) : Java/ J2EeDokument57 SeitenVTU 7 Sem B.E (CSE/ISE) : Java/ J2EeNikhilGuptaNoch keine Bewertungen

- 8259 Programmable ControllerDokument44 Seiten8259 Programmable ControllerShilpa ShettyNoch keine Bewertungen

- The Machine Stops - The New YorkerDokument8 SeitenThe Machine Stops - The New YorkermalvinaNoch keine Bewertungen

- Ielts Reading Test 10 - QuestionsDokument5 SeitenIelts Reading Test 10 - QuestionsĐinh Quốc LiêmNoch keine Bewertungen

- Sun Safety PresentationDokument14 SeitenSun Safety Presentationrichard_mikealNoch keine Bewertungen

- American Association For Medical Transcription 100 Sycamore Avenue, Modesto, CA 95354-0550 - 800-982-2182Dokument5 SeitenAmerican Association For Medical Transcription 100 Sycamore Avenue, Modesto, CA 95354-0550 - 800-982-2182JijoNoch keine Bewertungen

- Zhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)Dokument465 SeitenZhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)IrinaNoch keine Bewertungen