Beruflich Dokumente

Kultur Dokumente

Work Instruction FOR: Charpy Impact Test

Hochgeladen von

mahendra0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

86 Ansichten4 SeitenThis document provides work instructions for conducting Charpy impact tests on pipe samples. It outlines procedures for sample selection, preparation, testing, acceptance criteria, calibration, and record keeping. Samples are to be taken randomly and cut transversely from pipe walls. Specimens will be machined and tested at controlled temperatures based on applicable standards such as API 5L. Absorbed energy readings will be recorded and shear areas calculated to determine material toughness. Test equipment must be calibrated annually and results recorded and validated according to documentation requirements.

Originalbeschreibung:

Originaltitel

CHARMY IMPACT.doc

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides work instructions for conducting Charpy impact tests on pipe samples. It outlines procedures for sample selection, preparation, testing, acceptance criteria, calibration, and record keeping. Samples are to be taken randomly and cut transversely from pipe walls. Specimens will be machined and tested at controlled temperatures based on applicable standards such as API 5L. Absorbed energy readings will be recorded and shear areas calculated to determine material toughness. Test equipment must be calibrated annually and results recorded and validated according to documentation requirements.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

86 Ansichten4 SeitenWork Instruction FOR: Charpy Impact Test

Hochgeladen von

mahendraThis document provides work instructions for conducting Charpy impact tests on pipe samples. It outlines procedures for sample selection, preparation, testing, acceptance criteria, calibration, and record keeping. Samples are to be taken randomly and cut transversely from pipe walls. Specimens will be machined and tested at controlled temperatures based on applicable standards such as API 5L. Absorbed energy readings will be recorded and shear areas calculated to determine material toughness. Test equipment must be calibrated annually and results recorded and validated according to documentation requirements.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

NO.

: WGSRL/LS/QC/WI/15

WELSPUN REV.NO.: 03

GUJARAT STAHL ROHREN LTD. DATE : 25.09.2005

WELSPUN BHARUCH

PAGE NO.: 1 of 4

QUALITY ASSURANCE & CONTROL DEPT.

(LONGITUDINAL SAW PIPE DIVISION)

WORK INSTRUCTION

FOR

CHARPY IMPACT TEST

ISSUED BY :

ISSUED TO :

COPY NO :

PREPARED BY REVIEWED BY APPROVED BY

ENGINEER (LAB) MANAGER (LAB) H O D (QC)

NO.: WGSRL/LS/QC/WI/15

WORK INSTRUCTION REV.NO.: 03

FOR

DATE : 25.09.2005

CHARPY IMPACT TEST

WELSPUN PAGE NO.: 2 of 4

1.0 PURPOSE:

To establish and maintain the documented procedures to ensure that the testing is carried out as

per the applicable specifications / standards.

2.0 SCOPE:

This work instruction is intended to determine the % shear area and the absorbed energy of the

pipes manufactured at Longitudinal SAW Pipe Division.

3.0 RESPONSIBILITY:

Manager/ Sr. Engineer / Officer (Lab.) is responsible for testing and maintaining the record of

testing results in the specified formats.

4.0 APPLICABLE CODE & TESTING FRQUENCY:

As per API 5L (Latest Edition) / Customer Spec. / other specification. The same shall be

described in MPS/QAP/Process Chart.

5.0 SAMPLE ORIENTATION:

Samples are selected at random as per API 5L (Latest Edition) / Customer specification/ any

other relevant specifications. Samples are cut

a) From base metal in transverse direction from 90° to the weld seam.

b) From weld metal with weld in center.

c) From HAZ with HAZ in center or

d) As directed by customer specification.

6.0 PREPARATION OF TEST SAMPLE:

6.1 The samples shall be prepared as per API 5L (Latest Edition) / ASTM A 370 / IS: 1499.

6.2 Three base metal specimens shall be machined from a sample taken at 90° / as specified by the

customer from the longitudinal weld seam.. In additional, three transverse specimens with weld

in middle and three specimens with heat affected zone in the middle shall be taken. Samples

from other locations shall be taken as per the customer specification. The same shall be detailed

in MPS/QAP/Process Chart.

6.3 The specimen shall be full sized or largest obtainable sub-size in case pipe diameter and

thickness doesn’t permit full size specimen.

6.4 The specimen shall be oriented with the major axis transverse to the pipe axis with the axis of

notch oriented through the pipe wall thickness or as directed by the customer specification.

6.5 The specimens are finally prepared by milling & grinding.

6.6 All specimens shall be prepared and checked for dimensional tolerances and shall be as per

ASTM A370/ E-24 / Approved Drawing No.50010-397-10-01

7.0 METHOD:

7.1 All specimens shall be kept in cooling medium usually chilled fluids (such as water, ice plus

water, dry ice plus organic solvents or liquid nitrogen) & shall be cooled to the specified temp.

WELSPUN

7.2 Samples shall be kept for at least 5 min / as specified by the customer in liquid m

thermometer. Temperature control shall be within ±1°C.

7.3 Prior to each test, maintain the self centering tong and test anvil at the same tempe

7.4 Give a free swing to the pendulum for checking its zero.

7.5 Carefully center the test specimen in the anvil by self-centering tong and release the

7.6 Note the absorbed energy (in Joules) of each specimen.

7.7 If the pendulum is not released within 5sec after removing the specimen from the co

the conditioning medium.

7.8 Shear Area shall be determined by any of the following method.

7.8.1 Measure the length and width of brittle portion of fracture specimen and determine

7.8.2 Compare the appearance of the fracture of the specimen with a fracture appearance

8.0 CALIBRATION OF TESTING EQUIPMENT:

The Charpy Impact tester shall be calibrated once a year as specified in API 5L (i.e.

9.0 ACCEPTANCE CRITERIA:

As per MPS/QAP/ Process Chart.

10.0 RE-TEST CRITERIA:

As per API 5L (Latest Edition) / Customer specification /QAP

11.0 INVALIDATION OF TESTS :

Specimen showing material defects or defective preparation, whether observed

specimens.

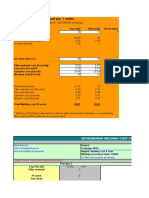

12.0 RECORDS:

Test results shall be recorded in Report No.: WGSRL/LS/QA/17.

13.0 REFERENCE:

Chapter 4.1 of DPM-LS/QA&C.

NO.: WGSRL/LS/QC/WI/15

WORK INSTRUCTION REV.NO.: 03

FOR DATE : 25.09.2005

CHARPY IMPACT TEST PAGE NO.: 4 of 4

WELSPUN

Das könnte Ihnen auch gefallen

- National Locksmith - Nov 2005Dokument100 SeitenNational Locksmith - Nov 2005Benjamin Dover100% (1)

- AC7114-4 Rev M Final EDITORIAL 2DECDokument60 SeitenAC7114-4 Rev M Final EDITORIAL 2DECRaja HoneNoch keine Bewertungen

- 307Dokument140 Seiten307Mihail Barna100% (3)

- Magnaflux & Sherwin Test Panels GuideDokument4 SeitenMagnaflux & Sherwin Test Panels GuideLuqman OsmanNoch keine Bewertungen

- Pentrmeter SpecificationDokument30 SeitenPentrmeter SpecificationJayeshNoch keine Bewertungen

- Non-Destructive Testing of Steel Forgings - Part 2: Penetrant Testing (BS EN 10228-2:1998) 1 ScopeDokument7 SeitenNon-Destructive Testing of Steel Forgings - Part 2: Penetrant Testing (BS EN 10228-2:1998) 1 ScopeKeng LengNoch keine Bewertungen

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDokument6 SeitenLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANoch keine Bewertungen

- EV charging standards guideDokument30 SeitenEV charging standards guidejoacochacoman100% (2)

- Raw Material Inspection ProcedureDokument2 SeitenRaw Material Inspection ProceduremahendraNoch keine Bewertungen

- Lapmaster Catalogue1Dokument20 SeitenLapmaster Catalogue1Hicham HrslNoch keine Bewertungen

- Astm e 317-21Dokument13 SeitenAstm e 317-21hashem Al-NasserNoch keine Bewertungen

- QC - 08 PTCDokument5 SeitenQC - 08 PTCmahendraNoch keine Bewertungen

- QC - 08 PTCDokument5 SeitenQC - 08 PTCmahendraNoch keine Bewertungen

- QC - 08 PTCDokument5 SeitenQC - 08 PTCmahendraNoch keine Bewertungen

- 1 Ml11229a721Dokument112 Seiten1 Ml11229a721Klea RoseniNoch keine Bewertungen

- Ultrasonic Testing Procedure for WeldsDokument11 SeitenUltrasonic Testing Procedure for WeldsSaut Maruli Tua SamosirNoch keine Bewertungen

- Automated Robotic InspectionDokument6 SeitenAutomated Robotic Inspectionprakush01975225403Noch keine Bewertungen

- X-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersDokument34 SeitenX-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersRahul DubeyNoch keine Bewertungen

- 757 Nondestructive Test Manual: BoeingDokument2 Seiten757 Nondestructive Test Manual: BoeingStephen Rincon GonzalezNoch keine Bewertungen

- Concrete Filled Steel TubeDokument12 SeitenConcrete Filled Steel TubeYogendra SINGH PATEL100% (1)

- LV System SiemenDokument1.468 SeitenLV System SiemenputrasejahtraNoch keine Bewertungen

- Iveco Magirus DLK 55 CsDokument6 SeitenIveco Magirus DLK 55 CsRicardo SilvaNoch keine Bewertungen

- Introduction To Fe Modeling of Composite Beam To CFST Column Connection - Phase - 1Dokument60 SeitenIntroduction To Fe Modeling of Composite Beam To CFST Column Connection - Phase - 1Harshil DevaniNoch keine Bewertungen

- Work Instruction For Macro ExaminationDokument4 SeitenWork Instruction For Macro Examinationmahendra50% (2)

- Measure Pipe Wall Thickness Using Tangential RadiographyDokument7 SeitenMeasure Pipe Wall Thickness Using Tangential Radiographykirubha_karan2000Noch keine Bewertungen

- Phasec2d Data SheetDokument2 SeitenPhasec2d Data SheetMaria DazaNoch keine Bewertungen

- 3.PAUT Qualification ProcedureDokument8 Seiten3.PAUT Qualification ProcedurePhan Tri ThongNoch keine Bewertungen

- E428Dokument6 SeitenE428valentinNoch keine Bewertungen

- Astm D7091 05Dokument7 SeitenAstm D7091 05IMSQA75% (4)

- PSM 5usage and MaintenanceDokument4 SeitenPSM 5usage and MaintenanceNguyễn Đức BìnhNoch keine Bewertungen

- 2008 Development of A Procedure For The Ultrasonic Examination of Nickel LNG Storage Tank Welds Using Phased Array TechnologyDokument5 Seiten2008 Development of A Procedure For The Ultrasonic Examination of Nickel LNG Storage Tank Welds Using Phased Array Technologyநந்த குமார் சம்பத் நாகராஜன்Noch keine Bewertungen

- Behaviour and Strength of Fully Encased Composite Columns PDFDokument198 SeitenBehaviour and Strength of Fully Encased Composite Columns PDFdxzaberNoch keine Bewertungen

- Handscan Mini MFL Tank Floor Scanner PDFDokument4 SeitenHandscan Mini MFL Tank Floor Scanner PDFMuhammad MajidNoch keine Bewertungen

- Ultrasonic Testing of Metal Pipe and Tubing: Standard Practice ForDokument11 SeitenUltrasonic Testing of Metal Pipe and Tubing: Standard Practice ForBauyrzhanNoch keine Bewertungen

- QC - 06 Surface Preparation & Painting 2Dokument6 SeitenQC - 06 Surface Preparation & Painting 2mahendraNoch keine Bewertungen

- General DNV Qualification Applus RTD Rotoscan AUT System - 2009-4129 - Rev.03 - SignedDokument60 SeitenGeneral DNV Qualification Applus RTD Rotoscan AUT System - 2009-4129 - Rev.03 - SignedfayyazdnvNoch keine Bewertungen

- PR - GEN-PAM-001 - Thickness - v7 - 2022-01-07Dokument25 SeitenPR - GEN-PAM-001 - Thickness - v7 - 2022-01-07Andrey Teston SantiniNoch keine Bewertungen

- Se 797Dokument7 SeitenSe 797donaldoguerreroNoch keine Bewertungen

- Heat Exchanger Tube Inspection With Olympus Nortec 500 Instrument Rev1Dokument8 SeitenHeat Exchanger Tube Inspection With Olympus Nortec 500 Instrument Rev1luu cong son ndtNoch keine Bewertungen

- ISO Specifications for Non-Destructive TestingDokument4 SeitenISO Specifications for Non-Destructive Testingskynyrd75Noch keine Bewertungen

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveVon EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNoch keine Bewertungen

- Aseptic FillingDokument5 SeitenAseptic FillingMIKENoch keine Bewertungen

- Symbol of Weld PDFDokument28 SeitenSymbol of Weld PDFSyarif IrwantoNoch keine Bewertungen

- Phased Array Probes Application MatrixDokument1 SeitePhased Array Probes Application MatrixFethi BELOUISNoch keine Bewertungen

- Measurement of Prep Ene Trant EtchDokument6 SeitenMeasurement of Prep Ene Trant EtchPDDELUCANoch keine Bewertungen

- Radiation Safety ProcedureDokument57 SeitenRadiation Safety ProcedureibrahimNoch keine Bewertungen

- Ultrasonic Angle-Beam Examination of Steel Plates: Standard Specification ForDokument3 SeitenUltrasonic Angle-Beam Examination of Steel Plates: Standard Specification ForSama UmateNoch keine Bewertungen

- MPI Reports for ROMFOR Oilfield EquipmentDokument21 SeitenMPI Reports for ROMFOR Oilfield EquipmentMehmet SoysalNoch keine Bewertungen

- Specification For Ultrasonic Inspection of Al-Alloy Plate For Pressure VesselsDokument6 SeitenSpecification For Ultrasonic Inspection of Al-Alloy Plate For Pressure Vesselsmarkieboy36Noch keine Bewertungen

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDokument28 SeitenSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenNoch keine Bewertungen

- Ultrasonic Testing Variables GuideDokument21 SeitenUltrasonic Testing Variables GuidepktienNoch keine Bewertungen

- Is 9902 2004Dokument11 SeitenIs 9902 2004cbbasakNoch keine Bewertungen

- Astm E428-00 PDFDokument6 SeitenAstm E428-00 PDFJORGE ARTURO TORIBIO HUERTA100% (1)

- Ultrasonic Inspection ExplainedDokument11 SeitenUltrasonic Inspection ExplainedMuh SubhanNoch keine Bewertungen

- WIKA Calibration Certificate for Process CalibratorDokument3 SeitenWIKA Calibration Certificate for Process CalibratorBalaji BobadeNoch keine Bewertungen

- E 1065 - 99-UT-transdDokument22 SeitenE 1065 - 99-UT-transdDemian PereiraNoch keine Bewertungen

- 38DLPlus Training Power PointDokument236 Seiten38DLPlus Training Power PointVegaGonzalezNoch keine Bewertungen

- Olympus NDT Canada Provides Recommended Calibration Tubes for Near Field TestingDokument1 SeiteOlympus NDT Canada Provides Recommended Calibration Tubes for Near Field TestingMahmood KhanNoch keine Bewertungen

- RT Procedure for Egyptian Gas Pipeline ProjectDokument14 SeitenRT Procedure for Egyptian Gas Pipeline ProjectaravindanNoch keine Bewertungen

- SA27 WedgesDokument1 SeiteSA27 WedgesPurvi RocksNoch keine Bewertungen

- E1158Dokument4 SeitenE1158Irish Manglicmot LagundinoNoch keine Bewertungen

- Safety valve testing report summaryDokument1 SeiteSafety valve testing report summarymurthy challapalliNoch keine Bewertungen

- SLB Check List-1Dokument2 SeitenSLB Check List-1Jitendra BhosaleNoch keine Bewertungen

- Epoch 650Dokument8 SeitenEpoch 650andrewgeorgecherianNoch keine Bewertungen

- NDE-Penetrant TestDokument2 SeitenNDE-Penetrant TestCandy KendeeNoch keine Bewertungen

- ISO - TC 135 - SC 5 - Radiographic TestingDokument2 SeitenISO - TC 135 - SC 5 - Radiographic TestingNilesh MistryNoch keine Bewertungen

- Ilac P10Dokument10 SeitenIlac P10BellbrujaNoch keine Bewertungen

- As 1816.1-2007 Metallic Materials - Brinell Hardness Test Test Method (ISO 6506-1-2005 MOD)Dokument3 SeitenAs 1816.1-2007 Metallic Materials - Brinell Hardness Test Test Method (ISO 6506-1-2005 MOD)SAI Global - APACNoch keine Bewertungen

- Computed Tomographic (CT) Examination of Castings: Standard Practice ForDokument4 SeitenComputed Tomographic (CT) Examination of Castings: Standard Practice ForEric GozzerNoch keine Bewertungen

- 6.4 - NDT-Magnetic Particle ExaminationDokument38 Seiten6.4 - NDT-Magnetic Particle ExaminationKatsaras SotirisNoch keine Bewertungen

- Accessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishDokument3 SeitenAccessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishimahidaNoch keine Bewertungen

- Internal RT Procedure Spread IIDokument4 SeitenInternal RT Procedure Spread IIravi00098100% (1)

- Surface Roughness TesterDokument6 SeitenSurface Roughness TesterLingga SetiawanNoch keine Bewertungen

- Digltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardDokument14 SeitenDigltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardSriniramu SriniramuNoch keine Bewertungen

- BeamTool has everything for ultrasonic inspection planningDokument4 SeitenBeamTool has everything for ultrasonic inspection planningdarouichNoch keine Bewertungen

- Selenium 75, Ir 192 and X-RaysDokument5 SeitenSelenium 75, Ir 192 and X-RaysLei LaniNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- 3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06Dokument1 Seite3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06mahendraNoch keine Bewertungen

- 3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06Dokument1 Seite3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06mahendraNoch keine Bewertungen

- PDF Created With Pdffactory Trial VersionDokument8 SeitenPDF Created With Pdffactory Trial VersionmahendraNoch keine Bewertungen

- WPS requirements for structural welding per AWS D1.1-2008Dokument2 SeitenWPS requirements for structural welding per AWS D1.1-2008mahendraNoch keine Bewertungen

- Inspection ProcesureDokument1 SeiteInspection ProcesuremahendraNoch keine Bewertungen

- Mild Steel Electrodes: Brand Aws A/Sfa 5.1 IS 814 DIN 1913 BS 639 EN 499Dokument5 SeitenMild Steel Electrodes: Brand Aws A/Sfa 5.1 IS 814 DIN 1913 BS 639 EN 499mahendraNoch keine Bewertungen

- Arc Welding PPT FinishDokument50 SeitenArc Welding PPT FinishmahendraNoch keine Bewertungen

- PaintCure PDFDokument8 SeitenPaintCure PDFmahendraNoch keine Bewertungen

- Attachment X - Specifications For Prefabrication PipingDokument6 SeitenAttachment X - Specifications For Prefabrication PipingmahendraNoch keine Bewertungen

- Calibrating Pressure Gauges Using Dead Weight TestersDokument3 SeitenCalibrating Pressure Gauges Using Dead Weight TestersmahendraNoch keine Bewertungen

- Attachment X - Specifications For Prefabrication PipingDokument25 SeitenAttachment X - Specifications For Prefabrication PipingmahendraNoch keine Bewertungen

- Attachment X - Specifications For Prefabrication PipingDokument25 SeitenAttachment X - Specifications For Prefabrication PipingmahendraNoch keine Bewertungen

- Steel Konnect India PVT Ltd. Procedure Manual: Procedure For Production PlanningDokument1 SeiteSteel Konnect India PVT Ltd. Procedure Manual: Procedure For Production PlanningmahendraNoch keine Bewertungen

- 2 DefectsDokument4 Seiten2 DefectsmahendraNoch keine Bewertungen

- Work Instruction FOR: Spectro AnalysisDokument3 SeitenWork Instruction FOR: Spectro AnalysismahendraNoch keine Bewertungen

- Final InspDokument6 SeitenFinal InspmahendraNoch keine Bewertungen

- Purpose: Steel Konnect (India) Pvt. Ltd. Procedure ManualDokument3 SeitenPurpose: Steel Konnect (India) Pvt. Ltd. Procedure ManualmahendraNoch keine Bewertungen

- QC - 16 Guided Bend Test.Dokument3 SeitenQC - 16 Guided Bend Test.mahendra100% (1)

- Internal Quality Audit ProcedureDokument2 SeitenInternal Quality Audit ProceduremahendraNoch keine Bewertungen

- QC - 06 Surface Preparation & Painting Rev. 01Dokument7 SeitenQC - 06 Surface Preparation & Painting Rev. 01mahendraNoch keine Bewertungen

- Manual Ultrasonic Testing ProcedureDokument7 SeitenManual Ultrasonic Testing ProceduremahendraNoch keine Bewertungen

- Lecture Slide 1: Introduction To Control SystemsDokument39 SeitenLecture Slide 1: Introduction To Control SystemsMuhammad HaziqNoch keine Bewertungen

- Emcore en 150 1 3 5 ImuDokument2 SeitenEmcore en 150 1 3 5 Imuachmad fitrio spnNoch keine Bewertungen

- Blocks M Sand RegisterDokument2 SeitenBlocks M Sand RegisterSarinNoch keine Bewertungen

- TestDokument1 SeiteTestkingNoch keine Bewertungen

- Re EntryDokument3 SeitenRe EntryCHEKOUFI SaidNoch keine Bewertungen

- Atomic 4 Parts ListDokument72 SeitenAtomic 4 Parts ListRobertNoch keine Bewertungen

- Basic SWOT MatrixDokument1 SeiteBasic SWOT MatrixTarenjeet SinghNoch keine Bewertungen

- UPV SoTech ChE Study PlanDokument4 SeitenUPV SoTech ChE Study PlanBoodjieh So ImbaNoch keine Bewertungen

- Ac Servos DrivesDokument357 SeitenAc Servos DrivesMario CarmonaNoch keine Bewertungen

- Geogrids in Walls and SlopesDokument6 SeitenGeogrids in Walls and SlopesYong Cheng Hung100% (1)

- Q-438222 Urban Mining - Phase 2 - REV0 - DNDokument14 SeitenQ-438222 Urban Mining - Phase 2 - REV0 - DNnknfiveNoch keine Bewertungen

- Matrix Series Metal Wall PanelsDokument10 SeitenMatrix Series Metal Wall PanelsBrendan PrattNoch keine Bewertungen

- Bill No. 1 Preliminaries and General ConditionsDokument14 SeitenBill No. 1 Preliminaries and General ConditionsOmoi CamillusNoch keine Bewertungen

- Assignment IDokument2 SeitenAssignment IShivpreet SharmaNoch keine Bewertungen

- Column Buckling em 327: Mechanics of MaterialsDokument2 SeitenColumn Buckling em 327: Mechanics of Materialsadi_ganteng12Noch keine Bewertungen

- Ofna/Picco .26 Engine 51214 Pull Start 51213 Non-Pull Start: New Engine Break-InDokument3 SeitenOfna/Picco .26 Engine 51214 Pull Start 51213 Non-Pull Start: New Engine Break-InClaude LerouxNoch keine Bewertungen

- Quotation For LED Light ProductsDokument17 SeitenQuotation For LED Light Productssalaar12Noch keine Bewertungen

- EXTENSION PROPOSAL 2015 (First Sem)Dokument14 SeitenEXTENSION PROPOSAL 2015 (First Sem)Arnold Magdalita FranciscoNoch keine Bewertungen

- Victor Aviation BrochureDokument19 SeitenVictor Aviation BrochureLucas CoelloNoch keine Bewertungen

- Enhanced Oil Recovery Using PolymerDokument12 SeitenEnhanced Oil Recovery Using Polymerkalpak jadhavNoch keine Bewertungen