Beruflich Dokumente

Kultur Dokumente

Barge Bumper Replacement at P1 Platforms

Hochgeladen von

Yehia HassanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Barge Bumper Replacement at P1 Platforms

Hochgeladen von

Yehia HassanCopyright:

Verfügbare Formate

BARGE BUMPER REPLACEMENT

AT

P1 PLATFORMS (LEG B1)

Document No. Page

EMC-044-PLAN-2018-Rev 00 1 of 7

Work Procedure

For

Barge Bumper Replacement at P1 Platforms (Leg B1)

File Reference

EMC-044-PLAN-2018

0 26/03/2018 Issued for Client Review Mohamed Ali Mohamed Elsabagh

Rev Date Description Issued By Checked By AQP Approval RINA Approval

DOC. NO. EMC-044-PLAN-2018-Rev 00

Work Procedure

For REV. 00

Barge Bumper Replacement at P1 DATE 26/03/2018

Platforms (Leg B1) Prepared By Eng. Mohamed Ali

Checked By Eng. Mohamed Elsabagh

Table of Contents

INTRODUCTION ....................................................................................................................................... 3

PURPOSE OF THIS DOCUMENT ............................................................................................................ 4

SCOPE OF WORK ..................................................................................................................................... 4

Detailed work procedures ............................................................................................................................ 5

4.1. PHASE "1" – Preparation Activities .................................................................................................... 5

4.2. PHASE "2" – Procurement. ................................................................................................................. 6

4.3. PHASE "3" –Onshore Fabrication. ...................................................................................................... 6

4.4. PHASE "4" –Offshore Installation. ...................................................................................................... 6

4.5. PHASE "5" –Final Documentation& Close out Report ....................................................................... 7

Barge Bumper Replacement at P1 Platforms (Leg B1) 2

DOC. NO. EMC-044-PLAN-2018-Rev 00

Work Procedure

For REV. 00

Barge Bumper Replacement at P1 DATE 26/03/2018

Platforms (Leg B1) Prepared By Eng. Mohamed Ali

Checked By Eng. Mohamed Elsabagh

INTRODUCTION

A/Q platform located at ABU QIR Petroleum Company at Alexandria

district in the Mediterranean Sea. AQP is currently operating 5 fixed

offshore platforms comprising 9 boats landing as follows:

P-I Platform :( 3 Boat landing); PI Eastern, PI Southern, and PI-C.

P-II Platform: (2 Boat landing); PII: and PII-Q.

NAQ-PI Platform: (2 Boat landing); PI-D, and PI-P/U.

NAQ-PII Platform: (1 Boat landing); NAQ-PII.

WAQ Platforms: (1 Boat landing); WAQ.

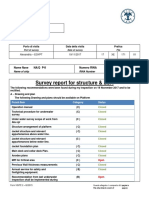

During the approach of the supply boat M/V Miser Gulf 13 to the P1

platform on 05/04/2016, an impact was occurred between the a/m

marine vessel and the platform barge bumper fixed on leg B1.

After Scaffolding and sand-blasting activities have been finished,

thorough inspection was performed on the subject barge bumper

especially on the upper welded fixation point of the barge bumper to

platform main leg (B1), and the following were observed:-

Crack was observed on the upper weld seam between upper beam

support & the barge bumper.

Crack was observed on the lower weld between upper beam support &

the barge bumper.

Dent, deformation and rupture with length of 35 cm were observed on

the barge bumper body (18” pipe).

Magnetic Particle Inspection (MPI) was performed for all welds between

the barge bumper and leg B1 and there is no sign of cracks.

Barge Bumper Replacement at P1 Platforms (Leg B1) 3

DOC. NO. EMC-044-PLAN-2018-Rev 00

Work Procedure

For REV. 00

Barge Bumper Replacement at P1 DATE 26/03/2018

Platforms (Leg B1) Prepared By Eng. Mohamed Ali

Checked By Eng. Mohamed Elsabagh

UT Thickness Measurements were performed for the support beam and

the barge bumper and found in fair condition except for the ruptured

area

EMC received award letter from Miser Gulf Company to covers the following

SOW.

EMC has a qualified mechanical and construction crew as well as a scaffolding

crew with all necessary equipment and special tools who are capable to perform

such offshore activities.

PURPOSE OF THIS DOCUMENT

The purpose of this document is to provide a work procedure for P1 Platform

Barge Bumper Replacement at P1 Platforms Project.

SCOPE OF WORK

Demolish the old Barge Bumper.

Fabrication and installation of the new Barge Bumper and the required

consumable material.

Barge Bumper Replacement at P1 Platforms (Leg B1) 4

DOC. NO. EMC-044-PLAN-2018-Rev 00

Work Procedure

For REV. 00

Barge Bumper Replacement at P1 DATE 26/03/2018

Platforms (Leg B1) Prepared By Eng. Mohamed Ali

Checked By Eng. Mohamed Elsabagh

DETAILED WORK PROCEDURES

4.1. PHASE "1" – Preparation Activities

1- Prepare the detailed work procedures for work implementation.

2- Received the approved drawing for barge bumper from AQP/RINA (Release for

fabrication).

3- Work pack preparation , the work pack includes the following :

Detail work schedule with time frame.

List of Required manpower & tools and special equipment.

Welding procedure.

Risk assessment ( level #2)

Lifting plans.

Inspection and test plan (ITP).

MTO

Painting system / Painting data sheets.

Barge Bumper Replacement at P1 Platforms (Leg B1) 5

DOC. NO. EMC-044-PLAN-2018-Rev 00

Work Procedure

For REV. 00

Barge Bumper Replacement at P1 DATE 26/03/2018

Platforms (Leg B1) Prepared By Eng. Mohamed Ali

Checked By Eng. Mohamed Elsabagh

4.2. PHASE "2" – Procurement.

1. Procurement of the new Barge Bumper materials shall be as the approved

drawing and MTO.

2. Materials packing and tagging.

4.3. PHASE "3" –Onshore Fabrication.

1. Fabrication phase will be carry out at EMC yard at IDKU.

2. Fabricate the new barge bumper as per approved drawing.

3. Applying PT test.

4. Sand blasting and painting the new barge bumper as per painting procedure.

5. Loading the new barge bumper to Middia jetty.

4.4. PHASE "4" –Offshore Installation.

1. Transfer the new barge bumper, equipment, tools and manpower to Middia Jetty

2. Loading the new barge bumper, equipment and tools to Misr Galf vessel by using

AQP crange facilities.

3. Heading to PI P/F and Issue the work Permit "HOT".

4. Be Sure that all the safety equipment are available (As life vest, safety harness ...).

6. Erection scaffolding according to OSHA standard.

7. Using Oxy acetylene to cutting the old barge bumper from Doublet plate at leg B1.

8. Fixing Chain Hoist 10 tons above the old barge bumper location at main deck level

(+9m).

9. Dismantling scaffolding.

10. Lifting the old barge bumper to vessel by using Chain Hoist 10 tons.

11. Erection scaffolding.

12. Grinding and cleaning for doublet plat (Welding location).

Barge Bumper Replacement at P1 Platforms (Leg B1) 6

DOC. NO. EMC-044-PLAN-2018-Rev 00

Work Procedure

For REV. 00

Barge Bumper Replacement at P1 DATE 26/03/2018

Platforms (Leg B1) Prepared By Eng. Mohamed Ali

Checked By Eng. Mohamed Elsabagh

13. Dismantling scaffolding.

14. Lifting the new barge bumper from vessel to B1 leg by using Chain Hoist and fixed

in location.

15. Erection scaffolding.

16. Welding the new barge bumper with Doublet plate at leg B1.

17. Apply PT for new welding.

18. Apply touch -up painting.

19. Dismantling scaffolding.

4.5. PHASE "5" –Final Documentation.

1. Plot as built drawings.

2. Prepare Close out report.

3. Delivering Final documentation.

End of Document…

Barge Bumper Replacement at P1 Platforms (Leg B1) 7

Das könnte Ihnen auch gefallen

- AWWA D100 Shell Buckling Check: (Method 1, Section 3.4.3.1)Dokument3 SeitenAWWA D100 Shell Buckling Check: (Method 1, Section 3.4.3.1)Chris BoppNoch keine Bewertungen

- GSPC Subsea Pipeline Inspection ProceduresDokument17 SeitenGSPC Subsea Pipeline Inspection ProceduresDanny BoysieNoch keine Bewertungen

- Double Wall TankDokument1 SeiteDouble Wall TankFerry Triyana AnirunNoch keine Bewertungen

- TBDP A M DS 0007 2Dokument7 SeitenTBDP A M DS 0007 2Bùi Văn HợpNoch keine Bewertungen

- Tiger Offshore Catalog LowresDokument64 SeitenTiger Offshore Catalog LowresRafaelNoch keine Bewertungen

- Report Rectangular Tank - REV 0 - 28.11.12Dokument26 SeitenReport Rectangular Tank - REV 0 - 28.11.12JijinJohn100% (1)

- Pipeline Integrity Basics KiefnerDokument35 SeitenPipeline Integrity Basics Kiefnerim4uim4uim4u100% (1)

- Skidbeam LoadoutDokument5 SeitenSkidbeam LoadoutBolarinwaNoch keine Bewertungen

- API Standard 650 Storage Tank Data SheetDokument3 SeitenAPI Standard 650 Storage Tank Data SheetLuis JaraNoch keine Bewertungen

- GLACIER LAr Tank Design (Deliverable 2.2)Dokument76 SeitenGLACIER LAr Tank Design (Deliverable 2.2)atiqulaNoch keine Bewertungen

- Tinh Dong Dat Va Gio Cho Tank-Full - Outer Tank123Dokument51 SeitenTinh Dong Dat Va Gio Cho Tank-Full - Outer Tank123Thinh Vipro100% (1)

- Floating Roof TankDokument2 SeitenFloating Roof TankVasant Kumar VarmaNoch keine Bewertungen

- 1 - PL - FEED Lvl2Dokument89 Seiten1 - PL - FEED Lvl2Gladys WilliamNoch keine Bewertungen

- 2.2.3 Floating Roof Tanks: Figure 1.4 Single Deck Pontoon Type Floating Roof (Bob. L & Bob. G, N.D, p.155)Dokument3 Seiten2.2.3 Floating Roof Tanks: Figure 1.4 Single Deck Pontoon Type Floating Roof (Bob. L & Bob. G, N.D, p.155)evrim77100% (1)

- WRC CalculationsDokument20 SeitenWRC Calculationsanu radha50% (2)

- Bb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Dokument24 SeitenBb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Luong AnhNoch keine Bewertungen

- Api 650Dokument42 SeitenApi 650samvendan100% (1)

- Zeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaDokument4 SeitenZeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaAmirah AqilahNoch keine Bewertungen

- 20100419043934!el Chaguite Tank DesignDokument37 Seiten20100419043934!el Chaguite Tank DesignSana UllahNoch keine Bewertungen

- One Foot Method Tank Shell DesignDokument3 SeitenOne Foot Method Tank Shell DesignMohan Varkey50% (2)

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADokument1 Seite2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNoch keine Bewertungen

- Pig Calc PDFDokument286 SeitenPig Calc PDFJaroslaw KoniecznyNoch keine Bewertungen

- NDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12Dokument7 SeitenNDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12ravivarmadatla2011Noch keine Bewertungen

- Tank API650 DesignDokument16 SeitenTank API650 Designwindy-200850% (2)

- Fuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke AreaDokument2 SeitenFuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke Areaananyo_senguptaNoch keine Bewertungen

- Skirt Design - For Small VesselsDokument7 SeitenSkirt Design - For Small VesselsSakthi VelNoch keine Bewertungen

- Out of Roundnesscalculations:: Max MinDokument6 SeitenOut of Roundnesscalculations:: Max MinAdekimi EmmanuelNoch keine Bewertungen

- Final Weld Strength CalnsDokument5 SeitenFinal Weld Strength CalnsamachmouchiNoch keine Bewertungen

- Calculation Sheet For 700mm SQ Metal FloatersDokument3 SeitenCalculation Sheet For 700mm SQ Metal FloatersAdagharaNoch keine Bewertungen

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Dokument23 SeitenES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsNoch keine Bewertungen

- Compressor Drive Engine Power CalculatorDokument2 SeitenCompressor Drive Engine Power CalculatorJoshi DhvanitNoch keine Bewertungen

- API 650 Tank Design CalculationDokument8 SeitenAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- 2WallTank NFPA ULDokument1 Seite2WallTank NFPA ULPolo VarsanNoch keine Bewertungen

- Bolt Tensioning: What is it and how does it workDokument2 SeitenBolt Tensioning: What is it and how does it work4jawwy markme026Noch keine Bewertungen

- AWS A5.12: Material Safety Data Sheet (MSDS)Dokument3 SeitenAWS A5.12: Material Safety Data Sheet (MSDS)Mani VannanNoch keine Bewertungen

- Internal Floating Roof DesignDokument38 SeitenInternal Floating Roof DesigncrnewsomNoch keine Bewertungen

- Pipeline Hydro Test Pressure DeterminationDokument7 SeitenPipeline Hydro Test Pressure Determinationgrimaguil0% (1)

- Chemical Composition of Carbon Steel, Carbon Steel Pipe, Carbon Steel Tubes, Alloy Steel Pipe, Alloy Steel Tubes, Mumbai, IndiaDokument2 SeitenChemical Composition of Carbon Steel, Carbon Steel Pipe, Carbon Steel Tubes, Alloy Steel Pipe, Alloy Steel Tubes, Mumbai, IndiaVamsikrishna LakamsaniNoch keine Bewertungen

- Final Bulk Storage CalculationDokument2 SeitenFinal Bulk Storage CalculationokahertaberNoch keine Bewertungen

- Storage Tank Safety and Emissions ManagementDokument96 SeitenStorage Tank Safety and Emissions ManagementenggmohanNoch keine Bewertungen

- Offshore ContainersDokument40 SeitenOffshore ContainerssalahjallaliNoch keine Bewertungen

- API 620 CalculationDokument114 SeitenAPI 620 Calculationvikram100% (4)

- LPG sphere data sheetDokument5 SeitenLPG sphere data sheetsukubutsuNoch keine Bewertungen

- API 675 pump specification sheetDokument2 SeitenAPI 675 pump specification sheetAKSHEYMEHTANoch keine Bewertungen

- SP-2069 Specification For Pressure VesselsDokument68 SeitenSP-2069 Specification For Pressure Vesselsarjunprasannan7Noch keine Bewertungen

- 18 Tanks CalculoDokument12 Seiten18 Tanks CalculoPedro DiazNoch keine Bewertungen

- Offcom Completa - v.01Dokument7 SeitenOffcom Completa - v.01Argonauta_navegadorNoch keine Bewertungen

- API 650 Water Storage Tank - Xls 36Dokument71 SeitenAPI 650 Water Storage Tank - Xls 36rudi 01Noch keine Bewertungen

- BOP stack and accumulator volumesDokument4 SeitenBOP stack and accumulator volumesAbdul Hameed OmarNoch keine Bewertungen

- Determing Calculation For Repair of Storage TankDokument4 SeitenDeterming Calculation For Repair of Storage TankHendra Yudistira100% (2)

- Fe Report of Base SkidDokument16 SeitenFe Report of Base SkidpawanNoch keine Bewertungen

- 0397 Mi20 00S1 0031 01 ADokument20 Seiten0397 Mi20 00S1 0031 01 AGalih Suksmono Adi100% (1)

- Floating Roofs Single DeckDokument8 SeitenFloating Roofs Single DeckJose David Perez TorricoNoch keine Bewertungen

- Storage Tank CALC Api 650Dokument10 SeitenStorage Tank CALC Api 650kuselanml100% (3)

- Nozzle Calculations 01Dokument32 SeitenNozzle Calculations 01Rohith V VNoch keine Bewertungen

- X388allegato1 2X Offshore Cranes BDokument15 SeitenX388allegato1 2X Offshore Cranes BMostafa BatourNoch keine Bewertungen

- Kurva HidrostatisDokument1 SeiteKurva HidrostatisMoch ArdiansyahNoch keine Bewertungen

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0002-0 General Testing Pre-Commissioning and Commissioning Procedure - Amended-signed-Code-3Dokument11 SeitenYET-AGRU-EXE-MEB-000-PCMM-PRC-0002-0 General Testing Pre-Commissioning and Commissioning Procedure - Amended-signed-Code-3mohsin moin100% (1)

- Raceway Method Statement: REV Date Reason For Issue BY CHK ApprDokument6 SeitenRaceway Method Statement: REV Date Reason For Issue BY CHK ApprCristinel NechiforNoch keine Bewertungen

- RFI for inspection of field maintenance workDokument1 SeiteRFI for inspection of field maintenance workManikandan MNoch keine Bewertungen

- Api 5L X65 Psl2 Seamless PipesDokument18 SeitenApi 5L X65 Psl2 Seamless PipesYehia HassanNoch keine Bewertungen

- Day 5 - Personal Branding & Emotional Intelligence PDFDokument65 SeitenDay 5 - Personal Branding & Emotional Intelligence PDFYehia HassanNoch keine Bewertungen

- Employment Log Sheet (Please Complete A Log Sheet For Each Employment)Dokument1 SeiteEmployment Log Sheet (Please Complete A Log Sheet For Each Employment)Yehia HassanNoch keine Bewertungen

- CRM QuoteCheckListDokument1 SeiteCRM QuoteCheckListYehia HassanNoch keine Bewertungen

- Day 2 - Motivation & Team Building PDFDokument79 SeitenDay 2 - Motivation & Team Building PDFYehia HassanNoch keine Bewertungen

- Pipe Wall Thickness Calculations and Allowable StressesDokument21 SeitenPipe Wall Thickness Calculations and Allowable StressesYehia HassanNoch keine Bewertungen

- Service Manual CPTDokument24 SeitenService Manual CPTYehia HassanNoch keine Bewertungen

- Zohr Field Development Project 193102 - EWR - AKO - ENI - U - 2017 - 11 - 24Dokument4 SeitenZohr Field Development Project 193102 - EWR - AKO - ENI - U - 2017 - 11 - 24Yehia HassanNoch keine Bewertungen

- Company PresentationDokument24 SeitenCompany PresentationYehia HassanNoch keine Bewertungen

- Bow Tie Module PipelineDokument11 SeitenBow Tie Module PipelineYehia HassanNoch keine Bewertungen

- NAQ-P3 Surveys - Topside Summary - 01.2020Dokument18 SeitenNAQ-P3 Surveys - Topside Summary - 01.2020Yehia HassanNoch keine Bewertungen

- Day 1 - Leadership - Management - Mentoring - Coaching PDFDokument64 SeitenDay 1 - Leadership - Management - Mentoring - Coaching PDFYehia HassanNoch keine Bewertungen

- Drilling Machine Serial Model Yzj-300y User Manual PDFDokument39 SeitenDrilling Machine Serial Model Yzj-300y User Manual PDFYehia HassanNoch keine Bewertungen

- Plan OverviewDokument1.064 SeitenPlan OverviewYehia HassanNoch keine Bewertungen

- 02 Corrosion Monitoring Manual PDFDokument92 Seiten02 Corrosion Monitoring Manual PDFYehia HassanNoch keine Bewertungen

- Pipeline PiggingDokument28 SeitenPipeline PiggingYehia Hassan100% (1)

- Corrosion Management System Audit: GOS Ian Roberts Atef Mohammed TarawaDokument6 SeitenCorrosion Management System Audit: GOS Ian Roberts Atef Mohammed TarawaYehia HassanNoch keine Bewertungen

- Pipeline PiggingDokument28 SeitenPipeline PiggingYehia Hassan100% (1)

- Pending List NAQ-II 19 Nov PhotoDokument5 SeitenPending List NAQ-II 19 Nov PhotoYehia HassanNoch keine Bewertungen

- Pending List PII 12 Novphoto - DocxDokument24 SeitenPending List PII 12 Novphoto - DocxYehia HassanNoch keine Bewertungen

- Day 3 - Decision Making & Strategic Thinking PDFDokument66 SeitenDay 3 - Decision Making & Strategic Thinking PDFYehia HassanNoch keine Bewertungen

- Day 4 - Creative Thinking PDFDokument38 SeitenDay 4 - Creative Thinking PDFYehia HassanNoch keine Bewertungen

- Day 1 - Leadership - Management - Mentoring - Coaching PDFDokument64 SeitenDay 1 - Leadership - Management - Mentoring - Coaching PDFYehia HassanNoch keine Bewertungen

- Pending List: Allegato Al ModDokument22 SeitenPending List: Allegato Al ModYehia HassanNoch keine Bewertungen

- PI P-F Barge Pumber On Leg B1Dokument9 SeitenPI P-F Barge Pumber On Leg B1Yehia HassanNoch keine Bewertungen

- PI P-F Barge Pumber On Leg B1Dokument9 SeitenPI P-F Barge Pumber On Leg B1Yehia HassanNoch keine Bewertungen

- مذكرة انجليزى ثانية ابتدائى ترم ثانى-unit 7-8-9 PDFDokument64 Seitenمذكرة انجليزى ثانية ابتدائى ترم ثانى-unit 7-8-9 PDFYehia HassanNoch keine Bewertungen

- 1 - Reference Section: Rotating Equipment Inspection ReportDokument3 Seiten1 - Reference Section: Rotating Equipment Inspection ReportYehia HassanNoch keine Bewertungen

- Maths PracticeDokument16 SeitenMaths Practicesamisoma2011Noch keine Bewertungen

- PI P-F Barge Pumber On Leg B1Dokument9 SeitenPI P-F Barge Pumber On Leg B1Yehia HassanNoch keine Bewertungen

- Sales Account Manager (Building Construction Segment) - Hilti UAEDokument2 SeitenSales Account Manager (Building Construction Segment) - Hilti UAESomar KarimNoch keine Bewertungen

- Citation GuideDokument21 SeitenCitation Guideapi-229102420Noch keine Bewertungen

- Confined Space SafetyDokument33 SeitenConfined Space SafetyEneyo VictorNoch keine Bewertungen

- Hercules SegersDokument15 SeitenHercules SegerssuneelaamjadNoch keine Bewertungen

- Module 2 What It Means To Be AI FirstDokument85 SeitenModule 2 What It Means To Be AI FirstSantiago Ariel Bustos YagueNoch keine Bewertungen

- Case Presentation - Bipolar Affective Disorder 2Dokument73 SeitenCase Presentation - Bipolar Affective Disorder 2Hemant's galaxy All is hereNoch keine Bewertungen

- CONNECTIFYDokument3 SeitenCONNECTIFYAbhishek KulshresthaNoch keine Bewertungen

- Module 7 - Assessment of Learning 1 CoursepackDokument7 SeitenModule 7 - Assessment of Learning 1 CoursepackZel FerrelNoch keine Bewertungen

- Culinary Nutrition BasicsDokument28 SeitenCulinary Nutrition BasicsLIDYANoch keine Bewertungen

- ROM Magazine V1i6Dokument64 SeitenROM Magazine V1i6Mao AriasNoch keine Bewertungen

- Pharma Pathway SopDokument350 SeitenPharma Pathway SopDinesh Senathipathi100% (1)

- SMChap 018Dokument32 SeitenSMChap 018testbank100% (8)

- Data Validation and Verification - BBC BitsizeDokument56 SeitenData Validation and Verification - BBC BitsizeluciferothegoatNoch keine Bewertungen

- Cypress Enable Basic Rer Erence ManualDokument2 SeitenCypress Enable Basic Rer Erence ManualCarlos RodasNoch keine Bewertungen

- Study Quran Online - The Online Quran Teaching Academy UK - QutorDokument9 SeitenStudy Quran Online - The Online Quran Teaching Academy UK - QutorQutor co ukNoch keine Bewertungen

- Amniotic Membrane in Oral and Maxillofacial SurgeryDokument13 SeitenAmniotic Membrane in Oral and Maxillofacial SurgerySooraj SNoch keine Bewertungen

- Reaction CalorimetryDokument7 SeitenReaction CalorimetrySankar Adhikari100% (1)

- Service: Audi A6 1998Dokument256 SeitenService: Audi A6 1998Kovács EndreNoch keine Bewertungen

- 1 Univalent Functions The Elementary Theory 2018Dokument12 Seiten1 Univalent Functions The Elementary Theory 2018smpopadeNoch keine Bewertungen

- Type of PoemDokument10 SeitenType of PoemYovita SpookieNoch keine Bewertungen

- Mutaz Abdelrahim - Doa - MT-103Dokument17 SeitenMutaz Abdelrahim - Doa - MT-103Minh KentNoch keine Bewertungen

- Working With Session ParametersDokument10 SeitenWorking With Session ParametersyprajuNoch keine Bewertungen

- Illegal FishingDokument1 SeiteIllegal FishingDita DwynNoch keine Bewertungen

- Gas Chromatography - COLIN F. POOLE 2012 PDFDokument743 SeitenGas Chromatography - COLIN F. POOLE 2012 PDFVo Manh Tien100% (1)

- 114 ArDokument254 Seiten114 ArJothishNoch keine Bewertungen

- Team Dynamics and Behaviors for Global ExpansionDokument15 SeitenTeam Dynamics and Behaviors for Global ExpansionNguyênNoch keine Bewertungen

- Programming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduDokument34 SeitenProgramming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduNaruto DragneelNoch keine Bewertungen

- 001 Gace Early Childhood TestDokument3 Seiten001 Gace Early Childhood Testapi-265795386Noch keine Bewertungen

- 6a. ICMR STSDokument15 Seiten6a. ICMR STSVishnu Praba ANoch keine Bewertungen

- Farm mechanization subsidy applications invitedDokument2 SeitenFarm mechanization subsidy applications inviteddraqbhattiNoch keine Bewertungen