Beruflich Dokumente

Kultur Dokumente

ADI DAYS Fabrizio La Verde

Hochgeladen von

Sinan YıldızCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ADI DAYS Fabrizio La Verde

Hochgeladen von

Sinan YıldızCopyright:

Verfügbare Formate

ADI

DAYS 2016 6th — 7th October Minerbe

Introducing ausferritic ductile iron in automotive

suspension system:

the Magneti Marelli’s experience.

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

AUTOMOTIVE

Magneti

Marelli SUSPENSION

SYSTEMS

LIGHTING POWERTRAIN

ELECTRONICS

(Suspensions,

Shock

absorber)

EXHAUST PLASTIC AFTERMARKET MOTORSPORT

SYSTEMS COMPONENTS PARTS & SERVICES

AND MODULES 2

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Magneti

Marelli

Magneti

Marelli

Suspension

Systems

designs

and

produces

suspension

modules

and

components

for

motor

vehicles.

lever arms

front and rear axles

steering knuckles

semicorners

complete

axles hubs

and

spindles brake

disks

and

drums

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Magneti Marelli

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Magneti Marelli’s experience

The

aim

of

ADI

introduction

was

to

take

advantage

of

its

higher

material

properties

towards

lightweight,

at

reasonable

industrial

costs.

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Product

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Comparison between old and new steering knuckle

Previous knuckle: before 2014 Current knuckle: today

Machined Machined

weight: weight:

9.5 Kg 7.5 Kg

Raw weight: Raw weight:

10.7 Kg 8.7 Kg

GH 60-‐38-‐10 ISO 17804/JS/900-‐8

Pearlitic – ferritic cast iron

Rp02 (MPa) 600

Rp02 (MPa) 370

Rm (MPa) 900

Rm (MPa) 590

A (%) 8

A (%) 10 7

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Comparison between old and new control arm

Previous control arm: before 2014 Current control arm: today

Machined

Machined

weight:

Raw

weight:

8.0

Kg

weight:

5.9

Kg

8.6

Kg

Raw

weight:

6.5

Kg

GH

60-‐38-‐10

Pearlitic

–

ferritic

cast

iron ISO

17804/JS/900-‐8

Rp02

(MPa) 370 Rp02

(MPa) 600

Rm

(MPa) 590 Rm

(MPa) 900

A

(%) 10 A

(%) 8 8

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Comparison between old and new parts

Advantages:

-‐ environmental

regulations

-‐ handling

-‐ performance

-‐ durability

-‐ innovation

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

MM STANDARDS: ISO 17804

Ausferritic spheroidal graphite cast irons -‐ Classification

10

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

About main test: hardness

Cast iron material hardness typical hardness

according (HB)

standard

(HB)

heat treated ADI 900-‐8 280÷340 300÷340

cast iron

not treated tipical cast iron -‐ 210÷280

cast iron

production cast pearlitic-‐ferritic 190÷250 190÷250

iron cast iron

11

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

About main test: tensile

Cast iron material Rm Rp02 A

(MPa) (MPa) (%)

standard typical standard typical standard typical

min medium min medium min medium

heat treated ADI 900-‐8 880 1030 600 730 7 11

cast iron

before treating pearlitic-‐ferritic -‐ 820 -‐ 500 -‐ 7

cast iron cast iron

production cast pearlitic-‐ferritic 590 370 10

iron cast iron

Values

for

tensile

strenght

and

elongation

for

test

pieces

machined

from

samples

cut

from

a

casting. Galdabini

dinamometer

30KN

12

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

About test: Charpy impact

Cast iron material impact resistance typical impact

according standard resistance

min (J) (J)

heat treated ADI 900-‐8 100 100÷150

cast iron

prodution cast pearlitic-‐ferritic -‐ 50

iron cast iron

Values of impact energy for unnotched test pieces machined from

samples cut from a casting. ISO 17804 target are informative, not

normative.

13

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

About main test: micrographic

graphite

acicular

ferrite

pearlite

ferrite

austenite

14

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

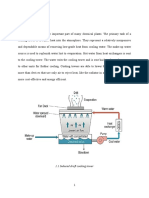

Process: heat treatment furnace

15

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: heat treatment furnace

Machining 250

16

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: heat treatment furnace

AUSTEMPER

FURNACE UBQA

PREHEAT

FURNACE UBT

17

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: heat treatment furnace

BASKET

TRANSFER CAR

UBCT

18

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: heat treatment furnace

ENDOTHERMIC GAS DUNK RINSE SYSTEM

GENERATOR UBR

4500 EZ

DUNK

WASHER

SYSTEM

UBW TRANSFER CAR

19

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: scheme of thermal treatment

20

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

21

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: scheme of thermal treatment

Material: increase of toughness, decrease of strength.

Material: increase of wear resistance, but decrease of toughness.

With equal chemical composition, by acting on the time and temperature parameters, it is

possible to obtain different kinds of ADI.

The «RECIPE» will be only one: no parameters change to balance

other process changes.

PS. On slide typical heat treatment parameters, not real process ones.

22

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process:

casting

Casting process doesn’t change introducing ADI. There was only a little change on chemical composition. This is

very important for high volume production

23

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

CONCLUSIONS

THE ADOPTION OF ADI IN THE SUSPENSION

SYSTEMS WAS A TOTAL SUCCESS.

24

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: why today not ADI in all parts?

It was said that:

what ADI Is Not

The following is a list of what the ADI process is not: But we have had no problems

-‐ It is not a remedy for casting defects. It does not weld cracked castings, related to defects on a vehicle

nor does it fill shrinkage holes. It does not eliminate eutectic carbides. mass production.

But MM automotive process

-‐ It is not a substitute for process control. On the contrary, it requires tight

and strict process control. Any discrepancy in the casting process will be quality methodology has been

amplified by the subsequent heat treating. able to ensure process control

BUT IT IS BEEN THE SOLUTION

-‐ Although ADI has a broad range of applications, it is not a solution to

every engineering problem. TO OUR PROBLEM.

25

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

Process: why today not ADI in all parts?

What ADI Is

-‐ Austempered ductile iron is a material which is strong, light, wear resistant, a good conductor of heat,

and a better damper of vibration than steel. In addition, ADI provides high design and manufacturing

flexibility, and is relatively inexpensive.

-‐ In general, ADI may be characterized as an alloyed and heat treated ductile cast iron with properties that

are highly versatile. It is a material that exhibits remarkable strength, ductility and wear resistance. Its

ausferritic matrix is unique to cast irons, and it should not be viewed as a special steel with graphite particles

dispersed within it. Steel metallurgy often does not apply to cast irons.

Kovacs, "Austempered ductile iron: fact and fiction”, from Modern casting 1990

26

Austempering, A Technology for Substitution

ADI DAYS 2016 6th — 7th October Minerbe

FINALLY

WE

HAVE

OBSERVED

THAT

THE

CAPABILITY

OF

THE

PROCESS

IS

VERY

HIGH.

THE

THERMAL

PROCESS

IS

VERY

STABLE.

NOWADAYS WE PRODUCE ~3000 t/year OF ADI.

THANKS FOR YOUR ATTENTION

27

Austempering, A Technology for Substitution

Das könnte Ihnen auch gefallen

- Effect of Degassing and Heat Treatment OnDokument9 SeitenEffect of Degassing and Heat Treatment OnSinan YıldızNoch keine Bewertungen

- Assessment of Depth of Case-Hardening in Steel Rods by ElectromagDokument67 SeitenAssessment of Depth of Case-Hardening in Steel Rods by ElectromagSinan YıldızNoch keine Bewertungen

- Aluminum Sheet Production Heat Treatment GuideDokument4 SeitenAluminum Sheet Production Heat Treatment GuideJhalbert BelmonteNoch keine Bewertungen

- High-Carbon, High Chromium Cold Work Tool Steel: Z Similar SteelsDokument3 SeitenHigh-Carbon, High Chromium Cold Work Tool Steel: Z Similar Steelsjaskaran singhNoch keine Bewertungen

- Teknovak Presentation PDFDokument22 SeitenTeknovak Presentation PDFSinan YıldızNoch keine Bewertungen

- Cooling Tower REPORTDokument25 SeitenCooling Tower REPORTSaroj KumarNoch keine Bewertungen

- Aam Products 4 Forged Products PDFDokument16 SeitenAam Products 4 Forged Products PDFSinan YıldızNoch keine Bewertungen

- Application Notes Nitrided Coatings EnglishDokument6 SeitenApplication Notes Nitrided Coatings EnglishIrina IrinushkaNoch keine Bewertungen

- Effect of Carburizing Time and Wear PropDokument6 SeitenEffect of Carburizing Time and Wear PropSinan YıldızNoch keine Bewertungen

- BALINIT C - Pin On DiscDokument2 SeitenBALINIT C - Pin On DiscSinan YıldızNoch keine Bewertungen

- Thermodynamics, Kinetics, and Process Control of Nitriding: Surface Engineering January 1997Dokument16 SeitenThermodynamics, Kinetics, and Process Control of Nitriding: Surface Engineering January 1997Sinan YıldızNoch keine Bewertungen

- 1.2714 enDokument2 Seiten1.2714 enreza razaviNoch keine Bewertungen

- Application Notes Nitrided Coatings EnglishDokument6 SeitenApplication Notes Nitrided Coatings EnglishIrina IrinushkaNoch keine Bewertungen

- 4340M or 300MDokument2 Seiten4340M or 300MfedaquiNoch keine Bewertungen

- Boron Nitrür NanotubesDokument71 SeitenBoron Nitrür NanotubesSinan YıldızNoch keine Bewertungen

- HT Index PDFDokument7 SeitenHT Index PDFxuangNoch keine Bewertungen

- Keyestudio 3D Printer KitDokument14 SeitenKeyestudio 3D Printer KitSinan YıldızNoch keine Bewertungen

- Abdullah 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012015Dokument14 SeitenAbdullah 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012015Sinan YıldızNoch keine Bewertungen

- Abdullah 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012015Dokument14 SeitenAbdullah 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012015Sinan YıldızNoch keine Bewertungen

- Atlas of CCT Diagram For Low Carbon and Low Alloy Steel Welds PDFDokument101 SeitenAtlas of CCT Diagram For Low Carbon and Low Alloy Steel Welds PDFSinan Yıldız100% (1)

- Abdullah 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012015Dokument14 SeitenAbdullah 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012015Sinan YıldızNoch keine Bewertungen

- Arduino Wireless Communication with NRF24L01Dokument10 SeitenArduino Wireless Communication with NRF24L01Sinan YıldızNoch keine Bewertungen

- The Effects of Contaminants On The Gas Nitriding of Nitralloy-135Dokument61 SeitenThe Effects of Contaminants On The Gas Nitriding of Nitralloy-135saltbathNoch keine Bewertungen

- Heat Treating Aluminum For Aerospace Applications: Figure 2 - Boeing F/A-18F During Sea TrialsDokument10 SeitenHeat Treating Aluminum For Aerospace Applications: Figure 2 - Boeing F/A-18F During Sea TrialsJuan David Baena UsugaNoch keine Bewertungen

- ListOptions - Rendered - Error in My SELECT StatementDokument4 SeitenListOptions - Rendered - Error in My SELECT StatementSinan YıldızNoch keine Bewertungen

- Document 15330 Section 7845Dokument10 SeitenDocument 15330 Section 7845Sinan YıldızNoch keine Bewertungen

- Surface Technology SpotlightDokument2 SeitenSurface Technology SpotlightSinan YıldızNoch keine Bewertungen

- Heat Treatment of Tool Steel PDFDokument20 SeitenHeat Treatment of Tool Steel PDFjassconsNoch keine Bewertungen

- Tutorial - Master - Detail PDFDokument8 SeitenTutorial - Master - Detail PDFSinan YıldızNoch keine Bewertungen

- Using PHP MySQL With Google Maps Alternative Using The Leaflet Library - PHP ClassesDokument45 SeitenUsing PHP MySQL With Google Maps Alternative Using The Leaflet Library - PHP ClassesSinan Yıldız100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 10 March 2018 - 15 March 2018Dokument4 Seiten10 March 2018 - 15 March 2018Abdul Ahad LoneNoch keine Bewertungen

- Wear of CeramicDokument3 SeitenWear of CeramicGhaith MdljNoch keine Bewertungen

- Literature Review of Precious Metal Analysis MethodsDokument67 SeitenLiterature Review of Precious Metal Analysis Methodspravin kondeNoch keine Bewertungen

- Mechanical Properties of High Carbon SteelDokument3 SeitenMechanical Properties of High Carbon SteelSabirul SkNoch keine Bewertungen

- AMPCO Metal Welding Materials CatalogueDokument28 SeitenAMPCO Metal Welding Materials Cataloguejhax90Noch keine Bewertungen

- Frontier Alloy Steels LTD: DatedDokument8 SeitenFrontier Alloy Steels LTD: DatedsushilpanwarNoch keine Bewertungen

- #15 Adhesion Test Report (3M VHB APT & Alpolic Panels)Dokument5 Seiten#15 Adhesion Test Report (3M VHB APT & Alpolic Panels)Senthil KumarNoch keine Bewertungen

- 904L (Valbruna)Dokument2 Seiten904L (Valbruna)Claudia MmsNoch keine Bewertungen

- Welding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationDokument6 SeitenWelding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationTaufikWibowoNoch keine Bewertungen

- Welding Repair Procedure for PT. Juhdi Sakti EngineeringDokument4 SeitenWelding Repair Procedure for PT. Juhdi Sakti EngineeringRiky SumantriNoch keine Bewertungen

- Mil A 8625Dokument20 SeitenMil A 8625Jose MoralesNoch keine Bewertungen

- Assignment - Metalsand Non MetalsDokument2 SeitenAssignment - Metalsand Non MetalsAkshita KambojNoch keine Bewertungen

- Conveyor DrivespulleysDokument55 SeitenConveyor DrivespulleysSaurabh JainNoch keine Bewertungen

- 2015-Formation Mechanisms of White Layers Induced byDokument10 Seiten2015-Formation Mechanisms of White Layers Induced byLucas Bonino SilvaNoch keine Bewertungen

- Shielded Metal WeldingDokument74 SeitenShielded Metal WeldingwernhowNoch keine Bewertungen

- Module-III Plasma Arc Machining (Pam) :: Modern Manufacturing Processes (Peme 5306)Dokument7 SeitenModule-III Plasma Arc Machining (Pam) :: Modern Manufacturing Processes (Peme 5306)Anonymous dL8dsCncNoch keine Bewertungen

- GROHE Specification Sheet 31574SD1Dokument2 SeitenGROHE Specification Sheet 31574SD1Muh. Yousuf KhanNoch keine Bewertungen

- Sheet Metal. GaugeDokument1 SeiteSheet Metal. GaugeVinu VenkidachalamNoch keine Bewertungen

- AWH Pipes & Accessories CatalogDokument52 SeitenAWH Pipes & Accessories CatalogTuan Anh Tran NguyenNoch keine Bewertungen

- Welding Proposed Pwps For Our Jubail WorkDokument2 SeitenWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- API RP 577 Welding Inspection GuideDokument34 SeitenAPI RP 577 Welding Inspection GuideNelson Bernardes100% (1)

- Valvulas Mariposa WSVDokument19 SeitenValvulas Mariposa WSVGuillermo ArandaNoch keine Bewertungen

- Engineering Materials Term Report PDFDokument15 SeitenEngineering Materials Term Report PDFZarar SaleemNoch keine Bewertungen

- Mbdaily 20150506Dokument37 SeitenMbdaily 20150506ClaudiaKlausyNoch keine Bewertungen

- DB double door mounting boardDokument3 SeitenDB double door mounting boardmaninderpreetNoch keine Bewertungen

- Tabel Besi ProfilDokument27 SeitenTabel Besi ProfilWildan PNoch keine Bewertungen

- Welding ProductsDokument40 SeitenWelding ProductsmuddogNoch keine Bewertungen

- Astm A967Dokument7 SeitenAstm A967Luciano Grassi Kuyven100% (1)

- GX5CrNi19-10 - 1Dokument2 SeitenGX5CrNi19-10 - 1Joe ClarkeNoch keine Bewertungen

- ABB Universal ClampsDokument3 SeitenABB Universal ClampsBoris CorralesNoch keine Bewertungen