Beruflich Dokumente

Kultur Dokumente

Allowable Stress 1a e 1b

Hochgeladen von

gabao123Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Allowable Stress 1a e 1b

Hochgeladen von

gabao123Copyright:

Verfügbare Formate

Table 1-100

Criteria for Establishing Allowable Stress Values for Tables 1A and 1B

Room Temperature and

Below Above Room Temperature

Tensile Yield

Product/Material Strength Strength Tensile Strength Yield Strength Stress Rupture Creep Rate

2 2 2

Wrought or cast /3 SY /3 SY /3 SYRY or 0.9 SYRY [Note FavgSR avg 0.8SR min 1.0Sc

ferrous and (1)]

No further reproduction or distribution is permitted.

nonferrous

2 2 2

Welded pipe or tube, /3 × 0.85SY /3 × 0.85SY /3 × 0.85SYRY or 0.9 × (Favg × 0.85)SR avg (0.8 × 0.85)SR min 0.85Sc

ferrous and 0.85SYRY [Note (1)]

nonferrous

NOTE:

(1) Two sets of allowable stress values may be provided in Table 1A for austenitic materials and in Table 1B for specific nonferrous alloys. The lower values are not specifically identified by a

footnote. These lower values do not exceed two‐thirds of the minimum yield strength at temperature. The higher alternative allowable stresses are identified by a footnote. These higher

stresses may exceed two‐thirds but do not exceed 90% of the minimum yield strength at temperature. The higher values should be used only where slightly higher deformation is not in

itself objectionable. These higher stresses are not recommended for the design of flanges or for other strain sensitive applications.

929

2013 SECTION II, PART D (METRIC)

Copyrighted material licensed to ABS by Thomson Scientific, Inc. (www.techstreet.com). This copy downloaded on 2013-08-25 23:09:18 -0500 by authorized user ABS AB

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Unfire Pressure VesselDokument146 SeitenUnfire Pressure Vesselsungkang83% (6)

- Isoparametric FormulationDokument42 SeitenIsoparametric FormulationLarryNoch keine Bewertungen

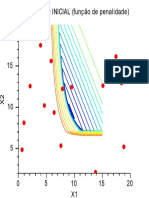

- Sensitivity Analysis With Unstructured Free Mesh Generators in 2-D and 3-D Shape OptimizationDokument11 SeitenSensitivity Analysis With Unstructured Free Mesh Generators in 2-D and 3-D Shape Optimizationgabao123Noch keine Bewertungen

- 2013 s1000rr Riders Manual 3rd EditionDokument181 Seiten2013 s1000rr Riders Manual 3rd Editiongabao123Noch keine Bewertungen

- A Sequential Quadratic Programming Algorithm With Non-Monotone Line SearchDokument24 SeitenA Sequential Quadratic Programming Algorithm With Non-Monotone Line Searchgabao123Noch keine Bewertungen

- 2 02-ArrayparDokument20 Seiten2 02-ArrayparSudhir KumarNoch keine Bewertungen

- Finite Element Method: Fem For 3D SolidsDokument46 SeitenFinite Element Method: Fem For 3D SolidsLK AnhDungNoch keine Bewertungen

- LeiauteDokument1 SeiteLeiautegabao123Noch keine Bewertungen

- Flow Patterns and Stresses On The Wall in A Moving Granular Bed With Eccentric DischargeDokument24 SeitenFlow Patterns and Stresses On The Wall in A Moving Granular Bed With Eccentric Dischargegabao123Noch keine Bewertungen

- Experimental Study On Mechanical Property of Soil-Cement: Hongxia YangDokument4 SeitenExperimental Study On Mechanical Property of Soil-Cement: Hongxia YangtoibihapNoch keine Bewertungen

- A Method For More Specific Simulation of Operative Temperature in Thermal Analysis ProgrammesDokument8 SeitenA Method For More Specific Simulation of Operative Temperature in Thermal Analysis Programmesmember124Noch keine Bewertungen

- Presentacion Bulk Solid HandlingDokument62 SeitenPresentacion Bulk Solid HandlingMiguel Prada100% (1)

- ARM Reference Board PDFDokument11 SeitenARM Reference Board PDFgabao123Noch keine Bewertungen

- Essential Properties of Fibres For Composite ApplicationsDokument36 SeitenEssential Properties of Fibres For Composite Applicationsgabao123Noch keine Bewertungen

- 591Dokument32 Seiten591gabao123Noch keine Bewertungen

- Finite-Element Analysis of Composite Pressure Vessels With Progressive DegradationDokument10 SeitenFinite-Element Analysis of Composite Pressure Vessels With Progressive Degradationgabao123Noch keine Bewertungen

- Ada 156622Dokument122 SeitenAda 156622gabao123Noch keine Bewertungen

- 1Dokument1 Seite1gabao123Noch keine Bewertungen

- Verification of Allowable Stresses in Asme Section Iii, Subsection NH For Grade 91 SteelDokument143 SeitenVerification of Allowable Stresses in Asme Section Iii, Subsection NH For Grade 91 SteelHarish TokiNoch keine Bewertungen

- Mechanical Properties of Carbon Fiber Composite MaterialsDokument2 SeitenMechanical Properties of Carbon Fiber Composite MaterialsAakashRanjanNoch keine Bewertungen

- Analysis & Performance of Fiber Composites SOLUTION MANUAL - Agarwal (3E)Dokument113 SeitenAnalysis & Performance of Fiber Composites SOLUTION MANUAL - Agarwal (3E)David Hoopes100% (6)

- © 1995-2006 Tsinghua Tongfang Optical Disc Co., Ltd. All Rights ReservedDokument15 Seiten© 1995-2006 Tsinghua Tongfang Optical Disc Co., Ltd. All Rights Reservedgabao123Noch keine Bewertungen

- KD 221.1Dokument2 SeitenKD 221.1gabao123Noch keine Bewertungen

- Pressure Relief Valve Engineering HandbookDokument93 SeitenPressure Relief Valve Engineering Handbookakrouti92% (12)

- Hessian - DelDokument9 SeitenHessian - Delgabao123Noch keine Bewertungen

- Scilab BeginnersDokument33 SeitenScilab BeginnersCarlos Soza RossNoch keine Bewertungen

- NBR ISO 724 - RoscasDokument2 SeitenNBR ISO 724 - Roscasgabao123Noch keine Bewertungen

- NBR ISO 724 - Roscas PDFDokument2 SeitenNBR ISO 724 - Roscas PDFgabao123Noch keine Bewertungen

- PR-TR009-006 4 Table of Contents PDFDokument5 SeitenPR-TR009-006 4 Table of Contents PDFgabao123Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Offshore Applications of SRTPDokument5 SeitenOffshore Applications of SRTPArif AshrafNoch keine Bewertungen

- Ammonia Injection SystemDokument21 SeitenAmmonia Injection SystemTutti Ganti A PezziNoch keine Bewertungen

- Rock Wool Glass WoolDokument3 SeitenRock Wool Glass WoolPrasanna IndrajithNoch keine Bewertungen

- 1434 20 Bal 88-10-2771-11-2010 enDokument186 Seiten1434 20 Bal 88-10-2771-11-2010 enmisternyckNoch keine Bewertungen

- Annam Ravi Kiran Shekhar ReddyDokument3 SeitenAnnam Ravi Kiran Shekhar ReddyKiran Reddy ANoch keine Bewertungen

- Load Bearing Pads (Symar)Dokument2 SeitenLoad Bearing Pads (Symar)zeroicesnowNoch keine Bewertungen

- Mechanical Department - ANNA UNIVERSITY Important Question and Answers - Regulation 2013,2017 - STUDY MATERIAL, NotesDokument4 SeitenMechanical Department - ANNA UNIVERSITY Important Question and Answers - Regulation 2013,2017 - STUDY MATERIAL, NotesKali Thaash100% (1)

- Manual Dibal PDFDokument61 SeitenManual Dibal PDFRafaela Lopes100% (1)

- Johnson Lift Sizes PDF PLANNING-GUIDE-HIGHRESDokument21 SeitenJohnson Lift Sizes PDF PLANNING-GUIDE-HIGHRESRajkumar DhanavelNoch keine Bewertungen

- Commodity CodesDokument116 SeitenCommodity Codesasif712Noch keine Bewertungen

- 2001 Ford Ranger Owners ManualDokument272 Seiten2001 Ford Ranger Owners ManualAaron Monk100% (1)

- Concrete Mix DesignDokument5 SeitenConcrete Mix DesignGlyn A. Brinquez100% (1)

- Leaflet ZRZT110-275 - LR - InekoDokument20 SeitenLeaflet ZRZT110-275 - LR - InekoSandro RibeiroNoch keine Bewertungen

- ACO StormBrixx BrochureDokument32 SeitenACO StormBrixx BrochureJose MariaNoch keine Bewertungen

- Guidelines On The Design of Sanitary SystemDokument57 SeitenGuidelines On The Design of Sanitary Systemhanafi86% (7)

- GENERON HPMB Series Membrane Nitrogen System Operating and Maintenance ManualDokument5 SeitenGENERON HPMB Series Membrane Nitrogen System Operating and Maintenance ManualardipangulihiNoch keine Bewertungen

- Analisis Kebutuhan Luas Lantai - PT Rizki Jaya AbadiDokument24 SeitenAnalisis Kebutuhan Luas Lantai - PT Rizki Jaya AbadiZiaNoch keine Bewertungen

- 3BDD010421R0401 A en S900 I O S - and N-System With SA920 InstallationDokument110 Seiten3BDD010421R0401 A en S900 I O S - and N-System With SA920 Installationilke HANNoch keine Bewertungen

- SOURSERVICE Brochure PDFDokument8 SeitenSOURSERVICE Brochure PDFshank100Noch keine Bewertungen

- PW SeriesDokument8 SeitenPW SeriesMt GrNoch keine Bewertungen

- SZL For Sea Final As 2Dokument12 SeitenSZL For Sea Final As 2Abo KolouNoch keine Bewertungen

- MB Electrical YaskawaDokument29 SeitenMB Electrical YaskawaMichael KennaNoch keine Bewertungen

- Training Record Book: 2Nd EditionDokument72 SeitenTraining Record Book: 2Nd EditionUpen TandelNoch keine Bewertungen

- WATO EX-55,65 Service Manual - English - 20131025Dokument380 SeitenWATO EX-55,65 Service Manual - English - 20131025travieso1120% (2)

- Human Skull 3D Papercraft: Paper ArtDokument8 SeitenHuman Skull 3D Papercraft: Paper ArtReyes Yess100% (1)

- BVG Integrated Services BroucherDokument8 SeitenBVG Integrated Services Broucherankit sharmaNoch keine Bewertungen

- Gs 2017Dokument540 SeitenGs 2017CHANNoch keine Bewertungen

- FPSO Topside Modules DynamacDokument28 SeitenFPSO Topside Modules DynamacJames100% (1)

- ElectronicsDokument3 SeitenElectronicsashishkumar218Noch keine Bewertungen

- Declaration of Conformity-Mercury Diesel Sterndrive (VW)Dokument118 SeitenDeclaration of Conformity-Mercury Diesel Sterndrive (VW)Aleksandar VeberovicNoch keine Bewertungen