Beruflich Dokumente

Kultur Dokumente

22 4.3 Process Piping Installation Precautions

Hochgeladen von

Ab RaúlOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

22 4.3 Process Piping Installation Precautions

Hochgeladen von

Ab RaúlCopyright:

Verfügbare Formate

<4.

Installing Impulse Piping> 22

4.3 Process Piping

NOTE

Installation Precautions

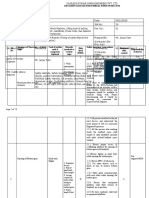

• If the process fluid is a gas, then as a rule the

4.3.1 Connecting Process Piping to manifold must be located at the downside of

the Transmitter the pressure-sensing assembly.

• If the process fluid is a liquid, then as a rule

(1) Confirming the Process Fluid the manifold must be located at the upside

Flow Direction of the pressure-sensing assembly.

The mark “ ” on the manifold indicates the direction in (2) Pipe Size for Process Piping

which the process fluid is flowed (from right to left). When Use a 15 mm (1/2-inch) pipe for process

connecting the process piping to the process connector,

piping connection to the process connector.

confirm the process fluid flow direction.

(3) Preventing Freezing

Flow direction (from right to left) Orifice name plate

Manifold If there is any risk that the process fluid in the transmitter

Process connection Process connection

(outflow side) (inflow side)

pressure-sensing assembly could freeze, use a steam

jacket or heater to maintain the temperature of the fluid.

(4) Process Piping Connection Examples

Figure 4.10 shows examples of typical process piping

Process connector Process connector connections. Before connecting the transmitter to the

(low pressure side) (high pressure side) process, study the transmitter installation location, the

F0409.ai process piping layout, and the characteristics of the

Figure 4.9 Manifold and Flow Direction Indication process fluid (corrosiveness, toxicity, flammability,

etc.), in order to make appropriate changes and

additions to the connection configurations.

(2) Tightening the Process

Connector Mounting Bolts Note the following points when referring to these

piping examples.

The transmitter is shipped with the process connector

mounting bolts only loosely tightened. After connecting • The process piping material used must be

the process piping, tighten these bolts uniformly to compatible with the process pressure,

prevent leaks with a torque of 39 to 49 N·m {4 to 5 kgf·m}. temperature, and other conditions.

• A variety of process piping-mounted stop valves

(3) Removing the Process Connector are available according to the type of connection

Port Dustproof Cap (flanged, screwed, welded), construction (globe,

The process connector port threads are covered with gate, or ball valve), temperature and pressure.

a plastic cap to exclude dust. This cap must be Select the type of valve most appropriate for

removed before connecting the piping. (Be careful the application.

not to damage the threads when removing this cap.

Gas flow measurement Union or flange

Never insert a screwdriver or other tool between the

cap and port threads to remove the cap.)

4.3.2 Routing the Process Piping Stop valve

(1) Relationship between Process Fluid Manifold

and Manifold Locations (For the Process piping

vertical impulse piping type) Liquid flow measurement

If condensate (or gas) generated in the process piping Manifold

were allowed to accumulate, then it would be necessary to Union or flange

remove it periodically by opening the drain (or vent) plug. Stop valve

However, this would generate a transient disturbance in

the pressure measurement. Therefore, the process piping

must be routed so that any condensate (or gas) generated Process piping

F0410.ai

in the process piping will not accumulate in the pressure-

sensing assembly of the transmitter. Figure 4.10 Process Piping Connection

Examples (EJA115)

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<5. Wiring> 23

5. Wiring

5.2 Connections of External

NOTE

Wiring to Terminal Box

For FOUNDATION Fieldbus and PROFIBUS PA

communication types, please refer to manuals in 5.2.1 Power Supply Wiring Connection

the attached CD-ROM.

Connect the power supply wiring to the SUPPLY +

and – terminals.

Transmitter terminal box

5.1 Wiring Precautions +

Power supply

–

IMPORTANT

• Lay wiring as far as possible from electrical F0502.ai

noise sources such as large capacity Figure 5.1 Power Supply Wiring Connection

transformers, motors, and power supplies.

• Remove electrical connection dust cap

before wiring. 5.2.2 Handheld Terminal Connection

• All threaded parts must be treated with Connect the handheld terminal to the SUPPLY + and

waterproofing sealant. (A non-hardening – terminals (Use hooks). Communication line

silicone group sealant is recommended.) requires a reception resistor of 250 to 600Ω in series.

• To prevent noise pickup, do not pass signal

and power cables through the same ducts. Transmitter terminal box

• Explosion-protected instruments must be wired +

Power supply

in accordance with specific requirements (and,

– 5

in certain countries, legal regulations) in order to 250 to 600 Ω

preserve the effectiveness of their explosion-

Wiring

Ignore the polarity

protected features. since it is AC-coupled

to the terminal box.

• The terminal box cover is locked by an Allen head BT200 etc.

bolt (a shrouding bolt) on CENELEC and IECEx F0503.ai

flameproof type transmitters. When the shrouding Figure 5.2 Handheld Terminal Connection

bolt is driven clockwise by an Allen wrench, it is

going in and cover lock is released, and then the

cover can be opened by hand. 5.3 Wiring

When a cover is closed it should be locked by

a shrouding bolt without fail. Tighten the

shrouding bolt to a torque of 0.7 N·m. CAUTION

For the intrinsically safe equipment and flameproof

equipment, wiring materials and wiring work for

Shrouding Bolt

Shrouding Bolt these equipment including peripherals are strictly

F0501.ai restricted. Users absolutely must read “Installation

and Operating Precautions for TIIS Intrinsically Safe

Equipment” and “Installation and Operating

Precautions for TIIS Flameproof Equipment” at the

end of this manual prior to the work.

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<5. Wiring> 24

5.3.1 Loop Configuration

Since the DPharp uses a two-wire transmission

system, signal wiring is also used as power wiring.

Flexible metal conduit

DC power is required for the transmitter loop. The

Apply a non-hardening

transmitter and distributor are connected as shown below. Wiring metal sealant to the threads for

For details of the power supply voltage and conduit waterproofing.

load resistance, see Section 5.6. Tee

Drain plug

(1) General-use Type and Flameproof Type F0506.ai

Hazardous Location Non-hazardous Location Figure 5.5 Typical Wiring Using Flexible

Metal Conduit

Transmitter terminal box

Distributor

(Power supply unit)

(2) Flameproof Type

Wire cables through a flameproof packing adapter,

Receiver

or using a flameproof metal conduit.

+ instrument

Wiring cable through flameproof packing adapter.

–

F0504.ai • Apply a non-hardening sealant to the terminal box

Figure 5.3 Connection between Transmitter connection port and to the threads on the

and Distributor flameproof packing adapter for waterproofing.

(2) Intrinsically Safe Type Flameproof packing

For intrinsically safe type, a safety barrier must adapter

Flexible metal conduit

be included in the loop.

Hazardous Location Non-hazardous Location Wiring metal Apply a non-hardening

conduit sealant to the threads for

Transmitter terminal box waterproofing.

Distributor Tee

(Power supply unit)

Drain plug

F0507.ai

Receiver Figure 5.6 Typical Cable Wiring Using

+ instrument Flameproof Packing Adapter

– • Measure the cable outer diameter in two directions

Safety barrier to within 1 mm.

F0505.ai

• Calculate the average of the two diameters, and

Figure 5.4 Connection between Transmitter

use packing with an internal diameter nearest to

and Distributor

this value (see Table 5.1).

5.3.2 Wiring Installation Table 5.1 Flameproof Packings and Applicable

Cable Outer Diameters

(1) General-use Type and Intrinsically Optional Wiring Port Applicable Identifying Part

Thread Cable OD

Safe Type Code Mark Number

Diameter (mm)

Make cable wiring using metallic conduit or G11

G 1/2 8 to 10 16 8-10 G9601AM

waterproof glands. G12 10.1 to 12 16 10-12

• Apply a non-hardening sealant to the terminal

box connection port and to the threads on the • Mounting flameproof packing adapter body to

flexible metal conduit for waterproofing. conduit connection (see Figure 5.7)

1) Screw the flameproof packing adapter into the

terminal box until the O-ring touches the wiring port

(at least 6 full turns), and firmly tighten the lock nut.

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<5. Wiring> 25

2) Insert the cable through the union cover, the 5.4 Grounding

union coupling, the clamp nut, the clamp ring,

the gland, the washer, the rubber packing, and Grounding is always required for the proper operation

the packing box, in that order. of transmitters. Follow the domestic electrical

3) Insert the end of the cable into the terminal box. requirements as regulated in each country. For a

4) Tighten the union cover to grip the cable. transmitter with builtin lightning protector, grounding

When tightening the union cover, tighten should satisfy ground resistance of 10Ω or less.

approximately one turn past the point where Ground terminals are located on the inside and outside of

the cable will no longer move up and down.

the terminal box. Either of these terminals may be used.

Proper tightening is important. If it is too

tight, a circuit break in the cable may occur;

if not tight enough, the flameproof

effectiveness will be compromised. WARNING

5) Fasten the cable by tightening the clamp nut. For TIIS flameproof type and intrinsically safe,

6) Tighten the lock nut on the union cover. grounding should satisfy Class D requirements

7) Connect the cable wires to each terminal.

(grounding resistance, 100Ω or less).

Transmitter terminal box

Apply a non-hardnening

Ground terminal

sealant to the threads for

(Inside)

waterproofing.

O-ring

Adapter body

Clamp nut

Lock nut

Wrench Union coupling Ground terminal

Packing box Lock nut

(Outside)

Rubber packing F0610.ai

Washer Wrench

Gland

Figure 5.9 Ground Terminals

Union cover

Clamp ring

Cable 5

F0508.ai

Figure 5.7 Installing Flameproof Packing Adapter 5.5 Power Supply Voltage

Wiring

Flameproof metal conduit wiring and Load Resistance

• A seal fitting must be installed near the terminal When configuring the loop, make sure that the external

box connection port for a sealed construction. load resistance is within the range in the figure below.

• Apply a non-hardening sealant to the threads of

(Note) In case of an intrinsically safe transmitter, external

the terminal box connection port, flexible metal load

conduit and seal fitting for waterproofing. resistance includes safety barrier resistance.

Non-hazardous area Gas sealing device

600

External E–10.5

load R= 0.0236 Communication

Flameproof flexible applicable range

resistance

Hazardous area metal conduit BRAIN and HART

R (Ω)

Flameproof Apply a non-hardening

heavy-gauge sealant to the threads 250

steel conduit of these fittings for

waterproofing

Tee

Drain plug Seal fitting

After wiring, impregnate the fitting

with a compound to seal tubing.

F0509.EPS

0 10.5 16.4 24.7 42

Figure 5.8 Typical Wiring Using Flameproof Metal Power supply voltage E (V DC)

Conduit F0511.ai

Figure 5.10 Relationship between Power Supply

Voltage and External Load Resistance

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<6. Operation> 26

6. Operation

Output Status Setting at CPU Failure

NOTE Set the burn-out direction as shown in the figures below.

For FOUNDATION Fieldbus and PROFIBUS PA The direction is set to the H side for delivery unless option

communication types and for the transmitter code /C1 is specified in the order. For option code /F1, the

operating confirmation and zeroing by any output signal for down-scale is -2.5%, 3.6 mA DC or less.

communication method, refer to manuals in the

● BRAIN and HART except option code /F1

attached CD-ROM for further information.

Setting pin (CN4)

6.1 Preparation for

Starting Operation CPU assembly

Confirming that Transmitter is Setting Pin (CN4) Burn-Out Output at

Position Direction Burn-Out

Operating Properly

On the integral indicator HIGH 110% or higher

H L

• If the wiring system is faulty, the display stays blank.

• If the transmitter is faulty, an error code will appear LOW -5% or lower

H L

on the display according to the nature of the error. F0602.ai

Figure 6.1 Burn-out Direction Setting Pin

● HART with option code /F1

CPU assembly

Self-diagnostic error on the integral indicator Slide switch Burn-out direction switch

(Faulty transmitter) F0601.ai

L H

Y N

Write protection switch

NOTE

If any of the error indications above appears on Burn-out direction switch

the display of the integral indicator, refer to Burnout Direction L H L H

Chapter 7 for corrective action. Switch Position Y N Y N

Burn-out Direction HIGH LOW

Verify and Change Transmitter

Hardware write protection switch

Parameter Setting and Values

Write Protection L H L H

The following parameters are the minimum

Switch Position Y N Y N

settings required for operation.

• Measuring range Write Protection NO YES

• Output/integral indicator mode

F0603.ai

• Operation mode

Figure 6.2 Burn-out Direction Slide Switch

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<6. Operation> 27

6.2 Zero Point Adjustment

Adjust the zero point after operating preparation is

completed.

IMPORTANT

Do not turn off the power to the transmitter

immediately after a zero adjustment. Powering off

within 30 seconds after a zero adjustment will return

the adjustment back to the previous settings.

Using the Transmitter Zero-adjustment

Screw

Use a slotted screwdriver to turn the zero-adjustment

screw. Turn the screw clockwise to increase the output or

counterclockwise to decrease the output. The zero point

adjustment can be made with a resolution of 0.01% of

the setting range. Since the degree of zero adjustments

varies with the screw turning speed, turn the screw slowly

for fine adjustment and quickly for coarse adjustment.

Zero-adjustment Screw

Zero-adjustment screw

F0604.ai

Operation

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<7. Errors and Countermeasures> 28

7. Errors and Countermeasures

NOTE

For FOUNDATION Fieldbus and PROFIBUS PA communication types, please refer to manuals in the attached CD-ROM.

The table below shows a summary of error messages for BRAIN and HART protocols.

Table 7.1 Error Message Summary

Integral

Indicator Description Cause Output Operation during Error Countermeasure Display

None GOOD

--- ERROR

1

Er. 01 CAP MODULE FAULT Capsule problem.* Outputs the signal according to Replace the capsule when

status of a burnout direction pin error keeps appearing even

or switch (the signal can be set as after restart.*2

“hold” for BRAIN protocol).

Er. 02 AMP MODULE FAULT Amplifier problem. Outputs the signal (Hold, Outputs Replace amplifier.

the signal according to status of

a burnout direction pin or switch

(the signal can be set as “hold” for

BRAIN protocol).

Er. 03 OUT OF RANGE Input is outside Outputs high range limit value or Check input.

measurement range limit low range limit value.

of capsule.

Er. 04 OUT OF SP RANGE Static pressure exceeds Displays present output. Check line pressure (static

3

specified range.* pressure).

Er. 05 OVER TEMP (CAP) Capsule temperature Displays present output. Use heat insulation or make

is outside range (-50 to lagging to keep temperature

130°C). within range.

Er. 06 OVER TEMP (AMP) Amplifier temperature Displays present output. Use heat insulation or make

is outside range (-50 to lagging to keep temperature

95°C). within range.

Er. 07 OVER OUTPUT Output is outside high or Outputs high or low range limit Check input and range

low range limit value. value. setting, and change them as

needed.

Er. 08 OVER DISPLAY Displayed value is Displays high or low range limit Check input and display

outside high or low range value. conditions and modify them

limit value. as needed.

Er. 09 ILLEGAL LRV LRV is outside setting Holds output immediately before Check LRV and modify as

range. error occurrence. needed.

Er. 10 ILLEGAL URV URV is outside setting Holds output immediately before Check URV and modify as

range. error occurrence. needed.

Er. 11 ILLEGAL SPAN SPAN is outside setting Holds output immediately before Check SPAN and change as

range. error occurrence. needed.

Er. 12 ZERO ADJ OVER Zero adjustment is too Displays present output. Readjust zero point.

large.

*1: This error code appears at a capsule problem or when an illegal overpressure is applied to the pressure sensor.

*2: If the normal pressure is regained, the Er.01 will disappear according to the setting of the parameter of E50:AUTO RECOVER.

When the E50:AUTO RECOVER is set to ON, the Er.01 will disappear automatically. The default setting for this parameter is

ON. When the E50:AUTO RECOVER is set to OFF, restart the transmitter to cancel Er.01. If no error code appears then, perform

necessary adjustments such as zero-adjustment to continue the operation. If the error code still appears, replace the capsule

assembly.

*3: For Model EJA120A, static pressure cannot be measured. The display is always 0 MPa, but this is not a measured value.

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<8. Parameter Summary> 29

8. Parameter Summary

NOTE IMPORTANT

For FOUNDATION Fieldbus and PROFIBUS PA If the transmitter is turned off within 30 seconds after

communication types, please refer to manuals in the parameters have been set, the set data will not be

attached CD-ROM. stored and the terminal returns to previous settings.

HART Communication Menu Tree

1 PROCESS 1 Pressure Hot Key 1 Keypad Input 1 LRV

VARIABLES 2 Percent Range 2 URV

3 Analog Output 3 Unit

4 Sensor Temperature 4 LSL

5 Static Pressure 5 USL

6 Engineering Unit 6 Min Span

7 Engineering Display

2 Wrt protect menu 1 Write protect

2 Enable wrt 10 min

2 DIAGNOSTICS 1 TEST/STATUS 1 Self Test

3 New password

AND SERVICE 2 Status 4 Software seal

2 Loop Test 1 RERANGE 1 Keypad Input

2 Apply Values

3 CALIBRATION

Errors and Countermeasures

2 TRIM ANALOG 1 Digital-to-Analog Trim

OUTPUT 2 Scaled Digital-to-Analog Trim

1 Tag 1 Zero Trim

3 SENSOR TRIM 2 Pressure

2 Unit 3 Lower Sensor Trim

4 Upper Sensor Trim

3 BASIC SETUP 3 RERANGE 1 Keypad Input 5 Sensor Trim Points

2 Apply Values 6 Clear snsr trim

4 DEVICE INFO 1 Date

2 Descriptor 1 Zero Trim

Online Menu 5 Transfer Function 3 Message 2 Pressure

1 DEVICE SETUP 6 Damp 4 Write Protect 1 Percent Range 3 Lower Sensor Trim

2 Pres 2 Pressure 4 Upper Sensor Trim

3 A01 Out 7 Low Cut 3 Unit 5 Sensor Trim Point

4 LRV 1 Pressure Sensor 4 Sensor Trim 6 Clear snsr trim

5 URV

8 Cut Mode

1 Snsr temp

2 Temperature 2 Amp temp

1 SENSORS Sensor 3 Sensor temp Unit 7

3 Static Pressure 1 Static Pressure

4 DETAILED

Sensor 2 Static Pressure Unit

SETUP

2 SIGNAL 1 PROCESS 1 Pressure 8

CONDITION VARIABLES 2 Percent Range

3 Sensor Temperature

Parameter Summary

2 RERANGE 1 Keypad Input

3 Unit 2 Apply Values

4 Transfer Function

5 Damp 1 Pressure

6 Low Cut 2 Percent Range

7 Cut Mode 3 Analog Output

8 Bi-dir Mode 4 Sensor Temperature

9 H2O Unit Select 5 Static Pressure

6 Engineering Unit

3 OUTPUT 1 PROCESS 7 Engineering Display

CONDITION VARIABLES 1 Loop Test

2 Digital-to-Analog Trim

2 ANALOG 3 Scaled D/A Trim

OUTPUT 4 Auto recover

5 AO lower limit %

3 Analog Output 6 AO upper limit %

Alarm 1 Poll Address

2 Number of Request Preambles

4 HART OUTPUT 3 Burst Mode

4 Burst Option

4 DISPLAY 1 Display Mode 1 Engineering Unit

CONDITION 2 Display Function 2 Engineering Display LRV

3 Engineering 3 Engineering Display URV

Display Range 4 Engineering Display Point

5 REVIEW 5 DEVICE

INFORMATION 1 Field Device Info

2 Sensor Info

3 Self Test

F0801.ai

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<8. Parameter Summary> 30

BRAIN Communication Parameter List

Instruments to which applicable:

F: Differential pressure transmitters: EJA110A, EJA120A, EJA130A, EJA118W, EJA118N, EJA118Y, and EJA115

P: Pressure transmitters: EJA310A, EJA430A, EJA440A, EJA510A, EJA530A, EJA438W, and EJA438N

L: Liquid level transmitters: EJA210A and EJA220A

Rewrita- Applicability

No. Item Description Remarks Default Value

bility F P L

01 MODEL Model+capsule type —

02 TAG NO. Tag number — 16 alphanumerics

03 SELF CHECK Self-diagnostic result — GOOD/ERROR

A DISPLAY Measured data display — Menu name

A10 OUTPUT (%) Output (in %) — –5 to 110%*3

A11 ENGR. OUTPUT Output (in engineering units) — –19999 to 19999

A20 AMP TEMP Amplifier temperature — Unit specified in D30

A21 CAPSULE TEMP Capsule temperature — Unit specified in D30

1

A30 STATIC PRESS Static pressure — Unit specified in D31* —

A40 INPUT Input (indicated as the — –32000 to 32000

value after zeroing)

A60 SELF CHECK Self-diagnostic — GOOD/ERROR, CAP MODULE FAULT, AMP

messages MODULE FAULT, OUT OF RANGE, OUT OF SP

RANGE*1, OVER TEMP (CAP),OVER TEMP

(AMP), OVER OUTPUT, OVER DISPLAY, ILLEGAL

LRV, ILLEGAL HRV, ILLEGAL SPAN, and ZERO

ADJ OVER

B SENSOR TYPE Sensor type — Menu name

B10 MODEL Model+span — 16 uppercase alphanumerics

B11 STYLE NO. Style number —

B20 LRL Lower range-limit — –32000 to 32000

B21 URL Upper range-limit — –32000 to 32000

B30 MIN SPAN Minimum span — –32000 to 32000

B40 MAX STAT.P. Maximum static pressure* 6 — —

B60 SELF CHECK Self-diagnostic — Same as A60

messages

C SETTING Setting data — Menu name

C10 TAG. NO. Tag number 16 alphanumerics As specified when

ordered.

C20 PRESS UNIT Measurement range units Selected from mmH2O, As specified when

mmAq, mmWG, mmHg, ordered.

Torr, Pa, hPa, kPa, MPa,

mbar, bar, gf/cm2, kgf/cm2,

inH2O, inHg, ftH2O, psi, or atm

C21 LOW RANGE Measurement range, lower –32000 to 32000(but within As specified when

range value measurement range) ordered.

C22 HIGH RANGE Measurement range, –32000 to 32000(but within As specified when

higher range value measurement range) ordered.

C30 AMP DAMPING Damping time constant Selected from 0.2*2, 0.5, 1.0, 2.0 s

2.0, 4.0, 8.0, 16.0, 32.0, or

64.0 sec.

C40 OUTPUT MODE Output mode and integral Selected from OUT:LIN; DSP: As specified when — —

indicator mode LIN, OUT:LIN; DSP:SQR, ordered.

OUT:SQR; DSP:SQR If not specified,

OUT: LIN; DSP: LIN.

C60 SELF CHECK Self-diagnostic messages — Same as A60

D AUX SET 1 Auxiliary setting data 1 — Menu name

D10 LOW CUT Low cut 0.0 to 20.0% 10.0%

D11 LOW CUT MODE Low cut mode LINEAR/ZERO LINEAR

7

D15 OUT LIMIT(L) Lower output range-limit –5.0 to 110.0% –5.0%*

D16 OUT LIMIT(H) Lower output range-limit –5.0 to 110.0% 110.0%

D20 DISP SELECT Display selection NORMAL %/USER SET, USER As specified when

& %/INP PRES, PRES & % ordered.

D21 DISP UNIT Engineering unit for display 8 uppercase alphanumerics

D22 DISP LRV Engineering range, lower –19999 to 19999 As specified when

range value ordered.

D23 DISP HRV Engineering range, higher –19999 to 19999 As specified when

range value ordered.

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<8. Parameter Summary> 31

Rewrita- Applicability

No. Item Description Remarks Default Value

bility F P L

D30 TEMP UNIT Temperature setting units deg C/deg F deg C

D31 STAT. P. UNIT Static pressure setting Selected from mmH2O, As specified when —

units mmAq, mmWG, mmHg, Torr, ordered. If not

Pa, hPa, kPa, MPa, mbar, specified, MPa.

2 2

bar, gf/cm , kgf/cm , inH2O,

inHg, ftH2O, psi, or atm

D40 REV OUTPUT Output reversal NORMAL/REVERSE If not specified,

NORMAL.

D45 H/L SWAP Impulse piping accessing NORMAL/REVERSE*4 NORMAL — —

direction

D52 BURN OUT CPU error — HIGH/LOW, –5 to 110%*3 HIGH

D53 ERROR OUT Hardware error HOLD/HIGH/LOW, –5 to HIGH

110%*3

D60 SELF CHECK Self-diagnostic messages — Same as A60

E AUX SET 2 Auxiliary setting data 2 — Menu name

E10 DFS MODE DFS mode OFF/ON*5 ON —

E14 TEMP SELECT Reference temperature sensor AMP. TEMP/CAP. TEMP*5 CAP. TEMP —

E15 TEMP ZERO Zero shift conpensation setup ±610.00*5 0.00 —

E30 BI DIRE MODE Bidirectional mode OFF/ON OFF — —

E50 AUTO RECOVER Auto-recover from sensor OFF/ON ON

error

E60 SELF CHECK Self-diagnostic messages — Same as A60

H AUTO SET Automatic setup — Menu name

H10 AUTO LRV Automatic measurement –32000 to 32000 Displays the same

range lower range value setup data as C21.

H11 AUTO HRV Automatic measurement range –32000 to 32000 Displays the same

higher range value setup data as C22.

H60 SELF CHECK Self-diagnostic messages — Same as A60

J ADJUST Adjustment data — Menu name

J10 ZERO ADJ Automatic zero adjustment –5 to 110.0%*3

J11 ZERO DEV. Manual zero adjustment

J15 SPAN ADJ Manual span adjustment –10.00 to 10.00% 0.00%

J20 EXT. ZERO ADJ External zero adjustment ENABLE/INHIBIT

screw permission

J30 OUTPUT 4mA 4mA adjustment –10.00 to 10.00% 0.00%

J31 OUTPUT 20mA 20mA adjustment –10.00 to 10.00% 0.00%

J60 SELF CHECK Self-diagnostic messages — Same as A60

K TEST Tests — Menu name

K10 OUTPUT in % Test output % setting –5 to 110.0%*3 Displays 8

‘ACTIVE’ while executing

—

Parameter Summary

K60 SELF CHECK Self-diagnostic messages Same as A60

M MEMO Memo — Menu name

M10 MEMO 1 Memo 8 uppercase alphanumerics

M20 MEMO 2 Memo 8 uppercase alphanumerics

M30 MEMO 3 Memo 8 uppercase alphanumerics

M40 MEMO 4 Memo 8 uppercase alphanumerics

M50 MEMO 5 Memo 8 uppercase alphanumerics

M60 SELF CHECK Self-diagnostic messages — Same as A60

P RECORD History of the errors —

P10 ERROR REC 1 Last error Display the error

P11 ERROR REC 2 One time before Display the error

P12 ERROR REC 3 Two time before Display the error

P13 ERROR REC 4 Three time before Display the error

P60 SELF CHECK Self-diagnostic messages — Same as A60

*1: In case of Model EJA120A, static pressure cannot be measured. The display is always 0 MPa, but this is not a measured value.

*2: When Optional code /F1 is specified, substitute the value with 0.1.

*3: When Optional code /F1 is specified, substitute the value –5 with –2.5.

*4: Not applicable for Model EJA115.

*5: Applicable only for Model EJA118W, EJA118N, EJA118Y, EJA438W, and EJA438N.

*6: See MWP(max. working pressure) on the nameplate. B40 shows an approximate value of maximum pressure for the capsule.

*7: Unless otherwise specified by order. When Optional code /F1 is specified, substitute the value –5 with –2.5.

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

<Installation and Operating Precautions for TIIS Intrinsically Safe Equipment> 32

Installation and Operating Precautions for TIIS Intrinsically Safe Equipment

Apparatus Certified Under Technical Criteria (IEC-compatible Standards) and from “RECOMMENDED PRACTICES for Explosion-

Protected Electrical Installations in General Industries,” published in 1979

1. General 3. Terminology

The following describes precautions on electrical (1) Intrinsically safe apparatus: Electrical apparatus in which

apparatus of intrinsically safe construction (hereinafter all the circuits are intrinsically safe circuits.

referred to as intrinsically safe apparatus). (2) Associated apparatus: Electrical apparatus in which there

Following the Labor Safety and Health Laws of Japan, an are both intrinsically safe circuits and non-intrinsically safe

intrinsically safe apparatus must undergo type tests in order circuits that can affect the safety of intrinsically safe circuits.

to be certified by the Technical Institute of Industrial Safety, (3) Safety barrier: A specific type of associated apparatus,

Inc. These tests are required to satisfy either the technical which consists mainly of safety barrier elements, and

criteria for electrical machinery and equipment in compliance serves to limit the flow of excessive electrical energy,

with explosionproof standards involving inflammable gases or which is capable of causing ignition of a given explosive

vapors and for machinery and equipment having gas or vapour of a non-intrinsically safe circuit into

explosionproof performance (standards notification no. 556 concerned intrinsically safe circuits.

from the Japanese Ministry of Labor) (hereinafter referred to

(4) Apparatus of category “ia”: Intrinsically safe electrical

as technical criteria), in conformity with IEC Standards, or the

“Recommended Practice for Explosion-Protected Electrical apparatus and associated apparatus which are incapable

Installations in General Industries,” published in 1979. Such a of causing ignition of a given explosive gas or vapour

certified apparatus can be used in hazardous locations where with the appropriate safety factors such as:

inflammable gases or vapors may be present. - when up to two countable faults are applied and,

Certified apparatus includes a certification label and an in addition,

equipment nameplate with the specifications necessary for - when non-countable faults produce an onerous condition.

explosion requirements as well as precautions on (5) Apparatus of category “ib”: Intrinsically safe electrical

explosion protection. Please confirm these precautionary apparatus and associated apparatus which are incapable

items and use them to meet specification requirements. of causing ignition of a given explosive gas or vapour,

For electrical wiring and maintenance servicing, please with the appropriate safety factors such as:

refer to “Internal Wiring Rules” in the Electrical Installation - when up to one countable fault is applied and, in addition,

Technical Standards as well as “USER’S GUIDELINES for - when non-countable faults produce an onerous condition.

Electrical Installations for Explosive Gas Atmospheres in

General Industry,” published in 1994. (6) Safety rating: A rating to be designated to intrinsically

To meet intrinsically safe requirements, equipment that can safe apparatus as well as associated apparatus and is

the maximum rating allowable for maintaining intrinsic

be termed an “intrinsically safe apparatus” must:

safety of concerned intrinsically safe circuits.

(1) be certified by the Technical Institute of Industrial Safety,

Inc. in accordance with the Labor Safety and Health Laws

of Japan and have the appropriate mark of certification 4. Caution on Combining Intrinsically

labeled on its case, and Safe Apparatus and Safety Barriers

(2) be used in compliance with the specifications marked on (1) A combination of certified intrinsically safe apparatus and

its certification label, equipment nameplate and safety barriers needs to satisfy combination requirements. If

precautionary information furnished. intrinsically safe apparatus specify safety barriers for

combination, safety barriers other than specified cannot be

Note: Intrinsically safe apparatus satisfy their performance under used (see Note 1 for more details).

specific conditions. They are not always absolutely safe under (2) Certified intrinsically safe systems specify specific safety

every operational and environmental condition. In other words, barriers in combination with intrinsically safe apparatus.

they are not safe products involved with factors such as So safety barriers other than specified cannot be used

chemical reactions, geographical changes or the like other than (see Note 2 for more details).

affected by electric energy from the equipment itself.

(3) Other than limitations of combining intrinsically safe apparatus

and safety barriers as given in (1) and (2) above, two or more

2. Electrical Apparatus of Intrinsic Safety Type pieces of apparatus certified under different standards cannot

of Explosion-Protected Construction be combined with each other (see Note 3 for more details). In

The intrinsic safety type of explosion-protected construction is addition, bear in mind that classifications of explosion

a method of protection applicable to a circuit or part of a protection such as “IIA,” “IIB” and “IIC” and category “ia” and

circuit in which, under prescribed test conditions, no spark or “ib” limit a combination of intrinsically safe apparatus and

thermal effect, whether produced normally or accidentally, is safety barriers.

capable of causing a prescribed explosive gas to ignite. In For more details, see the “Type Certificate Guide for

other words, electrical apparatus of this construction is Explosion-Protected Construction for Electrical Machinery

intended to suppress electrical energy thereby preventing and Equipment,” issued by the Japanese Ministry of

ignition of a given explosive gas atmosphere even though Labour, the Research Institute of Industrial Safety.

spark or high thermal effect occurs in the electric circuitry.

Intrinsically safe electrical apparatus generally comprise Note 1: Testing Apparatus

intrinsically safe apparatus installed in a hazardous location and Intrinsically safe apparatus and safety barriers are assessed

a safety barrier (associated apparatus), installed in a non- individually to ensure that their safety requirements are

hazardous location, aimed at preventing electrical energy from satisfied. Tested and certified intrinsically safe apparatus and

flowing into the electric circuitry of intrinsically safe apparatus. safety barriers incorporate individual certification numbers.

However, battery-operated, portable intrinsically safe A combination of intrinsically safe apparatus and safety

apparatus or the like may be used alone. barriers involves the following two limitations:

EX-A03E

Downloaded from www.Manualslib.com manuals search engine

<Installation and Operating Precautions for TIIS Intrinsically Safe Equipment> 33

(1) A safety barrier which meets the combination (a) refer to the equipment configuration diagram and

requirements by referring to its safety rating and make electrical wiring properly;

combination parameters shall be selected. (b) prevent intrinsically safe wiring from being contacted

(2) For pressure transmitters, pH transmitters, temperature with non-intrinsically safe wiring, and separate the

detectors and the like, safety barriers that can be combined intrinsically safe circuit from other electrical circuits;

are already specified. Other safety barriers cannot be used. (c) prevent intrinsically safe wiring from being electrostatically

Note 2: Testing Intrinsically Safe System and magnetically affected by non-intrinsically safe wiring;

An assembly (as a system) in which intrinsically safe apparatus

(d) reduce wiring inductance and capacitance produced

and safety barriers are combined is assessed to ensure that its between the intrinsically safe apparatus and safety

safety requirements are satisfied. A tested and certified system barrier where possible, and use a shorter cable between

incorporates a certification number (intrinsically safe apparatus the intrinsically safe apparatus and safety barrier than

and safety barriers have the same certification number). specified if the maximum permissible inductance of the

Note 3: Impossible Combinations of Apparatus Certified Under cable is specified as operating conditions;

Different Standards (e) conform to conditions of installation such as wiring

Intrinsically safe apparatus certified under technical criteria and method, earthing or the like, if any; and

safety barriers certified under the “Recommended Practice for (f) protect the outer sheath of cables from damage

Explosion-Protected Electrical Installations in General with appropriate measures.

Industries” (1979) and vice versa cannot be combined even if

their combination requirements are satisfied. 7. Maintenance and Inspection of Intrinsically

Safe Apparatus and Safety Barriers

5. Installation of Intrinsically Safe Apparatus

Maintenance and inspection of intrinsically safe apparatus and

and Safety Barriers safety barriers shall be limited to within the instructions

(1) Classification of installation location described in applicable instruction manuals. If other than this

is required, contact the manufacturers. For more information,

Intrinsically safe apparatus may be installed, depending upon refer to the “USER’S GUIDELINES for Electrical Installations

applicable gases, in a hazardous area in Zone 0, 1 or 2 (Note 4 for Explosive Gas Atmospheres in General Industry” issued in

below), where the specified gases are present. However, note 1994 by the Japanese Ministry of Labour, the Research

that apparatus certified under Technical Criteria, in category “ib” Institute of Industrial Safety.

shall be installed only in Zone 1 or 2. Safety barriers (associated

apparatus) that are combined with these intrinsically safe

apparatus shall be installed only in a non-hazardous area. In (1) Requirements for maintenance personnel

cases where safety barriers are installed in a hazardous area, Maintenance and inspection of intrinsically safe apparatus

they shall be enclosed, for example, in a flameproof enclosure. and safety barriers shall be conducted by maintenance

Note 4: Hazardous areas are classified in zones based upon the personnel skilled in intrinsically safe construction and

frequency of the appearance and the duration of an explosive installation of electrical devices as well as capable of

gas atmosphere as follows:

applying associated rules.

Zone 0: An area in which an explosive gas atmosphere is

present continuously or is present for long periods. (2) Maintenance and Inspection

Zone 1: An area in which an explosive gas atmosphere is (a) Visual inspection

likely to occur in normal operation. Visually inspect the external connections of intrinsically safe

Zone 2: An area in which an explosive gas atmosphere is not apparatus and safety barriers, and cables for damage or

likely to occur in normal operation and if it does corrosion as well as other mechanical and structural defects.

occur it will exist for a short period only. (b) Adjustments

Zero, span and sensitivity adjustments shall be made

(2) Ambient temperature limits for intrinsically with applicable adjusting potentiometers and

safe apparatus mechanical adjustment screws.

Intrinsically safe apparatus shall be installed in a location These maintenance adjustments shall be made in a

where the ambient temperature ranges from –20° to +40°C non-hazardous location.

(for those certified under Technical Criteria) or –10° to +40°C

(for those certified under the “Recommended Practice for

Explosion-Protected Electrical Installations in General

Industries” (1979). However, some field-mounted intrinsically CAUTION

safe apparatus may be used at an ambient temperature up

to 60°C. So, specifications should be checked before If intrinsically safe apparatus and safety barriers require

installing intrinsically safe apparatus. maintenance service and checking, a gas detector shall

If the intrinsically safe apparatus are exposed to direct be used to ensure that there is no explosive gas in the

sunshine or radiant heat from plant facilities, appropriate location (maintenance servicing shall be conducted in a

thermal protection measures shall be taken. non-hazardous location).

6. Wiring for Intrinsically Safe Circuits

In intrinsically safe construction, safety shall be maintained as (3) Repair

an intrinsically safe system involving intrinsically safe Intrinsically safe apparatus and safety barriers shall be

apparatus and safety barriers connected thereto, and repaired by manufacturers.

electrical wiring (through intrinsically safe circuits)

interconnected between them. In other words, even when

(4) Prohibition of modifications and

safety requirements are maintained individually by intrinsically

safe apparatus and safety barriers, they shall not be affected specification changes

by electrical or magnetic energy caused by electrical wiring. Do not attempt to make modifications or change

To make electrical wiring for intrinsically safe circuits, you must: specifications which may affect safety.

EX-A03E

Downloaded from www.Manualslib.com manuals search engine

<Installation and Operating Precautions for TIIS Flameproof Equipment> 34

Installation and Operating Precautions for TIIS Flameproof Equipment

Apparatus Certified Under Technical Criteria (IEC-compatible Standards)

1. General (4) Path length of joint surface

The following describes precautions on electrical apparatus On a joint surface, the length of the shortest path through which

of flameproof construction (hereinafter referred to as flame flows from the inside to outside of the flameproof

flameproof apparatus) in explosion-protected apparatus. enclosure. This definition cannot be applied to threaded joints.

Following the Labour Safety and Health Laws of Japan,

flameproof apparatus is subjected to type tests to meet either (5) Gaps between joint surfaces

the technical criteria for explosionproof electrical machinery The physical distance between two mating surfaces, or

and equipment (standards notification no. 556 from the

differences in diameters if the mating surfaces are cylindrical.

Japanese Ministry of Labour) (hereinafter referred to as

technical criteria), in conformity with the IEC Standards, or the Note: The permissible sizes of gaps between joint surfaces, the

“Recommended Practice for Explosion-Protected Electrical path length of a joint surface and the number of joint threads

Installations in General Industries,” published in 1979. These are determined by such factors as the enclosure’s internal

certified apparatus can be used in hazardous locations where

volume, joint and mating surface construction, and the

explosive or inflammable gases or vapours may be present.

explosion classification of the specified gases and vapours.

Certified apparatus includes a certification label and an

equipment nameplate with the specifications necessary for 4. Installation of Flameproof Apparatus

explosion requirements as well as precautions on

explosion protection. Please confirm these precautionary (1) Installation Area

items and use them to meet specification requirements. Flameproof apparatus may be installed, in accordance with

For electrical wiring and maintenance servicing, please applicable gases, in a hazardous area in Zone 1 or 2,

refer to “Internal Wiring Rules” in the Electrical Installation where the specified gases are present. Those apparatus

Technical Standards as well as “USER’S GUIDELINES for shall not be installed in a hazardous area in Zone 0.

Electrical Installations for Explosive Gas Atmospheres in

General Industry,” published in 1994. Note: Hazardous areas are classified in zones based upon the

To meet flameproof requirements, equipment that can be frequency of the appearance and the duration of an explosive

termed “flameproof” must: gas atmosphere as follows:

(1) Be certified by a Japanese public authority in Zone 0: An area in which an explosive gas atmosphere is

present continuously or is present for long periods.

accordance with the Labour Safety and Health Laws of

Zone 1: An area in which an explosive gas atmosphere is likely

Japan and have a certification label in an appropriate

to occur in normal operation.

location on its case, and

Zone 2: An area in which an explosive gas atmosphere is not

(2) Be used in compliance with the specifications marked on likely to occur in normal operation and if it does

its certification label, equipment nameplate and occur it will exist for a short period only.

precautionary information furnished.

(2) Environmental Conditions

2. Electrical Apparatus of Flameproof Type The standard environmental condition for the installation of

of Explosion-Protected Construction flameproof apparatus is limited to an ambient temperature range

Electrical apparatus which is of flameproof construction is from –20°C to +40°C (for products certified under Technical

subjected to a type test and certified by the Japanese Ministry of Criteria). However, some field-mounted instruments may be

Labour aiming at preventing explosion caused by electrical certified at an ambient temperature up to +60°C as indicated on

apparatus in a factory or any location where inflammable gases the instrument nameplates. If the flameproof apparatus are

or vapours may be present. The flameproof construction is exposed to direct sunshine or radiant heat from plant facilities,

of completely enclosed type and its enclosure shall appropriate thermal protection measures shall be taken.

endure explosive pressures in cases where explosive

gases or vapours entering the enclosure cause explosion. 5. External Wiring for Flameproof Apparatus

In addition, the enclosure construction shall be such that

Flameproof apparatus require cable wiring or flameproof metal

flame caused by explosion does not ignite gases or

conduits for their electrical connections. For cable wiring,

vapours outside the enclosure.

cable glands (cable entry devices for flameproof type) to

In this manual, the word "flameproof" is applied to the wiring connections shall be attached. For metal conduits,

flameproof equipment combined with the types of protection attach sealing fittings as close to wiring connections as

"e", "o", "i", and "d" as well as flameproof equipment. possible and completely seal the apparatus. All non-live metal

parts such as the enclosure shall be securely grounded.

3. Terminology For details, see the “USER’S GUIDELINES for

Electrical Installations for Explosive Gas Atmospheres

(1) Enclosure in General Industry,” published in 1994.

An outer shell of an electrical apparatus, which encloses

live parts and thus is needed to configure explosion- (1) Cable Wiring

protected construction.

• For cable wiring, cable glands (cable entry devices for

flameproof type) specified or supplied with the

(2) Shroud apparatus shall be directly attached to the wiring

A component part which is so designed that the fastening of joint connections to complete sealing of the apparatus.

surfaces cannot be loosened unless a special tool is used. • Screws that connect cable glands to the apparatus are those

for G-type parallel pipe threads (JIS B 0202) with no sealing

property. To protect the apparatus from corrosive gases

(3) Enclosure internal volume

or moisture, apply non-hardening sealant such as

This is indicated by:— the total internal volume of the liquid gaskets to those threads for waterproofing.

flameproof enclosure minus the volume of the internal

components essential to equipment functions.

EX-B03E

Downloaded from www.Manualslib.com manuals search engine

<Installation and Operating Precautions for TIIS Flameproof Equipment> 35

• Specific cables shall be used as recommended by the (2) Repair

“USER’S GUIDELINES for Electrical Installations for

If the flameproof apparatus requires repair, turn off the power

Explosive Gas Atmospheres in General Industry,”

and transport it to a safety (non-hazardous) location. Observe

published in 1994.

• In necessary, appropriate protective pipes (conduit or the following points before attempting to repair the apparatus.

flexible pipes), ducts or trays shall be used for preventing (a) Make only such electrical and mechanical repairs as will

the cable run (outside the cable glands) from damage. restore the apparatus to its original condition. For the

• To prevent explosive atmosphere from being flameproof apparatus, the gaps and path lengths of joints

propagated form Zone 1 or 2 hazardous location to and mating surfaces, and mechanical strength of

any different location or non-hazardous location enclosures are critical factors in explosion protection.

through the protective pipe or duct, apply sealing of the Exercise great care not to damage the joints or shock

protective pipes in the vicinity of individual boundaries, the enclosure.

or fill the ducts with sand appropriately. (b) If any damage occurs in threads, joints or mating

• When branch connections of cables, or cable connections surfaces, inspection windows, connections between the

with insulated cables inside the conduit pipes are made, a transmitter and terminal box, shrouds or clamps, or

flameproof or increased-safety connection box shall be used. external wiring connections which are essential in

In this case, flameproof or increased-safety cable glands flameproofness, contact Yokogawa Electric Corporation.

meeting the type of connection box must be used for cable

connections to the box.

(2) Flameproof Metal Conduit Wiring CAUTION

• For the flameproof metal conduit wiring or insulated wires

shall be used as recommended by the USER’S Do not attempt to re-process threaded connections or

GUIDELINES for Electrical Installations for Explosive Gas refinish joints or mating surfaces.

Atmospheres in General Industry, published in 1994.

• For conduit pipes, heavy-gauge steel conduits conforming (c) Unless otherwise specified, the electrical circuitry and

to JIS C 8305 Standard shall be used. internal mechanisms may be repaired by component

• Flameproof sealing fittings shall be used in the vicinity of the replacement, as this will not directly affect the requirements

wiring connections, and those fittings shall be filled with for flameproof apparatus (however, bear in mind that the

sealing compounds to complete sealing of the apparatus. In apparatus must always be restored to its original condition).

addition, to prevent explosive gases, moisture, or flame If you attempt to repair the flameproof apparatus, company-

caused by explosion form being propagated through the specified components shall be used.

conduit, always provide sealing fittings to complete sealing (d) Before starting to service the apparatus, be sure to check all

of the conduit in the following locations: parts necessary for retaining the requirements for flameproof

(a) In the boundaries between the hazardous and apparatus. For this, check that all screws, bolts, nuts, and

non-hazardous locations. threaded connections have properly been tightened.

(b) In the boundaries where there is a different

classification of hazardous location.

• For the connections of the apparatus with a conduit pipe (3) Prohibition of specification changes

or its associated accessories, G-type parallel pipe threads and modifications

(JIS B 0202) shall be used to provide a minimum of five- Do not attempt to change specifications or make modifications

thread engagement to complete tightness. In addition,

involving addition of or changes in external wiring connections.

since these parallel threads do not have sealing property,

non-hardening sealant such as liquid gaskets shall thus

be applied to those threads for ensuring waterproofness. 7. Selection of Cable Entry Devices for

• If metal conduits need flexibility, use flameproof Flameproof Type

flexible fittings.

6. Maintenance of Flameproof Apparatus IMPORTANT

To maintain the flameproof apparatus, do the following. (For

details, see Chapter 10 “MAINTENANCE OF EXPLOSION- The cable glands (cable entry devices for flameproof type)

PROTECTED ELECTRICAL INSTALLATION” in the USER’S conforming to IEC Standards are certified in combination

GUIDELINES for Electrical Installations for Explosive Gas with the flameproof apparatus. So, Yokogawa-specified

Atmospheres in General Industry.)

cable entry devices for flameproof type shall be used to

meet this demand.

(1) Maintenance servicing with the power on.

Flameproof apparatus shall not be maintenance-serviced with

its power turned on. However, in cases where maintenance References:

servicing is to be conducted with the power turned on, with the (1) Type Certificate Guide for Explosion-Protected Construction

equipment cover removed, always use a gas detector Electrical Machinery and Equipment (relating to Technical

to check that there is no explosive gas in that location. If it cannot Standards Conforming to International Standards), issued by

be checked whether an explosive gas is present or not, the Technical Institution of Industrial Safety, Japan

maintenance servicing shall be limited to the following two items:

(2) USER’S GUIDELINES for Electrical Installations for

(a) Visual inspection Explosive Gas Atmospheres in General Industry

Visually inspect the flameproof apparatus, metal (1994), issued by the Japanese Ministry of Labour, the

conduits, and cables for damage or corrosion, and other Research Institute of Industrial Safety.

mechanical and structural defects.

(b) Zero and span adjustments

These adjustments should be made only to the extent

that they can be conducted from the outside without

opening the equipment cover. In doing this, great care

must be taken not to cause mechanical sparks with tools.

EX-B03E

Downloaded from www.Manualslib.com manuals search engine

36

Revision Information

Title : EJA Series Differential Pressure and Pressure Transmitters Installation Manual

Manual No. : IM 01C22A01-01E

Edition Date Page Revised Item

1st Jan. 2008 New publication

2nd Oct.2008 12 2.4.4 Change explosion protection marking for type n from EEx to Ex.

13 2.5 Update EMC conformity standards.

28 7. Modify descriptions and notes for Er.01.

29 8. Add new parameters.

IM 01C22A01-01E

Downloaded from www.Manualslib.com manuals search engine

EJA Series Electronic User’s Manual IM 01C22A11-01E

System Requirements

for Windows

OS Microsoft Windows 2000 (Professional) / XP (Professional)

CPU Pentium 300 MHz or higher

RAM 128 MB or more

Display 800 × 600 SVGA or higher, 256 colors

Contents

This CD-R contains information in PDF format that is necessary for safe and effective operation of the product.

Trademarks

Microsoft, MS-DOS, Windows and Windows NT are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

Other company and product names are trademarks or registered trademarks of their respective holders.

www.yokogawa.com/fld/ Not for sale

WARNING: This CD contains software, and is for use in a computer only. Do not play this on

an audio CD player, as the high volume may damage your hearing or audio speakers.

Copyright © 2008 Yokogawa Electric Corporation. All Rights Reserved.

Downloaded from www.Manualslib.com manuals search engine

YOKOGAWA ELECTRIC CORPORATION

Headquarters

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 JAPAN

Branch Sales Offices

Nagoya, Osaka, Hiroshima, Fukuoka, Sapporo, Sendai, Ichihara, Toyota,

Kanazawa, Okayama, and Kitakyusyu.

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road, Newnan, Georgia 30265-1094, U.S.A.

Phone : 1-800-888-6400

Fax : 1-770-254-0928

YOKOGAWA EUROPE B. V.

Databankweg 20 Amersfoort 3821 AL, THE NETHERLANDS

Phone : 31-33-464-1611 Fax : 31-33-464-1610

Branch Sales Offices / Wien (Austria), Zaventem (Belgium), Ratingen

(Germany), Madrid (Spain), Runcorn (United Kingdom), Milano (Italy),

Velizy-Villacoublay (France), Budapest (Hungary), Stockholm (Sweden), Sola

(Norway), Warszawa (Poland), Vila Nova de Gaia (Portugal), Bucharest

(Romania)

YOKOGAWA AMERICA DO SUL LTDA.

Praca Acapulco, 31 - Santo Amaro. Sao Paulo/SP - BRAZIL

Phone : 55-11-5681-2400 Fax : 55-11-5681-4434

YOKOGAWA ENGINEERING ASIA PTE. LTD.

5 Bedok South Road, 469270 SINGAPORE

Phone : 65-6241-9933 Fax : 65-6241-2606

YOKOGAWA ELECTRIC KOREA CO., LTD.

14-1, Yangpyongdong-4Ga, Youngdeungpo-Gu, Seoul, 150-866 KOREA

Phone : 82-2-2628-6000 Fax : 82-2-2628-6400

YOKOGAWA AUSTRALIA PTY. LTD.

Tower A, 112-118 Talavera Road, Macquarie Park,

N.S.W.2113, AUSTRALIA

Phone : 61-2-8870-1100 Fax : 61-2-8870-1111

YOKOGAWA INDIA LTD.

Plot No.96 Electronic City Complex, Hosur Road, Bangalore 560100, INDIA

Phone : 91-80-4158-6000 Fax : 91-80-2852-0625

YOKOGAWA CHINA CO., LTD.

Tangyue Pavilion, Xi'an software park No.72,

Keji 2nd Road Xi'an High-tech Industries Development Zone Xi'an 710075,

CHINA

Phone : 86-29-87669988 Fax : 86-29-87607800

May ‘08

Printed in Japan

Downloaded from www.Manualslib.com manuals search engine

Das könnte Ihnen auch gefallen

- C6 PDFDokument4 SeitenC6 PDFgerardoNoch keine Bewertungen

- Foxboro - PSS 3-5A1 B - IFOADokument16 SeitenFoxboro - PSS 3-5A1 B - IFOAIrwin CastroNoch keine Bewertungen

- Flowfit CYA251: Technical InformationDokument12 SeitenFlowfit CYA251: Technical InformationAngelica BarbaraNoch keine Bewertungen

- EXXON IP-03-19-01 Piping Erection, Testing, Flushing and CleaningDokument6 SeitenEXXON IP-03-19-01 Piping Erection, Testing, Flushing and CleaningJJ WeldingNoch keine Bewertungen

- Best Practice No. 29 Steam Tracing Design and InstallationDokument6 SeitenBest Practice No. 29 Steam Tracing Design and InstallationDnyanehswar KinhalkarNoch keine Bewertungen

- API Sellos Mecanicos.Dokument56 SeitenAPI Sellos Mecanicos.Daniel Erasmo Avellaneda SanchezNoch keine Bewertungen

- Ensuring LNG Liquefaction Facilities Sys PDFDokument12 SeitenEnsuring LNG Liquefaction Facilities Sys PDFdhurjatibhuteshNoch keine Bewertungen

- A4 SPEC Surge Control Dynamics FIV AIV Station2014Dokument4 SeitenA4 SPEC Surge Control Dynamics FIV AIV Station2014Kroya HunNoch keine Bewertungen

- Condensate Pot For Steam Flow Measurements PDFDokument2 SeitenCondensate Pot For Steam Flow Measurements PDFshanks263Noch keine Bewertungen

- FlowMeasurement OilGasIndustryThapa16Dokument34 SeitenFlowMeasurement OilGasIndustryThapa16tsiftiNoch keine Bewertungen

- Installation Instructions: Durametallic MW-200 SeriesDokument8 SeitenInstallation Instructions: Durametallic MW-200 SeriesEli Emmanuel Cárcamo Rodríguez100% (1)

- Flange ALignmentDokument5 SeitenFlange ALignmentAnonymous O0lyGOShYG100% (1)

- 2007 Paper - Water Injection Effects On Compressor Stage OperationDokument30 Seiten2007 Paper - Water Injection Effects On Compressor Stage OperationBassam ElsayedNoch keine Bewertungen

- QuestionnaireDokument2 SeitenQuestionnairenmapeshawarNoch keine Bewertungen

- Instrument Impluse LineDokument1 SeiteInstrument Impluse Linesbpathi100% (1)

- 6017 - Cement UnitDokument3 Seiten6017 - Cement UnitBhupatiNoch keine Bewertungen

- T NFPA 20 T Chapter 4 General Requirements: Section 4.28Dokument2 SeitenT NFPA 20 T Chapter 4 General Requirements: Section 4.28AnoirNoch keine Bewertungen

- Downwhole Deployment Valve Specification - (CNPC) Option1Dokument13 SeitenDownwhole Deployment Valve Specification - (CNPC) Option1RobertNoch keine Bewertungen

- Method Statement For Plumbing System Domestic Water System: Rev. Description Date Prepared by Reviewed by Approved byDokument4 SeitenMethod Statement For Plumbing System Domestic Water System: Rev. Description Date Prepared by Reviewed by Approved byWalidNoch keine Bewertungen

- OMC 80S Seires - Manual (Pneu. Controller)Dokument17 SeitenOMC 80S Seires - Manual (Pneu. Controller)winhlaingooNoch keine Bewertungen

- O & M Manual - Flow Nozzle AssemblyDokument4 SeitenO & M Manual - Flow Nozzle Assemblyabdellah faqdaniNoch keine Bewertungen

- Installation and Service Instructions Neutralization SystemDokument12 SeitenInstallation and Service Instructions Neutralization SystemDavid MartinNoch keine Bewertungen

- Silo Overpressurisation Guidance PDFDokument27 SeitenSilo Overpressurisation Guidance PDFDorian StiopuNoch keine Bewertungen

- SIEP - ABC Guide To Temporary Pipework Ver 02Dokument50 SeitenSIEP - ABC Guide To Temporary Pipework Ver 02Sameer Parambath100% (2)

- Importance of Low Point DrainDokument10 SeitenImportance of Low Point Drainpesuk100% (1)

- Mechanical Seal Piping Plans For Centrifugal PumpsDokument66 SeitenMechanical Seal Piping Plans For Centrifugal PumpsShabir MansuriNoch keine Bewertungen

- Vortex Meter Forbes Marshall VFM 7700 ManualDokument83 SeitenVortex Meter Forbes Marshall VFM 7700 Manualltrongluanvn100% (1)

- Uncertainty and Reproducibility Analysis of A Laboratorial Scaled Pipe ProverDokument8 SeitenUncertainty and Reproducibility Analysis of A Laboratorial Scaled Pipe ProverOrlando GomezNoch keine Bewertungen

- Reporting Group 4Dokument12 SeitenReporting Group 4Kolokoy KasinNoch keine Bewertungen

- Questions & AnswersDokument72 SeitenQuestions & AnswersKhaleelullah KhanNoch keine Bewertungen

- Flowfit CPA250: Technical InformationDokument8 SeitenFlowfit CPA250: Technical Informationknightfelix12Noch keine Bewertungen

- A4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFDokument4 SeitenA4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFJose BijoyNoch keine Bewertungen

- Mitigations To Flow Induced Vibration (FIV) in Control Valve Piping System Using Visco-Elastic Dampers & Neoprene PadsDokument7 SeitenMitigations To Flow Induced Vibration (FIV) in Control Valve Piping System Using Visco-Elastic Dampers & Neoprene PadsIJSTENoch keine Bewertungen

- Man 80 eDokument17 SeitenMan 80 eseanNoch keine Bewertungen

- Thermocompressors Preventative Maintenance PDFDokument3 SeitenThermocompressors Preventative Maintenance PDFalicardozoNoch keine Bewertungen

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Dokument4 Seiten3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizNoch keine Bewertungen

- Facilities For Corrosion Monitoring in Process Equipment - Engineering Guide EG 19-6-1.1Dokument3 SeitenFacilities For Corrosion Monitoring in Process Equipment - Engineering Guide EG 19-6-1.1aminNoch keine Bewertungen

- Orifice Plate Installation GuidelinesDokument24 SeitenOrifice Plate Installation Guidelineskhavihong100% (1)

- Pipes Should Be Properly SupportedDokument3 SeitenPipes Should Be Properly SupportedGomathyselviNoch keine Bewertungen

- The Unsteady Pressure Field in A High Specific Speed Centrifugal Pump Impeller - Part I: Influence of The VoluteDokument6 SeitenThe Unsteady Pressure Field in A High Specific Speed Centrifugal Pump Impeller - Part I: Influence of The VoluteMichaelNoch keine Bewertungen

- Fire Hydrant System Design Installation Commisioning and TestingDokument5 SeitenFire Hydrant System Design Installation Commisioning and Testingjaianit89Noch keine Bewertungen

- Flow Through Chamber Data PDFDokument3 SeitenFlow Through Chamber Data PDFlunaritoNoch keine Bewertungen

- An Easy Method To Design Gas Vapor Relief System With Rupture DiskDokument8 SeitenAn Easy Method To Design Gas Vapor Relief System With Rupture DiskAlberto LazzarettiNoch keine Bewertungen

- C6 Fluid Friction Measurement (Issue 2) PDFDokument4 SeitenC6 Fluid Friction Measurement (Issue 2) PDFdjafarNoch keine Bewertungen

- SPE 27605 Hydraulic Workover Techniques: Their Versatility and ApplicationsDokument10 SeitenSPE 27605 Hydraulic Workover Techniques: Their Versatility and ApplicationsVera Linda Rios DiazNoch keine Bewertungen

- 8000A Series Compact Magnetic Flowtubes Wafer Body, Ceramic-Or Pfa-Lined 1.6 To 150 MM (1/16 To 6 In) Line SizesDokument16 Seiten8000A Series Compact Magnetic Flowtubes Wafer Body, Ceramic-Or Pfa-Lined 1.6 To 150 MM (1/16 To 6 In) Line Sizesdiana milena arredondo correaNoch keine Bewertungen

- Electromagnetic Flow Meter Catalogue.Dokument10 SeitenElectromagnetic Flow Meter Catalogue.mahipalNoch keine Bewertungen

- FMCTI ePRV Brochure 0Dokument2 SeitenFMCTI ePRV Brochure 0Julio Cesar Narvaez LaraNoch keine Bewertungen

- Evaporator Coil Installation Instructions 96654002 ADPDokument4 SeitenEvaporator Coil Installation Instructions 96654002 ADPgeoffffNoch keine Bewertungen

- Article Gain Insights From Diaphragm Seals en 7269906Dokument4 SeitenArticle Gain Insights From Diaphragm Seals en 7269906Miguel Praxedis Perez LeonNoch keine Bewertungen

- FLOW MEASUREMENT - Course NotesDokument38 SeitenFLOW MEASUREMENT - Course Notespawan deepNoch keine Bewertungen

- Valve Sizing: Technical BulletinDokument12 SeitenValve Sizing: Technical Bulletinherysyam1980Noch keine Bewertungen

- Valve Sizing: Technical BulletinDokument12 SeitenValve Sizing: Technical Bulletinpritesh29108068Noch keine Bewertungen

- bOLETIN VALVULAS SWAGELOK PDFDokument12 SeitenbOLETIN VALVULAS SWAGELOK PDFexergicNoch keine Bewertungen

- API冲洗方式 PDFDokument52 SeitenAPI冲洗方式 PDF唐文义Noch keine Bewertungen

- Testing and Commissioning of Irrigation SystemDokument2 SeitenTesting and Commissioning of Irrigation SystemMuhammad Ibrahim50% (6)

- 62-69 Engineer's Notebook DudaDokument5 Seiten62-69 Engineer's Notebook DudaMichael LagundinoNoch keine Bewertungen

- Application of Moment Restraining Supports in Process Plant Critical Piping-Full Paper-2019 PDFDokument5 SeitenApplication of Moment Restraining Supports in Process Plant Critical Piping-Full Paper-2019 PDFPratip BhattacharyaNoch keine Bewertungen

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsVon EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsBewertung: 5 von 5 Sternen5/5 (1)

- Catalogue Ong Nhua Xoan Hdpe SantoDokument13 SeitenCatalogue Ong Nhua Xoan Hdpe SantoLê Chí ThiệnNoch keine Bewertungen

- JSA Format Internal ReactorDokument13 SeitenJSA Format Internal Reactorsakthi venkatNoch keine Bewertungen

- MRO0000179 - 0010 - BautDokument3 SeitenMRO0000179 - 0010 - BautKEYZRULENoch keine Bewertungen

- File 3 ACSS AW DataDokument3 SeitenFile 3 ACSS AW Datafixer_007722Noch keine Bewertungen

- SEC ApprovedDokument60 SeitenSEC ApprovedAnonymous SkU7PyNoch keine Bewertungen

- Groove GaugingDokument3 SeitenGroove GauginghshobeyriNoch keine Bewertungen

- Sia-B: Overcurrent and Earth Fault Protection Relay For Secondary DistributionDokument5 SeitenSia-B: Overcurrent and Earth Fault Protection Relay For Secondary DistributionPaulo RebeloNoch keine Bewertungen

- Onshore Projects of Dutest QatarDokument3 SeitenOnshore Projects of Dutest QatarsajidziyanNoch keine Bewertungen

- PVC Coated Steel Wire Rope 2021Dokument1 SeitePVC Coated Steel Wire Rope 2021ELZEKKIWIRENoch keine Bewertungen

- Twisted Pair Wiring SchemesDokument9 SeitenTwisted Pair Wiring SchemesPedroNoch keine Bewertungen

- 8146 TerminalBoxes EK00 III en PDFDokument14 Seiten8146 TerminalBoxes EK00 III en PDFberry MikeNoch keine Bewertungen

- (BS EN 62275) - Cable Management Systems. Cable Ties For Electrical InstallationsDokument31 Seiten(BS EN 62275) - Cable Management Systems. Cable Ties For Electrical InstallationsAbdul Majeed SurmawalaNoch keine Bewertungen

- Doble Crane Girder Parts-1Dokument7 SeitenDoble Crane Girder Parts-1Ahmad AlaaNoch keine Bewertungen

- Eng CatDokument36 SeitenEng CatSanjay TripathiNoch keine Bewertungen

- CO2 AnsulDokument17 SeitenCO2 AnsulJorge RVNoch keine Bewertungen

- Md2 Plates No 4 Wire RopesDokument1 SeiteMd2 Plates No 4 Wire RopesDaniel Tanus MararangNoch keine Bewertungen

- Method Statement For Prestressing of HT StrandsDokument3 SeitenMethod Statement For Prestressing of HT StrandsBhanu Prasad EdemNoch keine Bewertungen

- Method Statement For Cable LayingDokument9 SeitenMethod Statement For Cable LayingRavi ManiNoch keine Bewertungen

- Chicago Pneumatic CPN 15-20 230-400V 60Hz Electrical Diagram EN 9828419490-01-1Dokument1 SeiteChicago Pneumatic CPN 15-20 230-400V 60Hz Electrical Diagram EN 9828419490-01-1Luiz Geniseli Fernanda OliveiraNoch keine Bewertungen

- 0 12 enDokument122 Seiten0 12 enHoangNoch keine Bewertungen

- Industrial Cable Glands: Pvt. LTDDokument6 SeitenIndustrial Cable Glands: Pvt. LTDProcurement PardisanNoch keine Bewertungen

- 006 Dozer Track LoaderDokument3 Seiten006 Dozer Track LoaderFuad Ahmad NafisNoch keine Bewertungen

- Installation Guide: Model 7040Dokument24 SeitenInstallation Guide: Model 7040Gusti WarmanNoch keine Bewertungen

- Is.3459.2004 0 PDFDokument12 SeitenIs.3459.2004 0 PDFRahul MandeliaNoch keine Bewertungen

- Closed Spelter SocketsDokument2 SeitenClosed Spelter SocketsKonstantinos SynodinosNoch keine Bewertungen

- Model Pl5 Service Manual 1418834752Dokument31 SeitenModel Pl5 Service Manual 1418834752LuisNoch keine Bewertungen

- Portique MobileDokument15 SeitenPortique MobilehamzaNoch keine Bewertungen

- pdf07 Mufa PDFDokument4 Seitenpdf07 Mufa PDFEduardo ReyesNoch keine Bewertungen

- Unit 12-Heavy Lift & Project Cargoes PDFDokument88 SeitenUnit 12-Heavy Lift & Project Cargoes PDFBisrat100% (3)

- Stranded Wire Ropes For Mine Hoisting - Technical Delivery RequirementsDokument16 SeitenStranded Wire Ropes For Mine Hoisting - Technical Delivery RequirementszhaobaoaixiaoyanNoch keine Bewertungen