Beruflich Dokumente

Kultur Dokumente

Splice Connection CHS

Hochgeladen von

Raveendra Babu CherukuriOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Splice Connection CHS

Hochgeladen von

Raveendra Babu CherukuriCopyright:

Verfügbare Formate

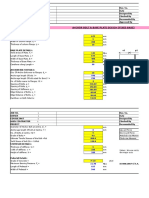

Connection Ref.(07.2-MC CHS splice .

)-01 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 340.00 kN Axial Load

Py = 2.74 kN Shear

Mz = 16.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 300 X 10

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 1 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 300 mm Pipe diameter

(ID) 280

tp = 10 mm Pipe thickness

sxc = 9589 cm4 Sec. moment of inertia

= 95889261.77 mm4

zxc = 639 cm3 Sec. modulu

= 639261.7 mm3

bp = 500 mm Plate width Assumed as per bolt arrangement

ts1 10 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 20 mm Splice Plate thickness

θ1 (b-a) = 30 deg angle of bolts spacing

θ2 (stif-a) = 30 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 20 mm Nominal diameter of bolts

dh = 22 mm Hole diameter Max Expected

n = 12 Nos. No of bolts 20

ey = 50 mm Min edge distance 1.5db = 30 mm e> emin"ok,"check"

ex = 50 mm Min edge distance 1.5db = 30 mm e> emin"ok,"check"

g = 400 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 104.72 mm See Fig.-01 60 mm e> Gmin"ok,"check"

w1 = 8 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 8 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 2 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 10 + 25 = 35 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 16 x 1000 /( 500 - 50 )+ 34 / 2 = 52.6 kn

n top = 4 Nos Bolt number in tension area

T = Ff / n top = 13.1 kn Bolt force

Ab = Pixdb^2 / 4 = 0.487 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.487 = 21.4 kips Table I-A, Ref[1]

= 95.3 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 12 Nos Bolt number in tension area

T = Px / n = 28.3 kn Bolt force

Ab = Pixdb^2 / 4 = 0.487 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.487 = 21.4 kips Table I-A, Ref[1]

= 95.3 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 2.7 kn

n sh = 12 Nos Bolt number in shear area

Vs = Pcompined/nsh 2.74 / 12 = 0.2 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 0.487 = 14.608 kips Table I-D, Ref[1]

= 65.0 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 0.2 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 215.28 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 3 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 340.0 / 0.928 (( 2 x 3.1416 x 300 ))

= 0.19 in/16 = 0.3 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 340.0 / 12 = 28.3 mm

Pe = ex - (db/4) -0.707 w = 50.0 - 5 - 6 = 39.3 mm Efective bolt distance.

Me = Pn x P e = 28.3 x 39.3 = 1114.7 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 1114.7 / ( 0.75 x 0.345 x 104.7 ) = 15.7 mm

tpl Req = 16 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE300X10

bp = 500 mm

ts1 = 10 mm

by = 100 mm

tpl = 20 mm

θ1 (b-a) = 30 deg

θ2 (stif-a) = 30 deg

END OF DESIGN

db = 20 mm

dh = 22 mm

n = 12 Nos.

ey = 50 mm

ex = 50 mm

g = 400 mm

p = 100 mm

Ln = 105 mm

w1 = 8 mm

w2 = 8 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 4 OF 180

Per AISC 9th Edition Manual (ASD) 5 OF 180

Per AISC 9th Edition Manual (ASD) 6 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 7 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 8 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 9 OF 180

Per AISC 9th Edition Manual (ASD) 10 OF 180

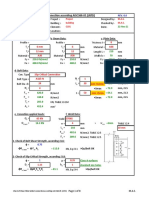

Connection Ref.(07.2-MC CHS splice .)-02 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 2200.00 kN Axial Load

Py = 30.00 kN Shear

Mz = 70.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 400 X 10

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 11 OF 180

Conclusion : 35mm Thick End Plate to be Provided

instead of 30mm

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 400 mm Pipe diameter

(ID) 380

tp = 10 mm Pipe thickness

sxc = 23310 cm4 Sec. moment of inertia

= 233098320.91 mm4

zxc = 1165 cm3 Sec. modulu

= 1165491.6 mm3

bp = 600 mm Plate width Assumed as per bolt arrangement

ts1 10 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 35 mm Splice Plate thickness

θ1 (b-a) = 22.5 deg angle of bolts spacing

θ2 (stif-a) = 45 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 24 mm Nominal diameter of bolts

dh = 26 mm Hole diameter Max Expected

n = 16 Nos. No of bolts 20

ey = 55 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

ex = 45 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

g = 490 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 96.21 mm See Fig.-01 72 mm e> Gmin"ok,"check"

w1 = 8 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 8 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 12 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 10 + 25 = 35 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 70 x 1000 /( 600 - 55 ) + 220 / 2 = 238.4 kn

n top = 5 Nos Bolt number in tension area

T = Ff / n top = 47.7 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 16 Nos Bolt number in tension area

T = Px / n = 136.9 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 30.0 kn

n sh = 16 Nos Bolt number in shear area

Vs = Pcompined/nsh 30.00 / 16 = 1.9 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 0.701 = 21.036 kips Table I-D, Ref[1]

= 93.6 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 1.9 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 452.09 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 13 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 2200.0 / 0.928 (( 2 x 3.1416 x 400 ))

= 0.94 in/16 = 1.5 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 2200.0 / 16 = 137.5 mm

Pe = ex - (db/4) -0.707 w = 45.0 - 6 - 6 = 33.3 mm Efective bolt distance.

Me = Pn x P e = 137.5 x 33.3 = 4584.8 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 4584.8 / ( 0.75 x 0.345 x 96.21 ) = 33.2 mm

tpl Req = 34 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE400X10

bp = 600 mm

ts1 = 10 mm

by = 100 mm

tpl = 35 mm

θ1 (b-a) = 23 deg

θ2 (stif-a) = 45 deg

END OF DESIGN

db = 24 mm

dh = 26 mm

n = 16 Nos.

ey = 55 mm

ex = 45 mm

g = 490 mm

p = 100 mm

Ln = 96 mm

w1 = 8 mm

w2 = 8 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 14 OF 180

Per AISC 9th Edition Manual (ASD) 15 OF 180

Per AISC 9th Edition Manual (ASD) 16 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 17 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 18 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 19 OF 180

Per AISC 9th Edition Manual (ASD) 20 OF 180

Connection Ref.(07.2-MC CHS splice .)-02 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 4300.00 kN Axial Load

Py = 48.94 kN Shear

Mz = 131.88 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 400 X 16

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 21 OF 180

Conclusion : M32 Bolts to be Provided instead of M24 &

45mm Thick End Plate instead of 36mm

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 400 mm Pipe diameter

(ID) 368

tp = 16 mm Pipe thickness

sxc = 35639 cm4 Sec. moment of inertia

= 356391117.35 mm4

zxc = 1782 cm3 Sec. modulu

= 1781955.6 mm3

bp = 600 mm Plate width Assumed as per bolt arrangement

ts1 15 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 45 mm Splice Plate thickness

θ1 (b-a) = 22.5 deg angle of bolts spacing

θ2 (stif-a) = 45 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 32 mm Nominal diameter of bolts

dh = 34 mm Hole diameter Max Expected

n = 16 Nos. No of bolts 15

ey = 50 mm Min edge distance 1.5db = 48 mm e> emin"ok,"check"

ex = 50 mm Min edge distance 1.5db = 48 mm e> emin"ok,"check"

g = 500 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 98.17 mm See Fig.-01 96 mm e> Gmin"ok,"check"

w1 = 16 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 12 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 22 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 16 + 25 = 41 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 132 x 1000 /( 600 - 50 ) + 430 / 2 = 454.8 kn

n top = 5 Nos Bolt number in tension area

T = Ff / n top = 91.0 kn Bolt force

Ab = Pixdb^2 / 4 = 1.247 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.247 = 54.8 kips Table I-A, Ref[1]

= 244.0 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 16 Nos Bolt number in tension area

T = Px / n = 241.9 kn Bolt force

Ab = Pixdb^2 / 4 = 1.247 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.247 = 54.8 kips Table I-A, Ref[1]

= 244.0 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 48.9 kn

n sh = 16 Nos Bolt number in shear area

Vs = Pcompined/nsh 48.94 / 16 = 3.1 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 1.247 = 37.398 kips Table I-D, Ref[1]

= 166.3 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 3.1 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 775.01 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 23 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 4300.0 / 0.928 (( 2 x 3.1416 x 400 ))

= 1.84 in/16 = 2.9 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 4300.0 / 16 = 268.8 mm

Pe = ex - (db/4) -0.707 w = 50.0 - 8 - 11 = 30.7 mm Efective bolt distance.

Me = Pn x P e = 268.8 x 30.7 = 8247.4 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 8247.4 / ( 0.75 x 0.345 x 98.17 ) = 44.1 mm

tpl Req = 44 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE400X16

bp = 600 mm

ts1 = 15 mm

by = 100 mm

tpl = 45 mm

θ1 (b-a) = 23 deg

θ2 (stif-a) = 45 deg

END OF DESIGN

db = 32 mm

dh = 34 mm

n = 16 Nos.

ey = 50 mm

ex = 50 mm

g = 500 mm

p = 100 mm

Ln = 98 mm

w1 = 16 mm

w2 = 12 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 24 OF 180

Per AISC 9th Edition Manual (ASD) 25 OF 180

Per AISC 9th Edition Manual (ASD) 26 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 27 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 28 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 29 OF 180

Per AISC 9th Edition Manual (ASD) 30 OF 180

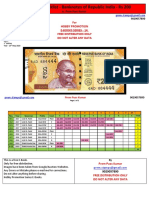

Connection Ref.(07.2-MC CHS splice .)-02 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 3630.00 kN Axial Load

Py = 10.00 kN Shear

Mz = 30.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 400 X 20

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 31 OF 180

Conclusion : M32 Bolts to be Provided instead of M24 &

45mm Thick End Plate instead of 36mm

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 400 mm Pipe diameter

(ID) 360

tp = 20 mm Pipe thickness

sxc = 43216 cm4 Sec. moment of inertia

= 432157485.43 mm4

zxc = 2161 cm3 Sec. modulu

= 2160787.4 mm3

bp = 600 mm Plate width Assumed as per bolt arrangement

ts1 20 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 45 mm Splice Plate thickness

θ1 (b-a) = 22.5 deg angle of bolts spacing

θ2 (stif-a) = 45 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 32 mm Nominal diameter of bolts

dh = 34 mm Hole diameter Max Expected

n = 16 Nos. No of bolts 15

ey = 50 mm Min edge distance 1.5db = 48 mm e> emin"ok,"check"

ex = 50 mm Min edge distance 1.5db = 48 mm e> emin"ok,"check"

g = 500 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 98.17 mm See Fig.-01 96 mm e> Gmin"ok,"check"

w1 = 16 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 12 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 32 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 20 + 25 = 45 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 30 x 1000 /( 600 - 50 ) + 363 / 2 = 236.0 kn

n top = 5 Nos Bolt number in tension area

T = Ff / n top = 47.2 kn Bolt force

Ab = Pixdb^2 / 4 = 1.247 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.247 = 54.8 kips Table I-A, Ref[1]

= 244.0 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 16 Nos Bolt number in tension area

T = Px / n = 226.9 kn Bolt force

Ab = Pixdb^2 / 4 = 1.247 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.247 = 54.8 kips Table I-A, Ref[1]

= 244.0 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 10.0 kn

n sh = 16 Nos Bolt number in shear area

Vs = Pcompined/nsh 10.00 / 16 = 0.6 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 1.247 = 37.398 kips Table I-D, Ref[1]

= 166.3 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 0.6 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 775.01 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 33 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 3630.0 / 0.928 (( 2 x 3.1416 x 400 ))

= 1.56 in/16 = 2.5 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 3630.0 / 16 = 226.9 mm

Pe = ex - (db/4) -0.707 w = 50.0 - 8 - 11 = 30.7 mm Efective bolt distance.

Me = Pn x P e = 226.9 x 30.7 = 6962.3 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 6962.3 / ( 0.75 x 0.345 x 98.17 ) = 40.6 mm

tpl Req = 41 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE400X20

bp = 600 mm

ts1 = 20 mm

by = 100 mm

tpl = 45 mm

θ1 (b-a) = 23 deg

θ2 (stif-a) = 45 deg

END OF DESIGN

db = 32 mm

dh = 34 mm

n = 16 Nos.

ey = 50 mm

ex = 50 mm

g = 500 mm

p = 100 mm

Ln = 98 mm

w1 = 16 mm

w2 = 12 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 34 OF 180

Per AISC 9th Edition Manual (ASD) 35 OF 180

Per AISC 9th Edition Manual (ASD) 36 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 37 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 38 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 39 OF 180

Per AISC 9th Edition Manual (ASD) 40 OF 180

Connection Ref.(07.2-MC CHS splice .)-03 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 485.00 kN Axial Load

Py = 105.00 kN Shear

Mz = 250.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 500 X 12

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 41 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 500 mm Pipe diameter

(ID) 476

tp = 12 mm Pipe thickness

sxc = 54798 cm4 Sec. moment of inertia

= 547978003.73 mm4

zxc = 2192 cm3 Sec. modulu

= 2191912.0 mm3

bp = 700 mm Plate width Assumed as per bolt arrangement

ts1 10 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 30 mm Splice Plate thickness

θ1 (b-a) = 20 deg angle of bolts spacing

θ2 (stif-a) = 40 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 24 mm Nominal diameter of bolts

dh = 26 mm Hole diameter Max Expected

n = 18 Nos. No of bolts 25

ey = 55 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

ex = 45 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

g = 590 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 102.97 mm See Fig.-01 72 mm e> Gmin"ok,"check"

w1 = 8 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 8 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 42 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 12 + 25 = 37 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 250 x 1000 /( 700 - 55 ) + 48.5 / 2 = 411.8 kn

n top = 6 Nos Bolt number in tension area

T = Ff / n top = 68.6 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 18 Nos Bolt number in tension area

T = Px / n = 26.9 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 105.0 kn

n sh = 18 Nos Bolt number in shear area

Vs = Pcompined/nsh 105.00 / 18 = 5.8 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 0.701 = 21.036 kips Table I-D, Ref[1]

= 93.6 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 5.8 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 387.50 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 43 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 485.0 / 0.928 (( 2 x 3.1416 x 500 ))

= 0.17 in/16 = 0.3 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 485.0 / 18 = 26.9 mm

Pe = ex - (db/4) -0.707 w = 45.0 - 6 - 6 = 33.3 mm Efective bolt distance.

Me = Pn x P e = 26.9 x 33.3 = 898.4 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 898.4 /( 0.75 x 0.345 x 103 ) = 14.2 mm

tpl Req = 15 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE500X12

bp = 700 mm

ts1 = 10 mm

by = 100 mm

tpl = 30 mm

θ1 (b-a) = 20 deg

θ2 (stif-a) = 40 deg

END OF DESIGN

db = 24 mm

dh = 26 mm

n = 18 Nos.

ey = 55 mm

ex = 45 mm

g = 590 mm

p = 100 mm

Ln = 103 mm

w1 = 8 mm

w2 = 8 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 44 OF 180

Per AISC 9th Edition Manual (ASD) 45 OF 180

Per AISC 9th Edition Manual (ASD) 46 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 47 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 48 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 49 OF 180

Per AISC 9th Edition Manual (ASD) 50 OF 180

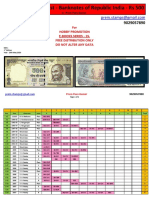

Connection Ref.(07.2-MC CHS splice .)-03 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 160.00 kN Axial Load

Py = 160.00 kN Shear

Mz = 360.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 500 X 16

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 51 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 500 mm Pipe diameter

(ID) 468

tp = 16 mm Pipe thickness

sxc = 71317 cm4 Sec. moment of inertia

= 713165458.73 mm4

zxc = 2853 cm3 Sec. modulu

= 2852661.8 mm3

bp = 700 mm Plate width Assumed as per bolt arrangement

ts1 15 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 30 mm Splice Plate thickness

θ1 (b-a) = 20 deg angle of bolts spacing

θ2 (stif-a) = 40 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 24 mm Nominal diameter of bolts

dh = 26 mm Hole diameter Max Expected

n = 18 Nos. No of bolts 25

ey = 55 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

ex = 45 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

g = 590 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 102.97 mm See Fig.-01 72 mm e> Gmin"ok,"check"

w1 = 8 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 8 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 52 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 16 + 25 = 41 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 360 x 1000 /( 700 - 55 )+ 16 / 2 = 566.1 kn

n top = 6 Nos Bolt number in tension area

T = Ff / n top = 94.4 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 18 Nos Bolt number in tension area

T = Px / n = 8.9 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 160.0 kn

n sh = 18 Nos Bolt number in shear area

Vs = Pcompined/nsh 160.00 / 18 = 8.9 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 0.701 = 21.036 kips Table I-D, Ref[1]

= 93.6 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 8.9 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 387.50 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 53 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 160.0 / 0.928 (( 2 x 3.1416 x 500 ))

= 0.05 in/16 = 0.1 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 566.1 / 18 = 31.5 mm

Pe = ex - (db/4) -0.707 w = 45.0 - 6 - 6 = 33.3 mm Efective bolt distance.

Me = Pn x P e = 31.5 x 33.3 = 1048.7 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 1048.7 / ( 0.75 x 0.345 x 103.0 ) = 15.4 mm

tpl Req = 16 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE500X16

bp = 700 mm

ts1 = 15 mm

by = 100 mm

tpl = 30 mm

θ1 (b-a) = 20 deg

θ2 (stif-a) = 40 deg

END OF DESIGN

db = 24 mm

dh = 26 mm

n = 18 Nos.

ey = 55 mm

ex = 45 mm

g = 590 mm

p = 100 mm

Ln = 103 mm

w1 = 8 mm

w2 = 8 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 54 OF 180

Per AISC 9th Edition Manual (ASD) 55 OF 180

Per AISC 9th Edition Manual (ASD) 56 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 57 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 58 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 59 OF 180

Per AISC 9th Edition Manual (ASD) 60 OF 180

Connection Ref.(07.2-MC CHS splice .)-03 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 1350.00 kN Axial Load

Py = 10.00 kN Shear

Mz = 26.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 500 X 16

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 61 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 500 mm Pipe diameter

(ID) 468

tp = 16 mm Pipe thickness

sxc = 71317 cm4 Sec. moment of inertia

= 713165458.73 mm4

zxc = 2853 cm3 Sec. modulu

= 2852661.8 mm3

bp = 700 mm Plate width Assumed as per bolt arrangement

ts1 15 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 30 mm Splice Plate thickness

θ1 (b-a) = 20 deg angle of bolts spacing

θ2 (stif-a) = 40 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 24 mm Nominal diameter of bolts

dh = 26 mm Hole diameter Max Expected

n = 18 Nos. No of bolts 25

ey = 55 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

ex = 45 mm Min edge distance 1.5db = 36 mm e> emin"ok,"check"

g = 590 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 102.97 mm See Fig.-01 72 mm e> Gmin"ok,"check"

w1 = 8 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 8 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 62 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 16 + 25 = 41 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 26 x 1000 /( 700 - 55 ) + 135 / 2 = 107.8 kn

n top = 6 Nos Bolt number in tension area

T = Ff / n top = 18.0 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 18 Nos Bolt number in tension area

T = Px / n = 75.0 kn Bolt force

Ab = Pixdb^2 / 4 = 0.701 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 0.701 = 30.9 kips Table I-A, Ref[1]

= 137.2 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 10.0 kn

n sh = 18 Nos Bolt number in shear area

Vs = Pcompined/nsh 10.00 / 18 = 0.6 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 0.701 = 21.036 kips Table I-D, Ref[1]

= 93.6 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 0.6 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 387.50 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 63 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 1350.0 / 0.928 (( 2 x 3.1416 x 500 ))

= 0.46 in/16 = 0.7 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 1350.0 / 18 = 75.0 mm

Pe = ex - (db/4) -0.707 w = 45.0 - 6 - 6 = 33.3 mm Efective bolt distance.

Me = Pn x P e = 75.0 x 33.3 = 2500.8 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 2500.8 / ( 0.75 x 0.345 x 103.0 ) = 23.7 mm

tpl Req = 24 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE500X16

bp = 700 mm

ts1 = 15 mm

by = 100 mm

tpl = 30 mm

θ1 (b-a) = 20 deg

θ2 (stif-a) = 40 deg

END OF DESIGN

db = 24 mm

dh = 26 mm

n = 18 Nos.

ey = 55 mm

ex = 45 mm

g = 590 mm

p = 100 mm

Ln = 103 mm

w1 = 8 mm

w2 = 8 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 64 OF 180

Per AISC 9th Edition Manual (ASD) 65 OF 180

Per AISC 9th Edition Manual (ASD) 66 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 67 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 68 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 69 OF 180

Per AISC 9th Edition Manual (ASD) 70 OF 180

Connection Ref.(07.2-MC CHS splice .)-04 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 1800.00 kN Axial Load

Py = 35.00 kN Shear

Mz = 130.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 500 X 20

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 71 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 500 mm Pipe diameter

(ID) 460

tp = 20 mm Pipe thickness

sxc = 87010 cm4 Sec. moment of inertia

= 870095501.34 mm4

zxc = 3480 cm3 Sec. modulu

= 3480382.0 mm3

bp = 900 mm Plate width Assumed as per bolt arrangement

ts1 20 mm

by = 200 mm See Fig.-1 Assumed as per bolt arrangement

tpl 60 mm Splice Plate thickness

θ1 (b-a) = 18 deg angle of bolts spacing

θ2 (stif-a) = 40 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 36 mm Nominal diameter of bolts

dh = 38 mm Hole diameter Max Expected

n = 20 Nos. No of bolts 20

ey = 140 mm Min edge distance 1.5db = 54 mm e> emin"ok,"check"

ex = 60 mm Min edge distance 1.5db = 54 mm e> emin"ok,"check"

g = 620 mm See Fig.-01

p = 200 mm See Fig.-01 e> emin"ok,"check"

Ln = 97.39 mm See Fig.-01 97.2 mm e> Gmin"ok,"check"

w1 = 16 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 12 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 72 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 20 + 25 = 45 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 130 x 1000 /( 900 - 140 ) + 180 / 2 = 261.1 kn

n top = 7 Nos Bolt number in tension area

T = Ff / n top = 37.3 kn Bolt force

Ab = Pixdb^2 / 4 = 1.578 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.578 = 69.4 kips Table I-A, Ref[1]

= 308.8 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 20 Nos Bolt number in tension area

T = Px / n = 90.0 kn Bolt force

Ab = Pixdb^2 / 4 = 1.578 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.578 = 69.4 kips Table I-A, Ref[1]

= 308.8 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 35.0 kn

n sh = 20 Nos Bolt number in shear area

Vs = Pcompined/nsh 35.00 / 20 = 1.8 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 1.578 = 47.331 kips Table I-D, Ref[1]

= 210.5 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 1.8 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 1162.51 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 73 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 1800.0 / 0.928 (( 2 x 3.1416 x 500 ))

= 0.62 in/16 = 1.0 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 1800.0 / 20 = 90.0 mm

Pe = ex - (db/4) -0.707 w = 60.0 - 9 - 11 = 39.7 mm Efective bolt distance.

Me = Pn x P e = 90.0 x 39.7 = 3571.9 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 3571.9 / ( 0.75 x 0.345 x 97.4 ) = 29.2 mm

tpl Req = 30 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE500X20

bp = 900 mm

ts1 = 20 mm

by = 200 mm

tpl = 60 mm

θ1 (b-a) = 18 deg

θ2 (stif-a) = 40 deg

END OF DESIGN

db = 36 mm

dh = 38 mm

n = 20 Nos.

ey = 140 mm

ex = 60 mm

g = 620 mm

p = 200 mm

Ln = 97 mm

w1 = 16 mm

w2 = 12 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 74 OF 180

Per AISC 9th Edition Manual (ASD) 75 OF 180

Per AISC 9th Edition Manual (ASD) 76 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 77 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 78 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 79 OF 180

Per AISC 9th Edition Manual (ASD) 80 OF 180

Connection Ref.(07.2-MC CHS splice .)-04 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 5800.00 kN Axial Load

Py = 50.00 kN Shear

Mz = 138.36 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 500 X 25

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 81 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 500 mm Pipe diameter

(ID) 450

tp = 25 mm Pipe thickness

sxc = 105507 cm4 Sec. moment of inertia

= 1055071986 mm4

zxc = 4220 cm3 Sec. modulu

= 4220287.9 mm3

bp = 900 mm Plate width Assumed as per bolt arrangement

ts1 25 mm

by = 200 mm See Fig.-1 Assumed as per bolt arrangement

tpl 60 mm Splice Plate thickness

θ1 (b-a) = 18 deg angle of bolts spacing

θ2 (stif-a) = 40 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 36 mm Nominal diameter of bolts

dh = 38 mm Hole diameter Max Expected

n = 20 Nos. No of bolts 20

ey = 140 mm Min edge distance 1.5db = 54 mm e> emin"ok,"check"

ex = 60 mm Min edge distance 1.5db = 54 mm e> emin"ok,"check"

g = 620 mm See Fig.-01

p = 200 mm See Fig.-01 e> emin"ok,"check"

Ln = 97.39 mm See Fig.-01 97.2 mm e> Gmin"ok,"check"

w1 = 16 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 12 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 82 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 25 + 25 = 50 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 138 x 1000 /( 900 - 140 ) + 580 / 2 = 472.1 kn

n top = 7 Nos Bolt number in tension area

T = Ff / n top = 67.4 kn Bolt force

Ab = Pixdb^2 / 4 = 1.578 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.578 = 69.4 kips Table I-A, Ref[1]

= 308.8 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 20 Nos Bolt number in tension area

T = Px / n = 290.0 kn Bolt force

Ab = Pixdb^2 / 4 = 1.578 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.578 = 69.4 kips Table I-A, Ref[1]

= 308.8 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 50.0 kn

n sh = 20 Nos Bolt number in shear area

Vs = Pcompined/nsh 50.00 / 20 = 2.5 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 1.578 = 47.331 kips Table I-D, Ref[1]

= 210.5 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 2.5 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 1162.51 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 83 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 5800.0 / 0.928 (( 2 x 3.1416 x 500 ))

= 1.99 in/16 = 3.2 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 5800.0 / 20 = 290.0 mm

Pe = ex - (db/4) -0.707 w = 60.0 - 9 - 11 = 39.7 mm Efective bolt distance.

Me = Pn x P e = 290.0 x 39.7 = 11509.5 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 11509.5 / ( 0.75 x 0.345 x 97.39 ) = 52.3 mm

tpl Req = 53 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE500X25

bp = 900 mm

ts1 = 25 mm

by = 200 mm

tpl = 60 mm

θ1 (b-a) = 18 deg

θ2 (stif-a) = 40 deg

END OF DESIGN

db = 36 mm

dh = 38 mm

n = 20 Nos.

ey = 140 mm

ex = 60 mm

g = 620 mm

p = 200 mm

Ln = 97 mm

w1 = 16 mm

w2 = 12 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 84 OF 180

Per AISC 9th Edition Manual (ASD) 85 OF 180

Per AISC 9th Edition Manual (ASD) 86 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 87 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 88 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 89 OF 180

Per AISC 9th Edition Manual (ASD) 90 OF 180

Connection Ref.(07.2-MC CHS splice .)-05 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 750.00 kN Axial Load

Py = 410.00 kN Shear

Mz = 910.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 600 X 16

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 91 OF 180

Conclusion : M30 Bolts to be Provided instead of M24 &

35mm Thick End Plate instead of 30mm

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 600 mm Pipe diameter

(ID) 568

tp = 16 mm Pipe thickness

sxc = 125240 cm4 Sec. moment of inertia

= 1252403501 mm4

zxc = 4175 cm3 Sec. modulu

= 4174678.3 mm3

bp = 800 mm Plate width Assumed as per bolt arrangement

ts1 15 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 35 mm Splice Plate thickness

θ1 (b-a) = 18 deg angle of bolts spacing

θ2 (stif-a) = 36 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 30 mm Nominal diameter of bolts

dh = 32 mm Hole diameter Max Expected

n = 20 Nos. No of bolts 25

ey = 55 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

ex = 45 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

g = 690 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 108.38 mm See Fig.-01 90 mm e> Gmin"ok,"check"

w1 = 10 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 8 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 92 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 16 + 25 = 41 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 910 x 1000 /( 800 - 55 )+ 75 / 2 = 1259.0 kn

n top = 7 Nos Bolt number in tension area

T = Ff / n top = 179.9 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 20 Nos Bolt number in tension area

T = Px / n = 37.5 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 410.0 kn

n sh = 20 Nos Bolt number in shear area

Vs = Pcompined/nsh 410.00 / 20 = 20.5 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 1.096 = 32.869 kips Table I-D, Ref[1]

= 146.2 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 20.5 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 565.11 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 93 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 750.0 / 0.928 (( 2 x 3.1416 x 600 ))

= 0.21 in/16 = 0.3 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 1259.0 / 20 = 62.9 mm

Pe = ex - (db/4) -0.707 w = 45.0 - 7.5 - 7 = 30.4 mm Efective bolt distance.

Me = Pn x P e = 62.9 x 30.4 = 1915.5 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 1915.5 / ( 0.75 x 0.345 x 108.4 ) = 20.2 mm

tpl Req = 21 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE600X16

bp = 800 mm

ts1 = 15 mm

by = 100 mm

tpl = 35 mm

θ1 (b-a) = 18 deg

θ2 (stif-a) = 36 deg

END OF DESIGN

db = 30 mm

dh = 32 mm

n = 20 Nos.

ey = 55 mm

ex = 45 mm

g = 690 mm

p = 100 mm

Ln = 108 mm

w1 = 10 mm

w2 = 8 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 94 OF 180

Per AISC 9th Edition Manual (ASD) 95 OF 180

Per AISC 9th Edition Manual (ASD) 96 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 97 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 98 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 99 OF 180

Per AISC 9th Edition Manual (ASD) 100 OF 180

Connection Ref.(07.2-MC CHS splice .)-05 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 4050.00 kN Axial Load

3250.00

Py = 680.00 kN Shear

Mz = 1500.00 kN'm Bending

750.00

2.2 MEMBERS

Beam Size = PIPE 600 X 16 STEEL COLUMN WITH CONCRETE

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 101 OF 180

Conclusion : M30 Bolts to be Provided instead of M24 &

35mm Thick End Plate instead of 30mm

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 600 mm Pipe diameter

(ID) 568

tp = 16 mm Pipe thickness

sxc = 125240 cm4 Sec. moment of inertia

= 1252403501 mm4

zxc = 4175 cm3 Sec. modulu

= 4174678.3 mm3

bp = 800 mm Plate width Assumed as per bolt arrangement

ts1 15 mm

by = 100 mm See Fig.-1 Assumed as per bolt arrangement

tpl 35 mm Splice Plate thickness

θ1 (b-a) = 18 deg angle of bolts spacing

θ2 (stif-a) = 36 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 30 mm Nominal diameter of bolts

dh = 32 mm Hole diameter Max Expected

n = 20 Nos. No of bolts 25

ey = 55 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

ex = 45 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

g = 690 mm See Fig.-01

p = 100 mm See Fig.-01 e> emin"ok,"check"

Ln = 108.38 mm See Fig.-01 90 mm e> Gmin"ok,"check"

w1 = 8 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 8 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 102 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 16 + 25 = 41 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 750 x 1000 /( 800 - 55 ) + 325 / 2 = 1169.2 kn

n top = 7 Nos Bolt number in tension area

T = Ff / n top = 167.0 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 20 Nos Bolt number in tension area

T = Px / n = 162.5 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 680.0 kn

n sh = 20 Nos Bolt number in shear area

Vs = Pcompined/nsh 680.00 / 20 = 34.0 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 1.096 = 32.869 kips Table I-D, Ref[1]

= 146.2 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 34.0 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 565.11 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 103 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 3250.0 / 0.928 (( 2 x 3.1416 x 600 ))

= 0.93 in/16 = 1.5 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 3250.0 / 20 = 162.5 mm

Pe = ex - (db/4) -0.707 w = 45.0 - 7.5 - 6 = 31.8 mm Efective bolt distance.

Me = Pn x P e = 162.5 x 31.8 = 5174.7 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 5174.7 / ( 0.75 x 0.345 x 108.4 ) = 33.3 mm

tpl Req = 34 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE600X16

bp = 800 mm

ts1 = 15 mm

by = 100 mm

tpl = 35 mm

θ1 (b-a) = 18 deg

θ2 (stif-a) = 36 deg

END OF DESIGN

db = 30 mm

dh = 32 mm

n = 20 Nos.

ey = 55 mm

ex = 45 mm

g = 690 mm

p = 100 mm

Ln = 108 mm

w1 = 8 mm

w2 = 8 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 104 OF 180

Per AISC 9th Edition Manual (ASD) 105 OF 180

Per AISC 9th Edition Manual (ASD) 106 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 107 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 108 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 109 OF 180

Per AISC 9th Edition Manual (ASD) 110 OF 180

Connection Ref.(07.2-MC CHS splice .)-06 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 3100.00 kN Axial Load

Py = 340.00 kN Shear

Mz = 1050.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 800 X 18

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 111 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 800 mm Pipe diameter

(ID) 764

tp = 18 mm Pipe thickness

sxc = 338207 cm4 Sec. moment of inertia

= 3382070752 mm4

zxc = 8455 cm3 Sec. modulu

= 8455176.9 mm3

bp = 1060 mm Plate width Assumed as per bolt arrangement

ts1 20 mm

by = 130 mm See Fig.-1 Assumed as per bolt arrangement

tpl 40 mm Splice Plate thickness

θ1 (b-a) = 15 deg angle of bolts spacing

θ2 (stif-a) = 30 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 30 mm Nominal diameter of bolts

dh = 32 mm Hole diameter Max Expected

n = 24 Nos. No of bolts 30

ey = 70 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

ex = 60 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

g = 920 mm See Fig.-01

p = 130 mm See Fig.-01 e> emin"ok,"check"

Ln = 120.43 mm See Fig.-01 90 mm e> Gmin"ok,"check"

w1 = 12 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 12 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 112 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 18 + 25 = 43 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 1050 x 1000 /( 1060 - 70 ) + 310 / 2 = 1215.6 kn

n top = 8 Nos Bolt number in tension area

T = Ff / n top = 152.0 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 24 Nos Bolt number in tension area

T = Px / n = 129.2 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 340.0 kn

n sh = 24 Nos Bolt number in shear area

Vs = Pcompined/nsh 340.00 / 24 = 14.2 Kn Shear in each bolt

Vallowable = Fvb x Ab = 30 x 1.096 = 32.869 kips Table I-D, Ref[1]

= 146.2 kn

Check = IF(Vs < Vallowable,"Ok","Not ok") = Ok

3.3 CHECK FOR BEARING STRENGTH

3.3.1 END PLATES BOLT HOLES

Pcompined = 14.2 Kn kn Shear in each bolt

Ppp = 1.2 F u

xd b

xtp1 = 645.84 kn J3-1, Ref[1]

Per AISC 9th Edition Manual (ASD) 113 OF 180

Check : if ( Pcompined < Ppp ) "OK","Not OK" = OK

3.4 MEMBER TO END PLATE WELD

Page 4-120, Ref[1]

W1 req'd = Px/ 0.928 (2*PI*R) = 3100.0 / 0.928 (( 2 x 3.1416 x 800 ))

= 0.66 in/16 = 1.1 mm

Check : if ( w1required < w1 ) "OK","USE GROOVE WELD" = OK

3.6 END PLATE DESIGN

Page 4-116 to 125, Ref[1]

Pn = Px / n = 3100.0 / 24 = 129.2 mm

Pe = ex - (db/4) -0.707 w = 60.0 - 7.5 - 8 = 44.0 mm Efective bolt distance.

Me = Pn x P e = 129.2 x 44.0 = 5685.4 kn-mm

Required plate thickness

tpl Req = √6Me/(0.75xFyxLn)

=√ 6 x 5685.4 / ( 0.75 x 0.345 x 120 ) = 33.1 mm

tpl Req = 34 mm

Check : if ( tpl Req < tpl ) "OK","Not OK" = OK

4.0 DESIGN SUMMARY

(See Fig-01)

PIPE800X18

bp = 1060 mm

ts1 = 20 mm

by = 130 mm

tpl = 40 mm

θ1 (b-a) = 15 deg

θ2 (stif-a) = 30 deg

END OF DESIGN

db = 30 mm

dh = 32 mm

n = 24 Nos.

ey = 70 mm

ex = 60 mm

g = 920 mm

p = 130 mm

Ln = 120 mm

w1 = 12 mm

w2 = 12 mm

Bolt Type = X (N, X, or SC)

END OF DESIGN

Per AISC 9th Edition Manual (ASD) 114 OF 180

Per AISC 9th Edition Manual (ASD) 115 OF 180

Per AISC 9th Edition Manual (ASD) 116 OF 180

ok

ok

ok

ok

Per AISC 9th Edition Manual (ASD) 117 OF 180

Bolt number in tension area

Bolt number in tension area

Bolt number in shear area

Per AISC 9th Edition Manual (ASD) 118 OF 180

Page 4-116 to 125, Ref[1]

Efective bolt distance.

Per AISC 9th Edition Manual (ASD) 119 OF 180

Per AISC 9th Edition Manual (ASD) 120 OF 180

Connection Ref.(07.2-MC CHS splice .)-06 Rv-00

Project :

COLUMN/BEAM TO COLUMN/BEAM SPLICE CONNECTION

1.0 SCOPE

This worksheet assesses the adequacy of the splice moment connection CHS

column to column splice plates.

REFERENCES:

Ref [1] : AISC Steel Construction Manual, AISC, 9th Edition

Ref [2] : AWS D1.1/D1.1 M:2010, Structural Welding Code- Steel

Ref [3] : ASTM A36 / A36M

Ref [4] : AISC Vol. I I , ( ASD ) Connections

2.0 INPUTS

2.1 LOADING Including 0 % increasing factor

Px = 4300.00 kN Axial Load

Py = 624.00 kN Shear

Mz = 710.00 kN'm Bending

2.2 MEMBERS

Beam Size = PIPE 800 X 18 BRACING MEMBERS

2.3 MATERIAL SPECIFICATION

Beam / Col = ASTM A572-GR50

Plate = ASTM A572-GR50

Bolts = A325M

Electrode = E70XX

2.4 MATERIAL STRENGTH

Fy = 50 ksi Specified minimum yield stress of connecting plt.

= 0.345 Kn/mm2 Table 3, Ref[3]

Fu = 65 ksi Specified minimum tensile strength of connecting plt.

= 0.449 Kn/mm2 Table 3, Ref[3]

Fye = 50 ksi Specified minimum yield stress of connecting elements

= 0.345 Kn/mm2 Table 3, Ref[3]

Fue = 65 ksi Specified minimum tensile strength of connecting elements

= 0.449 Kn/mm 2 Table 3, Ref[3]

Fexx = 70 ksi Minimum tensile strength of weld metal

= 0.483 Kn/mm 2

Fvb = 30 ksi Allowable stress for A325M bolts in shear Table I-D, Ref[1]

= 0.207 Kn/mm 2

Ftb = 44 ksi Allowable stress for A325M bolts in tension Table I-A, Ref[1]

= 0.304 Kn/mm2

Per AISC 9th Edition Manual (ASD) 121 OF 180

Conclusion : No Change in Approved Connection

2.5 DIMENSIONS (see Fig.-01)

dp (OD) = 800 mm Pipe diameter

(ID) 764

tp = 18 mm Pipe thickness

sxc = 338207 cm4 Sec. moment of inertia

= 3382070752 mm4

zxc = 8455 cm3 Sec. modulu

= 8455176.9 mm3

bp = 1060 mm Plate width Assumed as per bolt arrangement

ts1 20 mm

by = 130 mm See Fig.-1 Assumed as per bolt arrangement

tpl 40 mm Splice Plate thickness

θ1 (b-a) = 15 deg angle of bolts spacing

θ2 (stif-a) = 30 deg angle of stiffener spacing

2.6 BOLT & WELD DETAIL

db = 30 mm Nominal diameter of bolts

dh = 32 mm Hole diameter Max Expected

n = 24 Nos. No of bolts 30

ey = 70 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

ex = 60 mm Min edge distance 1.5db = 45 mm e> emin"ok,"check"

g = 920 mm See Fig.-01

p = 130 mm See Fig.-01 e> emin"ok,"check"

Ln = 120.43 mm See Fig.-01 90 mm e> Gmin"ok,"check"

w1 = 12 mm Assumed Size of weld between beam and end plate = 0.7 * tmin

w2 = 12 mm Assumed Size of weld between beam and stiffener plate = 0.7 * tmin

E = 200000 Pa Modulus of Elasticity of steel

Bolt Type = X (N, X, or SC) This program assumes the following bolt type:

N = Bearing bolt with threads included in shear plane

X = Bearing bolt with threads excluded from shear plane

SC = Slip-Critical bolt

END OF INPU T

Per AISC 9th Edition Manual (ASD) 122 OF 180

3.0 OUTPUTS

CALCULATIONS

3.1 CHECK BOLTS IN TENSION

bp = bf + 25 mm = 18 + 25 = 43 mm End plate width

Ff = (Mz / (hb-tf) - (Px /2) Flange force (tension)

= 710 x 1000 /( 1060 - 70 ) + 430 / 2 = 932.2 kn

n top = 8 Nos Bolt number in tension area

T = Ff / n top = 116.5 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

n = 24 Nos Bolt number in tension area

T = Px / n = 179.2 kn Bolt force

Ab = Pixdb^2 / 4 = 1.096 in2 Bolt area

Tallowable = Ftb x Ab = 44 x 1.096 = 48.2 kips Table I-A, Ref[1]

= 214.4 kn

Check : if (Tb < Tallowable ) "OK","Not OK" = OK

3.2 CHECK FOR BOLT IN SHEAR

Pcompined = Py = 624.0 kn

n sh = 24 Nos Bolt number in shear area