Beruflich Dokumente

Kultur Dokumente

Reboiler Circuit Debottleneck

Hochgeladen von

streamtCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reboiler Circuit Debottleneck

Hochgeladen von

streamtCopyright:

Verfügbare Formate

Cover Story

Reboiler Circuit

Debottleneck with No

Hardware Changes

With a thorough investigation and proper problem diagnosis, an entire gas plant limited by a

deethanizer reboiler circuit was successfully debottlenecked

T

Henry Kister his article de- 15'-6"

Fluor Corp. scribes a case

study of a

gas plant (de-

IN BRIEF signed by others) that

2'-6"

BACKGROUND was bottlenecked by 5'-9"

PROCESS DESCRIPTION the reboil system of a

deethanizer stripper.

INITIAL PERFORMANCE The reboiler system,

TROUBLESHOOTING which consisted of two

24"

parallel, once-through 20'-4" 24" 33'-3"

PRESSURE DROP

thermosiphon circuits,

LESSONS LEARNED had experienced two

CLOSING THOUGHTS different steady-state 28'-8"

10'-5"

18".

conditions. One con- 24"

dition had a good split 19'-0"

of liquid to each of the E-3A Tower E-3B

two circuits, as is nor- bottoms

mally expected. How- 24"

E-4A E-4B

ever, when operated

at relatively low rates, 18" 18"

a second, undesirable

steady state occurred, Ground level

with maldistribution be- FIGURE 1. Shown here are the deethanizer stripper A and B reboiler circits. The lower

tween the two circuits, reboiler in each circuit (E-4A or E-4B) is heated by hot naphtha, the upper reboiler (E-3A or

in which one circuit E-3B) is heated by high-pressure steam

was circulating while

the other remained full of liquid. This steady plant without any hardware modifications.

state persisted when tower feed rates were The desired steady state was established by

raised until the circulating reboiler reached an operation that, for a short period, gener-

its heat transfer limitation, still with the other ated higher liquid circulation and pressure

circuit full of liquid. drop through the reboiler circuits. Once es-

A variety of troubleshooting techniques — tablished, the desired steady state persisted

including pressure-drop calculations, close when the operation was returned to normal.

design reviews, examination of operating

charts, and gamma scans — led to a cor- Important lessons

rect diagnosis, which enabled debottleneck- A review of this detailed case teaches some

ing of the reboiler circuits and the entire gas very important lessons, discussed below:

30 CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017

• With a parallel reboiler system, mal- RR

distribution between parallel circuits CL

does occur and can cause severe Bottom tray downcomer

bottlenecks (To the best of our knowl- 1 rectangular notch on this side of the seal pan

edge, this is the first time that such 2 rectangualr notches on this side of the seal pan

maldistribution is reported in the lit- Bottom tray downcomer

erature). 2 rectangualr notches on this side of the seal pan

1 rectangular notch on this

• Pressure balances need to be consid- side of the seal pan

32" Min

ered at the design stage, not only for Bottom tray

downcomer 8"

the maximum design rates, but also Section E-E

for the minimum expected operation RR

Bottom of

seal pan Downcomer

rates

• It is important to provide flexibility in CL CL

once-through reboiler systems that E E

will permit operation as a circulating

3'-0" 2'-3" 2'-6"

3"-0' 2'-3" 2'-6"

thermosiphon system, at least at low

rates

• Good troubleshooting can provide RR RR Bottom-tray RR RR

90"

low-cost (in this case, no-cost) debot- 13" Baffle

seal pan

4’-6”

tlenecking of an entire gas plant

6'-8"

20'-4"

20'-4"

Baffle

Process description

Min

This newly built gas plant was bottle-

necked by its deethanizer stripper. The 24"

18"

tower bottleneck appeared in the re- Tower bottoms Vortex breaker

To rebuilders

Vortex breakers

boiler circuit. In early April 2014, the au-

thor’s company (which had no involve- ment by notched-bottom seal pans. FIGURE 2. As part of the deethanizer

ment in the tower or reboiler design, but As shown in Figure 2, the 8-in.-deep stripper tower base geometry, a preferen-

tial baffle divides the tower bottom into a

has extensive experience in distillation notches in the seal pans are located reboiler draw sump and a bottom product

design and troubleshooting), was re- right above the reboiler-draw compart- draw sump. All of the liquid from the trays

quested to assist with investigating the ment. There are no notches above the is directed into the reboiler draw sump via

a notch arrangement, while all the liquid

root cause of the bottleneck and to find bottom-draw compartment. The pur- returning from the reboilers is directed

ways to overcome it. pose is to feed all the bottom-tray liquid toward the bottom product draw sump via

A task force, including process and to the reboilers. cutouts in the reboiler return pipes

operation engineers from the operating The vapor-liquid mixture returning

company and Fluor’s distillation spe- from the thermosiphon reboilers enters

cialists, was created. The joint team above the bottoms-draw compartment

identified the root cause. Based on the via two opposite 24-in. nozzles. Each

root cause, a solution was successfully nozzle is equipped with a pipe that ex-

implemented. After this the deethanizer tends to close to the centerline of the

stripper and gas plant were returned tower and has a cutout that measures

to full operation, achieving the design 4 ft, 6 in. in the bottom quadrant. Both

rates. Described below is the trouble- cutouts are directed toward the bot-

shooting investigation that was carried toms-draw sump (Figures 1 and 2).

out, and the lessons learned. The purpose is to have all the reboiler-

The deethanizer stripper is a tower that return liquid enter the bottoms-draw

is 15 ft, 6 in. in diameter. It is equipped compartment, and to have none enter

with four-pass conventional valve trays the reboiler-draw compartment. The

with moving round valves. The tower vapor returning from the reboilers as-

base contains a preferential baffle that cends to the bottom tray, while the liquid

divides the bottom sump into a separate returning from the reboilers descends to

reboiler-draw compartment and a sepa- the bottoms-draw compartment.

rate bottoms-draw compartment. Liquid This design generates a once-through

leaving the bottom valve tray is diverted [1] thermosiphon reboiler system. Such

to the reboiler-draw compartment (Fig- a system intends to capture all of the

ure 1). From there it flows into a battery liquid leaving the bottom tray and feed

of four horizontal thermosiphon reboil- it directly to the reboiler. The reboiler-re-

ers. The liquid from the bottom tray is turn liquid is entirely drawn as bottoms

diverted to the reboiler-draw compart- product. None of the reboiler-return liq-

CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017 31

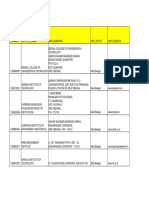

Operation __ (Design __)

Initial performance

Feed rate, bbl/h 2,100 (4,100) During the startup, the plant was at low

87°F (105°F) rates and to improve tower stability, it

was decided to take the steam out of re-

boiler E-3A. This was successful at cre-

ating a steady steam flow through the

E-3B reboiler circuit and provided tower

stability, but the plant has been unable

to re-establish flow through the E-3A/E-

4A set of reboilers ever since. For the

next six months or so, the E-3B/E-4B

368°F

(342°F) circuit did all the reboiling, while the

deethanizer-bottoms liquid circulation

had been difficult to establish through

79,000 lb/h

0 lb/h

(52,000 lb/h) (52,000 lb/h) the E-4A/E-3A circuit.

Figure 3 shows typical operating data

E-3A 308°F 249°F E-3B

(323°F) (272°F) 411°F from six months after start up and com-

411°F

(417°F)

(417°F) pares them to the design values. The

1,300 bbl/h

E-4A Bottoms E-4B (1,800 bbl/h) zero-steam flowrate through E-3A and

1,250 bbl/h

407°F (3600 bbl/h) 260°F

the absence of significant tempera-

(306°F) (306°F) ture difference across the heating side

Ground level

of E-4A indicate no boiling and no sig-

nificant circulation through the A circuit.

FIGURE 3. This figure shows the deetha- uid is recycled back to the reboiler — To maximize duty, steam to E-3B was

nizer stripper base, operation versus hence the name “once-through.” raised to the maximum, well above the

design. The zero-steam flowrate through

E-3A and the absence of significant tem-

Once-through systems can achieve design steam rate for this exchanger,

perature difference across the heating one full theoretical stage of separation, but still not high enough to make up

side of E-4A indicate no boiling and no if the trapout tray and draw pan do not the lost duty of E-3A. This restricted

significant circulation through the A circuit leak [1]. With the cold bottom-tray liq- the feed flowrate through the tower and

uid being fed to the reboiler, it can also bottlenecked the entire gas plant. There

maximize the reboiler temperature dif- was a need to get the stripper-bot-

ference and capacity. Reboil vapor is toms liquid to start flowing through the

limited to about 40% of the bottoms- E-4A/E-3A circuit.

product rate, due to the normal limi-

tation of 30% maximum vaporization Troubleshooting

(by weight) in thermosiphon reboilers Initial troubleshooting efforts focused on

[1]. This makes once-through ther- initiating flow through the A circuit by

mosiphon systems appropriate only inducing a gas lift. One possibility was

for low-boilup systems, such as strip- that the light components were stripped

pers. Many deethanizer-strippers use out of the A-circuit reboilers, leaving be-

once-through thermosiphon-reboiler hind heavy hydrocarbon liquid. Heating

systems. this heavy liquid may not have produced

This deethanizer stripper has four hor- enough vapor to initiate reboiler action.

izontal reboilers, arranged in two parallel Injecting a light gas, such as nitrogen,

circuits, A and B (Figure 1). In each cir- could possibly gas-lift the heavy liquid

cuit, the lower reboiler (E-4A or E-4B) is and initiate thermosiphon circulation.

heated by hot naphtha liquid, while the This technique has been successful in

upper reboiler (E-3A or E-3B) is heated the past for initiating circulation in liquid-

by high-pressure steam. In each circuit, full thermosiphon reboilers [2–4].

the naphtha and steam reboilers are A source of nitrogen was connected

designed to provide duties of 32 million to a bleeder valve immediately down-

Btu/h and 40 million Btu/h, respectively. stream of E-3A. Nitrogen was injected

On the boiling side, liquid to the re- for 4–6 hours in an attempt to provide

boilers is provided from the reboiler- lift and jump-start the thermosiphon

draw sump, via a 24-in. pipe that splits effect. This action was unsuccess-

into two 18-in. pipes, each going to ful in initiating circulation through the

one circuit. The reboiler effluent from A circuit.

each circuit returns to the tower via a This came as a surprise, as in other

24-in. line. reboilers [2–4], a similar action had been

32 CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017

successful. There were questions as to °F Flowrate, Flowrate

bbl/h lb/h

whether enough nitrogen was applied, 2,200 50,000

whether it was applied at the correct 400 Naphtha to reboilers, °F

point, and whether the liquid in the re- 2,000

40,000

boilers was just too heavy and needed Naphtha from E-4A, °F

to be drained and replaced by fresh 350 1,800 30,000

liquid before the gas lift attempt. Ad- Steam to E-3B, lb/h

Naphtha from E-4B, °F

dressing these problems would have 1,600

20,000

required some painful modifications or Steam to E-3A,

lb/h

operations with no assurance of suc- 300 1,400

10,000

cess. The validity of the theory — that

heavy liquids in the A-circuit are the root 1,200

Stripper feed rate, bbl/h

0

cause — was questioned. With these 250 Time 22:00 22:30 23:00 23:30 00:30 01:00

considerations in mind, the investigation 21:30 Day 1 00:00 Day 2

team decided to perform more trouble- Time, h

shooting before trying out a fix. the E-4A and B reboilers, the tem- FIGURE 4. Shown here are the process

One useful reference point was peratures of naphtha entering and data for the very initial operation of the

process data from the very initial op- leaving were about 400°F and 320°F, stripper-reboiler circuits. Before 23:00

hours, both circuits operated simultane-

eration of the stripper. The operating respectively. At time 22:40 hours, the ously and stably with the same steam

charts from shortly after initial start stripper feedrate plunged, steadying flows and naphtha temperature differ-

up (Figure 4), at a stripper feedrate of at about 1,200 bbl/h 40 minutes later. ences for each circuit. After 0:00 hour, the

steam rate to E-3A dropped and the tem-

about 1,700 barrel per hour (bbl/h), To improve stability, the plant manu- peratures of naphtha entering and leaving

show both the A and B circuits op- ally reduced the steam flowrate to E-3A, E-4A became the same, suggesting boiling

erating simultaneously and stably. to about 8,000 lb/h, with the steam rate and circulation in the circuit had stopped

Both E-3A and E-3B reboilers oper- to E-3B remaining at its previous value.

ated stably

CIC-10307 with

halfp a steam

page ad.qxd flowrate

3/25/07of 6:19

ThePMnaphtha Page 1temperatures into and out

about 32,000 lb/h to each. For both of E-4A became the same, about 360°F,

PLASTIC CONTROL VALVES FOR

ALL YOUR CORROSIVE APPLICATIONS

Collins plastic control valves are

highly responsive control valves

designed for use with corrosive

media and/or corrosive atmos-

pheres.

Collins valves feature all-plastic

construction with bodies in PVDF,

PP, PVC and Halar in various body

styles from 1/2" - 2" with Globe,

Angle or Corner configurations and

many trim sizes and materials.

Valves may be furnished without

positioner for ON-OFF applications.

Call for more information on our

plastic control valves.

P.O. Box 938 • Angleton, TX 77516

Tel. (979) 849-8266 • www.collinsinst.com

Circle 07 on p. 62 or go to adlinks.chemengonline.com/66431-07

CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017 33

suggesting it had stopped heating. Once the latter steady state forms,

At the same time the temperature out- the steam that is still going in (the 8,000

let from E-4B decreased to about 260°F, lb/h going to E-3A after midnight on the

suggesting that this reboiler was working second day, as shown in Figure 4) , will

harder than before. Both of these occur- strip the lights out of the near-stagnant

rences suggest that the A-circuit stopped liquid. Before long, heavy liquid will form

circulating. Early on the next day, the fee- in this circuit, and this liquid will be dif-

drate to the stripper rose again, to 1,500 ficult to boil. This situation will stabilize

bpl/h, but this time the A circuit remained this steady state and it will persist.

inactive. It was common practice to at- The proposed theory states that the

tempt to restart circulation by opening liquid level in the reboiler compart-

and closing the steam valve on the stalled ment would be very low, possibly ab-

set, but circulation remained stalled. sent, and will not approach the over-

This sequence of events suggests flow baffle. This can be easily tested

the possibility of the existence of two using gamma scans. The tower base

hydraulic steady states, with an easy was gamma scanned, both on the bot-

switchover from one to the other. This tom compartment side and on the re-

is likely to take place when the reboiler boiler compartments side. In addition,

pressure drop on the boiling side is low. neutron-backscatter scans were per-

formed to confirm or deny the gamma

Pressure drop scan results.

Calculations performed during the de- The gamma and neutron scans

sign by the engineering contractor that showed the following:

designed the circuits showed a total • Nothing abnormal showed up on the

pressure drop of 1 psi for the exchang- inner active area scans for the bot-

ers in each circuit at design conditions. tom six trays. Other trays were not

The contractor’s calculated pressure- scanned

drop values were 0.4 psi and 1.3 psi • Both the gamma and neutron scans

for the reboiler-liquid inlet line and the showed that the liquid level in the bot-

reboiler-return lines, respectively. The toms-draw compartment was 10–12

total pressure drop is equivalent to 11 ft ft above the tangent line. This was

of liquid head. the same as the level indicated by the

Figure 1 shows the elevations of the level instrument

reboiler circuits. The diagram shows • Both gamma and neutron scans had

that not much liquid head is required to difficulty finding a liquid level on the

overcome the pressure drop in the re- reboiler-draw compartment. There

boiler circuit. The liquid level in the re- definitely was no liquid level above

boiler draw compartment will therefore the bottom tangent line. The gamma

be near the bottom of the compartment, scans showed some absorption at

even at the design rates. the tangent line, about the same ab-

At the low rates, the pressure drop sorption as the froth on the trays, but

will be lower still, and the liquid level will this could have been due to the welds

drop further, possibly dropping out of at the tangent line. The neutron scans

the reboiler-draw compartment into the showed no liquid at all in the reboiler-

reboiler-liquid-inlet pipe. Further, at low draw compartment

boilup rates the bottom tray may weep, The absence of liquid level in the reboiler-

sending liquid directly into the bottom draw compartment gave strong support

draw compartment, and causing the liq- to the “two steady-states” theory.

uid level to be lower still.

At a low liquid head, fluids tend to Solution

form their favorite flow patterns. Two With the theory verified, the challenge

steady states can form: was now shifting from the steady state

• One with operation of the two reboil- with the stagnant A reboilers, back to

ers simultaneously, as intended that of the two reboiler circuits operating

• The other has all the boiling taking simultaneously.

place in one circuit, and the other In a circulating thermosiphon reboiler

circuit filling with liquid to the same (as distinct from a once-through thermo-

height as the liquid in the reboiler liq- siphon, such as the stripper reboilers),

uid inlet pipe increasing the liquid head in the tower

34 CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017

base generates more liquid circulation The plan was to raise the liquid level

through the reboiler circuit and reduces in the bottoms-draw compartment to

the fractional vaporization [4]. Consider- the level of the reboiler return, an in-

ing the pressure balance and assuming crease in height of about 20 ft. When

a constant heat duty, the higher liquid the level was first raised, it was con-

head supplied to the reboiler is matched trolled using the differential-pressure

by the additional friction head due to the transmitter. Subsequently, a pair of

enhanced liquid circulation rate plus the electronic pressure gages was added

additional static head due to a higher to the reboiler side of the column to

amount of liquid in the reboiler shell and monitor the level directly, and an ad-

outlet line. ditional gage was added to the prod-

Extending this reasoning to the

stripper reboilers, generating liquid

circulation and increasing the liquid

head in the reboiler-draw compart-

ment will raise the pressure drop

through the active reboiler circuit. INNOVATION

This higher pressure drop will induce

some of the liquid to follow the eas-

ier path (that is, the path with less

pressure drop) through the inactive

reboiler. Once this liquid is heated,

it will start boiling, and the thermosi-

phon will be established in the previ-

ously inactive circuit.

One way to generate circulation

and increase the level in the reboiler-

draw compartment is to raise the

level in the bottom-draw compart-

ment until it overflows the baffle, and

keep the bottom-draw compart-

ment full during the circulation. The

risk is that the liquid level may as-

cend to the trays and cause flooding

High performance

SUPERFRAC®

and possible damage there. It is im-

portant to avoid excessive buildup

of liquid up the tower.

In principle, the level transmitter trays for challenging separations

can be watched during the operation

to avoid excessive liquid level. This

Delivering exceptional capacity AND efficiency for over 25 years.

was difficult in this deethanizer strip-

per. Since the reboiler-return pipe is SUPERFRAC® trays are especially beneficial in applications requiring a large

only 2 feet above the baffle (Figure number of theoretical stages or where mass transfer efficiency is critical:

2), and the vapor from the reboiler

• Increased capacity AND efficiency when revamping conventional trays

return blows downward, causing a

or minimized tower dimensions for new plants

frothy dispersion, the frothiness may

reduce the specific gravity and lead • Complete access for maintenance inspections without needing to

to an optimistically low level mea- remove trays

surement. Also, the high tap of the

level transmitter is just less than 2

YOU CAN RELY ON US.

feet above the baffle, which may ™

make it difficult to see when the level

rises toward the trays. Fortunately,

there is a differential-pressure trans- United States (316) 828-5110 | Canada (905) 852-3381 | Italy +39-039-6386010 | Singapore +65-6831-6500

For a complete list of our offices, visit our Web site.

mitter across the stripper that comes www.koch-glitsch.com

from the upper tap of the level trans- For related trademark information, visit http://www.koch-glitsch.com/trademarks.

mitter and therefore can monitor This technology is protected by one or more patents in the USA. Other foreign patents may be relevant.

any accumulation of liquid above

the upper tap. Circle 11 on p. 62 or go to adlinks.chemengonline.com/66431-11

CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017 35

uct outlet line to monitor the level on bypasses the reboiler side of the baffle.

the bottoms-draw side of the baffle. In The bottom tray is an active tray. It re-

order to avoid damage due to entrain- mains unclear whether the tray weeps

ment of liquid through the trays the dif- enough liquid to cause the problem, or

ferential pressure across the bottom whether some of the liquid directed to

trays was closely monitored. the reboiler-draw side of the baffle falls

To raise the level on the reboiler side of into the bottoms-draw side of the tower

the baffle, the bottoms-draw side liquid base. To fix this in the future, the bottom

was overflowed to the reboiler side, by tray will be replaced with a total trapout

reducing the bottom-product flowrate. tray to ensure all bottoms liquid must

The level rose until it reached the top of pass through the reboilers.

the baffle when it "flat lined" as it over- Until the plant gets to an opportunity

flowed. to install the chimney tray, the reboiler

After one hour of overflowing the continues to stall periodically, so raising

baffle, the level had increased on the re- the liquid level has become a standard

boiler side by 13 ft. At that time, the fol- procedure that has been executed sev-

lowing two process indications provided eral times since by the operations team,

evidence that the A side reboilers were to regain lost reboiler circulation.

starting to circulate liquid:

1. A rapid decrease in steam consumed Lessons learned

by the 3B reboiler suggested a de- The investigation described here high-

crease in liquid flow to the B side re- lights the importance of good trouble-

boilers; and shooting and problem diagnosis for

2. A rapid decrease in 4A hot-side overcoming bottlenecks. In our case,

outlet temperature suggested an in- pressure-drop calculations, close de-

crease in duty in the 4A reboiler sign reviews, detailed examination

At low pressure drops, parallel once-through thermosiphon circuits may switch from

their intended steady-state with even split between the circuits to an unintended steady-

state with uneven split between the circuits. Reduced heat transfer and/or instability

may result.

Steam was quickly opened to 3A to of operating charts, and conducting

ensure we maintained A side reboiler cir- gamma scans led to the correct diag-

culation. Almost immediately, even split nosis, which enabled debottlenecking

and duties were confirmed between the an entire gas plant with no hardware

A and B side reboilers. The bottoms- modifications.

outlet flow was increased to stop over- Maldistribution between parallel re-

flowing the baffle, and the bottoms level boiler circuits has received little atten-

was returned to normal. tion in the literature, with no published

The 13-ft level increase was probably case studies identified by Kister’s survey

not enough to get the level of weathered [2]. To the best of our knowledge, this

liquid (the liquid that was sitting in the A is the first time this type of experience

reboiler circuit for a lengthy period) up to has been reported. This maldistribution

the reboiler-return nozzle on the tower. is especially severe at low rates, when

But the fresh liquid that had entered the the pressure drops in the reboiler cir-

reboiler as the level was being raised cuits are low. Due to the low pressure

provided enough vaporization to gas-lift drop, the fluids find their favorite path-

the weathered naphtha into the tower ways and steady states, and can easily

and start the circulation. swing from one steady state to another

The column remains prone to losing — promoting instability. With parallel

reboiler duty. This is believed to be be- reboiler circuits, careful analysis of the

cause a portion of the bottom-tray liquid pressure balance both at the normal-

36 CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017

and reduced-rate operation is impor- References

tant, and should be performed at the 1. Fractionation Research Inc., Design Practices Committee,

Reboiler Circuits for Tray Columns, Chem. Eng., January

design stage. This case demonstrates 2011, p. 26.

that increasing the pressure drop in 2. Kister, H.Z., “Distillation Troubleshooting,” Wiley-Inter-

these circuits can help route the fluids to science, 2006.

3. Kister, H.Z., T.C. Hower, Jr., P.R. de M. Freitas, and J.

the preferred pathways and counter this Nery, “Problems and Solutions in Demethanizers with

maldistribution. Interreboilers,” Proc. 8th Ethylene Producers Conf,. New

Orleans, La., 1996.

Baffled systems have their benefits 4. Kister, H.Z., “Distillation Operation,” McGraw-Hill, N.Y.,

[1], but can also generate or amplify 1990.

hydraulic problems; thus they need to

be designed carefully. In the case of the Author

deethanizer stripper, the baffle was far Henry Z. Kister is a senior fellow and

taller than it needed to be. Had it been director of fractionation technology at

Fluor Corp. (3 Polaris Way, Aliso Viejo,

even a couple of feet shorter, it would CA 92625; Phone +1-949-349-4679;

have been easy to raise the liquid level in Email: henry.kister@fluor.com). He has

the bottoms compartment above it and over 30 years experience in design,

troubleshooting, revamping, field con-

achieve better operational flexibility. sulting, control and startup of fraction-

It is important to provide flexibility ation processes and equipment. He is

the author of three books, the distilla-

when designing once-through thermo- tion equipment chapter in Perry’s Handbook, and more than

siphon circuits. As pointed out [1,2,4] 100 articles, and has taught the IChemE-sponsored

they can be quite troublesome, and “Practical Distillation Technology” course more than 450

times. A recipient of several awards, Kister obtained his B.E.

adding simple features that can convert and M.E. degrees from the University of New South Wales in

them temporarily to circulating thermosi- Australia. He is a Fellow of IChemE and AIChE, member of the

phon circuits can go a long way toward National Academy of Engineering (NAE), and serves on the

FRI Technical Advisory and Design Practices Committees.

easing startups and avoiding process

bottlenecks. n

Edited by Suzanne Shelley

TURNKEY FRACTIONAL DISTILLATION SYSTEMS

BATCH AND CONTINUOUS MODES

FOR OPTIMIZED PROCESSING,

FRACTIONAL DISTILLATION SYSTEMS

FROM POPE SCIENTIFIC OFFER THE WIDEST

RANGE OF CHOICES AND CAPABILITY:

• LAB, PILOT OR PRODUCTION SIZES, 0.1-1000 KG/HR

• STAINLESS STEEL, HASTELLOY, GLASS, OTHER MATERIALS

• RANDOM, STRUCTURED, OTHER PACKING & INTERNALS

• MODULAR COLUMNS, 1” – 24” DIAMETER

• AMBIENT, VACUUM OR PRESSURE CAPABILITY

• OPERATION VIA PLC/COMPUTER PACKAGES OR BASIC CONTROLS

1

• TURNKEY SYSTEMS OR INDIVIDUAL KEY COMPONENTS OFFERED

2 • EXPLOSION PROOF, ASME, CE, OTHER RATINGS AVAILABLE

3

x=y line

4

These proven systems are designed for critical

applications including high purity specialty chemicals

5

Feed composition

Bottoms

composition

and solvents, pharmaceutical intermediates, flavors,

fragrances, foods, oils, bio-based materials, and more.

POPE’S DISTILLATION EXPERTISE - SEPARATING OUR

CLIENTS FROM THEIR COMPETITION FOR OVER 50 YEARS!

www.popeinc.com

Batch Mode System Continuous Mode System

1-262-268-9300

CHEMICAL ENGINEERING WWW.CHEMENGONLINE.COM AUGUST 2017 37

Circle 16 on p. 62 or go to adlinks.chemengonline.com/66431-16

Das könnte Ihnen auch gefallen

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentVon EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNoch keine Bewertungen

- Two Reboiler Simultaneously RunDokument16 SeitenTwo Reboiler Simultaneously RunteddyNoch keine Bewertungen

- Natural Gas Processing from Midstream to DownstreamVon EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNoch keine Bewertungen

- Thermosiphon ReboilersDokument7 SeitenThermosiphon Reboilerssj_scribd100% (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersVon EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Jan11 GSO PDFDokument10 SeitenJan11 GSO PDFChakravarthy BharathNoch keine Bewertungen

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationVon EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNoch keine Bewertungen

- Multipass Tray DesignDokument12 SeitenMultipass Tray DesignAyoun Ul HaqueNoch keine Bewertungen

- MC Kee - Thermosiphon Reboileres A ReviewDokument7 SeitenMC Kee - Thermosiphon Reboileres A Reviewbltzkrig100% (1)

- CEeNews2 04 PDFDokument6 SeitenCEeNews2 04 PDFJohn AnthoniNoch keine Bewertungen

- Design Practices-ReboilerDokument7 SeitenDesign Practices-Reboileragarwalashwin32100% (1)

- Advanced Distillation Technologies: Design, Control and ApplicationsVon EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNoch keine Bewertungen

- Demethanizer OperationDokument6 SeitenDemethanizer OperationHoustonAbducteeNoch keine Bewertungen

- Distillation Design and Control Using Aspen SimulationVon EverandDistillation Design and Control Using Aspen SimulationBewertung: 5 von 5 Sternen5/5 (2)

- Reboiler DesignDokument12 SeitenReboiler DesignSuwat Kamolpanus100% (2)

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Thermosiphon OperationDokument63 SeitenThermosiphon OperationRajesh100% (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Von EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Noch keine Bewertungen

- Tray Sizing Presentation PDFDokument105 SeitenTray Sizing Presentation PDFLuis Enrique Leyva OvalleNoch keine Bewertungen

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsVon EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsBewertung: 2 von 5 Sternen2/5 (1)

- Distillation Column Troubleshooting Part IIDokument8 SeitenDistillation Column Troubleshooting Part IINishat M PatilNoch keine Bewertungen

- Caustic Scrubber Designs For Refinery Gases Compl PDFDokument27 SeitenCaustic Scrubber Designs For Refinery Gases Compl PDFSardeniantoNoch keine Bewertungen

- Select The Right ReboilerDokument2 SeitenSelect The Right ReboilerSteven A McMurray100% (2)

- Vertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyDokument9 SeitenVertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyPuskar GuptaNoch keine Bewertungen

- CEcover904 p2Dokument4 SeitenCEcover904 p2Antonio MezzopreteNoch keine Bewertungen

- Stripping Notes PDFDokument28 SeitenStripping Notes PDFnimi khalidNoch keine Bewertungen

- How To Design Overhead Condensing SystemsDokument7 SeitenHow To Design Overhead Condensing Systemsstudyendless100% (1)

- IFP Materials PDFDokument20 SeitenIFP Materials PDFProcess EngineerNoch keine Bewertungen

- Seleccion de EbullidoresDokument5 SeitenSeleccion de EbullidoresDaniela Jurado100% (2)

- Column-Base and Arrangements: ReboilerDokument27 SeitenColumn-Base and Arrangements: ReboilerPacyfik Kameron100% (1)

- Debottlenecking A Distillation ColumnDokument12 SeitenDebottlenecking A Distillation Columnrasik.kirane100% (1)

- Good Practices in Tray DesignDokument7 SeitenGood Practices in Tray Designmehul10941100% (2)

- Sloley - Properly Design Thermosyphon ReboilersDokument14 SeitenSloley - Properly Design Thermosyphon Reboilersbltzkrig100% (4)

- Thermosiphon ReboilerDokument6 SeitenThermosiphon Reboilerme12m11350% (2)

- Applying Relief Load Calculation MethodsDokument9 SeitenApplying Relief Load Calculation MethodsKamil Marszałek100% (1)

- Thermosiphon ReboilersDokument3 SeitenThermosiphon ReboilersMuhammadNoch keine Bewertungen

- Kettle ChoiceDokument5 SeitenKettle ChoiceHow Jie WeiNoch keine Bewertungen

- Efficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer ChemtechDokument31 SeitenEfficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer Chemtechmisscolgate100% (1)

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDokument10 SeitenEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyNoch keine Bewertungen

- Reboilers SelectionDokument4 SeitenReboilers SelectionPramod Dixit100% (1)

- Horizontal Shell-Side Thermosyphon Reboilers PDFDokument7 SeitenHorizontal Shell-Side Thermosyphon Reboilers PDFagnotts2009100% (3)

- Specifying Shell and Tube Heat ExchangersDokument10 SeitenSpecifying Shell and Tube Heat ExchangersMicheal BrooksNoch keine Bewertungen

- The Design and Layout of Vertical Thermosyphon ReboilersDokument39 SeitenThe Design and Layout of Vertical Thermosyphon Reboilersjdgh1986Noch keine Bewertungen

- Heat-Exchanger Bypass Control: William L. LuybenDokument9 SeitenHeat-Exchanger Bypass Control: William L. LuybenHens Christian FuentesNoch keine Bewertungen

- Reboiler Case StudyDokument6 SeitenReboiler Case StudyamlhrdsNoch keine Bewertungen

- Trol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsDokument14 SeitenTrol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsRimeli RoychoudhuryNoch keine Bewertungen

- Shortcut Methodsofdistillation Design PDFDokument15 SeitenShortcut Methodsofdistillation Design PDFAle SanzNoch keine Bewertungen

- FRI Internal Design Vol4Dokument55 SeitenFRI Internal Design Vol4syamsudin2006Noch keine Bewertungen

- OGJ Hot Vapor Bypass DesignDokument6 SeitenOGJ Hot Vapor Bypass DesignJesse Haney III100% (2)

- Design of ReboilersDokument24 SeitenDesign of ReboilersKrishanu SahaNoch keine Bewertungen

- 01) Pressure Vessels and Piping-NewDokument242 Seiten01) Pressure Vessels and Piping-NewHaytham Mohamed0% (1)

- Steam Condensate Drainage OptionsDokument6 SeitenSteam Condensate Drainage Optionssatishchemeng100% (2)

- Reboiler HydraulicDokument3 SeitenReboiler Hydraulic54yreyeNoch keine Bewertungen

- 10 - Distillation Revamp Pitfalls To AvoidDokument8 Seiten10 - Distillation Revamp Pitfalls To AvoidRenato GilbonioNoch keine Bewertungen

- DistillationDokument7 SeitenDistillationAbdus Saboor KhalidNoch keine Bewertungen

- Design and Control of Condensate-Throttling ReboilersDokument12 SeitenDesign and Control of Condensate-Throttling ReboilerscymyNoch keine Bewertungen

- How To Design Piping For Reboiling SystemsDokument7 SeitenHow To Design Piping For Reboiling SystemsSalim YilmazNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-28Dokument62 SeitenGhaisas Eknathi Bhagwat Ch-28streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-30Dokument38 SeitenGhaisas Eknathi Bhagwat Ch-30streamtNoch keine Bewertungen

- All About History Book of Ancient GreeceDokument164 SeitenAll About History Book of Ancient Greecestreamt0% (1)

- All About History Book of The Ottoman EmpireDokument132 SeitenAll About History Book of The Ottoman Empirestreamt100% (3)

- Ghaisas Eknathi Bhagwat Ch-25Dokument39 SeitenGhaisas Eknathi Bhagwat Ch-25streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-24Dokument48 SeitenGhaisas Eknathi Bhagwat Ch-24streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-31Dokument47 SeitenGhaisas Eknathi Bhagwat Ch-31streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-27Dokument41 SeitenGhaisas Eknathi Bhagwat Ch-27streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-29Dokument85 SeitenGhaisas Eknathi Bhagwat Ch-29streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-23Dokument83 SeitenGhaisas Eknathi Bhagwat Ch-23streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-17Dokument48 SeitenGhaisas Eknathi Bhagwat Ch-17streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-11Dokument123 SeitenGhaisas Eknathi Bhagwat Ch-11streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-16Dokument32 SeitenGhaisas Eknathi Bhagwat Ch-16streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-15Dokument24 SeitenGhaisas Eknathi Bhagwat Ch-15streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-13Dokument64 SeitenGhaisas Eknathi Bhagwat Ch-13streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-18Dokument38 SeitenGhaisas Eknathi Bhagwat Ch-18streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-14Dokument48 SeitenGhaisas Eknathi Bhagwat Ch-14streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-10Dokument63 SeitenGhaisas Eknathi Bhagwat Ch-10streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat Ch-12Dokument49 SeitenGhaisas Eknathi Bhagwat Ch-12streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat-Ch5Dokument52 SeitenGhaisas Eknathi Bhagwat-Ch5streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat-Ch1Dokument61 SeitenGhaisas Eknathi Bhagwat-Ch1streamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat-Ch3Dokument75 SeitenGhaisas Eknathi Bhagwat-Ch3streamtNoch keine Bewertungen

- Bhakti Sutras of Narada and Sandilya SutramDokument156 SeitenBhakti Sutras of Narada and Sandilya SutramstreamtNoch keine Bewertungen

- Ghaisas Eknathi Bhagwat-Ch2Dokument70 SeitenGhaisas Eknathi Bhagwat-Ch2streamtNoch keine Bewertungen

- Lakhmir Singh Physics Class 10 Solutions Chapter 1 ElectricityDokument40 SeitenLakhmir Singh Physics Class 10 Solutions Chapter 1 ElectricitystreamtNoch keine Bewertungen

- CBSE Class 10 Chemistry Worksheet - Metals and Non-Metals PDFDokument2 SeitenCBSE Class 10 Chemistry Worksheet - Metals and Non-Metals PDFstreamtNoch keine Bewertungen

- LP For EarthquakeDokument6 SeitenLP For Earthquakejelena jorgeoNoch keine Bewertungen

- Drive LinesDokument30 SeitenDrive LinesRITESH ROHILLANoch keine Bewertungen

- Hidrl1 PDFDokument7 SeitenHidrl1 PDFRajesh Kumar100% (1)

- Clark SM 616 Service ManualDokument20 SeitenClark SM 616 Service Manualenid100% (55)

- Performance Task 1Dokument3 SeitenPerformance Task 1Jellie May RomeroNoch keine Bewertungen

- WBDokument59 SeitenWBsahil.singhNoch keine Bewertungen

- ECE Companies ListDokument9 SeitenECE Companies ListPolaiah Geriki100% (1)

- B I o G R A P H yDokument17 SeitenB I o G R A P H yRizqia FitriNoch keine Bewertungen

- KsDokument5 SeitenKsnurlatifahNoch keine Bewertungen

- Government College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniqueDokument11 SeitenGovernment College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniquepriyankaNoch keine Bewertungen

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionDokument10 SeitenMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyNoch keine Bewertungen

- ML Ass 2Dokument6 SeitenML Ass 2Santhosh Kumar PNoch keine Bewertungen

- Thesis PaperDokument53 SeitenThesis PaperAnonymous AOOrehGZAS100% (1)

- Hướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangDokument4 SeitenHướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangHưng Quân VõNoch keine Bewertungen

- 1 - 2020-CAP Surveys CatalogDokument356 Seiten1 - 2020-CAP Surveys CatalogCristiane AokiNoch keine Bewertungen

- CL57T V4.0Dokument14 SeitenCL57T V4.0dimitriNoch keine Bewertungen

- Cisco BGP ASPATH FilterDokument115 SeitenCisco BGP ASPATH FilterHalison SantosNoch keine Bewertungen

- Implementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorDokument11 SeitenImplementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorChristie YohanaNoch keine Bewertungen

- Mechanical Production Engineer Samphhhhhle ResumeDokument2 SeitenMechanical Production Engineer Samphhhhhle ResumeAnirban MazumdarNoch keine Bewertungen

- Sources of Hindu LawDokument9 SeitenSources of Hindu LawKrishnaKousikiNoch keine Bewertungen

- 40 People vs. Rafanan, Jr.Dokument10 Seiten40 People vs. Rafanan, Jr.Simeon TutaanNoch keine Bewertungen

- DeliciousDoughnuts Eguide PDFDokument35 SeitenDeliciousDoughnuts Eguide PDFSofi Cherny83% (6)

- The Covenant Taken From The Sons of Adam Is The FitrahDokument10 SeitenThe Covenant Taken From The Sons of Adam Is The FitrahTyler FranklinNoch keine Bewertungen

- Kyle Pape - Between Queer Theory and Native Studies, A Potential For CollaborationDokument16 SeitenKyle Pape - Between Queer Theory and Native Studies, A Potential For CollaborationRafael Alarcón Vidal100% (1)

- Activity On Noli Me TangereDokument5 SeitenActivity On Noli Me TangereKKKNoch keine Bewertungen

- Lieh TzuDokument203 SeitenLieh TzuBrent Cullen100% (2)

- Fast Track Design and Construction of Bridges in IndiaDokument10 SeitenFast Track Design and Construction of Bridges in IndiaSa ReddiNoch keine Bewertungen

- Leadership Styles-Mckinsey EdDokument14 SeitenLeadership Styles-Mckinsey EdcrimsengreenNoch keine Bewertungen

- Wner'S Anual: Led TVDokument32 SeitenWner'S Anual: Led TVErmand WindNoch keine Bewertungen

- EPAS 11 - Q1 - W1 - Mod1Dokument45 SeitenEPAS 11 - Q1 - W1 - Mod1Alberto A. FugenNoch keine Bewertungen

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesVon EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesBewertung: 4 von 5 Sternen4/5 (2)

- Advanced Production Decline Analysis and ApplicationVon EverandAdvanced Production Decline Analysis and ApplicationBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Well Integrity for Workovers and RecompletionsVon EverandWell Integrity for Workovers and RecompletionsBewertung: 5 von 5 Sternen5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsVon EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNoch keine Bewertungen

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingVon EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNoch keine Bewertungen

- Abrasive Water Jet Perforation and Multi-Stage FracturingVon EverandAbrasive Water Jet Perforation and Multi-Stage FracturingNoch keine Bewertungen

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesVon EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNoch keine Bewertungen

- Casing and Liners for Drilling and Completion: Design and ApplicationVon EverandCasing and Liners for Drilling and Completion: Design and ApplicationBewertung: 5 von 5 Sternen5/5 (3)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsVon EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNoch keine Bewertungen

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsVon EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsBewertung: 4 von 5 Sternen4/5 (4)

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityVon EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityBewertung: 3 von 5 Sternen3/5 (2)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsVon EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- Oil: An Overview of the Petroleum IndustryVon EverandOil: An Overview of the Petroleum IndustryBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Oil and Gas Artificial Fluid Lifting TechniquesVon EverandOil and Gas Artificial Fluid Lifting TechniquesBewertung: 5 von 5 Sternen5/5 (1)