Beruflich Dokumente

Kultur Dokumente

Aggregate Crushing Value

Hochgeladen von

Ritesh PaliwalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aggregate Crushing Value

Hochgeladen von

Ritesh PaliwalCopyright:

Verfügbare Formate

Chapter 7 Standard Test Procedures

Tests For Aggregates And Bricks

7.7 Aggregate Crushing Value and 10% Fines Value

7.7.1 Aggregate Crushing Value (ACV)

7.7.1.1 Introduction. One of the requirements, for the suitability of aggregates for

construction, is the ability of the aggregate to resist crushing. The Aggregate Crushing

Value gives a relative measure of the resistance of the aggregate to crushing under a

gradually applied compressive load.

7.7.1.2 Scope. The particular purpose which an aggregate is meant to serve requires the

aggregate to have a particular strength. This strength is usually stated in the

specification. This test provides a method for measuring this strength. This method is

not suitable for testing aggregates with a crushing value higher than 30, and in this

case the ten percent fines value is recommended.

7.7.1.3 Method outline. A test specimen, of chosen fractions, is compacted in a standardised

manner, into a steel cylinder fitted with a freely moving plunger. The specimen is then

subjected to a standard loading regime applied through the plunger. This action

crushes the aggregate to a degree which is dependent on the aggregate’s crushing

resistance. This degree is assessed by a sieving test on the crushed specimen and is

taken as the Aggregate Crushing Value.

7.7.1.4 Sampling. The sample used for this test shall be taken in accordance with Chapter 2.

7.7.1.5 Equipment

a) Steel cylinder, open-ended, of nominal 150mm internal diameter with plunger and

base-plate of the general form and dimensions shown in Figure 7.7.1 and given in

Table 7.7.1. The surface in contact with the aggregate shall be machined and case

hardened, and shall be maintained in a smooth condition.

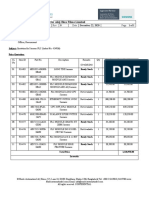

Table 7.7.1 Principal dimensions of cylinder and plunger apparatus

Component Dimensions Nominal 150 mm Nominal 75 mm internal

See Figure 7.7.1 internal diameter diameter of cylinder

of cylinder, mm mm

Cylinder Internal diameter, A 154±0.5 mm 78±0.5 mm

Internal diameter, B 125 to 140 mm 70.0 to 85.0 mm

Minimum wall thickness, C 16.0 mm 8.0 mm

Plunger Diameter of piston, D 152±0.5 mm 76.0±0.5 mm

Diameter of stem, E >95 to = or <D >45.0 to = or <D

Overall length of piston plus

stem, F 100 to 115 mm 60.0 to 80.0 mm

Minimum depth of piston, G Not less than 25.0 Not less than 19.0

Diameter of hole, H 20.0±0.1 mm 10.0±0.1 mm

Base-plate Minimum thickness, I 10 mm 10 mm

Length of each side of square,

J 200 to 230 mm 110 to 115 mm

b) A cylindrical metal measure, of sufficient rigidity to retain its form under rough

usage and with an internal diameter of 115 mm plus or minus 1 mm and an internal

depth of 180 mm plus or minus 1 mm.

c) A tamping rod, made out of straight iron or steel bar of circular cross section. 16

mm plus or minus 1 mm diameter and 600 mm plus or minus 5 mm long, with both

ends hemispherical.

d) A balance, of capacity not less than 3 kg and accurate to 1 g.

MAY 2001 Page 7.32

Chapter 7 Standard Test Procedures

Tests For Aggregates And Bricks

Figure 7.7.1 Outline form of cylinder and plunger apparatus for the aggregate crushing

value and ten percent fines test

e) A ventilated oven, thermostatically controlled at a temperature of 105 0C plus or

minus 50C.

f) A rubber mallet, a metal tray of known mass and large enough to contain 3 kg of

aggregate and a brush with stiff bristles.

g) Square-hole perforated plate test sieves, of sizes 14.0 mm and 10.0 mm and an

ovenware 2.36 mm test sieve.

h) A compression testing machine, capable of applying any force up to 400 kN at a

uniform rate of loading so that the force is reached in 10 min.

7.7.1.6 Preparation of test portions and specimens

a) Test portions. Reduce laboratory samples to test portions of sufficient mass to

produce 3 specimens of 14 mm to 10mm size fractions.

b) Sieve the entire dried test portion on the 14mm and the 10mm test sieve to remove

the oversize and undersize fraction. Divide the resulting 14mm to 10 mm size

MAY 2001 Page 7.33

Chapter 7 Standard Test Procedures

Tests For Aggregates And Bricks

fractions to produce 3 test specimens each of sufficient mass that the depth of the

material in the cylinder is approximately 100 mm after tamping.

c) Dry the test specimens by heating at a temperature of 1050C plus or minus 50C for

a period of not more than 4 h. Cool to room temperature and record the mass of the

material comprising the test specimen.

Table 7.7.2 Guide to minimum mass of test portions required to obtain a

suitable mass of material to determine the Aggregate Crushing

Value.

Grade of the aggregate Minimum mass of test portion

All-in aggregate 40 mm max. size 60 kg

All-in aggregate 20 mm max. size 45 kg

Graded aggregate 40 to 5 mm 40 kg

Graded aggregate 20 to 5 mm 25 kg

Graded aggregate 14 to 5 mm 15 kg

7.7.1.7 Procedure

a) Place the cylinder of the test apparatus in position on the base-plate and add the

test specimen in three layers of approximately equal depth, each layer being

compacted to 25 strokes from the tamping rod distributed evenly over the surface

of the layer and dropping from a height approximately 50 mm above the surface of

the aggregate. Carefully level the surface of the aggregate and insert the plunger

so that it rests horizontally on this surface. Ensure that the plunger is free to move.

b) Place the apparatus, with the test specimen prepared as described in 7.7.1.6(c)

and plunger in position, between the platens of the testing machine and load it as

uniform a rate as possible so that the required force of 400 kN is reached in 10 min

plus or minus 30 s.

c) Release the load and remove the crushed aggregate by holding the cylinder over a

clean tray of known mass and hammering on the outside with the rubber mallet

until the crushed aggregate falls freely on to the tray. Transfer fine particle adhering

to the inside of the cylinder and to the surface of the hammer to the tray by means

of the stiff bristle brush. Weight the tray and the aggregate and record the mass of

the aggregate to the nearest 1g (M1).

d) Sieve the whole of the specimen on the 2.36mm test sieve until no further

significant amount passes during a further period of 1 min. Weight and record the

mass of the fractions passing and retained on the sieve to the nearest 1g (M2 and

M3) respectively and if the total mass (M2 + M3) differs from the initial mass (M1) by

more than 10g, discard the result and test a further specimen.

e) Repeat the procedure from (a) to (b) above inclusive using a second specimen of

the same mass as the first specimen.

7.7.1.8 Calculation and expression of result. Calculate the Aggregate Crushing Value (ACV)

expressed as a percentage to the first decimal place, of the mass of fines formed to the

total mass of the test specimen from the following expression.

(ACV) = 100 x M2 / M1

Where,

M1 is the mass of the test specimen in grammes.

M2 is the mass of the material passing the 2.36mm test sieve in grammes.

MAY 2001 Page 7.34

Chapter 7 Standard Test Procedures

Tests For Aggregates And Bricks

7.7.1.9 Results. Calculate the mean of the two values determined to the nearest whole

number. Report the mean as the Aggregate Crushing Value, unless the individual

results differ by more than 0.07 times the mean value. In this case repeat the test on

two further specimens, calculate the median of the four results to the nearest whole

number and report the median as the Aggregate Crushing Value.

A data sheet is given as Form 7.7.1.

7.7.2 10% Fines Value Test

7.7.2.1 Scope. The particular purpose which an aggregate is meant to serve requires the

aggregate to have a particular strength. This strength is usually stated in the

specification. This test provides a method for measuring this strength. This method is

suitable for testing both strong and weak aggregate passing a 14.0 mm test sieve and

retained on a 10.0 mm test sieve.

7.7.2.2 Method outline. A test specimen, of chosen fractions, is compacted in a standardised

manner, into a steel cylinder fitted with a freely moving plunger. The specimen is then

subjected to a standard loading regime applied through the plunger. The action crushes

the aggregate to a degree which is dependent on the aggregate’s crushing resistance.

This degree is assessed by a sieving test on the crushed specimen. The procedure is

repeated with various loads to determine the maximum force which generates a given

sieve analysis. This force is taken as the ten percent fines value (TFV).

7.7.2.3 Sampling. The sample used for this test shall be taken in accordance with Chapter 2.

7.7.2.4 Equipment. The equipment required for this test is identical to the equipment required

for the ACV test as described in 7.7.1.5.

a) Additional equipment for testing aggregate in a soaked condition.

b) Drying cloths or absorbent paper, for the surface drying of the aggregate.

c) One or more wire-mesh baskets, with apertures greater than 6.5 mm.

d) A stout watertight container in which the basket may be immersed.

7.7.2.5 Preparation of test portions and specimens

a) Test portions

Reduce laboratory samples to test portions of sufficient mass to produce 3

specimens of 14 mm to 10mm size fraction.

Use Table 7.7.1 for a guide to the minimum mass of test portion required to obtain

a mass of material to determine the aggregate 10% fines value.

b) Test specimen in a dry condition

(i) Sieve the entire dried test portion on the 14 mm and the 10 mm test sieve to

remove the oversize and undersize fraction. Divide the resulting 14 mm to 10

mm size fractions to produce 3 test specimens each of sufficient mass such

that the depth of the material in the cylinder is approximately 100 mm after

tamping.

(ii) Dry the test specimens by heating at a temperature of 1050C plus or minus

50C for a period of not more than 4 h. Cool to room temperature before

testing. Record the mass of the material comprising the test specimen.

MAY 2001 Page 7.35

Chapter 7 Standard Test Procedures

Tests For Aggregates And Bricks

c) Test specimens in a soaked condition

(i) Prepare the test portion as in 7.7.1.6(b) except that the test portion is tested

in the as-received condition and not oven-dried. Place test specimen in a wire

basket and immerse it in the water in the container with a cover at least 50

mm of water above the top of the basket. Remove entrapped air by lifting the

basket 25 mm above the base of the container and allowing it to drop 25

times at a rate of approximately once per second. Keep the aggregate

completely immersed in water at all times and for the next 24 h plus or minus

2 h and maintain the water temperature at 200C plus or minus 50C.

(ii) After soaking, remove from the water and blot the free water from the surface

using the absorbent cloths. Carry out the test procedure immediately after this

operation.

7.7.2.6 Procedure: Aggregates in dry condition

a) Place the cylinder of the test apparatus in position on the base-plate and add the

test specimen in three layers of approximately equal depth, each layer being

compacted to 25 strokes from the tamping rod distributed evenly over the surface

of the layer and dropping from a height approximately 50 mm above the surface of

the aggregate. Carefully level the surface of the aggregate and insert the plunger

so that it rests horizontally on this surface. Ensure that the plunger is free to move.

b) Place the apparatus, with the test specimen and plunger in position, between the

platens of the testing machine and load it as uniform a rate as possible so as to

cause a total penetration of the plunger in 10 min plus or minus 30 s of

approximately:

(i) 15 mm for rounded or partially rounded aggregates (uncrushed gravels).

(ii) 20 mm for normal crushed aggregate.

(iii) 24 mm for vesicular (honeycombed) aggregates.

c) Record the force (f) applied to produce the required penetration. Release the load

and remove the crushed aggregate by holding the cylinder over a clean tray of

known mass and hammering on the outside with the rubber mallet until the crushed

aggregate falls freely on to the tray. Transfer fine particle adhering to the inside of

the cylinder and to the surface of the hammer to the tray by means of the stiff

bristle brush. Weigh the tray and the aggregate and record the mass of the

aggregate used to the nearest 1 g (M1).

d) Sieve the whole of the specimen on the 2.36 mm test sieve until no further

significant amount passes during a further period of 1 min. Weigh and record the

mass of the fractions passing and retained on the sieve to the nearest 1 g (M2 and

M3) respectively and if the total mass (M2 + M3) differs from the initial mass (M1) by

more than 10 g, discard the result and test a further specimen.

If the percentage of the material (m) passing the sieve, calculated from the

expression: M = 100 x M2 / M1 does not fall within the range 7.5% and 12.5%, test a

further specimen, using an adjusted maximum test loading to bring the percentage

of fines within the range and record the value of (m) obtained.

e) Repeat the complete test procedure with the same mass of aggregate at the same

force that gives percentage fines value within the range 7.5% and 12.5%.

7.7.2.7 Procedure; aggregates in a soaked condition

a) Follow the procedure described in 7.7.2.6(a) except that after the crushed

specimen has been removed from the cylinder, dry it in the oven at a temperature

MAY 2001 Page 7.36

Chapter 7 Standard Test Procedures

Tests For Aggregates And Bricks

of 1050C plus or minus 50C either to constant weight or for a minimum of 12 h.

Allow the dried material to cool and weigh to the nearest 1 g (M1). Complete the

procedure 7.7.2.6(d) and 7.7.2.6(e).

7.7.2.8 Calculation and expression of result

a) Calculate the force F (in kN), to the nearest whole number, required to produce

10% fines for each test specimen, with the percentage of material passing in the

range of 7.5% to 12.5%, from the following expression:

F = 14 f / (m + 4)

Where,

f is the maximum force in kN.

m is the percentage of material passing the 2.36 mm test sieve at the maximum

force.

b) Calculate the mean of the two results to the nearest 10 kN or more or to the

nearest 5 kN for forces of less than 100 kN. Report the mean as the aggregate

10% fines value, unless the individual results differ by more than 10 kN or by more

than 0.1 times the mean value. In this case repeat the test on two further

specimens, calculate the median of the four results to the nearest whole number

and report the median as the aggregate 10% fines value.

A data sheet is given as Form 7.7.1.

MAY 2001 Page 7.37

Chapter 7 Standard Test Procedures

Tests For Aggregates And Bricks

MAY 2001 Page 7.38

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Quality Standards For ECCE INDIA PDFDokument41 SeitenQuality Standards For ECCE INDIA PDFMaryam Ben100% (4)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Sla Agreement HousekeepingDokument20 SeitenSla Agreement HousekeepingRitesh PaliwalNoch keine Bewertungen

- Blake Mouton Managerial GridDokument3 SeitenBlake Mouton Managerial GridRashwanth Tc100% (1)

- 1994 Manual de Taller Bronco, Econoline, F-Series PDFDokument208 Seiten1994 Manual de Taller Bronco, Econoline, F-Series PDFOscar Cruz100% (1)

- Morth 1700 Structural ConcreteDokument23 SeitenMorth 1700 Structural ConcreteRamesh88% (40)

- BPS C1: Compact All-Rounder in Banknote ProcessingDokument2 SeitenBPS C1: Compact All-Rounder in Banknote ProcessingMalik of ChakwalNoch keine Bewertungen

- Eccentric FootingDokument3 SeitenEccentric FootingVarunn VelNoch keine Bewertungen

- Resume SampleDokument4 SeitenResume SampleRitesh PaliwalNoch keine Bewertungen

- Laboratory Compaction Characteristics and Moisture-Density Relationship of Subgrade, Embankment Soils, and Backfill MaterialDokument13 SeitenLaboratory Compaction Characteristics and Moisture-Density Relationship of Subgrade, Embankment Soils, and Backfill MaterialRitesh PaliwalNoch keine Bewertungen

- Section 3300Dokument2 SeitenSection 3300amintaka1025Noch keine Bewertungen

- Marshall Method of Asphalt-Concrete Mix DesignDokument16 SeitenMarshall Method of Asphalt-Concrete Mix DesignfitrianiNoch keine Bewertungen

- Fraud Notice Careers PDFDokument1 SeiteFraud Notice Careers PDFRitesh PaliwalNoch keine Bewertungen

- Handbook CPWD NoPWDokument498 SeitenHandbook CPWD NoPWAijaz Zende100% (6)

- Query in TenderDokument1 SeiteQuery in TenderRitesh PaliwalNoch keine Bewertungen

- Agreement For Security ServicesDokument13 SeitenAgreement For Security Serviceskishor pratap singhNoch keine Bewertungen

- Ushas Marketi NG: Wishing U Happy DeepawaliDokument1 SeiteUshas Marketi NG: Wishing U Happy DeepawaliRitesh PaliwalNoch keine Bewertungen

- Khandwavigyaptiphase 9Dokument10 SeitenKhandwavigyaptiphase 9Ritesh PaliwalNoch keine Bewertungen

- Detailed PDFDokument8 SeitenDetailed PDFRitesh PaliwalNoch keine Bewertungen

- SubcontractorAgreement8 15 08Dokument7 SeitenSubcontractorAgreement8 15 08Ritesh PaliwalNoch keine Bewertungen

- FT " FT FT: FTR.R:R 1Lgl "Fifctgt . R R G :E / 1Rff, 3R'FlfuDokument6 SeitenFT " FT FT: FTR.R:R 1Lgl "Fifctgt . R R G :E / 1Rff, 3R'FlfuRitesh PaliwalNoch keine Bewertungen

- Icmr-National Institute of VirologyDokument5 SeitenIcmr-National Institute of VirologyRitesh PaliwalNoch keine Bewertungen

- National Institute of Technology Calicut: Walk-In-InterviewDokument1 SeiteNational Institute of Technology Calicut: Walk-In-InterviewRitesh PaliwalNoch keine Bewertungen

- Notification GAIL India LTD SR Engineer Officer PostsDokument19 SeitenNotification GAIL India LTD SR Engineer Officer PostsRitesh PaliwalNoch keine Bewertungen

- IIT Dharwad Advt No. 012 V5 FinalDokument8 SeitenIIT Dharwad Advt No. 012 V5 FinalRitesh PaliwalNoch keine Bewertungen

- Walk-In Interview: Dec 2018 at Delhi For Delhi Team and On 22 Dec 2018 at Chennai For Chennai Team. For Details of TheDokument8 SeitenWalk-In Interview: Dec 2018 at Delhi For Delhi Team and On 22 Dec 2018 at Chennai For Chennai Team. For Details of TheRitesh PaliwalNoch keine Bewertungen

- Ipgtra Advt 2 2018 Teaching PostDokument5 SeitenIpgtra Advt 2 2018 Teaching PostRitesh PaliwalNoch keine Bewertungen

- Ipgtra Advt 2 2018 Teaching PostDokument4 SeitenIpgtra Advt 2 2018 Teaching PostKirankumar MutnaliNoch keine Bewertungen

- Notification English School Education Dept Karnataka KARTET 2018Dokument11 SeitenNotification English School Education Dept Karnataka KARTET 2018Ritesh PaliwalNoch keine Bewertungen

- FSTFT, F F FFTM /#FTV Hi FF : FTM M) GFFL $ FCHJDokument2 SeitenFSTFT, F F FFTM /#FTV Hi FF : FTM M) GFFL $ FCHJRitesh PaliwalNoch keine Bewertungen

- Name of The Department Post & No. of Vacancy Reservation Roster PointDokument4 SeitenName of The Department Post & No. of Vacancy Reservation Roster PointRitesh PaliwalNoch keine Bewertungen

- Notification BECIL Patient Care Manager Patient Care Coordinator PostsDokument3 SeitenNotification BECIL Patient Care Manager Patient Care Coordinator PostsRitesh PaliwalNoch keine Bewertungen

- Notification TRB Tripura STGT PostsDokument5 SeitenNotification TRB Tripura STGT PostsRitesh PaliwalNoch keine Bewertungen

- Advt ScientistDokument3 SeitenAdvt ScientistRitesh PaliwalNoch keine Bewertungen

- Detailed 05goaDokument11 SeitenDetailed 05goaRitesh PaliwalNoch keine Bewertungen

- Advt 232018Dokument7 SeitenAdvt 232018Ritesh PaliwalNoch keine Bewertungen

- Calculating Free Energies Using Adaptive Biasing Force MethodDokument14 SeitenCalculating Free Energies Using Adaptive Biasing Force MethodAmin SagarNoch keine Bewertungen

- Rankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothDokument111 SeitenRankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothphysicsNoch keine Bewertungen

- Arudha PDFDokument17 SeitenArudha PDFRakesh Singh100% (1)

- There Will Come Soft RainsDokument8 SeitenThere Will Come Soft RainsEng ProfNoch keine Bewertungen

- 28 TerminalsDokument42 Seiten28 TerminalsAlin FazacasNoch keine Bewertungen

- Executive Summary: 2013 Edelman Trust BarometerDokument12 SeitenExecutive Summary: 2013 Edelman Trust BarometerEdelman100% (4)

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Dokument2 SeitenLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNoch keine Bewertungen

- Naval TV SystemDokument24 SeitenNaval TV Systemsharmasandeep0010Noch keine Bewertungen

- The Bio-Based Economy in The NetherlandsDokument12 SeitenThe Bio-Based Economy in The NetherlandsIrving Toloache FloresNoch keine Bewertungen

- Unit 2: Air Intake and Exhaust SystemsDokument10 SeitenUnit 2: Air Intake and Exhaust SystemsMahmmod Al-QawasmehNoch keine Bewertungen

- Ce-Series - TK60981-ML-18 IM - Rev - 0 - 05-13Dokument96 SeitenCe-Series - TK60981-ML-18 IM - Rev - 0 - 05-13VERDADE MUNDIAL GUERRANoch keine Bewertungen

- 1188 2665 1 SMDokument12 Seiten1188 2665 1 SMRita BangunNoch keine Bewertungen

- Hofstede's Cultural DimensionsDokument35 SeitenHofstede's Cultural DimensionsAALIYA NASHATNoch keine Bewertungen

- Poster-Shading PaperDokument1 SeitePoster-Shading PaperOsama AljenabiNoch keine Bewertungen

- 11-Rubber & PlasticsDokument48 Seiten11-Rubber & PlasticsJack NgNoch keine Bewertungen

- Meta100 AP Brochure WebDokument15 SeitenMeta100 AP Brochure WebFirman RamdhaniNoch keine Bewertungen

- Gas Compressor SizingDokument1 SeiteGas Compressor SizingNohemigdeliaLucenaNoch keine Bewertungen

- 123Dokument3 Seiten123Phoebe AradoNoch keine Bewertungen

- For Accuracy and Safety: Globally ApprovedDokument4 SeitenFor Accuracy and Safety: Globally ApprovedPedro LopesNoch keine Bewertungen

- CPD - SampleDokument3 SeitenCPD - SampleLe Anh DungNoch keine Bewertungen

- Life and Works of Jose Rizal Modified ModuleDokument96 SeitenLife and Works of Jose Rizal Modified ModuleRamos, Queencie R.Noch keine Bewertungen

- TTDM - JithinDokument24 SeitenTTDM - JithinAditya jainNoch keine Bewertungen

- PTW Site Instruction NewDokument17 SeitenPTW Site Instruction NewAnonymous JtYvKt5XENoch keine Bewertungen

- Bone Surface MarkingsDokument2 SeitenBone Surface MarkingsNurul Afiqah Fattin AmatNoch keine Bewertungen

- TIA Guidelines SingaporeDokument24 SeitenTIA Guidelines SingaporeTahmidSaanidNoch keine Bewertungen