Beruflich Dokumente

Kultur Dokumente

Data Sheet API 2W Grade 50

Hochgeladen von

sagitroseOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Data Sheet API 2W Grade 50

Hochgeladen von

sagitroseCopyright:

Verfügbare Formate

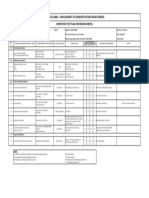

API 2W GRADE 50

API 2W GRADE 50

General Product Description

TMCP Structural Steel Plate

API 2W Grade 50 is an intermediate-strength, structural steel plate, produced by thermo-mechanical control processing (TMCP),that

is used in the welded construction of offshore structures. API 2W Grade 50 has a minimum yield strength of 50 ksi [345 MPa] and

a minimum, mid-thickness, transverse Charpy V-notch impact toughness of 30 ft-lbf [41 J] at -40°F [-40°C]. SSAB is an API Licensee

under the API Monogram Program.

Applications

API 2W Grade 50 is intended primarily for use in offshore structures in critical portions that must exhibit good impact toughness

and resistance to plastic fatigue loading and lamellar tearing. The primary use of API 2W Grade 50 is in tubular joints, stiffened plate

construction and other intersections where portions of the plates will be subjected to tension in the through-thickness (Z) direction.

Dimensions

Thickness Width Length

(Inches) (Inches) (Inches)

0.500 - 1.500 72 - 123 240 - 1080*

Inquire thickness <0.500” down to 0.250”, inquire thickness > 1.500”-2.000”, inquire widths <72” down to 60”

*

Rail shipments the maximum length of 1080” applies; for truck shipments the maximum length of 1020” applies

Mechanical Properties

Tensile Testing is performed in the transverse direction according to API 2W requirements. The required values are tabulated below:

Thickness 0.2% YS UTS Elongation in 2” Elongation in 8”

(Inches) (ksi) (min ksi) (min %) (min %)

0.500 - 1.000 50 - 75 65 23 18

1.001 - 1.500 50 - 70 65 23 18

Charpy V-Notch Impact Testing is performed on each plate using mid-thickness, mid-width, transverse specimens tested in

accordance with ASTM A673. The producer has the option of testing sub-size specimens to any of the combinations of specimen

size, energy requirement, and test temperature as shown below:

Data sheet API 2W Grade 50 2016-06-10

API 2W GRADE 50

Impact Properties

Specimen Size Minimum Average Energy Minimum Single Energy Test Temperature

0.394 x 0.394 Inches 30 ft-lbs 25 ft-lbs -40 °F

0.295 x 0.394 Inches 30 ft-lbs 25 ft-lbs -40 °F

0.197 x 0.394 Inches 30 ft-lbs 25 ft-lbs -40 °F

0.295 x 0.394 Inches 23 ft-lbs 19 ft-lbs -50 °F

0.197 x 0.394 Inches 15 ft-lbs 13 ft-lbs -80 °F

Chemical Composition

(heat analysis, wt %, max. unless indicated)

C Mn1) P S Si Al Total Ni Cr Mo Cu Ti Cb N2), 3) B2)

(max (wt %) (max (max (wt %) (wt %) (max (max (max (max (wt %) (max (max (max

wt %) wt %) wt %) wt %) wt %) wt %) wt %) wt %) wt %) wt %)

0.16 1.15 - 0.03 0.010 0.05 - 0.02 - 0.75 0.25 0.08 0.35 0.007 - 0.03 0.012 0.0005

1.60 0.50 0.06 0.02

1)

Manganese up to 1.65 (heat analysis) is permitted at the option of the material manufacturer

2)

Nitrogen and Boron shall not be intentionally added

3)

Nitrogen may be 0.013% max., if titanium is 0.010 to 0.02%

Carbon Equivalent Values

Thickness 0.500 - 1.500

(Inches)

CEIIW 0.39

(max wt %)

Pcm 0.22

(max wt %)

CEIIW Typical 0.36

(wt %)

Pcm Typical 0.16

(wt %)

Tolerances

Thickness, width, and length tolerances for API 2W Grade 50 steel plate are in accordance with the requirements of ASTM A6. The

flatness tolerance for as-supplied product is ½ ASTM A6.

Delivery Conditions

API 2W Grade 50 is supplied in the Thermo-Mechanical Control Processing (TMCP) condition.

Weldability

Welding of API 2W Grade 50 shall be performed in accordance with the applicable welding code. In the absence of a specified

welding code, the following suggested minimum preheat and interpass temperatures and welding consumables are provided.

Special welding consumables and welding procedures may be required to match the base metal toughness. Low hydrogen practices

Data sheet API 2W Grade 50 2016-06-10

API 2W GRADE 50

are strongly recommended, including the removal of surface moisture.

Welding Process Thickness Minimum Preheat and Inter- Consumables

(in. [mm]) pass Temperature

(°F [°C])

Shielded Metal Arc (SMAW) Up to 1.5 [38.1] 50 [10] AWS E7015-X, E7016-X,

E7018-X

Shielded Metal Arc (SMAW) >1.5 – 2.5 [ 38.1 – 63.5] 150 [65] AWS E7015-X, E7016-X,

E7018-X

Gas Metal Arc (GMAW) Up to 1.5 [38.1] 50 [10] AWS ER70S-X

Gas Metal Arc (GMAW) >1.5 – 2.5 [ 38.1 – 63.5] 150 [65] AWS ER70S-X

Submerged Arc (SAW) Up to 1.5 [38.1] 50 [10] AWS F7XX-EXXX-XX

Submerged Arc (SAW) >1.5 – 2.5 [ 38.1 – 63.5] 150 [65] AWS F7XX-EXXX-XX

Flux Cored Arc (FCAW) Up to 1.5 [38.1] 50 [10] AWS E7XTX-X

Flux Cored Arc (FCAW) >1.5 – 2.5 [ 38.1 – 63.5] 150 [65] AWS E7XTX-X

Supplementary Requirements

By agreement between the purchaser and plate manufacturer, the following Supplementary Requirements may be specified on

the purchase order: S1 (Ultrasonic Examination), S2 (Notch Toughness Test at Lower Temperature), S3 (Additional Tension Test),

S4 (Through-Thickness [Z-Direction] Testing), S5 (Low Sulfur Steel for Improved Through-Thickness Properties), S7 (Low Nitrogen

Content for Improved Notch Toughness in Strain-Aged Condition), S8 (Strain-Aged Charpy V—Notch Impact Tests) up to 1.000”

thickness and inquire for 1.001”–1.500” thickness, S11 Preproduction Qualification, and S12 (Notch Toughness Using Drop Weight),

S13 (Surface Quality) and S14 (Thickness Tolerance).

For referenced API standards, visit the API website, www.api.org. The information contained herein is only intended to provide guidance relative to SSAB’s capability to supply products complying with the

requirements of the referenced API standards. The information contained herein is in no way a guarantee or warranty of SSAB product. In the event of an order, the specifications as stated in the purchase

order and any subsequent order acknowledgment establish the basis for any product specifications, requirements and/or guarantees.

www.ssab.us

Data sheet API 2W Grade 50 2016-06-10

Das könnte Ihnen auch gefallen

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- Surface Tension Transfer (STT) : ApplicationDokument6 SeitenSurface Tension Transfer (STT) : ApplicationAnonymous dvrhf5Noch keine Bewertungen

- EGWDokument2 SeitenEGWpratishgnairNoch keine Bewertungen

- Welding Practice For Duplex-1 PDFDokument18 SeitenWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- Gas Pipeline Failures: by Failure Analysis Group WRD, CmrdiDokument44 SeitenGas Pipeline Failures: by Failure Analysis Group WRD, Cmrdiروشان فاطمة روشانNoch keine Bewertungen

- Saep 306Dokument15 SeitenSaep 306nadeem shaikh100% (1)

- Weld History Sheet-4Dokument4 SeitenWeld History Sheet-4MITHUNNoch keine Bewertungen

- Austenitic Ductile Iron Castings: Standard Specification ForDokument7 SeitenAustenitic Ductile Iron Castings: Standard Specification Forist93993Noch keine Bewertungen

- Corrosion Test PiecesDokument23 SeitenCorrosion Test PiecesGijoNoch keine Bewertungen

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelDokument16 SeitenGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanNoch keine Bewertungen

- Deviations During PWHT and ResponseDokument2 SeitenDeviations During PWHT and ResponseEIL NDT100% (1)

- Casting Slides 103-130Dokument28 SeitenCasting Slides 103-130Swaraj PrakashNoch keine Bewertungen

- Example Pump CalcsDokument4 SeitenExample Pump CalcsSourav ChattopadhyayNoch keine Bewertungen

- Ferrite Limitation For SS316LDokument12 SeitenFerrite Limitation For SS316LAntonio PerezNoch keine Bewertungen

- Steel Castings, Stainless, Instrument Calibration, For Estimating Ferrite ContentDokument4 SeitenSteel Castings, Stainless, Instrument Calibration, For Estimating Ferrite ContentNilton Santillan OrtegaNoch keine Bewertungen

- EpriDokument21 SeitenEprihubert_veltenNoch keine Bewertungen

- 1L11545A E 3 ManipulatorDokument130 Seiten1L11545A E 3 ManipulatorFerenc BalazsNoch keine Bewertungen

- Erw Steel Pipe Api5lb Psl1Dokument2 SeitenErw Steel Pipe Api5lb Psl1hdierkeNoch keine Bewertungen

- Iso 8100 2 2019Dokument15 SeitenIso 8100 2 2019AchmadNoch keine Bewertungen

- Case Studies in Engineering Failure Analysis: S.M.R. Ziaei, A.H. Kokabi, M. Nasr-EsfehaniDokument12 SeitenCase Studies in Engineering Failure Analysis: S.M.R. Ziaei, A.H. Kokabi, M. Nasr-Esfehanipinkan25Noch keine Bewertungen

- 2-Questions API 650 Question N°02 2022Dokument3 Seiten2-Questions API 650 Question N°02 2022korichiNoch keine Bewertungen

- Crack Detection (PII)Dokument6 SeitenCrack Detection (PII)Sh EnriqNoch keine Bewertungen

- Aws SpecificationDokument4 SeitenAws Specificationnike_y2kNoch keine Bewertungen

- Article CO2CorrosionCHEM409 - Background of CO2 CorrosionDokument4 SeitenArticle CO2CorrosionCHEM409 - Background of CO2 Corrosionmohamed samyNoch keine Bewertungen

- Dga Hic Sohic PDFDokument16 SeitenDga Hic Sohic PDFEur-Ing Nicola GalluzziNoch keine Bewertungen

- WWW Wollastonalloys Com Materials 2Dokument8 SeitenWWW Wollastonalloys Com Materials 2Mark RomeroNoch keine Bewertungen

- SB410 (JIS) - Worldwide Equivalent Grades 11Dokument1 SeiteSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- Asset Integrity Daily ReportDokument1 SeiteAsset Integrity Daily Reportعصمت ضيف اللهNoch keine Bewertungen

- Super Austenetic Steels P45 PDFDokument3 SeitenSuper Austenetic Steels P45 PDFSyed Mahmud Habibur RahmanNoch keine Bewertungen

- Zero Defect in P91-Report-2005Dokument20 SeitenZero Defect in P91-Report-2005sbmmla100% (1)

- ITP For Drum Screen InspectionDokument1 SeiteITP For Drum Screen InspectionkapsarcNoch keine Bewertungen

- MOTS-12 Welding and NDE of WeldsDokument1 SeiteMOTS-12 Welding and NDE of Weldsryan.sNoch keine Bewertungen

- 0700testing MultipleDokument5 Seiten0700testing MultipleIvan GutierrezNoch keine Bewertungen

- A Brief Synopsis ofDokument54 SeitenA Brief Synopsis ofNO ONENoch keine Bewertungen

- Consumable and Welding of Modified 9 Cr-1M0 Steel PDFDokument4 SeitenConsumable and Welding of Modified 9 Cr-1M0 Steel PDFmahmoud_allam3Noch keine Bewertungen

- Material Datea 2.4602Dokument3 SeitenMaterial Datea 2.4602Charwin XiaoNoch keine Bewertungen

- PWHT of Dissimilar: Metal WeldsDokument48 SeitenPWHT of Dissimilar: Metal WeldswchavezbNoch keine Bewertungen

- Effect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base MetalDokument8 SeitenEffect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base Metalshrikant tambeNoch keine Bewertungen

- Technical Monograph 39: A Reliable Base For High Nickel EquipmentDokument8 SeitenTechnical Monograph 39: A Reliable Base For High Nickel EquipmentAnkit GarachNoch keine Bewertungen

- Some Grades of Carbon Steel and 0.5mo SteelsDokument27 SeitenSome Grades of Carbon Steel and 0.5mo SteelsNidharshan Selvaraj RNoch keine Bewertungen

- ISO 8501-Pictorial Clasiification Standard For Surface CleanlinessDokument29 SeitenISO 8501-Pictorial Clasiification Standard For Surface CleanlinessabhibmaneNoch keine Bewertungen

- QW-451 Welding THK - June5Dokument17 SeitenQW-451 Welding THK - June5Raj SNoch keine Bewertungen

- Etching Stainless Steels For Delta FerriteDokument2 SeitenEtching Stainless Steels For Delta FerriteAPINoch keine Bewertungen

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDokument1 SeitePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNoch keine Bewertungen

- Twi Course Name and Description: BGAS/CSWIP CoursesDokument5 SeitenTwi Course Name and Description: BGAS/CSWIP Courseskhalidmh100% (1)

- ASME Sec VIII - Temper Bead TechniqueDokument1 SeiteASME Sec VIII - Temper Bead TechniquezanlogNoch keine Bewertungen

- Data Sheet Material 2.4819Dokument3 SeitenData Sheet Material 2.4819BoberNoch keine Bewertungen

- S 355 J2 + NDokument1 SeiteS 355 J2 + NValentin GalbenNoch keine Bewertungen

- Hastelloy B3 / Alloy B3 / UNS N10675 / DIN 2.4600Dokument3 SeitenHastelloy B3 / Alloy B3 / UNS N10675 / DIN 2.4600SamkitNoch keine Bewertungen

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFDokument1 SeiteAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFAzhar Ahmad100% (1)

- A F E S: Process Piping 670.200Dokument17 SeitenA F E S: Process Piping 670.200puwarin najaNoch keine Bewertungen

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDokument1 Seite22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforNoch keine Bewertungen

- API 653 Above Ground Storage Tank InspectorDokument2 SeitenAPI 653 Above Ground Storage Tank InspectorMohamed Hichem Guesmi0% (1)

- 625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFDokument5 Seiten625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFKara WhiteNoch keine Bewertungen

- Pfeifer Group PDF Schalungstraeger Durchbiegung enDokument2 SeitenPfeifer Group PDF Schalungstraeger Durchbiegung enaraboooNoch keine Bewertungen

- A 1092 - 15Dokument3 SeitenA 1092 - 15Pavan KumarNoch keine Bewertungen

- Sample Forms WPS PQRDokument22 SeitenSample Forms WPS PQRGMNoch keine Bewertungen

- Bright Annealing Process of Stainless S Teel TubeDokument2 SeitenBright Annealing Process of Stainless S Teel TubeViraj ShiroleNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistRijwan MohammadNoch keine Bewertungen

- Pipe Welding With WaveformDokument39 SeitenPipe Welding With Waveformprabu prasadNoch keine Bewertungen

- Quality Moment - January 2021Dokument7 SeitenQuality Moment - January 2021Mohd Dzaki B. SamsuriNoch keine Bewertungen

- Body of Knowledge: Certified Welding EngineerDokument4 SeitenBody of Knowledge: Certified Welding EngineerMalcolm Diamond100% (1)

- Risk Based Inspection A Complete Guide - 2020 EditionVon EverandRisk Based Inspection A Complete Guide - 2020 EditionNoch keine Bewertungen

- Lecture (SM Construction, Types and Operation)Dokument32 SeitenLecture (SM Construction, Types and Operation)kyaw winNoch keine Bewertungen

- Mayank Agrawal 2017UCH1725: Technical SkillsDokument2 SeitenMayank Agrawal 2017UCH1725: Technical SkillsMayank AgrawalNoch keine Bewertungen

- ME-341A - Heat and Mass TransferDokument34 SeitenME-341A - Heat and Mass TransferMukul ChandraNoch keine Bewertungen

- Electrical Resume Boyet PascuaDokument2 SeitenElectrical Resume Boyet PascuaAucsap BoyetNoch keine Bewertungen

- SHEET #1 Title Sheet Site Safety Logistic Plan ForDokument5 SeitenSHEET #1 Title Sheet Site Safety Logistic Plan ForRadha BuildtechNoch keine Bewertungen

- Megger DET14 DET24 An en V 01Dokument16 SeitenMegger DET14 DET24 An en V 01costelchelariuNoch keine Bewertungen

- CPP Schematic Diagram Duplex Complete 9 Jan 2019Dokument1 SeiteCPP Schematic Diagram Duplex Complete 9 Jan 2019BdSulianoNoch keine Bewertungen

- Carbon Nanotube: Properties and ApplicationsDokument22 SeitenCarbon Nanotube: Properties and ApplicationsmanuNoch keine Bewertungen

- SI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53Dokument2 SeitenSI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53strexxNoch keine Bewertungen

- MP-20x Datasheet 1Dokument2 SeitenMP-20x Datasheet 1Francisco MoragaNoch keine Bewertungen

- QUBEDokument2 SeitenQUBEJován MéridaNoch keine Bewertungen

- Google Assistant Home Automation CodeDokument3 SeitenGoogle Assistant Home Automation CodeStjepan BartolovićNoch keine Bewertungen

- Zener DiodeDokument3 SeitenZener DiodeAde MurtalaNoch keine Bewertungen

- MZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalDokument59 SeitenMZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalFaiyazsulthanNoch keine Bewertungen

- Institute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Dokument3 SeitenInstitute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Pramod DhaigudeNoch keine Bewertungen

- Business Plan: Syeda Zurriat & Aimen RabbaniDokument11 SeitenBusiness Plan: Syeda Zurriat & Aimen RabbanizaraaNoch keine Bewertungen

- Topobase Performance and ScalabilityDokument16 SeitenTopobase Performance and ScalabilityFernandoKNoch keine Bewertungen

- HQ Accessoriescatalogue 20142015 LRDokument28 SeitenHQ Accessoriescatalogue 20142015 LRapi-36492444Noch keine Bewertungen

- Transfer FunctionDokument19 SeitenTransfer FunctionVinay Kumar SmartyNoch keine Bewertungen

- Reference Jica-Chodai Scouring Manual in ThailandDokument175 SeitenReference Jica-Chodai Scouring Manual in ThailandSeptinurriandianiNoch keine Bewertungen

- IEEE Recommended Practice For Exc. Sys Models 2Dokument4 SeitenIEEE Recommended Practice For Exc. Sys Models 2Emmanuel ZamoranoNoch keine Bewertungen

- Health Care Facilities and Medical Gas and VacuumDokument27 SeitenHealth Care Facilities and Medical Gas and VacuumStephen TabiarNoch keine Bewertungen

- Instruction Manual of EDM MachineDokument18 SeitenInstruction Manual of EDM MachineJanak ValakiNoch keine Bewertungen

- Doosan IR Light SourceDokument2 SeitenDoosan IR Light SourceMolie1979Noch keine Bewertungen

- LAPORAN PRAKTIK KERJA LAPANGAN - Id.enDokument25 SeitenLAPORAN PRAKTIK KERJA LAPANGAN - Id.enAhmad JupriNoch keine Bewertungen