Beruflich Dokumente

Kultur Dokumente

Cargo Net l3 Ast Le Adma 314

Hochgeladen von

Anwar DeenOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cargo Net l3 Ast Le Adma 314

Hochgeladen von

Anwar DeenCopyright:

Verfügbare Formate

LIFTING EQUIPMENT INSPECTION

PROCEDURE

THOROUGH EXAMINATION OF CARGO NET

DOCUMENT TITLE : Thorough Examination of Cargo Net

REFERENCE NUMBER

DATE : 12-07-2017

REVISION NUMBER :0

Rev Date Section Outline of Revision Prepared Reviewed Approved

LIFTING EQUIPMENT INSPECTION

PROCEDURE

THOROUGH EXAMINATION OF CARGO NET

1. INTRODUCTION:

This Procedure has been prepared to comply the essential safety and

inspection requirements as per the Harmonized standard, Machinery Directive,

LOLER and Local Regulation.

2. SCOPE:

This Procedure details the general requirements and thorough examination of

Cargo Net.

3. TRAINING & KNOWLEDGE:

The Manager/Supervisor shall ensure that personnel performing this thorough

examination are proficient in these instructions. As a minimum, the individual

establishes proficiency by performing the process at least once. Using check

lists or reports, as on-the-job training under the supervision of someone

certified in this process.

Training for this process is defined as continuous monitoring of personnel

involved in thorough examination. A person is not to be certified until all the

defined trainings has taken place and the trainer is satisfied that the trainee

can carry out the process independently.

4. TERMS & DEFINITIONS:

Cargo Net: Cargo net is the type of net made up of thick rope usually of

rectangular, square or circular shapes, with cinched ropes extending from

the corners and or from the edges in some design. It is used in transferring

cargo to and from ships.

Safe Working Load (SWL): Maximum load in which the CARGO NET is rated

to sustain under specific service conditions.

Factor of Safety (F.O.S): Integer quotient between the final test load in the

cyclic top lift test and the SWL value rounded down.

Competent Person: Designated person, trained, qualified, and practical

experience to thoroughly examine the lifting equipment’s.

REV.00 Date: 12-07-2017 Page 2 of 6

LIFTING EQUIPMENT INSPECTION

PROCEDURE

THOROUGH EXAMINATION OF CARGO NET

5. REFERENCES:

BS 6756: 1986 – Specification of fibre rope cargo nets.

LOLER 1998 – Lifting Operations and Lifting Equipment

Regulations - Approved Code of Practice

Local Lifting Regulation – ADMA – Code of Practice for Lifting

Operations CP-113 Rev.1, PRO-141 & 142

6. GENERAL & TECHNICAL REQUIREMENT OF CARGO NET:

All categories of cargo net shall be manufactured from fibre ropes covered

by a written specification. The cargo net manufacturer shall have an

authorized statement of conformity for each separate batch of materials.

The size of the individual component shall be derived by the manufacturer

and the final SWL or WLL shall be given with appropriate testing.

7. THOROUGH EXAMINATION OF CARGO NET:

The primary purpose of thorough examination is to ensure that a cargo net is

safe to be taken into, or to continue in, use. It is in addition to any inspection

carried out as a part of the maintenance regime and is a statutory requirement.

Thorough Examination are classified as follows referring LOLER Regulation 9.,

Before being put into use for the first time a cargo net must be thoroughly

examined to ensure that it is safe to use. Cargo net shall be thoroughly

examined as follows.,

Break Load Test: Cargo Net shall be subjected maximum break load test to

verify the structural integrity of cargo net. Sample piece shall be taken from each

batch and subjected to break load test. The testing shall be carried out as per

the manufacturer instruction.,

A sample piece shall be taken from each batch and a test load of 6 x SWL shall

be loaded to the cargo net and it should withstand and hold the load even if

some breaking happens on the rope or joints for not less than 5 minutes.

Proof Load Test: Proof Load test shall be carried out as the part of periodic

examination as the discretion of competent person or as per local governing

body to assess the continued integrity of the lifting beam, considering its age,

REV.00 Date: 12-07-2017 Page 3 of 6

LIFTING EQUIPMENT INSPECTION

PROCEDURE

THOROUGH EXAMINATION OF CARGO NET

usage, conditions and operating environment. The magnitude of load shall be

2 x SWL.

Thorough Visual Inspection: A thorough visual examination shall be carried out

on no load condition and the following shall be examined.,

• Examination shall be carried out in a proper lighting and by a competent

person.

• Cargo net shall be traceable with unique identification number, WLL,

Name of the Manufacturer’s/Fabricator, Manufacturer’s Certificate of

Conformity and Proof Load Test Certificates.

• Check for fibre rope worn out, breaks, damage and stretch due to

overloading.

• Check for all the joints, edges and side rope for any damage.

Thorough Examination interval: The statutory maximum intervals of 6 months

and may be reduced, considering environmental factors or the general age

and condition of the frame etc. The decision to reduce the interval between

thorough examinations may be made by the competent person, owner or

user.

8. REPORTING & CERTIFICATION:

After satisfactory completion of examination, certificate shall be issued for each

cargo net.

However, a Defect report will be issued for cargo net failing to meet the

acceptance criteria of thorough examination.

The certificate shall contain at least the following information.

• The name and address of the manufacturer or where applicable the

authorized representative.

• The number and part of the Conforming Harmonised standard.

• The description of the cargo net including all component parts.

• The SWL of the cargo net.

• Factor of Safety

• Details of any Break load test and Proof Load test carried out.

REV.00 Date: 12-07-2017 Page 4 of 6

LIFTING EQUIPMENT INSPECTION

PROCEDURE

THOROUGH EXAMINATION OF CARGO NET

9. RECORDS:

Record No. Description Retention Period

L4-AST-LE-101 Certificate of Test and Thorough Examination8years

L4-AST-LE-102 Certificate of Thorough examination 8 years

L4-AST-LE-100 Inspection Report 8 years

REV.00 Date: 12-07-2017 Page 5 of 6

LIFTING EQUIPMENT INSPECTION

PROCEDURE

THOROUGH EXAMINATION OF CARGO NET

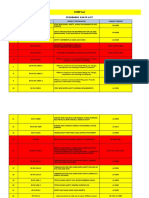

10. CARGO NET - INSPECTION CHECK LIST

OWNER: DATE:

LOCATION SURVEYOR

SERIAL NO: TYPE

SWL MAKE

Satisfactory/Not

ITEM DESCRIPTION REMARKS

Satisfactory

1 Mesh Rope

2 Side Rope

3 Joints

4 Lifting points

5 Break Load test (if applicable)

6 Proof Load test (if applicable)

Remarks (if any):

INSPECTED BY (SIGNATURE)

INSPECTOR(NAME):

INSPECTION DATE:

REV.00 Date: 12-07-2017 Page 6 of 6

Das könnte Ihnen auch gefallen

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDokument2 SeitenJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenNoch keine Bewertungen

- ANSI Requirements For Overhead and Gantry CranesDokument7 SeitenANSI Requirements For Overhead and Gantry CranesRizki SadikinNoch keine Bewertungen

- ANSI Requirements For Overhead and Gantry CranesDokument7 SeitenANSI Requirements For Overhead and Gantry CranesRizki SadikinNoch keine Bewertungen

- Pad Eyes Procedure Rev 0Dokument7 SeitenPad Eyes Procedure Rev 0AfzaalUmair100% (2)

- Iso 10325 2018Dokument9 SeitenIso 10325 2018Julio Andrés Casal Ramos0% (1)

- Basic Rigging 106-09 PDFDokument80 SeitenBasic Rigging 106-09 PDFAnwar DeenNoch keine Bewertungen

- Data IntegrationDokument7 SeitenData IntegrationHan MyoNoch keine Bewertungen

- Tips For Avoiding Crane Runway ProblemsDokument25 SeitenTips For Avoiding Crane Runway ProblemsAshishNoch keine Bewertungen

- F 1. 50 KG For 5 Min 2. 150 KG For 5 Min F 22 KN For Type A F 18 KN For Type BDokument2 SeitenF 1. 50 KG For 5 Min 2. 150 KG For 5 Min F 22 KN For Type A F 18 KN For Type BMauricio GaviriaNoch keine Bewertungen

- 01 - Accounting For Managers PDFDokument151 Seiten01 - Accounting For Managers PDFAmit Kumar PandeyNoch keine Bewertungen

- Crane Pre Commissioning ITPDokument6 SeitenCrane Pre Commissioning ITPAbdul Hamid TasraNoch keine Bewertungen

- Certex Wire Rope Slings LR Rev3Dokument34 SeitenCertex Wire Rope Slings LR Rev3jogi oscar sinagaNoch keine Bewertungen

- The 21 Irrefutable Laws of Leadership by John MaxwellDokument10 SeitenThe 21 Irrefutable Laws of Leadership by John MaxwellRemus Romano ReyesNoch keine Bewertungen

- Chain Hoist InstructionsDokument8 SeitenChain Hoist InstructionsnevadablueNoch keine Bewertungen

- EMMARDokument5 SeitenEMMARNisar DeenNoch keine Bewertungen

- Tally QuestionsDokument73 SeitenTally QuestionsVishal Shah100% (1)

- User Manual - X904Dokument26 SeitenUser Manual - X904Foad MirzaieNoch keine Bewertungen

- AIS PR INS 29 Rev 01 Crane Inspection Procedure (Repaired)Dokument11 SeitenAIS PR INS 29 Rev 01 Crane Inspection Procedure (Repaired)aymenmoatazNoch keine Bewertungen

- FM X EN 2015 Manual Web PDFDokument292 SeitenFM X EN 2015 Manual Web PDFAnwar Deen100% (1)

- FM X EN 2015 Manual Web PDFDokument292 SeitenFM X EN 2015 Manual Web PDFAnwar Deen100% (1)

- LEEA Lifting and Slinging Course OutlineDokument4 SeitenLEEA Lifting and Slinging Course OutlineSankaranarayananNoch keine Bewertungen

- Wire Rope Slings: Recommended Guideline For Proof Test Procedures ForDokument22 SeitenWire Rope Slings: Recommended Guideline For Proof Test Procedures Fordonnyars1979Noch keine Bewertungen

- Technical Data Manual: Developed & Manufactured in The UK by Millfield Enterprises (Manufacturing) LimitedDokument20 SeitenTechnical Data Manual: Developed & Manufactured in The UK by Millfield Enterprises (Manufacturing) LimitedAlberto CárdenasNoch keine Bewertungen

- Annual SCBA RefresherDokument97 SeitenAnnual SCBA RefresherDavid Edward100% (2)

- Annual SCBA RefresherDokument97 SeitenAnnual SCBA RefresherDavid Edward100% (2)

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Dokument2 Seiten0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNoch keine Bewertungen

- BS en Iso 10855-3-2018Dokument26 SeitenBS en Iso 10855-3-2018beshoyNoch keine Bewertungen

- Lifting Beams and Spreaders SI 8.3Dokument2 SeitenLifting Beams and Spreaders SI 8.3reda mesbahNoch keine Bewertungen

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDokument12 SeitenWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNoch keine Bewertungen

- GunneboDokument36 SeitenGunnebomordidomiNoch keine Bewertungen

- Crane Wire Rope Code PDFDokument1 SeiteCrane Wire Rope Code PDFraulbrlunaNoch keine Bewertungen

- Pad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesDokument3 SeitenPad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesAnirudh S. Goel83% (6)

- Pad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesDokument3 SeitenPad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesAnirudh S. Goel83% (6)

- BS Din en 13411-4 - 2011Dokument28 SeitenBS Din en 13411-4 - 2011sca8z4cb2aNoch keine Bewertungen

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Dokument6 SeitenGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- Opito Rigger TrainingDokument61 SeitenOpito Rigger TrainingTasia DiNoch keine Bewertungen

- Owen Falls MovementsDokument12 SeitenOwen Falls Movementssemuwemba100% (2)

- LEEA 059 5 Guidance To Documentation & Marking Part5Dokument23 SeitenLEEA 059 5 Guidance To Documentation & Marking Part5GaniyuNoch keine Bewertungen

- LEEA-015 BSI Reference Library List - Version 09 - Jan 2021Dokument32 SeitenLEEA-015 BSI Reference Library List - Version 09 - Jan 2021GaniyuNoch keine Bewertungen

- King Lifting Crane Hire Specification GuideDokument216 SeitenKing Lifting Crane Hire Specification Guidemohan115Noch keine Bewertungen

- As 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationDokument7 SeitenAs 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationSAI Global - APAC0% (1)

- BS-3037-2 Tyres For Crane - TMPDokument10 SeitenBS-3037-2 Tyres For Crane - TMPgazali0% (1)

- Sans2415 PDFDokument27 SeitenSans2415 PDFCwenga CwestarNoch keine Bewertungen

- LEEA 032 Guide To Written Schemes Free VersionDokument7 SeitenLEEA 032 Guide To Written Schemes Free VersionGaniyu100% (1)

- Haklift Webbing Slings and Roundslings GuideDokument10 SeitenHaklift Webbing Slings and Roundslings GuideYosses Sang NahkodaNoch keine Bewertungen

- Lifting Equipment StandardDokument4 SeitenLifting Equipment Standardpkannan100% (1)

- PDFDokument14 SeitenPDFBibhuti B. Bhardwaj100% (1)

- IS 11521: Cargo Handling NetsDokument16 SeitenIS 11521: Cargo Handling NetsGanesh ModiNoch keine Bewertungen

- Iso 4310 - 2009 Cranes - Test Code and Procedures - PDFDokument19 SeitenIso 4310 - 2009 Cranes - Test Code and Procedures - PDFpranayasharma022Noch keine Bewertungen

- A Comparison of BS en 287 Part 1 and ISO 9606Dokument3 SeitenA Comparison of BS en 287 Part 1 and ISO 9606Joe ClarkeNoch keine Bewertungen

- DLL Tle 6 Ict Entrepreneurship 6Dokument32 SeitenDLL Tle 6 Ict Entrepreneurship 6Jewels Garcia100% (1)

- Sabs GuideDokument3 SeitenSabs Guidealextentwenty0% (1)

- Taglineuse PEERREVIEWDOCDokument56 SeitenTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- Suds Wire Rope Grips Din741Dokument1 SeiteSuds Wire Rope Grips Din741Gerardo LobosNoch keine Bewertungen

- Pullmaster Brochure PDFDokument16 SeitenPullmaster Brochure PDFKSRNoch keine Bewertungen

- Iso 8792 1986Dokument9 SeitenIso 8792 1986Ather SeemabNoch keine Bewertungen

- StandardsDokument7 SeitenStandardsmac1677Noch keine Bewertungen

- SB 85XP - MS 3015 DSS13Dokument4 SeitenSB 85XP - MS 3015 DSS13amin110110100% (1)

- Copie de Standards Check ListDokument7 SeitenCopie de Standards Check ListAbakar MahamatNoch keine Bewertungen

- BS 6166-1 1986Dokument18 SeitenBS 6166-1 1986احمد عبداللاNoch keine Bewertungen

- Iso 3874 1997Dokument87 SeitenIso 3874 1997ferruxo69Noch keine Bewertungen

- Product CatalogueDokument44 SeitenProduct CatalogueTo Van TinhNoch keine Bewertungen

- Authorised Examiners Lifting EquipmentDokument13 SeitenAuthorised Examiners Lifting EquipmentdunglxNoch keine Bewertungen

- 8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureDokument5 Seiten8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureGbenga MoboladeNoch keine Bewertungen

- X 904 ManualDokument19 SeitenX 904 Manualuser123Noch keine Bewertungen

- EN 15151-1 enDokument1 SeiteEN 15151-1 enMulyana Ibex100% (1)

- DOC. No. Revision Date by E6DPA-WEIGHT-003 01 18.02.2015 1 of 2 Flora Braoh TitleDokument1 SeiteDOC. No. Revision Date by E6DPA-WEIGHT-003 01 18.02.2015 1 of 2 Flora Braoh TitleNasrul AdliNoch keine Bewertungen

- Crane Inspection Check List HSE. STDDokument1 SeiteCrane Inspection Check List HSE. STDEdy ElfianNoch keine Bewertungen

- As 2550.4-2004 Cranes Hoists and Winches - Safe Use Tower CranesDokument9 SeitenAs 2550.4-2004 Cranes Hoists and Winches - Safe Use Tower CranesSAI Global - APACNoch keine Bewertungen

- LEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFDokument14 SeitenLEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFopreamihNoch keine Bewertungen

- 64-Crane Operator Program NcmscurrentDokument5 Seiten64-Crane Operator Program NcmscurrentJojo Betanio AkajoknoNoch keine Bewertungen

- Inspection and Certification Procedure References For Lorry Loader CraneDokument1 SeiteInspection and Certification Procedure References For Lorry Loader CraneOussama AloulouNoch keine Bewertungen

- RR C 271DDokument53 SeitenRR C 271DJomon Varghese100% (1)

- Mobile CraneDokument18 SeitenMobile CraneHarris ShehzadNoch keine Bewertungen

- Inspector Bulletin: Interesting ObservationsDokument2 SeitenInspector Bulletin: Interesting ObservationsDavid DurhamNoch keine Bewertungen

- Cargo Handling EquipmentsDokument18 SeitenCargo Handling EquipmentsRajeewa Wickramahewage100% (1)

- FM-X Technical Data Driver Seated Reach TruckDokument11 SeitenFM-X Technical Data Driver Seated Reach TruckAnwar DeenNoch keine Bewertungen

- Offline Filter Pressure Olfp 1 / 3 / 6: Description Technical DetailsDokument4 SeitenOffline Filter Pressure Olfp 1 / 3 / 6: Description Technical DetailsAnwar DeenNoch keine Bewertungen

- B30 Standards Committee Publication StatusDokument3 SeitenB30 Standards Committee Publication StatusAnwar DeenNoch keine Bewertungen

- Truck Crane Stc250Dokument9 SeitenTruck Crane Stc250Anwar DeenNoch keine Bewertungen

- COA Full Syllabus-CSEDokument3 SeitenCOA Full Syllabus-CSEAMARTYA KUMARNoch keine Bewertungen

- Norlys 2016Dokument124 SeitenNorlys 2016elektrospecNoch keine Bewertungen

- Graphics Coursework GcseDokument7 SeitenGraphics Coursework Gcseafiwhlkrm100% (2)

- 9643 SoirDokument38 Seiten9643 SoirpolscreamNoch keine Bewertungen

- Frequently Asked Questions (And Answers) About eFPSDokument10 SeitenFrequently Asked Questions (And Answers) About eFPSghingker_blopNoch keine Bewertungen

- Importance and Behavior of Capital Project Benefits Factors in Practice: Early EvidenceDokument13 SeitenImportance and Behavior of Capital Project Benefits Factors in Practice: Early EvidencevimalnandiNoch keine Bewertungen

- Chapter-5-Entrepreneurial-Marketing Inoceno de Ocampo EvangelistaDokument63 SeitenChapter-5-Entrepreneurial-Marketing Inoceno de Ocampo EvangelistaMelgrey InocenoNoch keine Bewertungen

- Learn About Intensifiers and How to Use Them Effectively in WritingDokument3 SeitenLearn About Intensifiers and How to Use Them Effectively in WritingCheryl CheowNoch keine Bewertungen

- TROOP - of - District 2013 Scouting's Journey To ExcellenceDokument2 SeitenTROOP - of - District 2013 Scouting's Journey To ExcellenceAReliableSourceNoch keine Bewertungen

- JDC Merchanndising ActivityDokument6 SeitenJDC Merchanndising ActivityShaira Sahibad100% (1)

- MunnarDokument5 SeitenMunnarvisujinuNoch keine Bewertungen

- Creating Rapid Prototype Metal CastingsDokument10 SeitenCreating Rapid Prototype Metal CastingsShri JalihalNoch keine Bewertungen

- Index: Title Page Acknowledgement Chapter 1: ProfilesDokument43 SeitenIndex: Title Page Acknowledgement Chapter 1: ProfilesRaushan singhNoch keine Bewertungen

- Oteco 3Dokument12 SeitenOteco 3VRV.RELATORIO.AVARIA RELATORIO.AVARIANoch keine Bewertungen

- Real-Time Java and ATCDokument44 SeitenReal-Time Java and ATCdnk_victon6248Noch keine Bewertungen

- NURKSE's Balanced GrowthDokument7 SeitenNURKSE's Balanced GrowthArnab MutsuddyNoch keine Bewertungen

- Chapter 7 - Trade and Investment EnvironmentDokument7 SeitenChapter 7 - Trade and Investment EnvironmentMa. Cristel Rovi RibucanNoch keine Bewertungen

- G C Reddy ProfileDokument3 SeitenG C Reddy ProfileG.C.ReddyNoch keine Bewertungen

- Rbalance Rotor Balancing ProcedureDokument2 SeitenRbalance Rotor Balancing ProcedureBradley NelsonNoch keine Bewertungen

- Consumer Preference and Demand For Rice Grain QualityDokument38 SeitenConsumer Preference and Demand For Rice Grain QualityIRRI_SSDNoch keine Bewertungen

- 1 s2.0 S0313592622001369 MainDokument14 Seiten1 s2.0 S0313592622001369 MainNGOC VO LE THANHNoch keine Bewertungen

- SUTI Report - Metro ManilaDokument87 SeitenSUTI Report - Metro ManilaIvan Harris TanyagNoch keine Bewertungen

- Direct FileActDokument17 SeitenDirect FileActTAPAN TALUKDARNoch keine Bewertungen

- Parts 3121106 1-2-12 ANSI EnglishDokument246 SeitenParts 3121106 1-2-12 ANSI EnglishAndres JimenezNoch keine Bewertungen

- Project Proposal: Retail Environment Design To Create Brand ExperienceDokument3 SeitenProject Proposal: Retail Environment Design To Create Brand ExperienceMithin R KumarNoch keine Bewertungen