Beruflich Dokumente

Kultur Dokumente

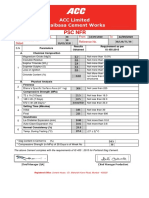

Design Condition: Bearing Dimension

Hochgeladen von

wirawanwillyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Condition: Bearing Dimension

Hochgeladen von

wirawanwillyCopyright:

Verfügbare Formate

1.

Design Condition

Design Code Element Node(I/J)

AASHTO-LRFD2012 9 J

■ Bearing Dimension

W 3180.000 (mm)

L 4300.000 (mm)

■ Bearing Dimension

Exterior Elastomeric Thckness

Interior Elastomeric Thickness

Steel Plate Thickness

No. of Interior elastomer layers

No. of steel ship plates

Total Elastomer Thckness

Total Bearing Height

■ PTFE

PTFE Thickness

■ Steel Shim Propoerties

Yield Strength of Steel

Allowable Fatigue Threshold

Insert picture here….

■ Bearing Loads

Maximum Support Reaction

■ Bearing Rotation

Include a construction tolerance of 0.005 radians to account for uncertainties in bearing seat construction

Construction Tolerance

■ Horizontal Movement

Uniform Temperature Movement Range :

Maximum Temperature

Minimum Temperature

Coefficient of thermal Expansion

Expansion Length

Construction Load Factor

AASHTO Reduction Factor

Creep, Shrinkage, Elastic Shortening, and Miscelllaneous Movements :

Creep movement

Shrinkage movement

Elastic Shortening

Live load movement

Miscellaneous movement

Assuming the substructure is stiff enough to prevent movement :

2. Solution

■ Shape Factor

Rectangular, steel reinforced bearing shape factor without holes

■ Computed Stresses

Average contact stresses

Edge contact stress

The contact stress at the edge shall be determined by considering the maximum service moment

transferred by the bearing, assuming a linear distribution of stress across the PTFE. The moment

is assumed to occur at the centerline of the bearing, perpendicular to the direction of the load

■ Coefficient of Friction of PTFE

For the given minimum temperature and the average pressure a,

■ Shear Deformations

Since a low friction sliding surface is implemented, Δs need not to be taken larger than the

deformation corresponding to first slip (AASHTO 14.7. 5.3.2) The minimum pressure will

create the largest coefficient of friction andn the largest movement.

The minimum service shear force transferred by the sliding srface at the specified minimum temperature

The deflection of the elastomeric baring, before first slip of the sliding surface, is estimated

as

The remaining movement is accommodated by the movement of the PTFE surface

earing seat construction.

service moment

FE. The moment

n of the load

minimum temperature

Das könnte Ihnen auch gefallen

- Introduction To Bearings - Hpy - PpsDokument32 SeitenIntroduction To Bearings - Hpy - PpsSiYing LaiNoch keine Bewertungen

- CTT Pot BearingsDokument16 SeitenCTT Pot Bearingslabsot100% (1)

- Design Factors When Using Small Bearings: Part 2: Mounting and FittingDokument11 SeitenDesign Factors When Using Small Bearings: Part 2: Mounting and FittingankitsarvaiyaNoch keine Bewertungen

- Elastomeric Bearing DesignDokument43 SeitenElastomeric Bearing Designoscargon19Noch keine Bewertungen

- OlDokument66 SeitenOlcarlosfilipegomes3994Noch keine Bewertungen

- CTT Pot BearingsDokument16 SeitenCTT Pot BearingsCT0011100% (1)

- Design of Elastomeric BearingDokument12 SeitenDesign of Elastomeric BearingSuman Nakarmi100% (3)

- 8.bearing DesignDokument38 Seiten8.bearing DesignAbel MulugetaNoch keine Bewertungen

- Bridge Bearing2Dokument10 SeitenBridge Bearing2sandbad2Noch keine Bewertungen

- Tension MembersDokument16 SeitenTension MembersArnab DuttaNoch keine Bewertungen

- PRES-1 External Presure Design - 07.02.16Dokument37 SeitenPRES-1 External Presure Design - 07.02.16mithuwanNoch keine Bewertungen

- Ridge Etails: Bridge Design Manual - 2002 Bridge DetailsDokument21 SeitenRidge Etails: Bridge Design Manual - 2002 Bridge DetailsHundeejireenyaNoch keine Bewertungen

- Design of Crush Height For Reliable Press Fit of High Performance BearingsDokument9 SeitenDesign of Crush Height For Reliable Press Fit of High Performance Bearingsstefan.vince536Noch keine Bewertungen

- Sheet Metal Bending-3Dokument15 SeitenSheet Metal Bending-3Sai Sujan100% (1)

- "Design of Jib Crane Type Rotating Derrick System" in EOT CRANE For Easy Lifting The Spare Parts During Heavy Maintenance in Confined SpaceDokument7 Seiten"Design of Jib Crane Type Rotating Derrick System" in EOT CRANE For Easy Lifting The Spare Parts During Heavy Maintenance in Confined SpaceijsretNoch keine Bewertungen

- Unit I Introduction To Limit State What Is Limit State?Dokument15 SeitenUnit I Introduction To Limit State What Is Limit State?rajNoch keine Bewertungen

- Conveyor Belt CalculationDokument14 SeitenConveyor Belt CalculationIman SatriaNoch keine Bewertungen

- Corbon Content Steel 1Dokument75 SeitenCorbon Content Steel 1Aditya GadhaviNoch keine Bewertungen

- 5.1 BearingDokument55 Seiten5.1 Bearingananiya dawitNoch keine Bewertungen

- NMDOT Bridge ProceduresDokument11 SeitenNMDOT Bridge Proceduressiva_civil4051Noch keine Bewertungen

- Unit II Limit State of Collapse-FlexureDokument44 SeitenUnit II Limit State of Collapse-Flexuresrujan jathanNoch keine Bewertungen

- What Are The Different Types of Fits? Explain?Dokument5 SeitenWhat Are The Different Types of Fits? Explain?shaikdesignNoch keine Bewertungen

- DAC Activity-1Dokument27 SeitenDAC Activity-1Samaroha NandiNoch keine Bewertungen

- Two Marks Ce8501Dokument12 SeitenTwo Marks Ce8501myidmaranNoch keine Bewertungen

- Bolted JointsDokument3 SeitenBolted JointsGiuseppe GiuseppeNoch keine Bewertungen

- Further Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionDokument7 SeitenFurther Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionMark SternNoch keine Bewertungen

- 6 Shafts PDFDokument23 Seiten6 Shafts PDFViven SharmaNoch keine Bewertungen

- Me QuestionsDokument21 SeitenMe QuestionsGoutam AcharjeeNoch keine Bewertungen

- Design As Per APIDokument82 SeitenDesign As Per APINeeraj BhallaNoch keine Bewertungen

- Two Marks AT6601Dokument13 SeitenTwo Marks AT6601Naveen Ashrae0% (2)

- Tension Part-2 and CompressionDokument42 SeitenTension Part-2 and Compressionsyed muneeb haiderNoch keine Bewertungen

- Bearing Shaft Fits and Tolerances 1Dokument9 SeitenBearing Shaft Fits and Tolerances 1Arun KumarNoch keine Bewertungen

- Analysis of Neoprene Bearings On Requests and Strains: Gustavo C. Braga, Luiz C. MendesDokument8 SeitenAnalysis of Neoprene Bearings On Requests and Strains: Gustavo C. Braga, Luiz C. MendesPrashantha NandavarNoch keine Bewertungen

- Fip SferopolDokument16 SeitenFip SferopolMarco BenedettiNoch keine Bewertungen

- What Are The Different Types of Fits? Explain?Dokument7 SeitenWhat Are The Different Types of Fits? Explain?Chukkur HaliNoch keine Bewertungen

- Ortlinghaus PlatesDokument19 SeitenOrtlinghaus PlatesErsin KamburoğluNoch keine Bewertungen

- PCDDokument42 SeitenPCDsalman khanNoch keine Bewertungen

- Extrusion Processes: Metal FormingDokument43 SeitenExtrusion Processes: Metal FormingisraelNoch keine Bewertungen

- Minimum Required InterferenceDokument4 SeitenMinimum Required InterferenceParag NaikNoch keine Bewertungen

- Sunu 1Dokument16 SeitenSunu 1Ayca Betul BingolNoch keine Bewertungen

- Bearing FitsDokument9 SeitenBearing Fitsm2110Noch keine Bewertungen

- Critical Load of Slender Elastomeric Seismic IsolatorsDokument7 SeitenCritical Load of Slender Elastomeric Seismic IsolatorsAhmad Basshofi HabiebNoch keine Bewertungen

- A Contribution To The Selection and Calculation of Screws in High Duty Bolted JointsDokument11 SeitenA Contribution To The Selection and Calculation of Screws in High Duty Bolted Jointsخوێندن لە ئەوروپاNoch keine Bewertungen

- Interview Questions and AnswersDokument18 SeitenInterview Questions and AnswersLisa MaloneNoch keine Bewertungen

- Design of Piston HeadDokument7 SeitenDesign of Piston HeadSouradeep BhattacharjaNoch keine Bewertungen

- 2 MarksDokument56 Seiten2 MarksKarthik PandiNoch keine Bewertungen

- Mechanical Engineering Interview Questions and AnswersDokument17 SeitenMechanical Engineering Interview Questions and AnswersprasathbalaNoch keine Bewertungen

- Stress Analysis of Piston Using Pressure Load and Thermal LoadDokument8 SeitenStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- 3-Limits Fits and TolerancesDokument22 Seiten3-Limits Fits and TolerancesAbhay Sharma100% (1)

- Slewing BearingDokument15 SeitenSlewing BearingVenkatesh Kumar100% (1)

- Factors Affecting The Friction Between SurfacesDokument12 SeitenFactors Affecting The Friction Between Surfacesmatealoredana8015Noch keine Bewertungen

- An Sys PaperDokument13 SeitenAn Sys PaperHitesh Kumar PrajapatiNoch keine Bewertungen

- Chapter 1+Casing+12Feb18Dokument47 SeitenChapter 1+Casing+12Feb18Mohamad ZakwanNoch keine Bewertungen

- 4 Shafts and Shaft ComponentsDokument7 Seiten4 Shafts and Shaft ComponentsGino JardinicoNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Pulling Test RecordDokument1 SeitePulling Test RecordwirawanwillyNoch keine Bewertungen

- Simulation 1: Actual Position of A16R & Simulated Elevation of B16L After Stressing & LaunchingDokument2 SeitenSimulation 1: Actual Position of A16R & Simulated Elevation of B16L After Stressing & LaunchingwirawanwillyNoch keine Bewertungen

- Perhitungan Elongasi & Jacking Force: PC-I Girder: H 1.70m, L 24.9m, CTC 1.067m, Tendon 2 X 10 + 2 X 11 42 StrandDokument1 SeitePerhitungan Elongasi & Jacking Force: PC-I Girder: H 1.70m, L 24.9m, CTC 1.067m, Tendon 2 X 10 + 2 X 11 42 StrandwirawanwillyNoch keine Bewertungen

- Run Down - 5th Infrastructure Training (Bridge Design and Engineering)Dokument3 SeitenRun Down - 5th Infrastructure Training (Bridge Design and Engineering)wirawanwillyNoch keine Bewertungen

- Result StressDokument1 SeiteResult StresswirawanwillyNoch keine Bewertungen

- Plan View & Section r1 (2019-08-28) - ModelDokument1 SeitePlan View & Section r1 (2019-08-28) - ModelwirawanwillyNoch keine Bewertungen

- Bridge KunciranDokument4 SeitenBridge KunciranwirawanwillyNoch keine Bewertungen

- Arragemnet Side Closure P206 ModelDokument1 SeiteArragemnet Side Closure P206 ModelwirawanwillyNoch keine Bewertungen

- Bridge KunciranDokument4 SeitenBridge KunciranwirawanwillyNoch keine Bewertungen

- Stress CekDokument15 SeitenStress CekwirawanwillyNoch keine Bewertungen

- P 4Dokument1 SeiteP 4wirawanwilly0% (1)

- Data Stressing 8 Feb - 19 Feb 2013Dokument2 SeitenData Stressing 8 Feb - 19 Feb 2013wirawanwillyNoch keine Bewertungen

- UT Data R1Dokument2 SeitenUT Data R1wirawanwillyNoch keine Bewertungen

- Losses Due To Draw inDokument1 SeiteLosses Due To Draw inwirawanwillyNoch keine Bewertungen

- IsometrikDokument1 SeiteIsometrikwirawanwillyNoch keine Bewertungen

- Braced Cuts (Excavations)Dokument6 SeitenBraced Cuts (Excavations)Rajeev KusugalNoch keine Bewertungen

- ASTMC469 XXXDokument1 SeiteASTMC469 XXXwirawanwillyNoch keine Bewertungen

- Iii. Referensi Peraturan: Delta Systech IndonesiaDokument1 SeiteIii. Referensi Peraturan: Delta Systech IndonesiawirawanwillyNoch keine Bewertungen

- Dywidag: Calculation of Tendon ElongationDokument1 SeiteDywidag: Calculation of Tendon ElongationwirawanwillyNoch keine Bewertungen

- BurstingDokument1 SeiteBurstingwirawanwillyNoch keine Bewertungen

- Iga 1Dokument1 SeiteIga 1wirawanwillyNoch keine Bewertungen

- SummaryDokument1 SeiteSummarywirawanwillyNoch keine Bewertungen

- Perhitungan Elongasi & Jacking Force: PC-I Girder: H 1.70m, L 24.9m, CTC 1.067m, Tendon 2 X 10 + 2 X 11 42 StrandDokument1 SeitePerhitungan Elongasi & Jacking Force: PC-I Girder: H 1.70m, L 24.9m, CTC 1.067m, Tendon 2 X 10 + 2 X 11 42 StrandwirawanwillyNoch keine Bewertungen

- Jak Logi?Lor Fol Roll De'Tii Iafiet D I Stalt+M: ?tojegtDokument1 SeiteJak Logi?Lor Fol Roll De'Tii Iafiet D I Stalt+M: ?tojegtwirawanwillyNoch keine Bewertungen

- Not Substantial DocumentDokument1 SeiteNot Substantial DocumentwirawanwillyNoch keine Bewertungen

- My Document - InknoteDokument1 SeiteMy Document - InknotewirawanwillyNoch keine Bewertungen

- TendoDokument1 SeiteTendowirawanwillyNoch keine Bewertungen

- Perhitungan Elongasi & Jacking Force: ProyekDokument1 SeitePerhitungan Elongasi & Jacking Force: ProyekwirawanwillyNoch keine Bewertungen

- Useful Standard UploadDokument22 SeitenUseful Standard UploadwirawanwillyNoch keine Bewertungen

- SUP032BR: Esp. E74104 Rev.01Dokument5 SeitenSUP032BR: Esp. E74104 Rev.01kimanski01Noch keine Bewertungen

- Chapter 1 - Water Supply System For BuildingsDokument33 SeitenChapter 1 - Water Supply System For BuildingsThế VinhNoch keine Bewertungen

- Roofing SafetyDokument38 SeitenRoofing SafetyDhârâñî KûmârNoch keine Bewertungen

- FireDos For Stationary Extinguishing Systems PDFDokument12 SeitenFireDos For Stationary Extinguishing Systems PDFYadir BojacaNoch keine Bewertungen

- 37.H. P. Khungar Semistic Sternghring of Softsteroy Using DamperDokument1 Seite37.H. P. Khungar Semistic Sternghring of Softsteroy Using DamperPREMALATHA JNoch keine Bewertungen

- 21 Weldability of SteelsDokument40 Seiten21 Weldability of Steelssaeidian100% (2)

- Types of Steel BarsDokument6 SeitenTypes of Steel BarsvitamkupaNoch keine Bewertungen

- Internal Flow: Mehmet KanogluDokument115 SeitenInternal Flow: Mehmet Kanogluizzet9696Noch keine Bewertungen

- Socket Weld Fittings: ASME B16.11-2009 (Revision of ASME B16.11-2005)Dokument1 SeiteSocket Weld Fittings: ASME B16.11-2009 (Revision of ASME B16.11-2005)SIMON S. FLORES G.Noch keine Bewertungen

- Plasticity and Structure of SoilDokument28 SeitenPlasticity and Structure of SoilJazmine ValenzonaNoch keine Bewertungen

- En14511 4 2004Dokument14 SeitenEn14511 4 2004pavlosmicNoch keine Bewertungen

- Sikagrout - 200Dokument3 SeitenSikagrout - 200Tan TounNoch keine Bewertungen

- Acc PSC - NFR - 38 - 2020Dokument1 SeiteAcc PSC - NFR - 38 - 2020kartick adhikaryNoch keine Bewertungen

- Vetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedDokument2 SeitenVetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedSHAIK ASIMUDDINNoch keine Bewertungen

- 2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsDokument31 Seiten2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsEleonora InghelleriNoch keine Bewertungen

- Fittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898Dokument40 SeitenFittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898nidhinNoch keine Bewertungen

- 1D and 2D PlasticityDokument24 Seiten1D and 2D PlasticityChandra ClarkNoch keine Bewertungen

- Analysis of RateDokument6 SeitenAnalysis of Ratehs_civilNoch keine Bewertungen

- Pe Ball Valves: CertusDokument4 SeitenPe Ball Valves: CertusheviNoch keine Bewertungen

- 3450 1 PDFDokument20 Seiten3450 1 PDFKen WalkerNoch keine Bewertungen

- Definitions and Nomenclature in Exergy Analysis and ExergoeconomicsDokument5 SeitenDefinitions and Nomenclature in Exergy Analysis and ExergoeconomicsGhassen KhalilNoch keine Bewertungen

- 444 ProjectDokument12 Seiten444 ProjectRafeeq WazirNoch keine Bewertungen

- Precedent Reliatel WiringDokument64 SeitenPrecedent Reliatel WiringMihai IavorschiNoch keine Bewertungen

- Premium Wall Mounted SeriesDokument5 SeitenPremium Wall Mounted SeriesjohnNoch keine Bewertungen

- Ice Amice SyllabusDokument57 SeitenIce Amice SyllabusBIJAY KRISHNA DAS100% (1)

- Triple Only Static ElectricityDokument32 SeitenTriple Only Static ElectricityMary Ann MaherNoch keine Bewertungen

- Names of All Materials WRT ASTM No.Dokument6 SeitenNames of All Materials WRT ASTM No.روشان فاطمة روشانNoch keine Bewertungen

- Cadenas Big Dutchman ChampionDokument4 SeitenCadenas Big Dutchman ChampionMichelle PedrozaNoch keine Bewertungen

- Ac Dur Sba G PDFDokument2 SeitenAc Dur Sba G PDFbhagwatpatilNoch keine Bewertungen

- Sabiana FC CRCDokument23 SeitenSabiana FC CRCIgor SpasovicNoch keine Bewertungen