Beruflich Dokumente

Kultur Dokumente

Zimbabwe 132kV Switching Guidelines

Hochgeladen von

Archiford NdhlovuOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Zimbabwe 132kV Switching Guidelines

Hochgeladen von

Archiford NdhlovuCopyright:

Verfügbare Formate

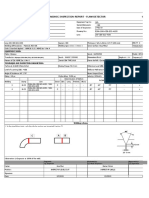

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page1 of 11

Appendix 1

132kV Switching Authorisation Guidelines

1.0 Minimum Requirements for Switching Authorisation for voltages Up to and including

132kV:

1.1. This document is listing down the minimum requirements for one to be ready for

an authorisation test. The requirements are grouped as follows:

- Practical Application of Safety rules.

- Knowledge and identification of Equipment.

- Knowledge and interpretation of protection schematics and control

diagrams.

- Knowledge of System Operation Memorandum.

- Practical switching.

2. Safety Rules

2.1. Purpose of the electrical safety rules

2.1.1. The need for electrical safety rules.

2.1.2. Understand how people contracted to work in ZESA installations are

covered by the Safety rules.

2.2. Competent and senior Authorised Persons.

2.2.1. Age limit for a competent person.

2.2.2. Understand why a competent person should have sufficient Technical.

knowledge and experiences. Competence of a first year Appy!.

2.2.3. Difference between Snr Authoriesd and Competent Person.

2.2.4. The competence of contractors.

2.3. Controller

2.3.1. The need for controller.

2.3.2. Handing over temporary control of a piece of equipment to senior

Authorised person on the field.

2.4. Switching

2.4.1. Personnel qualified do switching.

2.4.2. Emergency switching

2.4.3. Recording of switching

2.4.4. Writing switching instructions

2.4.5. Application of CME

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page2 of 11

Appendix 1

2.4.6. Writing switching instructions

2.5. Safety Documents

2.5.1. The need for safety documents

2.5.2. Differences between PTW, LLPTW, SFT, and LOA.

2.5.3. Reasons for issuing a SFT to a Senior Authorised Person and not to

Competent person

2.5.4. Indirect Issue of PMT.

2.5.5. Number of PMT, SFT and LOA, which can be issued on one piece of

Equipment.

2.5.6. Conditions that have to be satisfied when one decides to use a permit to

work as a test document.

2.5.7. Under Stand the concept of suspension and resumption of work on

LLPTW

2.6. Methods of discharging high voltage equipment.

2.6.1. The need for discharging equipment.

2.6.2. Circuit Main Earth.

2.6.3. Reasons for not removing CME until after the safety documents

have been cancelled.

2.6.4. Additional Earths.

2.6.5. Use of earthing switches.

2.6.6. Interlocks and their importance.

2.6.7. Use of Portable Earthing leads.

2.6.8. Use of an Earthing truck

2.6.9. Use of Circuit Breakers.

2.6.10. Precautions taken when using the above for Earthing purposes.

2.6.11. A procedure for applying Earthing leads.

2.7. Safety Clearances to live conductors

2.7.1 minimum clearances

2.7.2 point of reference

2.8. Conditions for working on High Voltage Plant and Equipment

2.8.1. Step to be met before one can work on high voltage equipment.

2.8.2. Explain why when equipment is DEAD - is not necessarily at Zero

potential.

2.8.3. Differences between a danger and caution notice.

2.8.4. Screening, where and how danger and caution notices are applied.

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page3 of 11

Appendix 1

2.9. Work on wooden poles carrying an overhead line.

2.9.1. Importance of safety belts and safety clothing.

2.9.2. Reasons for sounding the pole before it is climbed.

2.9.3. Reason for a person on a pole to be in visual range of second person

on the ground.

2.9.4. Work on poles carrying double circuits.

2.9.5. Work on poles supporting HV and LV for the purpose of working on the

LV circuit.

2.10. Work on Towers

2.10.1. Towers with all conductors dead.

2.10.2. Towers carrying live conductors.

2.10.3. Double circuit towers with one circuit live.

2.10 Work on High Voltage Cables

2.10.1 Methods of identifying the cable to be worked on.

2.11 Work on underground chambers and Cable gallaries.

2.11.1 Detection of gases and extraction of gases.

2.11.2 Reasons for prohibiting smoking and exposed flames.

2.11.3 Reasons for keeping one person outside the chamber when others are

working inside the chamber where dangerous gases are likely to be

present.

2.12 Work on High Voltage Equipment Containing Compressed air.

2.12.1 Closing and locking on off on closed position valves controlling the

supply of air to the plant.

2.13 Work on High Voltage Equipment Containing SF6 Gas

2.13.1 Isolating equipment from source of SF6

2.13.2 Locking on closed position of inlet and application of caution notices to

valves.

2.13.3 Reasons for use of approved clothing, respirators etc.

2.14 Work on oil Tanks

2.14.1 Need for ventilation

2.14.2 Prohibition of smoking and exposed flames inside the tank.

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page4 of 11

Appendix 1

2.15 Treatment of Electric Shock.

2.15.1 Making sure its safe to approach the casualty.

2.15.2 Emergency switching

2.15.3 First aid

3 Equipment and Equipment identification

3.1 POWER SYSTEM FAULTS

3.1.1 Types of faults

3.1.1.1 Phase-to- ground ( or single phase )

3.1.1.2 Phase-to-phase ( or Two phase )

3.1.1.3 Phase-to-phase-to- ground ( or Two phase-to-ground )

3.1.1.4 Three phase, with or without ground

3.1.1.5 Open-Circuit

3.1.2 Faults on Transformers, switchgear and cables

3.1.2.1 Short-circuits between turns of windings of transformers.

3.1.2.2 Failure of solid Insulation.

3.1.2.3 Contamination of insulating.

3.1.2.4 Effect of oil leakage on transformers and cables.

3.1.2.5 Common causes of faults on transformers, metal clad switchgear and

Cables

3.1.2.5.1 Failure of insulation because of moisture.

3.1.2.5.2 Mechanical damage.

3.1.2.5.3 Flashover caused by overvoltage or abnormal loading.

3.1.2.5.4 Snake, lizards and Rats on bushings of transformers and on

busbars on metalglad switchgears.

3.1.3 Faults on overhead transmission lines.

3.1.3.1 Flashovers as a result of break down of air insulation between phase to

phase or phase to earth.

3.1.3.2 Common causes of the faults on overhead lines

3.1.3.2.1 Lightning

3.1.3.2.2 Contaminated Insulators

3.1.3.2.3 Punctured or broken insulators

3.1.3.2.4 Birds and animals

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page5 of 11

Appendix 1

3.1.3.2.5 Aircraft and cars hitting lines and structures

3.1.3.2.6 Wind

3.1.3.2.7 Vandalism

3.1.3.3 Auto- reclosing on overhead transmission lines or feeders.

3.1.3.3.1 Effect of interrupting a flashover and reasons for introducing

an intentional time delay before auto- reclosing.

3.2 DETECTION OF FAULTS

3.2.1 Identification of Protection Schemes

3.2.1.1 Transformer Protection

3.2.1.1.1 Overcurrent

3.2.1.1.1.1 Instantaneous O/C.

3.2.1.1.1.2 Time delayed O/C.

3.2.1.1.1.3 Types of faults covered by O/C relays.

3.2.1.1.1.4 Time and plug settings.

3.2.1.1.2 Earth Fault

3.2.1.1.2.1 Restricted E/f (REF).

3.2.1.1.2.2 Types of faults covered by REF.

3.2.1.1.2.3 Neutral Earthfault.

3.2.1.1.2.4 Time and Plug settings.

3.2.1.1.3 Differential Protection (Duo bias)

3.2.1.1.3.1 Basic principle of operation.

3.2.1.1.3.2 Types of faults covered by Duo bias.

3.2.1.1.3.3 Zone covered by Duo bias.

3.2.1.1.4 Bulchholz relay

3.2.1.1.4.1 Basic principle of operation.

3.2.1.1.4.2 Buchholz Alarm.

3.2.1.1.4.3 Buchholz Surge.

3.2.1.1.4.4 Types of faults coverd by Buchholz relay.

3.2.1.1.5 Overload protection

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page6 of 11

Appendix 1

3.2.1.1.5.1 Oil temperature alarm and trip.

3.2.1.1.5.2 Winding temperature alarm and trip.

3.2.1.1.5.3 Alarm and trip setting.

3.2.1.2 Over head Line and Cable protection

3.2.1.2.1 Overcurrent.

3.2.1.2.1.1 Instantaneous O/C.

3.2.1.2.1.2 Time delayed O/C.

3.2.1.2.1.3 Types of faults covered by O/C relays.

3.2.1.2.1.4 Time and plug settings.

3.2.1.2.1.5 Earthfault

3.2.1.2.1.5.1 Residual Earthfault connection.

3.2.1.2.1.5.2 Time and plug settings.

3.2.1.2.1.6 Feeder Unit protection (Solkor).

3.2.1.2.1.6.1 Basic principle of operation.

3.2.1.2.1.6.2 Protected Zone.

3.2.1.2.1.6.3 Effect of short circuiting pilots.

3.2.1.2.1.6.4 Effect of opening pilots.

3.2.1.2.1.6.5 Pilot supervision relays.

3.2.1.2.1.7 Distance Protection.

3.2.1.2.1.7.1 Basic principle of operation.

3.2.1.2.1.7.2 Under standing of Zones.

3.2.1.2.1.7.2.1 Zone 1 reach and instantaneous trip.

3.2.1.2.1.7.2.2 Zone 2 reach and time delay.

3.2.1.2.1.7.3 Acceleration or permissive channel.

3.2.1.2.1.8 Busbar protection

3.2.1.2.1.8.1 Basic principle of operation.

3.2.1.2.1.8.2 Protected Zones.

3.2.1.2.1.9 Overvoltage protection.

3.2.1.2.1.9.1 Surge divertors.

3.2.1.2.1.9.2 Lightning arrestors.

3.2.1.2.1.9.3 Arcing horns.

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page7 of 11

Appendix 1

3.2.1.3 Analysis of Relay operation

3.2.1.3.1 Main protection and backup protection.

3.2.1.3.1.1 Transformers

3.2.1.3.1.1.1 Identifying main protection.

3.2.1.3.1.1.2 Steps to be taken when a transformer comes out on

main protection.

3.2.1.3.1.1.3 Identifying backup protection.

3.2.1.3.1.1.4 Steps to be taken when a transformer comes out on

backup protection.

3.2.1.3.1.2 Overhead Lines and Cable

3.2.1.3.1.2.1 Identifying main protection.

3.2.1.3.1.2.2 Steps to be taken when an overhead line comes out

on main protection.

3.2.1.3.1.2.3 Backup protection.

3.2.1.3.1.2.4 Steps to be taken when a line comes out on backup

protection.

3.3 Identification of General Substation Equipment

3.3.1 Substation general layout

3.3.1.1 Identify Hazards to personnel working in High voltage

substations.

3.3.1.1.1 Explain what is :

3.3.1.1.1.1 Step Voltage

3.3.1.1.1.2 Touch Voltage

3.3.1.1.1.3 Transferred voltage

3.3.1.1.2 The reasons for putting crashed stones in a substation.

3.3.1.1.3 Precautions to be taken when carrying out switching in a high

voltage substation.

3.3.1.2 Identify the general layout of the substation

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page8 of 11

Appendix 1

3.3.1.2.1 Main reserve busbars

3.3.1.2.1.1 Explain the Reasons for having the main and reserve

busbars.

3.3.1.2.2 Isolators

3.3.1.2.2.1 Explain the purpose of an isolator and when it can be

closed or opened.

3.3.1.2.2.2 Identify auxiliary contacts and explain what they are used

for.

3.3.1.2.2.3 Explain how interlocking is achieved.

3.3.1.2.3 Circuit breakers

3.3.1.2.3.1 Identify types of CBs in a substation

3.3.1.2.3.2 Identify quenching medium.

3.3.1.2.3.3 Explain the CB operating mechanism

3.3.1.2.3.4 Identify the Rating of a CB

3.3.1.2.3.5 Identify interlocks with other equipment

3.3.1.2.3.6 Identify CB control features and explain the local and

Remote control of a CB.

3.3.1.2.3.7 Identify tripping and closing coil. Explain why the tripping

coil is a critical element on the breaker.

3.3.1.2.3.8 Explain how you can operate a breaker that has lost its

quenching media in the interrupter.

3.3.1.2.4 Lines and Cables

3.3.1.2.4.1 Identify size and rating of the conductor or cable.

3.3.1.2.4.2 Identify Line construction types

3.3.1.2.4.3 Identify ring circuits and explain the advantages and

disadvantages of ring circuits.

3.3.1.2.4.4 Identify alternative feeds and routes to various substations.

3.3.1.2.5 Transformers

3.3.1.2.5.1 Identify a tapchanger and explain the difference between a

on-load tapchanging and off-load tapchanging.

3.3.1.2.5.2 Identify the buchhoz relay and explain why it is mounted

on the top pipes to the conservator.

3.3.1.2.5.3 Explain the purpose of a conservator.

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page9 of 11

Appendix 1

3.3.1.2.5.4 Explain why the tapchanger and main transformer windings

should have different chambers.

3.3.1.2.5.5 Identify rating and winding configuration of transformer.

3.3.1.2.5.6 Identify temperature gauge and settings.

3.3.1.2.5.7 Identify the flow of oil in the radiator and cooling method.

3.3.1.2.5.8 Explain the purpose of a breather and of an oil bath.

3.3.1.2.5.9 Identify the vector group of a transformer and explain the

condition necessary for paralleling two transformers.

3.3.1.2.6 Transformer Neutral Grounding

3.3.1.2.6.1 Identify and describe methods of grounding used on HV or

LV of distribution high voltage transformers.

3.3.1.2.6.2 Explain the necessity of grounding the neutral.

3.3.1.2.7 Current Transformers

3.3.1.2.7.1 Identify and describe the purpose of CTs.

3.3.1.2.7.2 Identify the ratio and rating of a CT

3.3.1.2.7.3 Explain why a metering CT cannot be used for protection

protection purposes.

3.3.1.2.7.4 Describe various commissioning Tests that must be

performed on a CT.

3.3.1.2.7.5 Explain why a CT in service should not be open-circuited.

3.3.1.2.8 Voltage Transformers

3.3.1.2.8.1 Identify and describe the purpose of VTs.

3.3.1.2.8.2 Identify the ratio and rating of a VT

3.3.1.2.8.3 Difference between an ordinary VT and CVT.

3.3.1.2.8.4 Explain why a VT cannot be used as an auxiliary supply

source for the substation.

3.3.1.2.8.5 Explain why a VT in service should not be Short-circuited.

3.3.1.2.9 Line Traps

3.3.1.2.9.1 Identify the components and describe the purposes of a line

trap.

3.3.1.2.9.2 Explain how the power line carrier system works.

3.3.1.2.10 Substation Remote Terminal Units and Radio

3.3.1.2.10.1 Identify and explain the purpose of an RTU and a

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page10 of 11

Appendix 1

Radio in a substation.

3.3.1.2.10.2 Explain how an RTU or Radio is reset.

3.3.1.3 Identify the control room layout and components

3.3.1.3.1 Control panel

3.3.1.3.1.1 Identify and explain how switchgear is operated from the

control room.

3.3.1.3.1.2 Explain how you can check for healthy trip indication and

the necessity to check.

3.3.1.3.1.3 Interpretation and action to be taken on receipt of alarms on

the control panel.

3.3.1.3.2 Relay Panel

3.3.1.3.2.1 Identify the protection and auxiliary relays in a panel.

3.3.1.3.2.2 Explain how you can check for healthy trip indication and

the necessity to check.

3.3.1.3.2.3 Identify the sequence in which relays should be reset.

3.3.1.3.3 Tapchanger control Panel

3.3.1.3.3.1 Identify the AVE relay and explain how the settings can be

changed and the reasons.

3.3.1.3.3.2 Identify and explain various Tapchanger controls and

selector switches.

3.3.1.3.4 Batteries and Battery chargers.

3.3.1.3.4.1 Differentiate between protection and communication

batteries.

3.3.1.3.4.2 Explain the purpose of batteries and chargers.

3.3.1.3.4.3 Identify the type of battery and no of cells.

3.3.1.3.4.4 Identify the rating and capacity of the battery.

3.3.1.3.4.5 Identify the components of a battery charger.

3.3.1.3.4.6 Alarms affecting batteries.

3.3.1.4 Interpreting control and wiring schematics

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

ZIMBABWE ELECTRICITY SUPPLY AUTHORITY

WESTERN AREA

132kV SWITCHING AUTHORISATION TRAINING PROGRAM

DOC No.

Copy: 1 Page11 of 11

Appendix 1

3.3.1.4.1 Distinguish and be able to interpret an AC and DC schematics

3.3.1.4.2 Identify symbols used on control and wiring schematics.

3.3.1.4.3 Understand the sequence of events.

3.4 Understand and Interpret System Operation Memorandum

3.4.1 Demarcations of area of control.

4.0 Practical Switching.

4.1 System Paralleling

4.1.1 Paralleling of Transformers in the same substation

4.1.1.1 Understand procedures to be followed on NTC or OLTC

transformers.

4.1.2 Feeder paralleling between 2 substations.

4.1.2.1 Understand procedures to be followed.

4.2 Complete Isolation of a transformer

4.2.1 Understand procedures to be followed.

4.3 Feeder By-pass

4.3.1 Understand procedures to be followed.

4.4 Complete Isolation of a feeder

4.4.1 Understand procedures to be followed.

4.5 Fault detection and Isolation of faults on ring circuits.

4.5.1 Understand procedures to be followed.

4.6 Switching for Live line maintenance

4.6.1 Understand procedures to be followed.

Prepared by: N. Revision Status: 0

Bukwele

Date: 3 September 1999 Signature: Date: Issue Date:

Das könnte Ihnen auch gefallen

- Naruto Vol 4Dokument171 SeitenNaruto Vol 4Andrew WongNoch keine Bewertungen

- Commercial Transformers: Type VR-1™ Single-Phase Step Type RegulatorsDokument32 SeitenCommercial Transformers: Type VR-1™ Single-Phase Step Type RegulatorsJohnatan HernándezNoch keine Bewertungen

- Technical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationDokument30 SeitenTechnical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationS.M.Touhidur RahmanNoch keine Bewertungen

- Sepam 10 User ManualDokument260 SeitenSepam 10 User ManualFelix Terres100% (2)

- Calculating Fault CurrentDokument8 SeitenCalculating Fault Currentenghassanain6486Noch keine Bewertungen

- Trafo RTCCDokument363 SeitenTrafo RTCCKrishna Chandavar0% (1)

- UKBP - TP106.16-Model Commissioning Documentation Filing ArrangementsDokument2 SeitenUKBP - TP106.16-Model Commissioning Documentation Filing ArrangementsScott NewtonNoch keine Bewertungen

- 11 KV VCB PanelDokument29 Seiten11 KV VCB PanelPrakash Rout100% (6)

- Manual Hardware FanucDokument445 SeitenManual Hardware Fanuced_guaitolini2161100% (2)

- Manual Hardware FanucDokument445 SeitenManual Hardware Fanuced_guaitolini2161100% (2)

- Determine synchronous machine impedancesDokument5 SeitenDetermine synchronous machine impedancesarjuna4306Noch keine Bewertungen

- M-Cubed 100 - Installation - Procedure - R1.18Dokument38 SeitenM-Cubed 100 - Installation - Procedure - R1.18Shrigonda Cogeneration100% (1)

- 1168 E Smart Grid Trainer Electrical Power Engineering Short PDFDokument191 Seiten1168 E Smart Grid Trainer Electrical Power Engineering Short PDFClaudiu NicolaeNoch keine Bewertungen

- User Manual Accuchek ERS MeterDokument39 SeitenUser Manual Accuchek ERS MeterBashir Ahmad100% (5)

- Is Limiter Overview PresentationDokument23 SeitenIs Limiter Overview PresentationGobinath BalasubramanianNoch keine Bewertungen

- HV Switching ProcedureDokument6 SeitenHV Switching Procedurekyawswarpm100% (3)

- 8DA11 ManualDokument136 Seiten8DA11 ManualCostin DavidoiuNoch keine Bewertungen

- Safe6 Hpa InstrucitonsDokument63 SeitenSafe6 Hpa Instrucitonsphelo1Noch keine Bewertungen

- VIP300 Protection Relay For Ringmaster MGMV5477Dokument24 SeitenVIP300 Protection Relay For Ringmaster MGMV5477Ibrahim NashidNoch keine Bewertungen

- OLTC Control Diagram PDFDokument20 SeitenOLTC Control Diagram PDFThant ZinNoch keine Bewertungen

- Electrical Interview QuestionsDokument26 SeitenElectrical Interview Questionsprathikgala2324234Noch keine Bewertungen

- Inspection AND Test Procedures 7.6.4 Circuit Breakers, SFDokument7 SeitenInspection AND Test Procedures 7.6.4 Circuit Breakers, SFCarlos AguiarNoch keine Bewertungen

- Training Report On Switchgears and ProtectionDokument80 SeitenTraining Report On Switchgears and ProtectionThulasi NarendranNoch keine Bewertungen

- Smart Grid Manual Exp.1Dokument6 SeitenSmart Grid Manual Exp.1DineshKanawat100% (1)

- 11kV Switchgear SchemesDokument17 Seiten11kV Switchgear SchemesEdciel EbuenNoch keine Bewertungen

- Operating Instructions for DGC-11 Digital Genset ControllerDokument15 SeitenOperating Instructions for DGC-11 Digital Genset Controllergigo_dreamNoch keine Bewertungen

- Ukbp TP109Dokument51 SeitenUkbp TP109Arun das100% (1)

- Protection Relays TrainingDokument5 SeitenProtection Relays Trainingrajpre1213Noch keine Bewertungen

- SIFANG - CSC-2000 (V2) Substation Automation System Product Guide (0SF.492.071E) - V1.0Dokument145 SeitenSIFANG - CSC-2000 (V2) Substation Automation System Product Guide (0SF.492.071E) - V1.0MarkusKunNoch keine Bewertungen

- 110V - BDT - O&M Manual PDFDokument412 Seiten110V - BDT - O&M Manual PDFJos100% (3)

- Primary Checkpoint - Science (0846) October 2016 Paper 2 MSDokument12 SeitenPrimary Checkpoint - Science (0846) October 2016 Paper 2 MSdinakarc78% (9)

- RCW Recloser Installation ManualDokument9 SeitenRCW Recloser Installation ManualCesar VenturoNoch keine Bewertungen

- Event Logger, Distrubance Recorder and Fault LocatorDokument12 SeitenEvent Logger, Distrubance Recorder and Fault LocatorShila Nightingale Chittu100% (1)

- Singular and Plural NounsDokument3 SeitenSingular and Plural NounsJosé BulquesNoch keine Bewertungen

- NR Pcs 9691 Overcurrent Management Relay Instruction ManualDokument139 SeitenNR Pcs 9691 Overcurrent Management Relay Instruction Manualgebeyehu100% (1)

- Abinitio Interview QuesDokument30 SeitenAbinitio Interview QuesVasu ManchikalapudiNoch keine Bewertungen

- Bhuvanesh A. Oza - Power System Protection and Switchgear (2011, Tata McGraw-Hill Education Private LTD)Dokument488 SeitenBhuvanesh A. Oza - Power System Protection and Switchgear (2011, Tata McGraw-Hill Education Private LTD)Hiral Hingol75% (4)

- Teleprotection Equipment ManualDokument71 SeitenTeleprotection Equipment ManualThạch TháiNoch keine Bewertungen

- 3AK6 VCB Tech Description PDFDokument3 Seiten3AK6 VCB Tech Description PDFArunava Basak50% (2)

- EA 4.2C Kenya Distribution Master Plan, 2013 PDFDokument598 SeitenEA 4.2C Kenya Distribution Master Plan, 2013 PDFJonathan ColeNoch keine Bewertungen

- Zimbabwe 132kV Switching GuidelinesDokument11 SeitenZimbabwe 132kV Switching GuidelinesArchiford Ndhlovu100% (1)

- Fundamentals of Protection Practice: Network Protection & Automation GuideDokument589 SeitenFundamentals of Protection Practice: Network Protection & Automation GuideShailesh Chetty100% (1)

- High Voltage Switching SheetDokument2 SeitenHigh Voltage Switching SheetKrishna Jasha50% (2)

- Typical Authorisation Test QuestionsDokument11 SeitenTypical Authorisation Test QuestionsArchiford NdhlovuNoch keine Bewertungen

- Electrical Design Training Course PDFDokument5 SeitenElectrical Design Training Course PDFconsultnadeem7067% (3)

- Siemens 8DA10Dokument64 SeitenSiemens 8DA10Jhon Sanchez ChNoch keine Bewertungen

- 21-06-2017 16-45-31 - MCOMP - Protection Relays - Manual PDFDokument249 Seiten21-06-2017 16-45-31 - MCOMP - Protection Relays - Manual PDFmehtaabhi99_27916695Noch keine Bewertungen

- User Manual-PM - PE5120Dokument47 SeitenUser Manual-PM - PE5120NM Group50% (2)

- Industrial Training ReportDokument82 SeitenIndustrial Training ReportThulashan SakalasuriyaNoch keine Bewertungen

- Atv1200 Installation Manual en st03196 01Dokument52 SeitenAtv1200 Installation Manual en st03196 01adum turnipNoch keine Bewertungen

- Explanation of RoutineTests For FATs On Current Transformers According To IEC 60044Dokument6 SeitenExplanation of RoutineTests For FATs On Current Transformers According To IEC 60044Hung VuNoch keine Bewertungen

- ASR Commissioning ChecklistDokument11 SeitenASR Commissioning Checklistdinkarbhel67% (3)

- Installation Manual M1M 12Dokument2 SeitenInstallation Manual M1M 12Ruben Arredondo Corpus100% (1)

- Testing of Current Relay, Voltage Relay, PTC Relay, OLP & CapacitorDokument5 SeitenTesting of Current Relay, Voltage Relay, PTC Relay, OLP & Capacitorsantosh Indulkar100% (2)

- ZAHRA Product CatalogueDokument76 SeitenZAHRA Product Catalogueraza23967% (3)

- PLC Training Kit Omron CPM1ADokument1 SeitePLC Training Kit Omron CPM1Alaihingkok9071Noch keine Bewertungen

- 7SG14 - Duobias M Complete Technical Manual PDFDokument142 Seiten7SG14 - Duobias M Complete Technical Manual PDFsteve_osullivanNoch keine Bewertungen

- PCS-902S - X - DataSheet - EN - Overseas General - X - R1.00Dokument52 SeitenPCS-902S - X - DataSheet - EN - Overseas General - X - R1.00Marcio BonfimNoch keine Bewertungen

- Manual Book Soft Starter Renle JJR8000Dokument70 SeitenManual Book Soft Starter Renle JJR8000Herie HeriadieNoch keine Bewertungen

- CPP Ballynahulla Rev6Dokument53 SeitenCPP Ballynahulla Rev6Scott NewtonNoch keine Bewertungen

- System Protections and Uses of Switchgear Devices in Distrbution SubstationsDokument82 SeitenSystem Protections and Uses of Switchgear Devices in Distrbution SubstationsPrem AzimNoch keine Bewertungen

- Tariff Metering PanelsDokument2 SeitenTariff Metering PanelsSaraswatapalitNoch keine Bewertungen

- Firmware Manual ACS850 Standard Control ProgramDokument296 SeitenFirmware Manual ACS850 Standard Control Programen_deepak100% (1)

- 2 Standard - Operating - Procedures-ELECTRICAL - 27072010 - Final - Sent - To - Zones - Muthyam.29.09.10Dokument33 Seiten2 Standard - Operating - Procedures-ELECTRICAL - 27072010 - Final - Sent - To - Zones - Muthyam.29.09.10VijayNoch keine Bewertungen

- NZECP 11 1993 New Zealand Electrical Code of Practice For Inspection and Testing of Low Voltage Installations For Certification Purposes PDFDokument16 SeitenNZECP 11 1993 New Zealand Electrical Code of Practice For Inspection and Testing of Low Voltage Installations For Certification Purposes PDFAHMED YOUSEFNoch keine Bewertungen

- KOC-E-004 Pt. 2Dokument18 SeitenKOC-E-004 Pt. 2Nagarajakumar DNoch keine Bewertungen

- Paper - Protection of MV - LV Substation TransformerDokument37 SeitenPaper - Protection of MV - LV Substation TransformerWalter Castellanos VilcaNoch keine Bewertungen

- Cahiertechnique N 1 9 2: Protection of MV/LV Substation TransformersDokument37 SeitenCahiertechnique N 1 9 2: Protection of MV/LV Substation TransformersonyiabNoch keine Bewertungen

- ADB (MCR5000) - Manual - MultiwireDokument129 SeitenADB (MCR5000) - Manual - Multiwirecosteniuc75% (4)

- Advanced Excel: Multiple WorksheetsDokument9 SeitenAdvanced Excel: Multiple WorksheetsGajendra TodakarNoch keine Bewertungen

- EBPro Manual All in One en EasybuilderDokument770 SeitenEBPro Manual All in One en EasybuilderArchiford NdhlovuNoch keine Bewertungen

- Calibration Essentials Temperature Ebook PDFDokument53 SeitenCalibration Essentials Temperature Ebook PDFpk250385Noch keine Bewertungen

- Calibration Essentials Temperature Ebook PDFDokument53 SeitenCalibration Essentials Temperature Ebook PDFpk250385Noch keine Bewertungen

- Interview Princ Tech Aug555568Dokument1 SeiteInterview Princ Tech Aug555568Archiford NdhlovuNoch keine Bewertungen

- Series 90-30 PLC Installation and Hardware Manual PDFDokument450 SeitenSeries 90-30 PLC Installation and Hardware Manual PDFCleiton de Oliveira FlauzinoNoch keine Bewertungen

- Industrial AutomationDokument38 SeitenIndustrial Automationatanas penovNoch keine Bewertungen

- MatrikonOPC Server For GE PLCs User ManualDokument193 SeitenMatrikonOPC Server For GE PLCs User ManualMichael Adu-boahenNoch keine Bewertungen

- U2 Thyristor Open Circuit Troubleshooting 23 - Jan - 2019Dokument15 SeitenU2 Thyristor Open Circuit Troubleshooting 23 - Jan - 2019Archiford NdhlovuNoch keine Bewertungen

- Guide To Safety Relays and Safety CircuitsDokument9 SeitenGuide To Safety Relays and Safety CircuitsArchiford NdhlovuNoch keine Bewertungen

- CODE OF CONDUCT 2013 With Grivience Handling Procedures PDFDokument42 SeitenCODE OF CONDUCT 2013 With Grivience Handling Procedures PDFArchiford NdhlovuNoch keine Bewertungen

- Kariba South Power StationDokument1 SeiteKariba South Power StationArchiford NdhlovuNoch keine Bewertungen

- Indg232 PDFDokument6 SeitenIndg232 PDFmuhammadsuhaibNoch keine Bewertungen

- Automation Interposing Relays Wiring SchematicsDokument5 SeitenAutomation Interposing Relays Wiring SchematicsArchiford NdhlovuNoch keine Bewertungen

- Automation Interposing Relays Wiring SchematicsDokument44 SeitenAutomation Interposing Relays Wiring SchematicsArchiford NdhlovuNoch keine Bewertungen

- Profibus Cable, Connector and Termination TipsDokument8 SeitenProfibus Cable, Connector and Termination TipsArchiford NdhlovuNoch keine Bewertungen

- Multicore Cable Schedule 21-12-01Dokument14 SeitenMulticore Cable Schedule 21-12-01Archiford NdhlovuNoch keine Bewertungen

- Layout For Staion Aoutromation Aulisirires WiringDokument10 SeitenLayout For Staion Aoutromation Aulisirires WiringArchiford NdhlovuNoch keine Bewertungen

- Zimbabwe Electricity Supply Authority: Internal CorrespondenceDokument3 SeitenZimbabwe Electricity Supply Authority: Internal CorrespondenceArchiford NdhlovuNoch keine Bewertungen

- Multicore Cable Schedule 14-11-01x2Dokument14 SeitenMulticore Cable Schedule 14-11-01x2Archiford NdhlovuNoch keine Bewertungen

- Switchyard PicturesDokument4 SeitenSwitchyard PicturesArchiford NdhlovuNoch keine Bewertungen

- Inputs and Output AllocationsDokument6 SeitenInputs and Output AllocationsArchiford NdhlovuNoch keine Bewertungen

- Multicore Cable Schedule 15-9-01Dokument16 SeitenMulticore Cable Schedule 15-9-01Archiford NdhlovuNoch keine Bewertungen

- Pilot Cables For AutomationDokument20 SeitenPilot Cables For AutomationArchiford NdhlovuNoch keine Bewertungen

- Kariba South Power Station Unit 4 Commissioning ReportDokument1 SeiteKariba South Power Station Unit 4 Commissioning ReportArchiford NdhlovuNoch keine Bewertungen

- Coca Cola Live-ProjectDokument20 SeitenCoca Cola Live-ProjectKanchan SharmaNoch keine Bewertungen

- ADD MATH ProjectDokument13 SeitenADD MATH Projectmegazat27Noch keine Bewertungen

- Entrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Dokument35 SeitenEntrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Ameen KolachiNoch keine Bewertungen

- WFP-Remote Household Food Security Survey Brief-Sri Lanka Aug 2022Dokument18 SeitenWFP-Remote Household Food Security Survey Brief-Sri Lanka Aug 2022Adaderana OnlineNoch keine Bewertungen

- Ut ProcedureDokument2 SeitenUt ProcedureJJ WeldingNoch keine Bewertungen

- Certification of Psychology Specialists Application Form: Cover PageDokument3 SeitenCertification of Psychology Specialists Application Form: Cover PageJona Mae MetroNoch keine Bewertungen

- CEA-2010 by ManishDokument10 SeitenCEA-2010 by ManishShishpal Singh NegiNoch keine Bewertungen

- MRI Week3 - Signal - Processing - TheoryDokument43 SeitenMRI Week3 - Signal - Processing - TheoryaboladeNoch keine Bewertungen

- #1Dokument7 Seiten#1Ramírez OmarNoch keine Bewertungen

- GTA Max Profit Bunker Locations Update v1.4Dokument1 SeiteGTA Max Profit Bunker Locations Update v1.4Sam FarrelNoch keine Bewertungen

- User Manual - Rev3Dokument31 SeitenUser Manual - Rev3SyahdiNoch keine Bewertungen

- Future War in Cities Alice Hills PDFDokument5 SeitenFuture War in Cities Alice Hills PDFazardarioNoch keine Bewertungen

- Dinflo DFCSDokument2 SeitenDinflo DFCSvictorharijantoNoch keine Bewertungen

- Lehman BrothersDokument10 SeitenLehman BrothersJaikishin RuprajNoch keine Bewertungen

- Vortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimDokument7 SeitenVortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimhiraNoch keine Bewertungen

- Laptop repair messageDokument3 SeitenLaptop repair messagePonpes Manbaul MaarifNoch keine Bewertungen

- Data Structures LightHall ClassDokument43 SeitenData Structures LightHall ClassIwuchukwu ChiomaNoch keine Bewertungen

- Lesson Plan Earth & SpaceDokument5 SeitenLesson Plan Earth & SpaceSol Vega PagdangananNoch keine Bewertungen

- Viviana Rodriguez: Education The University of Texas at El Paso (UTEP)Dokument1 SeiteViviana Rodriguez: Education The University of Texas at El Paso (UTEP)api-340240168Noch keine Bewertungen

- JMC250Dokument2 SeitenJMC250abhijit99541623974426Noch keine Bewertungen

- Vestax VCI-380 Midi Mapping v3.4Dokument23 SeitenVestax VCI-380 Midi Mapping v3.4Matthieu TabNoch keine Bewertungen

- Oxyacetylene Welding (OAW)Dokument26 SeitenOxyacetylene Welding (OAW)athyrahNoch keine Bewertungen

- Aluminium FOil SearchDokument8 SeitenAluminium FOil SearchAtul KumarNoch keine Bewertungen

- Television: Operating InstructionsDokument40 SeitenTelevision: Operating InstructionsNitin AgrawalNoch keine Bewertungen

- Importance of Geometric DesignDokument10 SeitenImportance of Geometric DesignSarfaraz AhmedNoch keine Bewertungen

- LEONI Dacar® 110 enDokument1 SeiteLEONI Dacar® 110 engshock65Noch keine Bewertungen