Beruflich Dokumente

Kultur Dokumente

EXM ATEX en PDF

Hochgeladen von

OtavioOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EXM ATEX en PDF

Hochgeladen von

OtavioCopyright:

Verfügbare Formate

Electromagnetic holder

E X P L O S I O N P R O O F 650... 2000 N

Explosion proof, electromagnetic holder Type EXM-... List 6.0

for hazardous areas zone 1, 2, 21, 22 / 24 V- / 650 N, 1300 N, 2000N - tested acc. to ATEX EX-MAG

APPLICATION II2G Ex mb II T6

Zone 1, 2

EXM-... Electrical, explosionproof magnets for fire dampers, fire doors and safety doors. When the II2D Ex tD A21 IP65 T80°C

supply voltage is cut off, the magnet loses his force and the safety operation is working. The magnets Zone 21, 22

are certified in accordance with protection class II2G Ex mb II T6 zone 1, 2 (gas, mist, vapour). II2D

Ex tD A21 IP65 T80°C, for use in zone 21, 22 (dust).

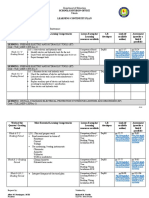

TECHNICAL DATA

Type EXM-650 EXM-1300 EXM-2000

Supply voltage 24 VDC ± 10% 24 VDC ± 10% 24 VDC ± 10%

Surge max. 20% max. 20% max. 20%

Power consumption ~1 W ~1,5 W ~3,7 W

Current 45 mA 65 mA 160 mA

Force 650 N 1300 N 2000 N

Cable ca. 1m ca. 1m ca. 1m PVC

Maintenance free free free

Ambient temperature -20... 55 °C -20... 55 °C -20... 55 °C

Storage temperature -20... 80 °C -20... 80 °C -20... 80 °C

Housing material steel/plastic steel/plastic steel/plastic Polycarbonate

Weight ~650 g ~1950 g ~1950 g

Indication CE Nr. 0158 ACCESSORIES

Permission PTB-tested acc. to directive 94/9/EC (ATEX)

PTB 02 ATEX 2121X GH 6 Anchor for EXM-650

Explosionproof II2G Ex mb II T6, CENELEC EN 60079-0 / EN 60079-18 GH 13/20 Anchor for EXM-1300,EXM-2000

II2D Ex tD A21 IP65 T80°C, CENELEC EN 61241-0 / EN 61241-1 ExBox-3P II2GD EEx e terminal box

External PE-connector Connectable lines: 4mm2 multiple-wire, 6mm2single-wire EXC-K4/S II2GD EEx e terminal box with integral fuse

Prot. in acc. with EN 60529 IP 65 EXC-T1 II2G EEx d Push button for manual release

Operating mode 100%ED

N1 supply unit 120 230 VAC, 24 VDC, max. 0,5 A

Attention Exceeding the admissible supply voltage or the max. admissible

AC-ripple will destroy the internal fuse irreparably (Ex-Regulations).

The magnet power is reduced by increasing the AC-ripple (AC-ripple from

0 to max. 20%). ATTENTION!

Included Ex m magnet with 1m cable.

Installation area hazardous areas zone 1, 2, 21, 22 Every single magnet has to be connected with an

external normal-lag fuse according to its rated current

(max. 3 x Inominal).

We recommend a stabilised power supply. The max. AC-ripple

ELECTRICAL CONNECTION ACCESSORIES

must not exceed 20%.

The cable must be installed in a fixed position and protected

24 VDC II2GD against mechanical damage.

+ 120 mm For installation, use and maintenance the official standards

and rules must be applied.

Safe area The temperature class T6 is in accordance with the magnet.

Cable entry The force of the magnet can deviate depending on different

80 mm

Hazardous area 2 × M20 × 1,5

6 12 mm types of material, dimension and surface of the anchor.

PE 1 2 EEx e

A possible remedy would be a thin, non-magnetic foil.

PA

+

ExBox-3P

EXM-... EEX e Terminal box

DIMENSIONS

B E K M

C Dim. in mm EXM-650 EXM-1300 EXM-2000

A 113 138 138

B 66 86 86

C 52 70 70

C

H

F

L

D 54 64 64

E 42 58 58

A

ø 6,3 I

F ø 54 ø 81 ø 81

G 38 45 45

H

H 60 80 80

I 44 60 60

K 50 62 62

38

60° L ø 56 ø 86 ø 86

D

M ø 6,3 ø 8,0 ø 8,0

G

Page 1 of 4 subject to change

SCHISCHEK GMBH D-90579 Langenzenn Mühlsteig 45 Gewerbegebiet V Phone +49-(0)9101-90810 Fax +49-(0)9101-908177 2008/10/20

info@schischek.com www.schischek.com

Installation Instructions

1. General Terms

Each piece of equipment may only be used for the respective purpose. By use of the equipment, other than for the

specified purpose, no guarantee can be given.

The magnets are delivered in 3 grades of 650 N, 1300 N and 2000 N.

During the mounting please be aware that the anchor plate and the magnet must be in alignment. The material for

the installation is not included.

Improper installation will lead to breakdowns and a reduction in the force.

It is strictly important to protect this equipment from knocks and vibrations, that are stronger than the nominal force

of the magnets (even for a short time).

Important Note!

It is mandatory that only especially trained personnel should use this equipment. Installation, operation and servicing

of the equipment may also only be carried out by specialist on this field, who are experienced with the dangers

and have also read and understood the instructions.

Proper transportation, storage, installation (within the specialised area) and maintenance, are absolutely necessary

for precise and exact usage.

Should the equipment show damage that leaves the assumption that safe use is not possible the equipment must

not remain in operation and must be decommissioned.

If the explosion proof equipment is operated in aggressive surroundings (e.g. in the chemical industry or off shore,

on shore) it should be cleared that the casing or parts of such are suitable for the surrounding conditions. In case

of ambiguities or for information that hasnt been provided please contact your dealer or our centre.

Customers may not open the magnet (loss of explosion protection and lapse of guarantee claims).

The assembly may be carried out only by skilled electrical personnel in accordance to EN 60079-14 / VDE 0165

and such skilled personnel, who comply with the guidelines prevalent in the respective country.

The regulations on electrical apparatus in explosion proof areas (ExVO) must be adhered to ! In addition to this,

the rules and regulations which may possibly vary in other countries outside the EU.

The magnet itself is maintenance free. The servicing is only related to the inspection of the casing for damage and

the functioning of the equipment which should be inspected e.g. 1-2 times a year (Ex-protection guarantee)

The ATEX 118a as well as the ExVO are applicable within the EU in general, whereas national guidelines and

regulations are to be observed in other places. For non EU zones, the corresponding national guidelines and

regulations are applicable.

2. Type Designation

The type designation structure for different types can be found in the diagram. (example)

Schischek GmbH D-90579 Langenzenn

Type EXM-1300 E X P L O S I O N S S C H U T Z

U : 24 V DC + / - 10% Ta -20 ... + 55 °C

I : 65 mA IP IP65

P : ca. 1,5 W Ser.-Nr.

F : 1300 N Made in Germany 2007

Besondere Bedingungen beachten!

Pay attention to special conditions for installation!

II 2G Ex mb II T6 PTB 02 ATEX 2121X

0158

II 2D Ex tD A21 IP65 T80°C www.schischek.com

3. Electrical Connection

Electrical installation must be performed according to the rules and regulations of the respective country. The

connection must be executed as in the following wiring diagram.

During the electrical installation and the start up of explosion proof equipment the rules and regulations for installation

of electrical equipment in explosive hazardous areas of the respective countries must be followed. Differences

are also nationally possible.

Electrical connections inside the Ex-area are only allowed to be installed by means of Ex e connection clamps.

During this procedure you must take into account that the cable glands must be tighten completely by the contractor.

The terminal box must not be opened when the voltage is on!

Electric wires must be secured and must be so laid out that they are sufficiently protected against damages.

The electrical connections of the magnet must always be made with the current switched off.

The operating voltage of the magnet is indicated on the name plate. Please compare with supply voltage.

The Schischek Company does not accept damaged magnets because of excess voltage as case of guarantee

demands.

Page 2 of 4 subject to change

SCHISCHEK GMBH D-90579 Langenzenn Mühlsteig 45 Gewerbegebiet V Phone +49-(0)9101-90810 Fax +49-(0)9101-908177 2008/10/20

info@schischek.com www.schischek.com

4.Commissioning

Before the equipment is switched on it must be tested that the voltage is 24 VDC +/- 10%.

The magnet should show no sign of mechanical damage (ex-protection).

The commissioning starts with the inspection of the installation of the magnet and the anchor-plate , the

wiring and the following function-control.

Furthermore, all the ex-relevant components, that are found between the magnet and the switch-gear in the

hazardous area, should be examined to ensure no damage has been done and that the installation is correct.

5. Decommissioning

Before switching off, consider the effects on the system as well as on the following devices. Disconnect the

main connection before starting mechanical dismantling. The terminal box must be free of voltage.

6. Maintenance

The magnet should never be opened by the operator (loss of the Ex-protection). Please exchange damaged

terminal boxes or magnets for new ones immediately, or have them overhauled at Schischek GmbH.

7. Checklists in the event of Operational Difficulties

Problem Possible cause Solution

Magnet does not provide - Mains failure Check mains, establish mains again

enough force. - Incorrect mains voltage Magnet must be repaired by manufacturer.

- Magnet connected incorrectly If the magnet has now been connected correctly

and still does not function, the magnet has to

be repaired by manufacturer.

- Magnet and anchor plate Check mounting of both parts

are not in alignment

- Wrong choice of magnet Choose stronger magnet

(force insufficient)

Magnet function is occasionally - Loose contact in the feed lines Check and secure connections.

interrupted - Loose contact inside the magnet Magnet must be repaired by manufacturer

- Increase of temperature Check ambient-temperature

Page 3 of 4 subject to change

SCHISCHEK GMBH D-90579 Langenzenn Mühlsteig 45 Gewerbegebiet V Phone +49-(0)9101-90810 Fax +49-(0)9101-908177 2008/10/20

info@schischek.com www.schischek.com

Erklärung der Declaration of Attestation de

EG-Konformität EC-Conformity conformité CE

Wir, die We, the Nous, la

(Name des Herstellers) (manufacturer name) (nom de fournisseur)

(Anschrift) (address) (adresse)

Schischek GmbH

Mühlsteig 45 Gewerbegebiet V

D-90579 Langenzenn

erklären in alleiniger Verantwortung declare under our sole responsibility, déclarons sous notre seulement

gemäß den Bestimmungen following the provisions responsibilité conformément aux

der Richtlinien : of directives : dispositions de directives :

89/336/EWG 89/336/EEC 89/336/CEE

94/9/EG 94/9/EC 94/9/CE

dass das Produkt : that the product : que le produit :

EXM-650 EXM-1300 EXM-2000

auf das sich diese Erklärung bezieht, to which this declaration refers, auquel se référe cette déclaration,

mit den folgenden Normen oder den conforms with the following est conforme aux normes ou

normativen Dokumenten übereinstimmt : standards or normative documents: autres documents normatifs :

EN 50081-1 EN 50082-1

EN 60079-0 EN 60079-18 EN 61241-0 EN 61241-1

Kennzeichnung : Marking : Marquage :

II2G Ex mb II T6 PTB 02 ATEX 2121X

II2D Ex tD A21 IP65 T80°C

Geschäftsführer : Manager: Directeur gérant:

(Ort und Datum) (Place and date of issue) (Lieu et date)

(Name und Unterschrift) (Name and signature) (Nom et signature)

Langenzenn, 26.11.2007

Roland Graf

Die Erklärung bescheinigt die Übereinstimmung mit den genannten Richtlinien, sie beinhaltet jedoch keine Zusicherung von Eigenschaften im Sinne des Produkthaftungs-

Gesetzes. Die Sicherheitshinweise der mitgelieferten Produktdokumentation sind zu beachten. Bei einer mit dem Hersteller nicht abgestimmten Änderung des Gerätes

und/ oder bei Nichtbeachtung der Sicherheitshinweise verliert diese Erklärung ihre Gültigkeit.

The declaration certifies the conformity with the directives mentioned, it does not, however contain any warranty of qualities as defined in the act on produkt liability.

The safety instruc-tions contained in the product documentation accompanying the product have to be ob-served. If apparatus is modified without having obtained the

manufacturer´s prior consent and/or if instructions are not followed, this declaration will become void.

La déclaration certifie la conformité avec les dispositions nommées, elle ne comporte cependant aucune garantie de caractéristiques dans le sens de la loi sur la responsabilité

du producteur pour vice de la marchandise. Les instructions en matière de sécurité dans la documentation du produit, livrées avec le produit, sont à observer. En cas de

modification de l´appareil n´ayant pas eu I´accord du fabricant et/ou cas de non-respect des instructions de sécurité, cette déclaration perd sa vigueur.

Page 4 of 4 subject to change

SCHISCHEK GMBH D-90579 Langenzenn Mühlsteig 45 Gewerbegebiet V Phone +49-(0)9101-90810 Fax +49-(0)9101-908177 2008/10/20

info@schischek.com www.schischek.com

Das könnte Ihnen auch gefallen

- Varitrans® P 27000-S007 Universal Isolators: Ta-251.103-Kne01 20120802 84762Dokument12 SeitenVaritrans® P 27000-S007 Universal Isolators: Ta-251.103-Kne01 20120802 84762Alan Barros SallesNoch keine Bewertungen

- E WIMA MP 3-Y2 3R-Y2-1375650Dokument9 SeitenE WIMA MP 3-Y2 3R-Y2-1375650Ilton GomesNoch keine Bewertungen

- E 92/32 fuse switch disconnector product detailsDokument4 SeitenE 92/32 fuse switch disconnector product detailsAngel WalazNoch keine Bewertungen

- Sensor de Presión MH-1Dokument4 SeitenSensor de Presión MH-1Sergio Suárez RiesgoNoch keine Bewertungen

- Tsm190Ex Solar Module: Atex/Iecex CertifiedDokument2 SeitenTsm190Ex Solar Module: Atex/Iecex CertifiedIrwanNoch keine Bewertungen

- Pressure Transmitters: PXT-K SeriesDokument2 SeitenPressure Transmitters: PXT-K SeriesBraulio GomezNoch keine Bewertungen

- Moeller Datasheet ESR4-NV3-30Dokument4 SeitenMoeller Datasheet ESR4-NV3-30Anton SemenyuraNoch keine Bewertungen

- Fuse and Fuse Holder - Leaflet PDFDokument2 SeitenFuse and Fuse Holder - Leaflet PDFsilence nestNoch keine Bewertungen

- T2INM2-20-20-220DC & R vPD1Dokument1 SeiteT2INM2-20-20-220DC & R vPD1desider_e3nNoch keine Bewertungen

- Edb 6881721 GBR enDokument2 SeitenEdb 6881721 GBR endavor.joc1976Noch keine Bewertungen

- D00sal12 13Dokument8 SeitenD00sal12 13amir.bptpkaNoch keine Bewertungen

- Pressure Transmitters: PXT-K SeriesDokument2 SeitenPressure Transmitters: PXT-K Serieskarim karimNoch keine Bewertungen

- Wima MP 3-X2: Metallized Paper (MP) RFI-Capacitors Class X2 PCM 10 MM To 27.5 MMDokument4 SeitenWima MP 3-X2: Metallized Paper (MP) RFI-Capacitors Class X2 PCM 10 MM To 27.5 MMFirdaus HanipahNoch keine Bewertungen

- Uni-Solar ES 62-T (PV Amorfos)Dokument2 SeitenUni-Solar ES 62-T (PV Amorfos)luysfNoch keine Bewertungen

- Sanyou WJ31X RelayDokument3 SeitenSanyou WJ31X Relaypratik gautamNoch keine Bewertungen

- Surge ArresterDokument4 SeitenSurge Arresterizaqui bernardoNoch keine Bewertungen

- Ex Solenoid Interlock Ex STM 298 01/12 R-3G/D Material No.: 1273831Dokument3 SeitenEx Solenoid Interlock Ex STM 298 01/12 R-3G/D Material No.: 1273831suadNoch keine Bewertungen

- Capacitores - WIMA - FKP - 1 Del VFDDokument12 SeitenCapacitores - WIMA - FKP - 1 Del VFDAlex RamirezNoch keine Bewertungen

- EPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Dokument4 SeitenEPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Mansoor AsifNoch keine Bewertungen

- Three-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmDokument12 SeitenThree-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmSalaar AnsarNoch keine Bewertungen

- ABB Spec MCB SH200Dokument2 SeitenABB Spec MCB SH200Jirayu KhumwanichNoch keine Bewertungen

- American - Zettler AZ732 053 52 DatasheetDokument2 SeitenAmerican - Zettler AZ732 053 52 DatasheetZoro DNoch keine Bewertungen

- Wima FKP 1: Special Features Electrical DataDokument14 SeitenWima FKP 1: Special Features Electrical Datatutankamon20010Noch keine Bewertungen

- Euro XPK Puck Type Programmable SensorDokument2 SeitenEuro XPK Puck Type Programmable SensorMgc ElektronikNoch keine Bewertungen

- A81a500xx1490 CsDokument4 SeitenA81a500xx1490 Csminhhieuhanam93Noch keine Bewertungen

- 3-Electrode-Arrester B88069X9380C203Dokument2 Seiten3-Electrode-Arrester B88069X9380C203hgfgffgfggffgNoch keine Bewertungen

- Az 850Dokument2 SeitenAz 850Aravindh RaNoch keine Bewertungen

- + DS2000-ExdDokument3 Seiten+ DS2000-Exdmarcello_oliveiraNoch keine Bewertungen

- HVC500B 24e X2300C011Dokument11 SeitenHVC500B 24e X2300C011Craciun Razvan IlieNoch keine Bewertungen

- Zener Diode Barrier MTL 7787+: DescriptionDokument1 SeiteZener Diode Barrier MTL 7787+: DescriptionMas AgusNoch keine Bewertungen

- 2CDC002137D0201_Data Sheet S200SDokument8 Seiten2CDC002137D0201_Data Sheet S200Sadelone23Noch keine Bewertungen

- SCP-EX Pressure Sensors: Device FeaturesDokument3 SeitenSCP-EX Pressure Sensors: Device FeaturesMahendra Tyre Works RaigarhNoch keine Bewertungen

- CHL Protecta III EmergencyDokument4 SeitenCHL Protecta III EmergencyWill BuickNoch keine Bewertungen

- Compact 150W Enclosed Switching Power SuppliesDokument3 SeitenCompact 150W Enclosed Switching Power Suppliestk1958Noch keine Bewertungen

- 786A-M12-IS Spec (99164) D.4Dokument1 Seite786A-M12-IS Spec (99164) D.4estebanNoch keine Bewertungen

- Chipguard MLC Series - Esd Protectors: Features ApplicationsDokument4 SeitenChipguard MLC Series - Esd Protectors: Features ApplicationsPhan Ngọc DuyNoch keine Bewertungen

- Balluff-Abs-Enc.Dokument2 SeitenBalluff-Abs-Enc.ersenNoch keine Bewertungen

- 4 Rpi-M20a Data Sheet v4Dokument3 Seiten4 Rpi-M20a Data Sheet v4KARTIKNoch keine Bewertungen

- GDTR3RD7 230 PDFDokument2 SeitenGDTR3RD7 230 PDFJuscelino SaraivaNoch keine Bewertungen

- Foundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureDokument1 SeiteFoundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureJosé CallisayaNoch keine Bewertungen

- Miniature Circuit Breaker - S200M - 1P - C - 6 Ampere: Product-DetailsDokument5 SeitenMiniature Circuit Breaker - S200M - 1P - C - 6 Ampere: Product-DetailssyamnjNoch keine Bewertungen

- Wima FKP 4Dokument9 SeitenWima FKP 4M-BasicNoch keine Bewertungen

- 60 Monocrystalline Cell ModulesDokument1 Seite60 Monocrystalline Cell ModulesEmmvee SolarNoch keine Bewertungen

- Ac925 Series: Unconditional, Lifetime WarrantyDokument1 SeiteAc925 Series: Unconditional, Lifetime WarrantyNessuno Crede Jr.Noch keine Bewertungen

- WIMA Snubber FKP Capacitors GuideDokument13 SeitenWIMA Snubber FKP Capacitors GuideSoheil GhasemiNoch keine Bewertungen

- Static / Dynamic Resistance Measurement Accessory For TM1800 / TM1600 / EGILDokument2 SeitenStatic / Dynamic Resistance Measurement Accessory For TM1800 / TM1600 / EGILNilesh MahajanNoch keine Bewertungen

- Limit-Value Switch For Temperature Thermistor Input (NTC)Dokument2 SeitenLimit-Value Switch For Temperature Thermistor Input (NTC)AlexanderNoch keine Bewertungen

- UgT IgT MU EDokument2 SeitenUgT IgT MU EAlfredo AntonioNoch keine Bewertungen

- Safety Switch Technical Data SheetDokument3 SeitenSafety Switch Technical Data SheetEFLANİ DEMİRLİ İNCÜĞEZNoch keine Bewertungen

- EXBF - Onoff - IECEx - FICHA TECNICA MOTORDokument7 SeitenEXBF - Onoff - IECEx - FICHA TECNICA MOTORbasvkaranNoch keine Bewertungen

- Dut250vg-300 TNSDokument2 SeitenDut250vg-300 TNSTrịnh MinhNoch keine Bewertungen

- Characteristics: Technical DataDokument2 SeitenCharacteristics: Technical DataAdnan SalihbegovicNoch keine Bewertungen

- Wima FKP 1: Special Features Electrical DataDokument10 SeitenWima FKP 1: Special Features Electrical DataАлексей АндрияшNoch keine Bewertungen

- Halogen-free fire warning cable with insulation integrity up to E 90Dokument1 SeiteHalogen-free fire warning cable with insulation integrity up to E 90bebeNoch keine Bewertungen

- SBL2030PT, SBL2040PT: Vishay General SemiconductorDokument4 SeitenSBL2030PT, SBL2040PT: Vishay General SemiconductortallertecuNoch keine Bewertungen

- EFR-25RM7Q: Product DatasheetDokument2 SeitenEFR-25RM7Q: Product DatasheetRio AribowoNoch keine Bewertungen

- BI5-G18-Y1X Inductive Sensor: FeaturesDokument4 SeitenBI5-G18-Y1X Inductive Sensor: Featuresersanjeeb_456Noch keine Bewertungen

- Miniature Circuit Breaker - S200 - 3P - C - 32 Ampere: Product-DetailsDokument5 SeitenMiniature Circuit Breaker - S200 - 3P - C - 32 Ampere: Product-DetailsAbdullrahim AlastalNoch keine Bewertungen

- S203-C16 Circuit Breaker DetailsDokument5 SeitenS203-C16 Circuit Breaker DetailsYsabel AliagaNoch keine Bewertungen

- CH 07Dokument148 SeitenCH 07OtavioNoch keine Bewertungen

- KFD0-CS-Ex1 51P EN PDFDokument3 SeitenKFD0-CS-Ex1 51P EN PDFOtavioNoch keine Bewertungen

- 10 5923 J Control 20201002 03Dokument6 Seiten10 5923 J Control 20201002 03OtavioNoch keine Bewertungen

- CH 05Dokument119 SeitenCH 05OtavioNoch keine Bewertungen

- Barriers and Isolators: AccessoriesDokument3 SeitenBarriers and Isolators: AccessoriesOtavioNoch keine Bewertungen

- Selecting The Correct Zener Barriers: Intrinsic SafetyDokument20 SeitenSelecting The Correct Zener Barriers: Intrinsic SafetyOtavioNoch keine Bewertungen

- Basic Engineering Circuit Analysis 8th Ed SolutionsDokument1.254 SeitenBasic Engineering Circuit Analysis 8th Ed SolutionsAndrew David Bushner87% (188)

- Solution For Basic Engineering Circiut Analysis 8th Edition ChapterDokument110 SeitenSolution For Basic Engineering Circiut Analysis 8th Edition ChapterMuzammil Ali Khan67% (12)

- Solution For Basic Engineering Circiut Analysis 8th Edition ChapterDokument126 SeitenSolution For Basic Engineering Circiut Analysis 8th Edition ChapterMuzammil Ali KhanNoch keine Bewertungen

- Fuel Fuel: Fig. 1 Positive Single-Channel Zener Barrier With Negative GroundDokument2 SeitenFuel Fuel: Fig. 1 Positive Single-Channel Zener Barrier With Negative GroundOtavioNoch keine Bewertungen

- Protection Types For Gas Protection: Luciano SantosDokument2 SeitenProtection Types For Gas Protection: Luciano SantosOtavioNoch keine Bewertungen

- System Components: Separating and Protective InstrumentsDokument10 SeitenSystem Components: Separating and Protective InstrumentsOtavioNoch keine Bewertungen

- Zener Barrier Applications PDFDokument36 SeitenZener Barrier Applications PDFOtavioNoch keine Bewertungen

- Practical Guidelines For Electrical Area Classification inDokument11 SeitenPractical Guidelines For Electrical Area Classification inaliris322Noch keine Bewertungen

- Hazardous Area Classification MoxrexDokument48 SeitenHazardous Area Classification MoxrexMuhammad Mubashir Hassan100% (4)

- Electromagnetic Holder 650... 2000 NDokument4 SeitenElectromagnetic Holder 650... 2000 NOtavioNoch keine Bewertungen

- KFD0-CS-Ex1 51P EN PDFDokument3 SeitenKFD0-CS-Ex1 51P EN PDFOtavioNoch keine Bewertungen

- Hazardous Area Motors and Generators EN 2006 - 2006 PDFDokument8 SeitenHazardous Area Motors and Generators EN 2006 - 2006 PDFOtavioNoch keine Bewertungen

- Electromagnetic Holder 650... 2000 NDokument4 SeitenElectromagnetic Holder 650... 2000 NOtavioNoch keine Bewertungen

- Barriers and Isolators: AccessoriesDokument3 SeitenBarriers and Isolators: AccessoriesOtavioNoch keine Bewertungen

- System Components: Separating and Protective InstrumentsDokument10 SeitenSystem Components: Separating and Protective InstrumentsOtavioNoch keine Bewertungen

- Fuel Fuel: Fig. 1 Positive Single-Channel Zener Barrier With Negative GroundDokument2 SeitenFuel Fuel: Fig. 1 Positive Single-Channel Zener Barrier With Negative GroundOtavioNoch keine Bewertungen

- Hazardous Area Classification MoxrexDokument48 SeitenHazardous Area Classification MoxrexMuhammad Mubashir Hassan100% (4)

- Hazardous Areas Tech GuideDokument70 SeitenHazardous Areas Tech GuideMadhan Kumar100% (1)

- Selecting The Correct Zener Barriers: Intrinsic SafetyDokument20 SeitenSelecting The Correct Zener Barriers: Intrinsic SafetyOtavioNoch keine Bewertungen

- System Components: Separating and Protective InstrumentsDokument10 SeitenSystem Components: Separating and Protective InstrumentsOtavioNoch keine Bewertungen

- Hazardous Area Motors and Generators EN 2006 - 2006 PDFDokument8 SeitenHazardous Area Motors and Generators EN 2006 - 2006 PDFOtavioNoch keine Bewertungen

- KFD0-CS-Ex1 51P EN PDFDokument3 SeitenKFD0-CS-Ex1 51P EN PDFOtavioNoch keine Bewertungen

- Fuel Fuel: Fig. 1 Positive Single-Channel Zener Barrier With Negative GroundDokument2 SeitenFuel Fuel: Fig. 1 Positive Single-Channel Zener Barrier With Negative GroundOtavioNoch keine Bewertungen

- Department of Education Manila: Week 1-2 / 1 Grading PeriodDokument2 SeitenDepartment of Education Manila: Week 1-2 / 1 Grading PeriodJhobhel Christopher GalivoNoch keine Bewertungen

- Float Switch InstructionsDokument3 SeitenFloat Switch InstructionsNana-Osei MainooNoch keine Bewertungen

- 01-Division 15-Section 15002 Standards & Regulations-VersionDokument41 Seiten01-Division 15-Section 15002 Standards & Regulations-VersionKrishna Kumar100% (1)

- OCP Electrical ShockDokument9 SeitenOCP Electrical ShockSharif KhanNoch keine Bewertungen

- DO3000 InstructionsDokument38 SeitenDO3000 InstructionsMoh Asat Dullah100% (3)

- Los Angeles Abrasion Machine HM-70A & HM-70AF: Operating ManualDokument16 SeitenLos Angeles Abrasion Machine HM-70A & HM-70AF: Operating ManualSalvatore LombardoNoch keine Bewertungen

- Wiring Audio2002 UKDokument48 SeitenWiring Audio2002 UKvfanNoch keine Bewertungen

- PF-9497 Chrysler PDFDokument10 SeitenPF-9497 Chrysler PDFGustavo PereiraNoch keine Bewertungen

- Query LetterDokument2 SeitenQuery LetterNIKUNJ PARMARNoch keine Bewertungen

- Hydrovane HV01!02!04Dokument29 SeitenHydrovane HV01!02!04Mark Carter100% (4)

- Classes Laboratory Project Seminar Number of Hours of Organized Classes in University (ZZU) 30 15Dokument495 SeitenClasses Laboratory Project Seminar Number of Hours of Organized Classes in University (ZZU) 30 15Javier Oyarzun GoyaldeNoch keine Bewertungen

- GE19122 - EPL Manual With BonafideDokument26 SeitenGE19122 - EPL Manual With BonafidejitheeswaranNoch keine Bewertungen

- DOLE Construction Safety and Health Program OverviewDokument18 SeitenDOLE Construction Safety and Health Program OverviewRyan Vincent Jarabejo100% (4)

- KCGG R8551eDokument292 SeitenKCGG R8551egovindarulNoch keine Bewertungen

- BMW 3 Series wiring information for car locks and turn signalsDokument13 SeitenBMW 3 Series wiring information for car locks and turn signalsCrow CrowNoch keine Bewertungen

- Trunking CatlougeDokument306 SeitenTrunking CatlougeKishore KrishnaNoch keine Bewertungen

- DSR Elec 2022 PDFDokument155 SeitenDSR Elec 2022 PDFShivam50% (2)

- Wire Size SpecificationsDokument2 SeitenWire Size Specificationsjaveeed0401Noch keine Bewertungen

- O&m Wa600-6Dokument393 SeitenO&m Wa600-6PaolaNoch keine Bewertungen

- Solar PV Methodology - BRIDokument20 SeitenSolar PV Methodology - BRI2020dlb121685Noch keine Bewertungen

- Setting eDokument598 SeitenSetting eSøren PeterNoch keine Bewertungen

- Electrical Audit TenderDokument8 SeitenElectrical Audit Tenderamol31179Noch keine Bewertungen

- Operating Instructions As30 Array Sensor en Im0084437Dokument52 SeitenOperating Instructions As30 Array Sensor en Im0084437DeFacto76Noch keine Bewertungen

- Freezemaster 300 Series: Models 336, 338 & 339Dokument52 SeitenFreezemaster 300 Series: Models 336, 338 & 339kanodapogiNoch keine Bewertungen

- Specifications - ILSDokument35 SeitenSpecifications - ILSZhang GuoquanNoch keine Bewertungen

- Safe Hospitals ManualDokument43 SeitenSafe Hospitals ManualMaeDaphneYapNoch keine Bewertungen

- A380 General Familiarization CourseDokument908 SeitenA380 General Familiarization CourseDiego Ruddy Arcaine Zegarrundo100% (5)

- 2013-2014 Electrical Book ListDokument2 Seiten2013-2014 Electrical Book Listmohamad nouhNoch keine Bewertungen

- IKS-6700A and IKS-6728A Quick Install GuideDokument11 SeitenIKS-6700A and IKS-6728A Quick Install GuideSVS SVSNoch keine Bewertungen

- Niles Intellipad CI Solo ManualDokument18 SeitenNiles Intellipad CI Solo Manualquillman74Noch keine Bewertungen