Beruflich Dokumente

Kultur Dokumente

Wheel Speed Sensors

Hochgeladen von

Ion IoviOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wheel Speed Sensors

Hochgeladen von

Ion IoviCopyright:

Verfügbare Formate

TECH TIPS!

Selling Services: Wheel Speed Sensors

There are two main types of magnetic wheel speed sensors — passive and active. Both

use a tone ring to reference against and each look very similar to one another. As the

raised portions of the tone ring pass by the tip of the sensor, the sensor creates a signal.

The passive type of sensor is a simple AC signal generator. As the teeth pass the sensor,

it produces a sine wave. As the wheel speeds up, the frequency of the sine increases

as well. The ABS module reads the frequency to determine the speed of the wheel. The

downfall with this design is that the frequency is not the only thing to change with rotational

speed. The amplitude also changes.

The faster the wheel turns, the greater the peak voltages are. The high end of that aspect

is not a problem. The problem lays in the low end. When the wheel is turning at very

low speeds, such as under 3 mph, the sensor becomes unreliable because it is barely

producing a readable signal to the ABS module, especially when wiring resistance and

RF noise are factored in. You may notice that a scan tool will show the wheel speeds starting at 3 mph for these types of sensors.

Some scan tools might report 3 mph when sitting still, and others might report 0 mph until a vehicle speed of 3 mph is achieved

and suddenly the PID will jump from 0 to 3 mph. That is normal for a vehicle with passive wheel speed sensors. These sensors can

be tested for coil circuit integrity with an ohm meter. More preferred methods of testing are AC volt meter for voltage output and

oscilloscope.

To get reliable readings at very slow speeds, the active wheel speed sensor is employed. An active wheel sensor has a tiny processor

chip in it that reads the tone ring with the same signal generator method as the passive speed sensor, but does not use that

conventional signal to share with the ABS module.

Instead, the ABS module sends the sensor a 9 volt power supply and the active sensor produces a square sine, also referred to as a

modified sine wave. It is a digital high/low toggle rather than an analog voltage ramp-up like with passive sensors. Since the chip can

read the minute voltage generated at the coil end of the sensor and convert that to a signal to the module, it can read speeds below 3

mph reliably.

The amplitude of this signal to the ABS module does not change with speed, only the frequency does. An ohmmeter can not be used

to test the coil side of the sensor. If you use an ohmmeter on it, you will get a measurement because the ohmmeter will find a path

down one wire, through the chip, and back up the other wire. But that will not be an indicator of the coil windings at the sensor tip. The

preferred methods are with an amp meter that can measure in the 7mA to 14mA range and an oscilloscope. A DC voltmeter can be

used to test the ABS module’s ability to send voltage to the wheel speed sensor. In the picture here, labeled active wss, the housing of

the sensor has been ground away so that you can see the tiny little processor chip inside.

DIAGNOSIS

The first signs of trouble may be the ABS system kicking it when braking at low speed, and/or the ABS warning light coming on. Until

you hook up a scan tool and pull the codes, though, there’s no telling why the light is on. The fault may be a bad wheel speed sensor

or it might be something else, so don’t jump to conclusions — especially if there are no codes to guide you.

ARTICLE SOURCE:

“The Official Auto Parts Store of The Cincinnati Reds”

w w w. KO I AU TOPARTS.com • 1-800-354-0408

Reading ABS codes requires an ABS code reader, scan tool or scanner software that

can access the ABS system. An inexpensive OBD II code reader or an entry-level

scan tool designed for a do-it-yourselfer won’t work here. You need a professional tool

designed for ABS diagnostics, or a digital storage oscilloscope to look at the wheel

speed sensor waveforms.

If the ABS light is on and you find a code for a wheel speed sensor, check the sensor

wires for breaks or a loose/corroded connector. Broken wires are probably the leading

cause of wheel speed sensor related failures. One some vehicles, the wires tend to be

brittle and break as a result of fatigue from road vibration and/or steering maneuvers.

Replacing the WSS wiring harness is usually the recommended fix for these situations.

You could try to patch the broken wire, but crimp connectors are vulnerable to road

splash and corrosion, and solder is usually too rigid and will crack again. Better to

replace the wiring harness than to risk a comeback.

If there are no codes, but the vehicle owner complains about the ABS system engaging when braking (noise, vibrations and pedal

pulsations), the problem is likely a bad wheel speed sensor. But which one? That’s where a scope can really help you identify which

sensor is acting up. Connect the scope to the sensor leads and spin the tire by hand. If you get a good clean signal, move on to the

next WSS sensor and so on until you find the one that is generating a bad signal.

If the scope pattern produced by the sensor is flattened (diminished amplitude) or is erratic, it usually indicates a weak signal caused

by an excessively wide air gap between the tip of the sensor and its ring, or a buildup of metallic debris on the end of the sensor. A

weak signal can also be caused by internal resistance in the sensor or its wiring circuit, or loose or corroded wiring connectors. You can

also measure the wheel speed sensor’s output with a DVOM. The most accurate way to do this is with a breakout box connected to

the wiring harness at the ABS module. You can also connect the DVOM test leads directly to the wheel speed sensor itself, but testing

the sensor this way won’t tell you if the signal is getting through to the control module. Spin the wheel by hand and note the sensor’s

voltage reading.

A good wheel speed sensor will typically produce an alternating current (AC) voltage reading of 50 to 700 MV when the wheel is turning

one revolution per second.

If the voltage reading is low or nonexistent, check the sensor’s resistance (with the key off). This should also be done at the breakout

box. Checking resistance of the wheel speed sensor circuit where it plugs into the module will tell you if the sensor’s wiring harness is

OK. If you don’t get the specified value (typically 900 to 1,400 ohms), go to the wheel and unplug the sensor from its wiring harness,

then measure the sensor’s resistance by attaching the DVOM test probes directly to the sensor leads.

A resistance reading that is now within range tells you the problem is in the wiring, not the sensor. If the sensor itself out of range, high

or low, the sensor is defective and the sensor or hub assembly (if the sensor is not removable) needs to be replaced.

ARTICLE SOURCE:

w w w. KO I AU TOPARTS.com • 1-800-354-0408

Das könnte Ihnen auch gefallen

- Scala de Apreciere A Gradului de Severitate A Comei Si Analiza Lor ComparativaDokument585 SeitenScala de Apreciere A Gradului de Severitate A Comei Si Analiza Lor ComparativaIon Iovi0% (1)

- Bosch Tips Correct Assessment and Handling of Lambda SensorsDokument1 SeiteBosch Tips Correct Assessment and Handling of Lambda SensorsIon IoviNoch keine Bewertungen

- Manual Supplement: Important. Fieldbusses Often Are Controlling Delicate Processes That Must Not BeDokument10 SeitenManual Supplement: Important. Fieldbusses Often Are Controlling Delicate Processes That Must Not BeIon IoviNoch keine Bewertungen

- ABS M4 BrochureDokument156 SeitenABS M4 BrochureIon IoviNoch keine Bewertungen

- Manual Utilizare Reflectometru Albrecht SWR 30 Power Meter Cod 4412Dokument31 SeitenManual Utilizare Reflectometru Albrecht SWR 30 Power Meter Cod 4412Ion IoviNoch keine Bewertungen

- Protectia MunciiDokument4 SeitenProtectia MunciiIon IoviNoch keine Bewertungen

- 4D-An-P5003 Serial Connecting A 4D Display To An Arduino Host R 1 00Dokument15 Seiten4D-An-P5003 Serial Connecting A 4D Display To An Arduino Host R 1 00Ion IoviNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ARX24-SR-T Technical Data Sheet: Modulating, Non-Spring Return, 24 V, For DC 2... 10 V or 4... 20 MaDokument2 SeitenARX24-SR-T Technical Data Sheet: Modulating, Non-Spring Return, 24 V, For DC 2... 10 V or 4... 20 MaFrancisco VelasquezNoch keine Bewertungen

- 8 WorksheetDokument5 Seiten8 WorksheetRujual BainsNoch keine Bewertungen

- PLC BitsDokument10 SeitenPLC Bitssivakumar_kalepu555491% (11)

- Lecture 1Dokument19 SeitenLecture 1rafey amerNoch keine Bewertungen

- Econoled by Trend LightingDokument1 SeiteEconoled by Trend LightingFrederickNoch keine Bewertungen

- Roboteq Controllers User Manual v2.0 PDFDokument360 SeitenRoboteq Controllers User Manual v2.0 PDFali beyNoch keine Bewertungen

- Subject Orientation: Radar EngineeringDokument16 SeitenSubject Orientation: Radar EngineeringNilesh NagraleNoch keine Bewertungen

- MCCB Easy Pact SchneDokument6 SeitenMCCB Easy Pact Schnetruongthang87Noch keine Bewertungen

- Johnson Electric Tech Brief 3 Pull Vs Push SolenoidsDokument12 SeitenJohnson Electric Tech Brief 3 Pull Vs Push Solenoidsfahad pirzadaNoch keine Bewertungen

- Difference Between Singlet and Triplet StateDokument11 SeitenDifference Between Singlet and Triplet StateUsman Ghani100% (2)

- EECE 1312: Chapter 1: Introduction To Electronics Section 10 & 11 DR Aliza Aini MD RalibDokument51 SeitenEECE 1312: Chapter 1: Introduction To Electronics Section 10 & 11 DR Aliza Aini MD RalibMuhammad nuruddinNoch keine Bewertungen

- LG 60pa6500-Tm Chassis Pa23aDokument49 SeitenLG 60pa6500-Tm Chassis Pa23aJ Fernando GarciaNoch keine Bewertungen

- Gmail - Order 8117270258209721 Is Good To Go! PDFDokument4 SeitenGmail - Order 8117270258209721 Is Good To Go! PDFEug. Sam.Noch keine Bewertungen

- Mini, 7/8"-Round-Plug Connector, Single-Ended Cordsets, US Color CodeDokument2 SeitenMini, 7/8"-Round-Plug Connector, Single-Ended Cordsets, US Color CodeAlfredo Hernandez FernandezNoch keine Bewertungen

- IEEE Xplore Full-Text PDFDokument10 SeitenIEEE Xplore Full-Text PDFpshyciNoch keine Bewertungen

- Report GSM Based Remote Monitoring of 3 Parameters On TransformersDokument16 SeitenReport GSM Based Remote Monitoring of 3 Parameters On TransformersJilly ArasuNoch keine Bewertungen

- Network Analysis and SynthesisDokument987 SeitenNetwork Analysis and SynthesisRITIKNoch keine Bewertungen

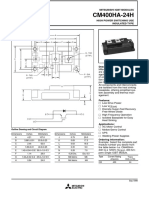

- Igbt Mitsubishi Cm400ha-24hDokument4 SeitenIgbt Mitsubishi Cm400ha-24hELBIN RINCONNoch keine Bewertungen

- 100 Series: 100 Series Low-Profile Plug-In Smoke DetectorsDokument2 Seiten100 Series: 100 Series Low-Profile Plug-In Smoke DetectorsLogan Marquez AguayoNoch keine Bewertungen

- Teori TheveninDokument6 SeitenTeori TheveninAwa StelkNoch keine Bewertungen

- Cut Off Rank Uget 2016 MergeDokument5 SeitenCut Off Rank Uget 2016 Mergeprabs20069178Noch keine Bewertungen

- Electrical Powerircuit - Test..Dokument10 SeitenElectrical Powerircuit - Test..Anonymous 86w3RKNoch keine Bewertungen

- Arn 200 05 8Dokument3 SeitenArn 200 05 8defsyNoch keine Bewertungen

- Expt 4-Trapezoidal PatternDokument8 SeitenExpt 4-Trapezoidal PatternRainier RamosNoch keine Bewertungen

- 10 - Group - 16 - Engine - Electrical - Triton PDFDokument4 Seiten10 - Group - 16 - Engine - Electrical - Triton PDFlaudi shofaniNoch keine Bewertungen

- Fire Rated CableDokument1 SeiteFire Rated CableSLC ScaleneNoch keine Bewertungen

- Physics PracticalDokument24 SeitenPhysics PracticalPeddini Pradeep KumarNoch keine Bewertungen

- CH 24 HWDokument23 SeitenCH 24 HWGiancarlo SantosNoch keine Bewertungen

- 2009 Kamaraju - Electrical Power Distribution Systems-McGraw HillDokument278 Seiten2009 Kamaraju - Electrical Power Distribution Systems-McGraw HillC071Ridho Setiawan TuitantoNoch keine Bewertungen

- Block Proving With Axle CounterDokument21 SeitenBlock Proving With Axle CounterVikas Srivastav100% (4)