Beruflich Dokumente

Kultur Dokumente

Sop Ls Crusher

Hochgeladen von

vinodsnCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sop Ls Crusher

Hochgeladen von

vinodsnCopyright:

Verfügbare Formate

UNITED CEMENTS PVT.

LIMITED

STANDARD OPERATING PROCEDURE (SOP)

Doc.No. UCPL/ME/SOP/001

Rev.No: 00

Lime Stone Crusher Page 1 of 2

(Single Rotor Impactor & Eff. Dt.: 15TH AUGUST-2018

Hammer Crusher)

Approved By: Issued By:

Date: Date:

1. PURPOSE:-

Housekeeping & avoided to unsafe works & generate revenue

2. SCOPE

Applicable to used waste cotton/cloth & scrap generated in whole plant.

3. RESPONSIBILITY

3.1 Respective area incharge is responsible for operation of this procedure.

3.2 HOD (stores) is responsible for disposal of waste cotton/cloth & scrap from scrap yard.

4. PROCEDURE

4.1 For Waste Paper / Wood / Dry Cloth (not grease/oil soaked)

4.1.1 Collecting container painted in GREEN & printed as “waste bin” are placed in specified areas.

4.1.2 After using the waste cotton/cloth (not grease/oil soaked) the user placed the same into the bin.

4.1.3 Waste material collection from bin (in every three day) from all area is done by plant civil incharge in

tractor & shifted to waste yard.

4.1.4 During rainy season, the collecting containers to be covered properly.

4.2 For waste cotton/cloth (grease/oil soaked)

4.2.1 Collecting container painted in RED color & printed as “waste bin” are placed in

Specified areas.

4.2.2 After using the waste cotton/cloth (grease/oil soaked) the user placed the same into

the bin.

4.2.3 Whenever the bin get filled up of cotton/cloth (grease/oil soaked) the same should be returned to

stores for proper disposal

4.3 For Iron ,Rubber & Plastic Waste

4.31 Collecting Container Painted in Yellow colour and printed as “Waste Bin” are

placed in Specified area.

4.32 All the waste material should be placed in the bins

4.33 Whenever the bin gets filled, it should be shifted to specified area.

4.4 For Scrap

4.4.1 Places are specified as sub scrap yard for collecting the scrap in respective sections.

4.4.2 Scrap generated is placed at specified area of respective sections.

4.4.3 The scrap segregated to M.S, castings of grade7, grade9, bag filter bags, v belts etc. in

the knowledge of respective area incharge.

4.4.4 Segregated scrap timely sends to scrap yard through stores Deptt. in the Store return voucher

form SF: 150415.

4.4.5 Unloading of scrap is done at scrap yard in the presence of stores person for unloading the right

grade material at identified area and is the responsibility of stores.

4.5 Oil soaked sand

During cleaning of oil contaminated area , the generated Oil Soaked Sand / Raw Meal

Dust is shifted to lime stone pile for recycling purpose.

5. RECORDS:

a. Proper record should be maintained in shift log register /maintenance register related

with operation and maintenance jobs.

b.Safety i.e. work permits should be maintained as per the safety requirement.

c. Keep record to hand over to store department

UNITED CEMENTS PVT. LIMITED

STANDARD OPERATING PROCEDURE (SOP)

Doc.No. UCPL/ME/SOP/001

Rev.No: 00

Lime Stone Crusher Page 2 of 2

(Single Rotor Impactor & Eff. Dt.: 15TH AUGUST-2018

Hammer Crusher)

Approved By: Issued By:

Date: Date:

1. PURPOSE

To establish a system for handling, storage & disposal of used oil & grease generated in

the plant.

2. SCOPE

Applicable to used oil & grease generated in whole plant.

3. RESPONSIBILITY

3.1 Respective area in-charge is responsible for proper storage of used oil and grease at site

and sending same to scrap yard through stores department .

3.2 HOD (stores) is responsible for disposal of used oil & grease from scrap yard.

4. PROCEDURE

4.1 The used oil & grease generated in the plant is kept on the secondary containment like

steel tray / drum at specified place of respective area.

4.2 The place is properly identified as “USED OIL & GREASE”.

4.3 The drums are kept vertical and Cap/ Lid cover on used oil drum & cover of grease drum are

properly closed.

4.5 Then send to hazardous waste collection site through store return voucher (form no. SF:

150415) with the help of crane & tipper.

4.6 Used grease/oil is unloaded at identified area in scrap yard. In presence of authorized

Store’s person.

4.7 Disposal of grease & oil from scrap yard is the responsibility of stores.

4.8 Avoid spillage of Oil / Grease on ground to avoid earth contamination.

5. RECORDS:

a. Proper record should be maintained in shift log register /maintenance register related

with operation and maintenance jobs.

b.Safety i.e. work permits should be maintained as per the safety requirement.

c. Keep record of used oil stock & hand over to store

Das könnte Ihnen auch gefallen

- Sop For Ls CrusherDokument5 SeitenSop For Ls CrusherVinod Kumar VermaNoch keine Bewertungen

- ENG SOP 106 - Crusher MaintenanceDokument7 SeitenENG SOP 106 - Crusher MaintenanceJohn Lawing100% (2)

- SOP For Operation and Cleaning of Conveyer BeltDokument2 SeitenSOP For Operation and Cleaning of Conveyer BeltSudheer Nair100% (1)

- SOP of Conveyor ReplacementDokument11 SeitenSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- Sop - Belt ConveyorDokument2 SeitenSop - Belt Conveyorvinodsn100% (2)

- Sop - Belt ConveyorDokument2 SeitenSop - Belt Conveyorvinodsn100% (2)

- 13-SOP For Safe Operation Limestone CrusherDokument2 Seiten13-SOP For Safe Operation Limestone Crushergothic centuary67% (3)

- SOP-MOD-001 Primary Crushing Plant Operation Version 2 WITHOUT COMMENTDokument3 SeitenSOP-MOD-001 Primary Crushing Plant Operation Version 2 WITHOUT COMMENTRuGgED11thNoch keine Bewertungen

- 08-SOP For Belt Conveyor 6ABDokument14 Seiten08-SOP For Belt Conveyor 6ABTamil VananNoch keine Bewertungen

- Apron Feeder Inspection Sheet PDFDokument2 SeitenApron Feeder Inspection Sheet PDFJack CianfaglioneNoch keine Bewertungen

- Determination of Copper in Anode and Blister Copper: Standard Test Method ForDokument3 SeitenDetermination of Copper in Anode and Blister Copper: Standard Test Method ForEric GozzerNoch keine Bewertungen

- AM2020-AFP1010 Installation Programming OperatingDokument268 SeitenAM2020-AFP1010 Installation Programming OperatingBaron RicthenNoch keine Bewertungen

- Mil Tos (1ST Quarter)Dokument3 SeitenMil Tos (1ST Quarter)Rhea Carillo100% (14)

- Harvester Main MenuDokument3 SeitenHarvester Main MenuWonderboy DickinsonNoch keine Bewertungen

- SOP OB RemovalDokument9 SeitenSOP OB RemovalAgus Budiluhur100% (1)

- Form RitaseDokument6 SeitenForm Ritaseshanti RafikNoch keine Bewertungen

- 621-CC#09 Idler and Frame ChangingDokument4 Seiten621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- Sikasil®-111 Multipurpose: Product Data SheetDokument3 SeitenSikasil®-111 Multipurpose: Product Data SheetDunia SealNoch keine Bewertungen

- Material Safety Data Sheets WDDokument5 SeitenMaterial Safety Data Sheets WDWhitedove BatamNoch keine Bewertungen

- Presentasi Company Profile PRIME SAFETY INDONESIA 2011Dokument16 SeitenPresentasi Company Profile PRIME SAFETY INDONESIA 2011marianaivorettyNoch keine Bewertungen

- Mechanic Name: . Shift: . No Unit: . ModelDokument2 SeitenMechanic Name: . Shift: . No Unit: . ModelAsef Dwy AfixxNoch keine Bewertungen

- 01.work Instruction For Operation of Belt Conveyor-UpdatedDokument6 Seiten01.work Instruction For Operation of Belt Conveyor-UpdatedRahul VermaNoch keine Bewertungen

- PT - Sinar Terang Mandiri - Site Weda Bay Nickel Daily Operational ChecklistDokument1 SeitePT - Sinar Terang Mandiri - Site Weda Bay Nickel Daily Operational ChecklistNurhida Lukman100% (2)

- 07 IOT - Form - Inspection Generator Set 1Dokument2 Seiten07 IOT - Form - Inspection Generator Set 1Oneesa Chandra0% (1)

- SOP 11 - Lime Stone Circuit OprationDokument9 SeitenSOP 11 - Lime Stone Circuit Oprationfaraz ahmedNoch keine Bewertungen

- KPC HSE Induction Application - For Project AreaDokument1 SeiteKPC HSE Induction Application - For Project AreaOneesaChandraKencanaNoch keine Bewertungen

- 9.inspeksi Belt ConveyorDokument18 Seiten9.inspeksi Belt ConveyorYogi Prakoso NNoch keine Bewertungen

- SOP - Maintenance of Bag FilterDokument22 SeitenSOP - Maintenance of Bag FilterAkash SharmaNoch keine Bewertungen

- Commissioning Procedures For ConveyorsDokument2 SeitenCommissioning Procedures For ConveyorsNur KhamidNoch keine Bewertungen

- Permit To Work: Surat Izin KerjaDokument3 SeitenPermit To Work: Surat Izin Kerjaluki0% (1)

- Sop For Operation of EotDokument2 SeitenSop For Operation of Eotsaji kumarNoch keine Bewertungen

- LV Prestart Inspection Checklist Form - IEDokument1 SeiteLV Prestart Inspection Checklist Form - IEyuwantoniNoch keine Bewertungen

- Checklist For WeighbridgeDokument4 SeitenChecklist For Weighbridgemuhamad.badar9285Noch keine Bewertungen

- Hammer Crusher User ManualDokument10 SeitenHammer Crusher User ManualJuan MoralesNoch keine Bewertungen

- Method Statement For Coal Feeder ErectionDokument20 SeitenMethod Statement For Coal Feeder ErectiontreyNoch keine Bewertungen

- Ball MillDokument8 SeitenBall Milltanmay035100% (1)

- Sno G D&C f001 HiradcDokument5 SeitenSno G D&C f001 HiradcTri SubaktiNoch keine Bewertungen

- 615-Hydraulic Pipe Changing of SCR#3Dokument5 Seiten615-Hydraulic Pipe Changing of SCR#3Buddy HartNoch keine Bewertungen

- Msds Sun Chlor Tcca Tablet 200 GRDokument8 SeitenMsds Sun Chlor Tcca Tablet 200 GRtito rahmanNoch keine Bewertungen

- Eonsolv 135 MailDokument11 SeitenEonsolv 135 MailChristiyan Chandra AntonoNoch keine Bewertungen

- SOP For Operation and Cleaning of Conveyer BeltDokument2 SeitenSOP For Operation and Cleaning of Conveyer BeltSudheer Nair100% (7)

- LAMPIRAN A Struktur OrganisasiDokument1 SeiteLAMPIRAN A Struktur OrganisasiAf RiNoch keine Bewertungen

- Inspection Checklist (Crusher 3)Dokument1 SeiteInspection Checklist (Crusher 3)Irfan AhmedNoch keine Bewertungen

- 07-SOP For Belt Conveyor 5ABDokument14 Seiten07-SOP For Belt Conveyor 5ABTamil VananNoch keine Bewertungen

- Batu Pack MateriDokument11 SeitenBatu Pack MateriBabang SwissNoch keine Bewertungen

- Conveyor SafetyDokument5 SeitenConveyor Safetyrize1159Noch keine Bewertungen

- Conveyor Check ListDokument2 SeitenConveyor Check Listh1549697100% (1)

- SMKP Safety Mining ProcedurDokument27 SeitenSMKP Safety Mining Proceduraiueo100% (1)

- Form Ibpr (Hira)Dokument218 SeitenForm Ibpr (Hira)Sadam ParenrengiNoch keine Bewertungen

- Inspection Sheet UNTUK DozerDokument12 SeitenInspection Sheet UNTUK DozerkkmechNoch keine Bewertungen

- MSDS Three BondDokument6 SeitenMSDS Three Bondadika fawaz safitraNoch keine Bewertungen

- 731-CC-8 Gear Box Oil Seal Changing From Hold Back SideDokument5 Seiten731-CC-8 Gear Box Oil Seal Changing From Hold Back SideBuddy HartNoch keine Bewertungen

- Mobile Crusher Plant IntroductionDokument6 SeitenMobile Crusher Plant IntroductionsunndyNoch keine Bewertungen

- Penilaian Keterampilan Operator Forklift Formula VicksDokument3 SeitenPenilaian Keterampilan Operator Forklift Formula Vicksberto hutama100% (1)

- Standard Test Method For Ash From Petroleum Products PDFDokument4 SeitenStandard Test Method For Ash From Petroleum Products PDFGabriel MoralesNoch keine Bewertungen

- Powder Coating ProcedureDokument1 SeitePowder Coating Procedurenastyn-1Noch keine Bewertungen

- Form Order SparepartDokument1 SeiteForm Order SparepartWendra HakaNoch keine Bewertungen

- Equipment Commissioning Safety ChecklistDokument1 SeiteEquipment Commissioning Safety Checklistjeffry EscletoNoch keine Bewertungen

- Coal Handling Plant Pre Start CheckDokument11 SeitenCoal Handling Plant Pre Start CheckBlitz Xyrus100% (2)

- SOP - Movement of Light Vehicles in MinesDokument6 SeitenSOP - Movement of Light Vehicles in MinesMUHAMMAD KASHIF Siddiqi100% (1)

- JSA Form 2Dokument7 SeitenJSA Form 2ekapadwiNoch keine Bewertungen

- Sop For Om For Ball MillDokument7 SeitenSop For Om For Ball MillvinodsnNoch keine Bewertungen

- Sop Inert GasDokument5 SeitenSop Inert GasvinodsnNoch keine Bewertungen

- Sop For Cleaning & HousekeepingDokument4 SeitenSop For Cleaning & HousekeepingvinodsnNoch keine Bewertungen

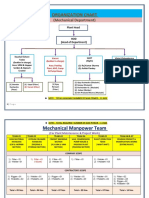

- Organization Chart: (Mechanical Department)Dokument3 SeitenOrganization Chart: (Mechanical Department)vinodsn100% (1)

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDokument2 SeitenBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNoch keine Bewertungen

- Lime Stone Cleaning Station - Project Proposal-03Dokument4 SeitenLime Stone Cleaning Station - Project Proposal-03vinodsnNoch keine Bewertungen

- Offer Letter-Manpower Supply & Project WorkDokument10 SeitenOffer Letter-Manpower Supply & Project WorkvinodsnNoch keine Bewertungen

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDokument1 SeiteBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNoch keine Bewertungen

- Sop For Cleaning & HousekeepingDokument4 SeitenSop For Cleaning & HousekeepingvinodsnNoch keine Bewertungen

- 3.20 Removal of Conveyor Belt With New BeltDokument2 Seiten3.20 Removal of Conveyor Belt With New Beltvinodsn100% (1)

- Sop Welding & Gas CuttingDokument9 SeitenSop Welding & Gas CuttingvinodsnNoch keine Bewertungen

- Sop For Om For Ball MillDokument7 SeitenSop For Om For Ball MillvinodsnNoch keine Bewertungen

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Dokument1 SeiteEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnNoch keine Bewertungen

- Sop For Bag FilterDokument5 SeitenSop For Bag FiltervinodsnNoch keine Bewertungen

- Cover Letter: Curriculam VitaeDokument4 SeitenCover Letter: Curriculam VitaevinodsnNoch keine Bewertungen

- Sop ListDokument1 SeiteSop ListvinodsnNoch keine Bewertungen

- 1-SOP For Raw Mill StartDokument2 Seiten1-SOP For Raw Mill Startvinodsn100% (2)

- Sop Inert GasDokument5 SeitenSop Inert GasvinodsnNoch keine Bewertungen

- Costing Details E & I (2074-75)Dokument8 SeitenCosting Details E & I (2074-75)vinodsnNoch keine Bewertungen

- Monthly Action Plan Process (March-2016)Dokument1 SeiteMonthly Action Plan Process (March-2016)vinodsnNoch keine Bewertungen

- Gist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalDokument1 SeiteGist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalvinodsnNoch keine Bewertungen

- Girth Gear RunoutDokument1 SeiteGirth Gear RunoutvinodsnNoch keine Bewertungen

- Girth Gear RunoutDokument1 SeiteGirth Gear RunoutvinodsnNoch keine Bewertungen

- Housekeeping Summary For Ucpl Plant: Raw Mill Section Area Date: 14/11/2017Dokument1 SeiteHousekeeping Summary For Ucpl Plant: Raw Mill Section Area Date: 14/11/2017vinodsnNoch keine Bewertungen

- Kiln Workshop Guide 4 - PPE PDFDokument3 SeitenKiln Workshop Guide 4 - PPE PDFvinodsnNoch keine Bewertungen

- Employee Salary Slip: Charkhal, Dillibazar, KathmanduDokument1 SeiteEmployee Salary Slip: Charkhal, Dillibazar, KathmanduvinodsnNoch keine Bewertungen

- D'Shawn M. Haines: 423 East Fox Trail, Williamstown, NJ 08094 (856) 366-7049Dokument2 SeitenD'Shawn M. Haines: 423 East Fox Trail, Williamstown, NJ 08094 (856) 366-7049dshawnNoch keine Bewertungen

- Basic Customer Service SkillsDokument90 SeitenBasic Customer Service SkillsGillian Delos ReyesNoch keine Bewertungen

- AEC 34 - ACB Assignment: Module 1: Problem 1-1.TRUE OR FALSEDokument5 SeitenAEC 34 - ACB Assignment: Module 1: Problem 1-1.TRUE OR FALSEDrew BanlutaNoch keine Bewertungen

- Thermo Exam QuestionsDokument4 SeitenThermo Exam QuestionssiskieoNoch keine Bewertungen

- Battle Group Builder + Commonwealth Infantry Roster - Wargames DesignDokument12 SeitenBattle Group Builder + Commonwealth Infantry Roster - Wargames DesignPete PoliNoch keine Bewertungen

- Annual Premium Statement: Bhupesh GuptaDokument1 SeiteAnnual Premium Statement: Bhupesh GuptaBhupesh GuptaNoch keine Bewertungen

- Student EssaysDokument41 SeitenStudent EssaysAsif RahmanNoch keine Bewertungen

- EL119 Module 2Dokument4 SeitenEL119 Module 2Kristine CastleNoch keine Bewertungen

- Accessing Biodiversity and Sharing The BenefitsDokument332 SeitenAccessing Biodiversity and Sharing The BenefitsNelson MartínezNoch keine Bewertungen

- Relative ClausesDokument11 SeitenRelative Clausessaeed100% (1)

- Popis Na OK KoziDokument325 SeitenPopis Na OK KoziViktor ArsovNoch keine Bewertungen

- Chapter 1 - Lesson 2 - Transforming Equations From Standard Form To General FormDokument8 SeitenChapter 1 - Lesson 2 - Transforming Equations From Standard Form To General FormhadukenNoch keine Bewertungen

- Entrance 2021: Indira Gandhi Rashtriya Uran AkademiDokument2 SeitenEntrance 2021: Indira Gandhi Rashtriya Uran Akademird meshramNoch keine Bewertungen

- Civil Engineering Construction Manager in ST Louis MO Resume Mark JensenDokument3 SeitenCivil Engineering Construction Manager in ST Louis MO Resume Mark JensenMark JensenNoch keine Bewertungen

- Cover PageDokument209 SeitenCover PageABHISHREE JAINNoch keine Bewertungen

- Cognitive InfocommunicationsDokument229 SeitenCognitive Infocommunicationsradhakodirekka8732Noch keine Bewertungen

- SOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalDokument10 SeitenSOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalAlba R.Noch keine Bewertungen

- Times Like This Strip-by-Strip (Part 1)Dokument49 SeitenTimes Like This Strip-by-Strip (Part 1)Joseph HoukNoch keine Bewertungen

- The Sphere Circumscribing A TetrahedronDokument4 SeitenThe Sphere Circumscribing A TetrahedronRaghuveer ChandraNoch keine Bewertungen

- How To Deliver A Good PresentationDokument9 SeitenHow To Deliver A Good PresentationGhozi Fawwaz Imtiyaazi LabiibaNoch keine Bewertungen

- Caribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Dokument1 SeiteCaribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Cawasa St-LuciaNoch keine Bewertungen

- ShowimgDokument76 SeitenShowimgROSHAN ROBERTNoch keine Bewertungen

- Phyto Pharmacy: Current Concepts and GMP NormsDokument22 SeitenPhyto Pharmacy: Current Concepts and GMP NormsSunitha Katta100% (1)

- Lecture # 3 Introduction To JqueryDokument88 SeitenLecture # 3 Introduction To JqueryDanial AhmadNoch keine Bewertungen

- 2002PCDFCADokument78 Seiten2002PCDFCATin NguyenNoch keine Bewertungen

- SFA TRAINING MODULE Week 1Dokument14 SeitenSFA TRAINING MODULE Week 1Ivan Perez100% (1)

- Website Design Proposal DentistDokument8 SeitenWebsite Design Proposal DentistNamanNoch keine Bewertungen