Beruflich Dokumente

Kultur Dokumente

Data Sheets FOR Pressure Safety Valves

Hochgeladen von

sunildubey02Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Data Sheets FOR Pressure Safety Valves

Hochgeladen von

sunildubey02Copyright:

Verfügbare Formate

FORMAT NO : 0060-F-28

This documenton it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

DATA SHEETS

FOR

PRESSURE SAFETY VALVES

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

CLIENT : INDIAN OIL CORPORATION LTD., PARADIP

PROJECT : NATURAL GAS DISTRUBUTION NETWORK

JOB NO. : 6890

0 12.10.18 ISSUED WITH BDEP PA AM ND/SML

A 10.09.18 ISSUED FOR REVIEW AND COMMENTS PA AM ND/SML

REV. NO. DATE DESCRIPTION PREP. REV. APP.

DOCUMENT TYPE : INSTRUMENT DATASHEET

PROCON INDIA PVT. PSV & TSV INSTRUMENT REV.

DOCUMENT NO.

LTD. NEW DELHI DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

SHEET1 OF 8

File Name : 6890-6500-IDS-012-4-R0

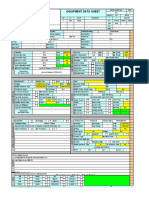

DATASHEETS FOR PSV : 140-PSV-9001 A/B

1 Tag Number Case No. 140-PSV 9001 A/B

GENERAL 2 Service LP Stream condensate

3 Line No. 6"-SL-140-9044-A1AS/A1AA-IH / 6"-SL-140-9026-A1AS/A1AA-IH

4 Vessel Protected 140-V-101

FORMAT NO : 0060-F-28

5 Application Type Relief without RD

6 Type of Valves Conventional

7 Design Full Nozzle

VALVE 8 Bonnet Type Open

This document and the information it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

9 Inlet : Size and Rating * *

Facing and Finish *

10 Outlet : Size and Rating * *

Facing and Finish -

11 Body and Bonnet ASTM A216 Gr.WCB

12 Nozzle and Disc *

MATERIAL 13 Guide and Rings *

14 Spring Chrome Alloy Steel

15 Bellows N/A

16 Resilient Seat Seal Required, SS *

17 Cap Over Adj. Bolt Required, Screwed

OPTIONS 18 Lever (lifting) Packed

19 Test Gag Required

BASIS 20 Code Basis Of Selection ASME VIII Tube Repture Case

21 Fluid State LP Steam condensate Liquid

22 Required Flow Capacity kg/h 123200

23 Molecular Weight g/mol -

24 Density at inlet kg/m3 902.3

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

25 Operating Pressure kg/cm²(g) 3.3

26 Set Pressure Cold Bench Test Pressure kg/cm²(g) 7.0 *

27 Operating Temperature °C 150

28 Relieving Temperature °C 152

FLUID DATA 29 Back Pressure Low High kg/cm²(g) Constant -

30 Allowable Overpressure(%) Blow Down (%) kg/cm²(g) 10 Standard

31 Compressibility Factor -

32 Degree of Super Heat

33 Ratio of Specific Heat -

34 Corrosive Constituents

35 Viscosity at Relieving Temperature cP 0.1788

36 Vessel Wall Temperature °C

37 Surface Area m²

38 Valve Discharges to ATM

39 Calculated Area Selected Area cm² * -

ORIFICE 40 Orifice Designation *

41 No. of Valves for Capacity Total Area cm² * *

42 Total Flow Capacity kg/h

CERTIFICATION 43 Statutory IBR

44 Others -

OTHERS 45 Number of Valves (To meet capacity) *

46 Model Number *

NOTES:

* Vendor to confirm and specify.

1. sizing shall be done as per IBR Regulations.

2. Vendor to provide the calculation of PSV sizing.

3. Body flang attached by weilding shall be 100% radiographed.

4. Vendor to give actual sizing for PSV. Sizes mentioned in Datasheet need to be verified by vendor.

5. Vendor to specify any other required accessories if required, Besides the standard accessories as mentioned in Datasheet.

6. Valve shall be asme code marked.

7. Total No. of PSV required is 2 (1 working +1 Stand-By)

PROCON INDIA DOCUMENT TYPE : INSTRUMENT DATASHEET REV.

PSV INSTRUMENT DOCUMENT NO.

PVT. LTD.

DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

NEW DELHI SHEET 2 OF 8

File Name : 6890-6500-IDS-012-4-R0

DATASHEETS FOR PSV : 140-PSV-9002 A/B

1 Tag Number Case No. 140-PSV 900 2A/B

GENERAL 2 Service LP Stream condensate

3 Line No. 6"-SL-140-9032-A1AS/A1AA-IH

FORMAT NO : 0060-F-28

4 Vessel Protected 140-V-102

5 Application Type Relief without RD

6 Type of Valves Conventional

7 Design Full Nozzle

VALVE 8 Bonnet Type Open

This document and the information it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

9 Inlet : Size and Rating * *

Facing and Finish *

10 Outlet : Size and Rating * *

Facing and Finish -

11 Body and Bonnet ASTM A216 Gr.WCB

12 Nozzle and Disc *

MATERIAL 13 Guide and Rings *

14 Spring Chrome Alloy Steel

15 Bellows N/A

16 Resilient Seat Seal Required, SS *

17 Cap Over Adj. Bolt Required, Screwed

OPTIONS 18 Lever (lifting) Packed

19 Test Gag Required

BASIS 20 Code Basis Of Selection ASME VIII Tube Repture Case

21 Fluid State LP Stream condensate

Liquid

22 Required Flow Capacity kg/h 121700

23 Molecular Weight g/mol -

24 Density at inlet kg/m3 902.3

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

25 Operating Pressure kg/cm²(g) 3.3

26 Set Pressure Cold Bench Test Pressure kg/cm²(g) 7.0 *

27 Operating Temperature °C 150

28 Relieving Temperature °C 152

FLUID DATA 29 Back Pressure Low High kg/cm²(g) Constant -

30 Allowable Overpressure(%) Blow Down (%) kg/cm²(g) 10 Standard

31 Compressibility Factor -

32 Degree of Super Heat

33 Ratio of Specific Heat -

34 Corrosive Constituents

35 Viscosity at Relieving Temperature cP 0.1788

36 Vessel Wall Temperature °C

37 Surface Area m²

38 Valve Discharges to ATM

39 Calculated Area Selected Area cm² * -

ORIFICE 40 Orifice Designation *

41 No. of Valves for Capacity Total Area cm² * *

42 Total Flow Capacity kg/h

CERTIFICATION 43 Statutory IBR

44 Others -

OTHERS 45 Number of Valves (To meet capacity) *

46 Model Number *

NOTES:

* Vendor to confirm and specify.

1. Vendor to provide the calculation of PSV sizing.

2. Body flang attached by weilding shall be 100% radiographed.

3. Vendor to give actual sizing for PSV. Sizes mentioned in Datasheet need to be verified by vendor.

4. Vendor to specify any other required accessories if required, Besides the standard accessories as mentioned in Datasheet.

5. Valve shall be asme code marked.

6. Total No. of PSV required is 2 (1 working +1 Stand-By)

PROCON INDIA DOCUMENT TYPE : INSTRUMENT DATASHEET REV.

PSV INSTRUMENT DOCUMENT NO.

PVT. LTD.

DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

NEW DELHI SHEET 3 OF 8

File Name : 6890-6500-IDS-012-4-R0

DATASHEETS FOR PSV : 140-PSV-9003 A/B

1 Tag Number Case No. 140-PSV 9003 A/B

GENERAL 2 Service Natural Gas

3 Line No. 12"-NG-140-9016-A1AP-IH / 12"-NG-140-9046-A1AP-IH

FORMAT NO : 0060-F-28

4 Vessel Protected -

5 Application Type Relief without RD

6 Type of Valves Conventional

7 Design Full Nozzle

VALVE 8 Bonnet Type Open

This document and the information it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

9 Inlet : Size and Rating * *

Facing and Finish *

10 Outlet : Size and Rating * *

Facing and Finish -

11 Body and Bonnet ASTM A216 Gr.WCB

12 Nozzle and Disc *

MATERIAL 13 Guide and Rings *

14 Spring Chrome Alloy Steel

15 Bellows N/A

16 Resilient Seat Seal Required, SS *

17 Cap Over Adj. Bolt Required, Screwed

OPTIONS 18 Lever (lifting) Packed

19 Test Gag Required

BASIS 20 Code Basis Of Selection ASME VIII Blocked discharge

21 Fluid State Natural Gas Vapour

22 Required Flow Capacity kg/h 48286

23 Molecular Weight g/mol 17.52

24 Density at Rel. Temp. -

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

25 Operating Pressure kg/cm²(g) -

26 Set Pressure Cold Bench Test Pressure kg/cm²(g) 6 *

27 Operating Temperature °C 34

28 Relieving Temperature °C 34

0.8 kg/cm²(g) -

FLUID DATA 29 Back Pressure Low High kg/cm²(g) Constant

30 Allowable Overpressure(%) Blow Down (%) kg/cm²(g) 10 Standard

31 Compressibility Factor 0.9863

32 Degree of Super Heat

33 Ratio of Specific Heat 1.278

34 Corrosive Constituents

35 Viscosity at Relieving Temperature cP 0.01167

36 Vessel Wall Temperature °C

37 Surface Area m²

38 Valve Discharges to Flare Header

39 Calculated Area Selected Area cm² * -

ORIFICE 40 Orifice Designation *

41 No. of Valves for Capacity Total Area cm² * *

42 Total Flow Capacity kg/h

CERTIFICATION 43 Statutory -

44 Others -

OTHERS 45 Number of Valves (To meet capacity) *

46 Model Number *

NOTES:

* Vendor to confirm and specify.

1. Vendor to provide the calculation of PSV sizing.

2. Body flang attached by weilding shall be 100% radiographed.

3. Vendor to give actual sizing for PSV. Sizes mentioned in Datasheet need to be verified by vendor.

4. Vendor to specify any other required accessories if required, Besides the standard accessories as mentioned in Datasheet.

5. Valve shall be asme code marked.

6. Total No. of PSV required is 2 (1 working +1 Stand-By)

PROCON INDIA DOCUMENT TYPE : INSTRUMENT DATASHEET REV.

PSV INSTRUMENT DOCUMENT NO.

PVT. LTD.

DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

NEW DELHI SHEET 4 OF 8

File Name : 6890-6500-IDS-012-4-R0

DATASHEETS FOR PSV : 140-PSV-9004 A/B

1 Tag Number Case No. 140-PSV 9004A/B

GENERAL 2 Service Natural Gas

3 Line No. 14"-NG-140-9012-A1AP/A2AQ-IH / 14"-NG-140-9043-A1AP/A2AQ-IH

4 Vessel Protected -

FORMAT NO : 0060-F-28

5 Application Type Relief without RD

6 Type of Valves Conventional

7 Design Full Nozzle

VALVE 8 Bonnet Type Open

9 Inlet : Size and Rating * *

This document and the information it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

Facing and Finish *

10 Outlet : Size and Rating * *

Facing and Finish -

11 Body and Bonnet ASTM A216 Gr.WCB

12 Nozzle and Disc *

MATERIAL 13 Guide and Rings *

14 Spring Chrome Alloy Steel

15 Bellows N/A

16 Resilient Seat Seal Required, SS *

17 Cap Over Adj. Bolt Required, Screwed

OPTIONS 18 Lever (lifting) Packed

19 Test Gag Required

BASIS 20 Code Basis Of Selection ASME VIII failure of PCV-9011/9012

21 Fluid State Natural Gas Vapour

22 Required Flow Capacity kg/h 50000

23 Molecular Weight g/mol 17.52

24 Density at Rel. Temp. -

25 Operating Pressure kg/cm²(g) -

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

26 Set Pressure Cold Bench Test Pressure kg/cm²(g) 6 *

27 Operating Temperature °C 34

28 Relieving Temperature °C 34

0.8 kg/cm²(g) -

FLUID DATA 29 Back Pressure Low High kg/cm²(g) Constant

30 Allowable Overpressure(%) Blow Down (%) kg/cm²(g) 10 Standard

31 Compressibility Factor 0.9863

32 Degree of Super Heat

33 Ratio of Specific Heat 1.27

34 Corrosive Constituents

35 Viscosity at Relieving Temperature cP 0.01167

36 Vessel Wall Temperature °C

37 Surface Area m²

38 Valve Discharges to Flare Header

39 Calculated Area Selected Area cm² * -

ORIFICE 40 Orifice Designation *

41 No. of Valves for Capacity Total Area cm² * *

42 Total Flow Capacity kg/h

CERTIFICATION 43 Statutory -

44 Others -

OTHERS 45 Number of Valves (To meet capacity) *

46 Model Number *

NOTES:

* Vendor to confirm and specify.

1. Vendor to provide the calculation of PSV sizing.

2. Body flang attached by weilding shall be 100% radiographed.

3. Vendor to give actual sizing for PSV. Sizes mentioned in Datasheet need to be verified by vendor.

4. Vendor to specify any other required accessories if required, Besides the standard accessories as mentioned in Datasheet.

5. Valve shall be asme code marked.

6. Total No. of PSV required is 2 (1 working +1 Stand-By)

PROCON INDIA DOCUMENT TYPE : INSTRUMENT DATASHEET

PSV INSTRUMENT REV.

PVT. LTD. DOCUMENT NO.

DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

NEW DELHI SHEET 5 OF 8

File Name : 6890-6500-IDS-012-4-R0

DATASHEETS FOR PSV : 140-PSV-9005

1 Tag Number Case No. 140-PSV 9005

GENERAL 2 Service Natural Gas

3 Line No. '12"-NG-140-9041-A1AP/A2AQ-IH

4 Vessel Protected -

FORMAT NO : 0060-F-28

5 Application Type Relief without RD

6 Type of Valves Conventional

7 Design Full Nozzle

VALVE 8 Bonnet Type Open

9 Inlet : Size and Rating * *

This document and the information it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

Facing and Finish *

10 Outlet : Size and Rating * *

Facing and Finish -

11 Body and Bonnet ASTM A216 Gr.WCB

12 Nozzle and Disc *

MATERIAL 13 Guide and Rings *

14 Spring Chrome Alloy Steel

15 Bellows N/A

16 Resilient Seat Seal Required, SS *

17 Cap Over Adj. Bolt Required, Screwed

OPTIONS 18 Lever (lifting) Packed

19 Test Gag Required

BASIS 20 Code Basis Of Selection ASME VIII failure of PCV-9011/9012

21 Fluid State Natural Gas Vapour

22 Required Flow Capacity kg/h 50000

23 Molecular Weight g/mol 17.52

24 Density at Rel. Temp. -

25 Operating Pressure kg/cm²(g) -

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

26 Set Pressure Cold Bench Test Pressure kg/cm²(g) 6.3 *

27 Operating Temperature °C 34

28 Relieving Temperature °C 34

0.8 kg/cm²(g) -

FLUID DATA 29 Back Pressure Low High kg/cm²(g) Constant

30 Allowable Overpressure(%) Blow Down (%) kg/cm²(g) 10 Standard

31 Compressibility Factor 0.9863

32 Degree of Super Heat

33 Ratio of Specific Heat 1.27

34 Corrosive Constituents

35 Viscosity at Relieving Temperature cP 0.01167

36 Vessel Wall Temperature °C

37 Surface Area m²

38 Valve Discharges to Flare Header

39 Calculated Area Selected Area cm² * -

ORIFICE 40 Orifice Designation *

41 No. of Valves for Capacity Total Area cm² * *

42 Total Flow Capacity kg/h

CERTIFICATION 43 Statutory -

44 Others -

OTHERS 45 Number of Valves (To meet capacity) *

46 Model Number *

NOTES:

* Vendor to confirm and specify.

1. Vendor to provide the calculation of PSV sizing.

2. Body flang attached by weilding shall be 100% radiographed.

3. Vendor to give actual sizing for PSV. Sizes mentioned in Datasheet need to be verified by vendor.

4. Vendor to specify any other required accessories if required, Besides the standard accessories as mentioned in Datasheet.

5. Valve shall be asme code marked.

PROCON INDIA DOCUMENT TYPE : INSTRUMENT DATASHEET

PSV INSTRUMENT REV.

PVT. LTD. DOCUMENT NO.

DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

NEW DELHI SHEET 6 OF 8

File Name : 6890-6500-IDS-012-4-R0

DATASHEETS FOR PSV : 140-PSV-9006 A/B

1 Tag Number Case No. 140-PSV 9006 A/B

GENERAL 2 Service Natural Gas

3 Line No. 10"-NG-140-9048-B1GP/A2AQ-NI / 10"-NG-140-9048-B1GP/A2AQ-NI

4 Vessel Protected -

FORMAT NO : 0060-F-28

5 Application Type Relief without RD

6 Type of Valves Conventional

7 Design Full Nozzle

VALVE 8 Bonnet Type Open

This document and the information it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

9 Inlet : Size and Rating * *

Facing and Finish *

10 Outlet : Size and Rating * *

Facing and Finish -

11 Body and Bonnet ASTM A216 Gr.WCB

12 Nozzle and Disc *

MATERIAL 13 Guide and Rings *

14 Spring Chrome Alloy Steel

15 Bellows N/A

16 Resilient Seat Seal Required, SS *

17 Cap Over Adj. Bolt Required, Screwed

OPTIONS 18 Lever (lifting) Packed

19 Test Gag Required

BASIS 20 Code Basis of Selection ASME VIII Over pressure

21 Fluid State Natural Gas Vapour +Liquid (Mixed)

22 Required Flow Capacity kg/h 264000

23 Molecular Weight g/mol 17.5

24 Density at Rel. Temp. -

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

25 Operating Pressure kg/cm²(g) 45

26 Set Pressure Cold Bench Test Pressure kg/cm²(g) 50 *

27 Operating Temperature °C -5

28 Relieving Temperature °C -5

2.82

FLUID DATA 29 Back Pressure Low High kg/cm²(g) Constant -

30 Allowable Overpressure(%) Blow Down (%) kg/cm²(g) 10 Standard

31 Compressibility Factor -

32 Degree of Super Heat

33 Ratio of Specific Heat -

34 Corrosive Constituents

35 Viscosity at Relieving Temperature cP

36 Vessel Wall Temperature °C

37 Surface Area m²

38 Valve Discharges to Flare Header

39 Calculated Area Selected Area cm² * -

ORIFICE 40 Orifice Designation *

41 No. of Valves for Capacity Total Area cm² * *

42 Total Flow Capacity kg/h

CERTIFICATION 43 Statutory -

44 Others -

OTHERS 45 Number of Valves (To meet capacity) *

46 Model Number *

NOTES:

* Vendor to confirm and specify.

1. sizing shall be done as per IBR Regulations.

2. Vendor to provide the calculation of PSV sizing.

3. Body flang attached by weilding shall be 100% radiographed.

4. Vendor to give actual sizing for PSV. Sizes mentioned in Datasheet need to be verified by vendor.

5. Vendor to specify any other required accessories if required, Besides the standard accessories as mentioned in Datasheet.

6. Valve shall be asme code marked.

7. Total No. of PSV required is 2 (1 working +1 Stand-By)

8. Valves shall be suitable fot low temperature applications

PROCON INDIA DOCUMENT TYPE : INSTRUMENT DATASHEET REV.

PSV INSTRUMENT DOCUMENT NO.

PVT. LTD.

DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

NEW DELHI SHEET 7 OF 8

File Name : 6890-6500-IDS-012-4-R0

DATASHEETS FOR PSV : 140-PSV-9401

1 Tag Number Case No. 140-PSV 9401

GENERAL 2 Service Steam Condensate

3 Line No. 6"-CL-140-9412-A2AS-IH

4 Vessel Protected 140-V-103

FORMAT NO : 0060-F-28

5 Application Type Relief without RD

6 Type of Valves Conventional

7 Design Full Nozzle

VALVE 8 Bonnet Type Open

9 Inlet : Size and Rating * *

This document and the information it covers is the sole property of PROCON INDIA PVT. LTD. and is merely lent on the express or implied agreement of the Borrower

Facing and Finish *

10 Outlet : Size and Rating * *

Facing and Finish -

11 Body and Bonnet ASTM A216 Gr.WCB

12 Nozzle and Disc *

MATERIAL 13 Guide and Rings *

14 Spring Chrome Alloy Steel

15 Bellows N/A

16 Resilient Seat Seal Required, SS *

17 Cap Over Adj. Bolt Required, Screwed

OPTIONS 18 Lever (lifting) Packed

19 Test Gag Required

BASIS 20 Code Basis Of Selection ASME VIII Control Valve Fail case LV-9001

21 Fluid State Steam Condensate Steam

22 Required Flow Capacity kg/h 15000

23 Molecular Weight g/mol 18.02

24 Density at Rel. Temp.

25 Operating Pressure kg/cm²(g) 0.7

that it shall not be reproduced, copied, transferred or used for a purpose other than the one for which it is given.

26 Set Pressure Cold Bench Test Pressure kg/cm²(g) 3.5 *

27 Operating Temperature °C 0.151

28 Relieving Temperature °C 0.151

FLUID DATA 29 Back Pressure Low High kg/cm²(g) Constant -

30 Allowable Overpressure(%) Blow Down (%) kg/cm²(g) 10 Standard

31 Compressibility Factor 0.9717

32 Degree of Super Heat

33 Ratio of Specific Heat 1.317

34 Corrosive Constituents

35 Viscosity at Relieving Temperature cP

36 Vessel Wall Temperature °C

37 Surface Area m²

38 Valve Discharges to ATM

39 Calculated Area Selected Area cm² * -

ORIFICE 40 Orifice Designation *

41 No. of Valves for Capacity Total Area cm² * *

42 Total Flow Capacity kg/h

CERTIFICATION 43 Statutory IBR

44 Others -

OTHERS 45 Number of Valves (To meet capacity) *

46 Model Number *

NOTES:

* Vendor to confirm and specify.

1. Vendor to provide the calculation of PSV sizing.

2. Body flang attached by weilding shall be 100% radiographed.

3. Vendor to give actual sizing for PSV. Sizes mentioned in Datasheet need to be verified by vendor.

4. Vendor to specify any other required accessories if required, Besides the standard accessories as mentioned in Datasheet.

5. Valve shall be asme code marked.

PROCON INDIA DOCUMENT TYPE : INSTRUMENT DATASHEET

PSV INSTRUMENT REV.

PVT. LTD. DOCUMENT NO.

DATASHEET 6 8 9 0 6 5 0 0 - I D S 0 1 2 4 0

NEW DELHI SHEET 8 OF 8

File Name : 6890-6500-IDS-012-4-R0

Das könnte Ihnen auch gefallen

- Annexure-I Instrument Datasheet For Self Actuating Pressure Control ValveDokument5 SeitenAnnexure-I Instrument Datasheet For Self Actuating Pressure Control ValveAmit BansalNoch keine Bewertungen

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDokument22 SeitenPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405Noch keine Bewertungen

- 1520-Dtx-110-3 - Boq - CPVC Pipes Fittings Tender r2Dokument5 Seiten1520-Dtx-110-3 - Boq - CPVC Pipes Fittings Tender r2Smit BhivgadeNoch keine Bewertungen

- 000 Emi2200987 VD PRDokument106 Seiten000 Emi2200987 VD PRjaidikarimNoch keine Bewertungen

- 2.ANNEXUREDokument89 Seiten2.ANNEXUREAnonymous fLgaidVBhzNoch keine Bewertungen

- BB2 Rev03Dokument8 SeitenBB2 Rev03Ahmed El-AzharyNoch keine Bewertungen

- Measuring Point List - Turbine PDFDokument43 SeitenMeasuring Point List - Turbine PDFKhushboo PandeyNoch keine Bewertungen

- Inst Hook Up PDFDokument18 SeitenInst Hook Up PDFRinaBhattacharya50% (2)

- PEMEX Exploración y Producción Paraiso - Tabasco Tg-2 Unit: Battery Charger Data SheetDokument13 SeitenPEMEX Exploración y Producción Paraiso - Tabasco Tg-2 Unit: Battery Charger Data SheetdanieldayettddNoch keine Bewertungen

- Write Up On LPBP SystemDokument9 SeitenWrite Up On LPBP SystemKhushboo PandeyNoch keine Bewertungen

- Saudi Arabian Oil Company: Instrument Specification Sheet - Hydrocarbon Liquid Sampling SystemsDokument1 SeiteSaudi Arabian Oil Company: Instrument Specification Sheet - Hydrocarbon Liquid Sampling SystemsMuhammad SalmanNoch keine Bewertungen

- Area13-IO LIST-R3 (IFC)Dokument36 SeitenArea13-IO LIST-R3 (IFC)Hân TiênNoch keine Bewertungen

- API 610 11th Data Sheets Centrifugal Pump Si Units 79-P-906 Rev BDokument9 SeitenAPI 610 11th Data Sheets Centrifugal Pump Si Units 79-P-906 Rev BMichael PiñaNoch keine Bewertungen

- 10p125-I0001-001-0-Instrument IndexDokument137 Seiten10p125-I0001-001-0-Instrument IndexMonaNoch keine Bewertungen

- Recipiente: Equipment Data SheetDokument1 SeiteRecipiente: Equipment Data SheetAlonso DIAZNoch keine Bewertungen

- Engineering Design Basis FOR Project: Client: Projec T: Job No.Dokument11 SeitenEngineering Design Basis FOR Project: Client: Projec T: Job No.Priyanka KumariNoch keine Bewertungen

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDokument53 SeitenPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405Noch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Flow Control Valve Specification SheetDokument7 SeitenFlow Control Valve Specification SheetKrishNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- New Welder Register 18 08 2020Dokument16 SeitenNew Welder Register 18 08 2020Deepu CNoch keine Bewertungen

- Report Control Room Lawe 220218-RE0Dokument78 SeitenReport Control Room Lawe 220218-RE0ajiNoch keine Bewertungen

- C05-Uu00-Q-7856 - 1 - PS1, Emg-Ff Building, Lighting Layout and Lighting Fixture Schedule, SHT 2of2Dokument1 SeiteC05-Uu00-Q-7856 - 1 - PS1, Emg-Ff Building, Lighting Layout and Lighting Fixture Schedule, SHT 2of2sartajNoch keine Bewertungen

- Name of Project:: 2 X 4.4Mw Rudi Khola HepDokument5 SeitenName of Project:: 2 X 4.4Mw Rudi Khola HepapsNoch keine Bewertungen

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDokument5 Seiten05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- GLP 001Dokument1 SeiteGLP 001Alonso DIAZNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataShubham kgc100% (1)

- NBC Jaf GQC RT A 150,151,152,153Dokument4 SeitenNBC Jaf GQC RT A 150,151,152,153Akansha SharmaNoch keine Bewertungen

- Recipiente: Equipment Data SheetDokument1 SeiteRecipiente: Equipment Data SheetAlonso DIAZNoch keine Bewertungen

- 1 969490 4Dokument1 Seite1 969490 4lev501Noch keine Bewertungen

- 000 SLT2101316 Pe PiDokument27 Seiten000 SLT2101316 Pe PijaidikarimNoch keine Bewertungen

- Gas Development Project For Unitization of The Jambaran - Tiung Biru FieldDokument1 SeiteGas Development Project For Unitization of The Jambaran - Tiung Biru FieldBintang AtdiNoch keine Bewertungen

- DRP001 Puc Hyo A60 160P 014a 0001 Com R6 - Te 9586 - 87 - 90 - 91Dokument16 SeitenDRP001 Puc Hyo A60 160P 014a 0001 Com R6 - Te 9586 - 87 - 90 - 91John AlmasNoch keine Bewertungen

- Saudi Arabian Oil Company Valve Data Sheet General DataDokument2 SeitenSaudi Arabian Oil Company Valve Data Sheet General Datasalihmohammed533Noch keine Bewertungen

- 9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Dokument15 Seiten9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Pottem VanithareddyNoch keine Bewertungen

- DS - DP Type Flow IndicatorsDokument5 SeitenDS - DP Type Flow IndicatorsNawfel ArafathNoch keine Bewertungen

- Ipc & Ipp Logbook or FlowDokument8 SeitenIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- Rotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryDokument3 SeitenRotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryeduinNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Air TubeDokument7 SeitenAir TubeLakshmi KishoreNoch keine Bewertungen

- HKZB-PET-03575-001-MA-EN - 00 - PMI PROCEDURE For MOVDokument6 SeitenHKZB-PET-03575-001-MA-EN - 00 - PMI PROCEDURE For MOVShanky guptaNoch keine Bewertungen

- Emerson Ups ManualDokument73 SeitenEmerson Ups Manualvdrizzils100% (2)

- Gel in Hmel Poly LTP V Doc 001Dokument25 SeitenGel in Hmel Poly LTP V Doc 001rinkukachhelaNoch keine Bewertungen

- J06 PT PDT 5988 5989 PDFDokument10 SeitenJ06 PT PDT 5988 5989 PDFnashittNoch keine Bewertungen

- CUSTOMER - GID-208-CI-ECC-LA-80901SCR - PLC IO ListDokument7 SeitenCUSTOMER - GID-208-CI-ECC-LA-80901SCR - PLC IO Listsivasakti chp2Noch keine Bewertungen

- Recipiente: Equipment Data SheetDokument1 SeiteRecipiente: Equipment Data SheetAlonso DIAZNoch keine Bewertungen

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Dokument6 SeitenMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82Noch keine Bewertungen

- 195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0Dokument8 Seiten195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0leejo100% (1)

- Motor ListDokument19 SeitenMotor ListSivaram KumarNoch keine Bewertungen

- Gel in Hmel Asrs LTP V Doc 001Dokument38 SeitenGel in Hmel Asrs LTP V Doc 001rinkukachhelaNoch keine Bewertungen

- DS - Flow Element (Orifice)Dokument5 SeitenDS - Flow Element (Orifice)Nawfel ArafathNoch keine Bewertungen

- Revision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsDokument2 SeitenRevision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsAdilson MirandaNoch keine Bewertungen

- DS - Pressure GaugeDokument5 SeitenDS - Pressure GaugeNawfel ArafathNoch keine Bewertungen

- D000-EL-701 Rev 4Dokument19 SeitenD000-EL-701 Rev 4Sardar PerdawoodNoch keine Bewertungen

- Gas Development Project For Unitization of The Jambaran - Tiung Biru FieldDokument2 SeitenGas Development Project For Unitization of The Jambaran - Tiung Biru FieldBintang AtdiNoch keine Bewertungen

- B-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteDokument3 SeitenB-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteMuhammad TeguhNoch keine Bewertungen

- DS - Diiferential Pressure TransmitterDokument5 SeitenDS - Diiferential Pressure TransmitterNawfel ArafathNoch keine Bewertungen

- ProfessionsDokument7 SeitenProfessionssunildubey02Noch keine Bewertungen

- Karmic Soulmates - AstrologyDokument2 SeitenKarmic Soulmates - Astrologysunildubey02Noch keine Bewertungen

- Which Planet Gives SuccessDokument2 SeitenWhich Planet Gives Successsunildubey02Noch keine Bewertungen

- What Does An Astrologer DoDokument1 SeiteWhat Does An Astrologer Dosunildubey02Noch keine Bewertungen

- Early Marriage - JyotishDokument1 SeiteEarly Marriage - Jyotishsunildubey02Noch keine Bewertungen

- Karma To MarriageDokument1 SeiteKarma To Marriagesunildubey02Noch keine Bewertungen

- Divorce - AstrologyDokument1 SeiteDivorce - Astrologysunildubey02Noch keine Bewertungen

- Marriage - StepsDokument1 SeiteMarriage - Stepssunildubey02Noch keine Bewertungen

- 7 HabitsDokument10 Seiten7 Habitssunildubey02Noch keine Bewertungen

- Safety While Taking MedicinesDokument4 SeitenSafety While Taking Medicinessunildubey02Noch keine Bewertungen

- SikkimDokument6 SeitenSikkimsunildubey02Noch keine Bewertungen

- The Karma Alignment TechniqueDokument2 SeitenThe Karma Alignment Techniquesunildubey02Noch keine Bewertungen

- Vedic Mantra For All Type of DiseasesDokument33 SeitenVedic Mantra For All Type of Diseasessunildubey02100% (7)

- 7 HabitsDokument10 Seiten7 Habitssunildubey02Noch keine Bewertungen

- The World History of 5000 YearsDokument6 SeitenThe World History of 5000 Yearssunildubey02Noch keine Bewertungen

- For Stickers List PDFDokument271 SeitenFor Stickers List PDFsunildubey02100% (1)

- Line ListDokument3 SeitenLine Listsunildubey02Noch keine Bewertungen

- Diet and HealthDokument21 SeitenDiet and Healthsunildubey02Noch keine Bewertungen

- 32 Names of DurgaDokument1 Seite32 Names of DurgashreethalNoch keine Bewertungen

- TERI SUPI SUGANDH Brochure PDFDokument4 SeitenTERI SUPI SUGANDH Brochure PDFsunildubey02Noch keine Bewertungen

- HR DetailsDokument209 SeitenHR Detailssunildubey02Noch keine Bewertungen

- How To Use Acupressure For Back PainDokument18 SeitenHow To Use Acupressure For Back Painsunildubey02Noch keine Bewertungen

- Diabetes by AsanasDokument2 SeitenDiabetes by Asanassunildubey02Noch keine Bewertungen

- India Rankings 2017 2014 Batch: SR - No. Name of The Employer/Company/Organizations Location HR Contact Name DesignationDokument10 SeitenIndia Rankings 2017 2014 Batch: SR - No. Name of The Employer/Company/Organizations Location HR Contact Name Designationsunildubey02Noch keine Bewertungen

- NRI Group HousingDokument66 SeitenNRI Group Housingsunildubey02100% (1)

- Someka Templates InfoDokument12 SeitenSomeka Templates Infosunildubey02Noch keine Bewertungen

- DLF Moti NagarDokument30 SeitenDLF Moti Nagarsunildubey0250% (2)

- DU-6th Cut-Off - Arts & CommerceDokument14 SeitenDU-6th Cut-Off - Arts & Commercesunildubey02Noch keine Bewertungen

- Applying Remote Sensing To Avian ResearchDokument28 SeitenApplying Remote Sensing To Avian Researchsunildubey02Noch keine Bewertungen

- Applying Remote Sensing To Avian ResearchDokument15 SeitenApplying Remote Sensing To Avian Researchsunildubey02Noch keine Bewertungen

- Mid-Semester Examination: Solution: PHY103A: Physics II Semester II, 2017-18 IIT KanpurDokument11 SeitenMid-Semester Examination: Solution: PHY103A: Physics II Semester II, 2017-18 IIT KanpurPaola GongoraNoch keine Bewertungen

- English Vocab - Sheet6Dokument15 SeitenEnglish Vocab - Sheet6mohd dilshadNoch keine Bewertungen

- 5991 8252enDokument8 Seiten5991 8252enRocketManNoch keine Bewertungen

- Unit 3.2: Unit 3.2 Mass-Energy RelationshipDokument33 SeitenUnit 3.2: Unit 3.2 Mass-Energy RelationshipGabriel FungNoch keine Bewertungen

- Catalogue - Proflex Disc DiffuserDokument2 SeitenCatalogue - Proflex Disc DiffuserAzhar MandhraNoch keine Bewertungen

- How To Read Electronic Circuit Diagrams (1970)Dokument225 SeitenHow To Read Electronic Circuit Diagrams (1970)smupy_122-1100% (3)

- Brochure OTOMEC 2016Dokument10 SeitenBrochure OTOMEC 2016Le LanNoch keine Bewertungen

- BESI Actuators (Hydraulic)Dokument2 SeitenBESI Actuators (Hydraulic)mister_no34Noch keine Bewertungen

- Design Handbook IRC112Dokument111 SeitenDesign Handbook IRC112zulfekharNoch keine Bewertungen

- Mine Detection Using Radar Bullets Full Seminar ReportDokument17 SeitenMine Detection Using Radar Bullets Full Seminar Reportabhishek18051988100% (2)

- GR 9 ICSE Final Exam Question Paper PhysicsDokument4 SeitenGR 9 ICSE Final Exam Question Paper PhysicsanjalimenonNoch keine Bewertungen

- Quantum Mechanical Explanation For Dark Energy, Cosmic Coincidence, Flatness, Age, and Size of The UniverseDokument8 SeitenQuantum Mechanical Explanation For Dark Energy, Cosmic Coincidence, Flatness, Age, and Size of The UniverseAsemSalehNoch keine Bewertungen

- DS EN ISO 527-1 1993 - Determination of Tensile PropertiesDokument12 SeitenDS EN ISO 527-1 1993 - Determination of Tensile PropertiesSoo Seo100% (1)

- 03 - Potential of Flow Ver 1.1Dokument29 Seiten03 - Potential of Flow Ver 1.1Kamel EsaNoch keine Bewertungen

- BITS Pilani AssignmentDokument9 SeitenBITS Pilani AssignmentNaresh SehdevNoch keine Bewertungen

- تأثير تأرجح القدرةDokument15 Seitenتأثير تأرجح القدرةiipmnpti iipmNoch keine Bewertungen

- DQ1702 Utility Heater, Brown - Instructions WalmartDokument6 SeitenDQ1702 Utility Heater, Brown - Instructions Walmart240GL guy25% (4)

- EMACH1 - DC GeneratorDokument60 SeitenEMACH1 - DC GeneratorKiyoshi Jiro MalinaoNoch keine Bewertungen

- A Detailed Lesson Plan in Science 10: Fernandez College of Arts and TechnologyDokument7 SeitenA Detailed Lesson Plan in Science 10: Fernandez College of Arts and TechnologyAdrian DionisioNoch keine Bewertungen

- 120 X 120 X 38 MM SERIES: Dimensions DrawingDokument2 Seiten120 X 120 X 38 MM SERIES: Dimensions DrawingElias CoelhoNoch keine Bewertungen

- AP Biology Unit 1 Biochemistry Cheat SheetDokument2 SeitenAP Biology Unit 1 Biochemistry Cheat Sheetf2vn65zbh9Noch keine Bewertungen

- Mathematics/Eng Eco/Basic Eng Trivia Examination: Dugs (The Undergraduates) Review CenterDokument9 SeitenMathematics/Eng Eco/Basic Eng Trivia Examination: Dugs (The Undergraduates) Review CenterJaypee BucatcatNoch keine Bewertungen

- MCQ MicrosDokument5 SeitenMCQ Microsamitrameshwardayal50% (2)

- Type 1: Technical ParametersDokument7 SeitenType 1: Technical ParametersMuhammad AliNoch keine Bewertungen

- ABB Sace - Protection and Control Device - Handbook PDFDokument551 SeitenABB Sace - Protection and Control Device - Handbook PDFartemariayancyNoch keine Bewertungen

- Spotlight Advanced - 16 Aug To 30 Sep Batch 1Dokument2 SeitenSpotlight Advanced - 16 Aug To 30 Sep Batch 1Gamer Helper0% (1)

- Electrical Workshop - ExperimentsDokument7 SeitenElectrical Workshop - ExperimentsMirza Bilal100% (1)

- 6.5 Moles and Solution Chemistry IGCSEDokument43 Seiten6.5 Moles and Solution Chemistry IGCSETsetse GanboldNoch keine Bewertungen

- Fluid Mechanics Is The Branch of Physics and Engineering That Studies The Behavior of FluidsDokument2 SeitenFluid Mechanics Is The Branch of Physics and Engineering That Studies The Behavior of FluidsIkechukwu OkekeNoch keine Bewertungen

- VLSI System Design Lab Digital Assignment 1Dokument11 SeitenVLSI System Design Lab Digital Assignment 1SMNoch keine Bewertungen