Beruflich Dokumente

Kultur Dokumente

GBC 01-1005-00 SavantAA Software Operation Manual

Hochgeladen von

ngobaochanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GBC 01-1005-00 SavantAA Software Operation Manual

Hochgeladen von

ngobaochanCopyright:

Verfügbare Formate

SYSTEM 2000/3000

GRAPHITE FURNACE

GBC SCIENTIFIC EQUIPMENT

PTY LTD

AUTHORS:

Graeme Chapple

Nick Athanasopoulos

Edition: 1.1

Manual No. 01-0202-00

Designed and published by GBC Scientific Equipment Pty Ltd

GBC reserves the right to change specifications without notice.

Publication number 01-0202-00

Edition 1.1

July, 1991

2 GBC Graphite Furnace Methods Manual

Table of Contents

Page

1. Introduction 5

1.1 Atomic Absorption Spectroscopy 5

1.2 Choice of method, flame or furnace 6

1.2.1 Flame 6

1.2.2 Furnace 6

2. Furnace Atomic Absorption 7

2.1 Graphite tubes 7

2.2 Temperature program development 7

2.2.1 Dry 8

2.2.2 Ash 8

2.2.3 Atomize 9

2.2.4 Measurement mode 9

2.2.5 Gas flow selection 9

2.2.6 Reduced gas flow during atomization 9

2.3 Interferences 11

2.3.1 Physical 11

2.3.2 Chemical 11

2.3.3 Chemical Modification 11

2.3.4 Background correction 13

2.3.5 Incandescence 14

3. Platforms 15

3.1 Platform theory 15

3.2 Platform temperature program 15

3.2.1 Dry 15

3.2.2 Ash 16

3.2.3 Atomize 16

3.2.4 Cool down step 17

3.2.5 Sample volume optimization 17

4. Sample Preparation 18

4.1 Ashing technique 18

4.1.1 Wet Digestion Methods 18

4.1.2 Dry ashing 18

4.2 Chemical separations and concentration 20

GBC Graphite Furnace Methods Manual 3

Table of Contents (cont’d.)

4.2.1 Ammonium pyrolidine dithiocarbamate

extractions (APDC) 20

4.2.2 8-Hydroxyquinoline (oxine) extractions 22

4.2.3 Sodium diethyl-dithiocarbamate

extractions (NaDDC) 22

4.2.4 Ion exchange 23

4.3 Contamination 24

4.3.1. Storage Materials 24

4.3.2. Washing Procedures 24

4.3.3. Purity of Solutions 25

5. Developing a Method 26

5.1 Sample preparation 26

5.2 Instrument set up 26

5.3 Furnace optimization 26

5.4 Ash-Atomize plots 27

5.5 Furnace program testing 28

5.6 Background correction 28

5.7 Interferences 29

6. Analytical Methodology 31

6.1 Agricultural 31

6.2 Air particulates 32

6.3 Biological 33

6.4 Food products 35

6.5 Geochemical 36

6.6 Metallurgical 37

6.7 Petrochemical 38

6.8 Waters 39

6.9 Sensitivity 41

7. Analytical Data for the GF 2000/3000 43

8. References 53

4 GBC Graphite Furnace Methods Manual

1. Introduction

1.1 Atomic Absorption Spectroscopy

The technique of atomic absorption developed by Sir Alan Walsh of CSIRO in

the mid 1950’s has become the preferred method of elemental analysis. Walsh

discovered that the majority of free atoms in the commonly used flames are in

the ground state, and that the flames do not have enough energy to excite these

atoms (except for group 1 elements). A light source emitting a narrow spectral

line of characteristic energy is used to excite the free atoms formed in the flame.

The decrease in energy (absorption) is then measured.

The absorption is proportional to the concentration of free atoms in the flame,

given by the Beer-Lambert law.

Absorbance = 1og10 (I0/It ) = K.C.L.

Where I0 = intensity of incident radiation emitted by the light source.

It = intensity of transmitted radiation (amount not absorbed).

C = concentration of sample (free atoms).

K = Constant (can be determined experimentally).

L = Path length.

In practical atomic absorption analysis the Beer-Lambert law can be reduced to :

Absorbance = Log10 (I0/It) ∫C

The instrument is calibrated against standards of known concentrations and the

sample concentrations interpolated. The method is not absolute but comparative

and the constant KL does not have to be determined. As well as atomic

absorption occurring, there is also emission from the analyte element, other

species in the sample and the flame or graphite tube. To isolate the atomic

absorption from all other effects, the energy from the light source is “coded” by

modulation (turning ON and OFF at regular intervals) and the electronics are

synchronized to “see” only signals from this source. By this method, emission,

which is basically steady-state, is not seen by the electronics. Only atomic

absorption is observed.

GBC Graphite Furnace Methods Manual 5

1. Introduction

1.2 Choice Of Method—Flame Or Furnace

1.2.1 Flame

Flame atomic absorption is the more commonly used method of analysis,

providing excellent precision and ease of use. However, the nebulizer is at best

only 10% efficient, requiring moderately large sample volumes.

The nebulizer is also sensitive to physical properties of the sample such as

viscosity and the presence of dissolved solids. Viscosity changes affect the rate

of sample uptake, and hence the absorbance, requiring the samples and

standards to be closely matched. Nebulizers cannot accept high salt

concentrations or slurries.

1.2.2 Furnace

In a graphite furnace a discrete volume of sample (between 1 and 100 µL) is

atomized in a small cell. The cross sectional area of the cell (or, more commonly

called, tube) is small enough to create a dense population of atoms at

atomization, increasing sensitivity over flame by a factor of 20 - 1000. The

advantages of the furnace method include:

• High sensitivity

• Small sample volumes required

• Highly efficient sample usage (no waste)

• Low detection limits achievable

• Most samples can be analysed with little or no pretreatment

6 GBC Graphite Furnace Methods Manual

2. Furnace Atomic Absorption

2.1 Graphite Tubes

Many different materials have been investigated for use in electrothermal

atomizers, but none have been as successful as the pyrolytically coated graphite

tube. The furnace material must exhibit certain properties to ensure good

sensitivity and reproducibility of results. The following are typical of these

requirements:

• low porosity

• chemical inertness

• low levels of metal impurities

• good thermal and electrical conductivity

• high rigidity

• high melting point

• reasonable cost

• good machinability

• low thermal expansion

Graphite as a furnace material responds well to these criteria, but problems do

exist with porosity and chemical inertness.

By pyrolytically coating the tube, the sample is prevented from leaching through

the tube surface, thus reducing memory effects. This also reduces the risk of

carbide formation, a problem often associated with refractory elements.

The coating itself, typically 30 µm thick, is applied by thermally decomposing a

low molecular weight hydrocarbon such as methane (in its vapour state).

Oxidation of carbon is probably the most recognised obstacle in any carbon

furnace design. Once heated to high temperature, oxides of carbon are readily

formed, often creating tube-life problems. Two inert gases, argon and nitrogen,

are commonly used to create a shielding effect around the carbon components.

The latter is more commonly used because of its relatively low cost, but nitride

compounds can be formed with some elements (e.g. B, Ba, V). Argon should be

used with these elements.

Tube life also depends on the nature of the matrix, and the atomization

temperature used. The higher the temperature, the more susceptible the tube is to

oxidation. Similarly, highly acidic solutions (e.g. perchloric acid, hydrofluoric

acid) or oxidizing agents within the sample, will cause the surface to deteriorate.

2.2 Temperature Program Development

Temperature program development for graphite furnace analysis can be

categorized into three main stages, i.e., drying, ashing and atomizing the

sample.

GBC Graphite Furnace Methods Manual 7

2. Furnace Atomic Absorption

2.2.1 Dry

Two methods can be used for this stage. For aqueous samples, the injection can

be made at an elevated temperature (120 ⊃C). Here the capillary is programmed

to contact the bottom of the tube and the sample is dried as it contacts the

surface, (flash volatilization). This method can also be applied to organic

solutions or high acid solutions where the sample tends to creep out of the tube

due to low surface tension.

The second method involves an injection at ambient temperature and a slow

ramp through the evaporation temperature. For complex matrix samples this

method is recommended. In a sodium chloride matrix, water can be entrained in

the crystal. A hot injection will cause rapid expansion of the water inside the

crystal, subsequently exploding the crystal and losing sample. This sample must

be dried and ashed through a series of stages, ensuring a uniform breakdown and

evaporation of solvent. If spitting or frothing occurs, particles can be ejected and

sensitivity will suffer.

Hot Injection Cold Injection

Fig. 1. Hot and cold sample injection

2.2.2 Ash

Depending on the complexity of the matrix, the ashing stage can be the hardest

area to refine. In the simplest case, an understanding of the individual matrix

components can assist in predicting their behaviour. Reference material quoting

melt and evaporation temperatures is readily available.

Successive measurements should be made using increasing ash temperatures

while monitoring the analyte absorbance (measured during the atomize stage).

The optimum ash temperature is usually the highest that can be used without

reducing the analyte absorbance. The ramp rate during the ash stage should be

chosen so as to avoid violent reactions or excessive release of smoke.

For more difficult unknown matrices, ashing can be quite complex, involving

trial and error method development. When volatilization of the matrix occurs at

the same temperature as atomization of the analyte, matrix modification can be

used to either decrease or increase either the ash or atomize temperature.

Volatile elements such as Cd, Zn and Pb, existing as chlorides, can be easily lost

during low temperature ashing but in the hydroxide or oxide form they are stable

at much higher temperatures. For example PbCl2 is volatile around 500 ⊃C,

whereas Pb(NO3)2 is stable at 800 ⊃C. If it is not possible to completely remove

the matrix during the ash stage, background correction can be used, provided

that the level of background does not exceed 2 absorbance units.

8 GBC Graphite Furnace Methods Manual

2. Furnace Atomic Absorption

For aqueous solutions, extensive ashing is not required but an intermediate stage

is recommended to provide a starting point for ramping to atomize. (Maximum

ramp rate is 2000 ⊃C/sec). The intermediate stage should not exceed the

maximum ash temperature for the element.

2.2.3 Atomize

The atomization temperature will vary depending on the element being analysed

and the recommended temperatures in Table 5 should normally be followed. The

optimum ramp rate also varies with element. Most elements show maximum

sensitivity at 2000 ⊃C/sec but some (e.g. Pb) will exhibit better results at half

this rate. A compromise between atomize temperature and tube life must also be

examined. Ideally the lowest temperature showing good sensitivity is selected,

because at high temperature, oxidation of the carbon surface will be accelerated.

The atomize hold time should also be considered. Unnecessarily long hold times

at high temperature will also shorten the life of the tube.

2.2.4 Measurement Mode

The type of measuring mode will also be element and matrix dependent. The

peak height and peak area choice is usually decided by the mode giving the best

precision and accuracy for that particular application. Peak area will quite often

show better calibration linearity. The peak area mode often shows less chemical

interference and is usually used with the pyrolytic graphite platform.

2.2.5 Gas Flow Selection

Inert gas, typically nitrogen or argon is used to shield the graphite from a highly

oxidizing atmosphere, and to remove various sample components during the

program. Inert gas should always be selected during dry and ash stages. A gas

stop is usually used at the atomization stage to ensure sufficient residence time

of the atoms in the light path. The time of the gas stop should be minimized to

prevent air entering the tube.

Quite often argon can yield better sensitivity for particular elements. This is due

to the different chemical processes initiated by the two gases.

2.2.6 Reduced Gas Flow during Atomization

Where sensitivity is too high, selection of gas flow during atomization will

reduce the sensitivity by sweeping the atoms from the tube more quickly. This

reduced flow can be selected by programming AUXILIARY gas for 1-2 seconds

before and during the atomize steps, thus you can use the normal gas flow rate

during the DRY and ASH stages.

The figure overleaf shows the variation in Peak absorbance with gas flow for

three elements: Pb (a volatile element), Cu (an element with intermediate

atomization temperature), and V (a refractory element).

Maximum sensitivity is obtained with gas stop during the atomize stage.

GBC Graphite Furnace Methods Manual 9

2. Furnace Atomic Absorption

Fig. 2. Variation in peak absorbance with gas flow

10 GBC Graphite Furnace Methods Manual

2. Furnace Atomic Absorption

2.3 Interferences

2.3.1 Physical

The main problems associated with physical interferences include surface

tension, viscosity and background absorption.

If the sample solution matrix consists of organic solutions, high acid

concentrations or detergents, sample spreading may cause reduced sensitivity

and poor reproducibility. This is due to the variations in atomic distribution at

the atomization stage. These effects can be overcome by:

• reducing the sample volume

• lengthening the drying program

• flash volatilizing the sample (hot injection)

(The latter is discussed in detail under drying conditions).

In the GBC System 2000/3000, sample spreading is minimized by the ridges in

the graphite tube which confine the sample to the central part of the tube.

At the other end of the scale, if a sample is highly viscous, the auto sampler can

retain small quantities on the outside of the capillary. This amount can vary

from one injection to another, subsequently giving poor reproducibility. This

can be overcome by diluting the sample with a low viscosity solvent or

detergent.

Background absorption is often encountered and is the most documented of all

physical interferences. Carbon particles can be released from the tube at the

atomization stage, momentarily attenuating the light beam. Organic matter still

present after ashing can be pyrolysed, causing attenuation by smoke. Most salts

will also cause significant background effects, if present during atomization.

2.3.2 Chemical

Stable compound formation can occur if the analyte element reacts with carbon

or nitrogen, yet the temperature is not high enough to dissociate these

compounds during atomization. This can be avoided by using pyrolytically

coated tubes and argon as an inert gas.

Volatile compound formation should be avoided to prevent premature loss of the

element during the ashing stages. Most metal chlorides will exhibit this trend.

Matrix modification should be used to convert the metal into another compound

which remains stable at higher temperatures. e.g. maximum ash for BaCl2 is 900

⊃C, minimum ash for BaO is 1500 ⊃C.

Acid selection can also play a major role in method development. Some acids

will cause severe depression, some will enhance the response, depending on the

element being analysed. Hydrochloric acid should be avoided as it can cause the

volatile compound formation previously described. (For further reading, see

references 101, 102, 106).

2.3.3 Chemical Modification

Quite often problems can exist where sample is lost due to volatile compound

formation. By reacting the sample with a desirable compound, the interference

can be avoided. For example:

REF. 1. Adding nickel in excess to arsenic solutions forms a stable nickel

arsenide which can withstand high ashing temperatures, but will readily

dissociate at a reasonable atomize temperature. Without nickel, arsenic is lost

before 300 ⊃C in the form of As2O3 or AsCl3.

GBC Graphite Furnace Methods Manual 11

2. Furnace Atomic Absorption

REF. 2. Lead in a sodium chloride matrix is another difficult application. Lead

can be atomized at 1100 ⊃C and NaCl will vaporize at this temperature.

Addition of NH4NO3will increase the lead atomization temperature by forming

lead nitrate and form two new compounds of low ashing temperature.

PbCl2 + NaCl + 3NH4NO3 ® Pb(NO3)2 + 3NH4Cl + NaNO3

atomize vaporize atomize vaporize vaporize

1100 ⊃C 1100⊃C 1400⊃C 300⊃C 300⊃C

REF. 3. For trace analysis of drinking water, magnesium nitrate can increase

ashing temperatures quite considerably for Al, Be and Mn, and show slight

improvement for Cr, Co and Ni.

These three examples of modifier represent the three main categories of sample

modification:

• stabilizing volatile elements

• reduction of non atomic absorption at the atomize stage

• increasing analyte element sensitivity

The following table shows some more examples of the use of chemical

modifiers.

Table 1. List of common modifiers

Analyte Modifier Effect Reference

Cd, Al H3PO4 Converts to less volatile 6, 7

(1000 µg/mL) phosphate. Atomizes at higher

temperature.

Pb EDTA, citrate Atomize lead at lower 8, 9

(0.5-1% V/V) temperature than matrix

e.g., chloride.

P La(NO3)3 0.2% Permits higher ashing. 10

Pb, Cd Mg(NO3)2 Stabilizes Pb and Cd for 11

NH4H2PO4 higher ashing.

Hg (NH4)2S Allows higher ashing. 12

Pb NH4NO3 Products can be ashed at 13

low temperature.

As, Se Ni Forms arsenide or selenide 14

which atomizes at higher

temperature.

Si Ca(NO3)2 Enhances sensitivity 15

1000 µg/mL

12 GBC Graphite Furnace Methods Manual

2. Furnace Atomic Absorption

2.3.4 Background Correction

Non specific attenuation of the hollow cathode lamp output by molecular

species or by scatter from particles is a major interference in graphite furnace

AA.

Typically a deuterium arc continuum source, having a broad-band output, is

used for background correction.

The hollow cathode lamp measurement (total absorbance) is taken, then the

deuterium lamp reading (background only) is subtracted from this value giving a

value for the analyte element being examined. These measurements are taken

very rapidly, (200 times per second), and the corrected atomic absorbance

computed electronically.

Fig. 3. Background absorbance profile

GBC Graphite Furnace Methods Manual 13

2. Furnace Atomic Absorption

2.3.5 Incandescence

If the emission from the furnace is strong enough to “flood” the photomultiplier

tube with DC emission, a spurious absorption can be obtained. This is because

the amplification circuit cannot separate the modulated signal from the emission.

This incandescence is only a problem for elements that require high

temperatures and have wavelengths between 400-600 nm. Elements such as Ca,

Ba, Dy, Er, Sr, and Tb may show incandescence problems.

To minimise this interference:

• Properly align the furnace

• Increase the lamp current to reduce the photomultiplier gain

• Use reduced slit heights (G.F. slit mask)

• Reduce the atomization temperature

Fig. 4. Incandescent emission at atomization temperatures

14 GBC Graphite Furnace Methods Manual

3. Platforms

3.1 Platform Theory

Atomization from the wall of a furnace provides excellent sensitivity and

reproducibility for most applications. Occasionally, matrix effects cause

interferences that are unsolvable by program modification or by chemical

addition. These interferences stem from the atoms leaving the heated furnace

surface and re-combining in the cooler inert gas atmosphere inside the tube. This

re-combination usually occurrs with volatile elements (such as Pb, Cd etc.), in a

complex matrix (e.g., saline solutions, oil). Many of these samples, once

classified as too hard to analyse, can now be studied using a pyrolytic graphite

platform. (L’vov Platform. Ref. No. 17).

Fig. 5. Pyrolytic graphite platform

As can be seen from the diagram, the platform rests between the two small

partitions in the tube. It can be easily inserted in the tube using a pair of

tweezers and aligned properly when the tube is installed in the workhead.

L’vov has shown that vapour phase interferences can be reduced by atomising

from a furnace that has already achieved a steady state temperature.

This is achieved by placing the sample onto a platform made of solid pyrolytic

carbon that sits on the furnace wall.

The platform is in very weak thermal contact with the furnace wall, and as a

consequence, is heated by radiation from the tube walls. This ensures that it lags

behind the furnace wall temperature. Using this technique, the analyte

compounds are not vaporized until the furnace has reached a steady state

temperature.

3.2 Platform Temperature Program

3.2.1 Dry

Since the platform is in weak thermal contact to the furnace wall, the use of a

slow ramp during the dry stage is not required. A typical program is to ramp to

an elevated temperature (approx. 140-150 ⊃C), in one second and hold this

temperature for a long time, (typically 40-60 seconds). This will ensure the

platform slowly ramps to this temperature. The dry should be watched using a

dental mirror and the temperature and/or time adjusted. The temperature is too

high if the sample spits or bubbles during the dry stage.

GBC Graphite Furnace Methods Manual 15

3. Platforms

In some cases a second dry step may be required where the temperature is

increased to approx. 200-250 ⊃C to dry the sample more evenly in preference to

very long holds.

3.2.2 Ash

The ash stage is programmed in a similar manner to the dry stage. A higher than

normal wall ash temperature (approx. 200-400 ⊃C higher) is selected with a

ramp time of 1-5 seconds, and a hold of 10-40 seconds. The aim is to vaporize

into a hotter region and not to recombine. Since the platform heats up through

radiation, it will heat up slowly and duplicate a normal ramp used in wall

atomization. The aim in the ash stage is to select as high an ash temperature as

possible in order to eliminate as much matrix as possible without losing any

analyte.

3.2.3 Atomize

The atomization temperature for platforms is normally set similar to, or slightly

lower than, the typical wall atomization temperature. A platform is used to

atomize the sample into a constant temperature environment. This is

accomplished if the ramp rate is rapid and the final temperature is close to the

ash temperature (usually a temperature difference of 600-1500 ⊃C is used from

ash to atomize). In almost all cases use the maximum ramp rate for this step of

2000 ⊃C/sec. A CLEAN stage will always be required in platform atomization.

Fig. 6. Temperature vs. time curve for a graphite tube

The figure above shows the typical temperature versus time curve of a graphite

tube. It shows that the tube takes a finite time to stabilize the temperature, and

the analyte atomized from the wall will be atomized into this gas phase,

changing in temperature. When atomization is performed from the platform, it is

delayed for a short time, (typically 1-2 seconds) until the platform reaches the

16 GBC Graphite Furnace Methods Manual

3. Platforms

wall temperature. This ensures that the furnace walls and the gas phase have

reached equilibrium. The choice of maximum ramp rate and low atomization

temperature, accompanied by a higher ash temperature, ensures that the furnace

will reach the steady state more quickly.

If the final temperature is too high or the heating rate is too slow, the risk is that

the analyte will be vaporized into the gaseous phase while the temperature of the

gas is still changing, thus producing an interference. Since the actual heating rate

for the platform is slower than for wall atomization, most elements in a simple

matrix will show a loss in peak height measurement. The slower heating rate

however, produces a broadened peak and the use of integrated measurements

(peak area) will show no loss of sensitivity.

3.2.4 Cool Down Step

Where the platform is used at high temperatures (above 2400 ⊃C) a cool down

step may be required to be performed in order to allow the platform to cool

down to the same temperature as the tube wall. A typical cool down step is to

program 30 ⊃C at a ramp rate of 10 seconds and a hold of 10-15 seconds.

3.2.5 Sample Volume Optimization

The maximum volume that may be pipetted onto a platform will depend largely

on the type of sample. For samples with high surface tensions a volume of 40-50

µL can be injected, however with samples containing a large concentration of

nitric acid or surfactants, the maximum volume must be reduced due to

spreading of the sample. If too large a volume is used, the sample may spill over

the platform onto the furnace wall during the dry stage, yielding erroneous

results and shortening the tube life. For most applications the use of 10-20 µL

sample size has shown to be optimum. If greater volumes are required the

sample should be deposited, dried, and a further sample deposited (this can be

performed using multiple injections).

GBC Graphite Furnace Methods Manual 17

4. Sample Preparation

4.1 Ashing Techniques

4.1.1 Wet Digestion Methods

Wet digestion methods will often vary, depending on the complexity of the

matrix present. The correct combination of acids must be chosen to ensure no

loss of analyte element during digestion, and also the complete breakdown of

the matrix present.

The following description outlines a method for the analysis of heavy metals in

fish tissue.

REF. 5. A 1-5 g sample of tissue is accurately weighed, placed in a 50 mL

kjeldahl flask, and stoppered to prevent evaporation. The flask and tissue are

then incubated in a 95 0.5 ⊃C water bath enclosed in a perchloric acid fume

hood. 5 mL concentrated HNO3 is added to the flask. When the mixture turns

deep brown, a 5 mL solution of 3 parts concentrated sulphuric acid and 2 parts

concentrated perchloric acid is added. This mixture maximizes the oxidation of

the sample. The sulphuric acid and relatively low temperature prevents the

solution from either concentrating or going to dryness.

+

Note: Perchloric acid concentrations greater than 80 % and perchlorates formed

upon drying are highly unstable and very dangerous. For 1 g of sample the

digestion is accomplished in 45 minutes. Slightly longer times are required for

larger samples. Complete digestion of fatty acids is not accomplished. These are

separated via MIBK extraction.

4.1.2 Dry Ashing

A typical procedure for dry ashing involves a sample of known weight being

placed in a crucible, then into a muffle furnace which has been preheated to a

constant known temperature. The crucible is preferably made of platinum, but

materials such as porcelain, fused silica, vycor, iron or nickel are available.

When applying this technique, care must be taken, as three possible sources of

element loss are common:

1. Mechanical losses can occur during sample drying, e.g., if the sample

is dried too fast, particles may be ejected from the crucible. A slow,

even drying is required to prevent this from occurring.

2. Volatilization during the muffle furnace stage is often the cause of

sample loss. Low vapour pressure elements such as Sb, Cr, Mo, Fe,

Mg, Al, etc., are recovered quite easily from an ash at 550 ⊃C.

However, elements such as Cu, Cd, Se, Hg, etc., will be lost.

3. Retention of the sample on the walls of the crucible can occur with

most materials, but platinum can be an exception. The worst cases

can occur if the sample contains a metal halide or any phosphate

compound.

Losses from these processes can be quantified by comparison with a reference

standard of similar composition to that of the samples. This standard, (if

available), should be carried through the same procedure as sample and

calibration standards. If losses prove to be significant, another digestion

technique should be examined.

18 GBC Graphite Furnace Methods Manual

4. Sample Preparation

If the sample exists as a slurry, it must first be dried, preferably on a steam bath.

This is followed by charring with a bunsen burner. The crucible lid should

partially cover the crucible. This stage is complete when the distillation appears

to be finished. (i.e., no smoke is being expelled). The crucible is then transferred

to the muffle furnace (preheated to 220 ⊃C) and the temperature is slowly raised

to 550 ⊃C (element dependent). The crucible lid should also be placed in the

muffle furnace. Using 1:1 nitric acid, transfer the ash to a volumetric flask and

rinse the crucible and lid with acid into the volumetric flask.

Some examples of ashing techniques for individual elements are:

Lead:

Dry ash: 500 ⊃C. If present as a chloride severe losses occur.

Wet ash: Nitric acid/perchloric acid digestion. If organics are present in the

matrix, perchloric acid is not recommended as this is a potentially hazardous

combination. Problems can also occur if large amounts of calcium are present.

Selenium:

Dry ash: not applicable.

Wet ash: Perchloric/nitric acid or perchloric/nitric/sulphuric acid mixtures are

recommended. Excess nitric acid must always be present to prevent

preconcentration of the perchloric acid. Slow ramping to elevated temperature is

recommended.

Arsenic:

Dry ash: not applicable.

Wet ash: Nitric/perchloric/sulphuric acid. Nitric/perchloric acid. Nitric/sulphuric

acid.

Mercury:

Dry ash: not applicable.

Wet ash: 3:2:1 mixture of nitric/perchloric/sulphuric acid in digestion block is

commonly used, or a reflux system.

Chromium:

Dry ash: not recommended.

Wet ash: Nitric/sulphuric acid combinations are recommended as perchloric can

cause slight losses.

GBC Graphite Furnace Methods Manual 19

4. Sample Preparation

4.2 Chemical Separations and Concentrations

Sample preparation prior to analysis can often be complex, depending on the

matrix present and the concentration of the element in solution. If the element is

below the detection limit, or is affected by an interferent, some sample

pretreatment is required.

For example:

1. Deproteinization of biochemical samples can be achieved by the

addition of 1:1 10% trichloroacetic acid with the sample (e.g., serum,

blood). This is then shaken and centrifuged. The metal-protein bonds

are broken and the metal is taken into the supernatant. This method is

usually applied to flame techniques, as furnaces can break down

protein bonds in situ.

2. Preconcentration by evaporating the solvent is often used to bring low

concentration samples into the range of the furnace’s capability. e.g.,

100 mL evaporated to 10 mL will concentrate the element to 10 times

the previous concentration.

3. Wet and dry ashing procedures are used to remove an interfering

matrix. These methods are explained in a later section.

4. Co-precipitation involves an exchange of the matrix from a difficult

one to a matrix that will not interfere. e.g., La(OH)3 can be used for

As, Se, Sn, and Te. (REF. 16).

Solvent extraction of trace metals is the most common separation technique used

by analysts today. The popularity of the technique is due to the fact that it

presents few problems with interferences and can be highly specific in

extracting individual elements. Particular elements can be separated individually

by adjusting the pH of the solution.

4.2.1 APDC

Ammonium pyrolidine dithiocarbamate (APDC) is often used because the

complexes formed are readily soluble in a number of ketones:

• Methyl-iso-butyl-ketone (MIBK) allows a concentration of 10 times.

• N-amyl methyl ketone allows a concentration of up to 50 times.

• Chloroform allows a concentration of more than 50 times.

20 GBC Graphite Furnace Methods Manual

4. Sample Preparation

Table 2. pH factors for the solvent extraction of trace elements.

APDC - MIBK, pH EXTRACTION RANGE

Element pH Element pH

As 1-6 Rh 1-12

Bi 1-6 Ni 2-4

Cd 1-6 Pb 2.5-3

Co 2-4 Pd 4-6

Cu 1-8 Pt 3

Fe 2-5 Sb 4

Ga 4 Se 3-6

In 2-10 Te 4

Mn 2-4 Tl 3-10

Mo 3-4 V 4

Ru 1-10 Zn 2-6

Procedure for extraction with MIBK (from Watson, REF. 18).

Dissolve 1 g of APDC in water, dilute to 100 mL and filter before use. To

50 mL of sample, add 5 mL of APDC solution and adjust to the required pH

with ACETIC ACID or CAUSTIC SODA solution. The pH should be 5 except

for arsenic, molybdenum, thallium and tungsten (pH3). For manganese, raise to

pH12, mix, stand for 2 min then adjust to pH5. With chromium and

molybdenum, heat to 80 ⊃C for 5 min before proceeding. Transfer the solution

to a 100 mL separating funnel and extract the complex (which may have

precipitated) into 4 mL of methyl-isobutyl ketone by vigorously shaking for 30

seconds, then stand for 2 minutes. Transfer the aqueous phase to another

separating funnel and repeat the extraction with 1 mL of

methyl-iso-butyl-ketone. Discard the aqueous phase (which should now be

colourless), combine the extracts in the first funnel, mix and filter through a

cotton wool plug into a small beaker. This solution is injected into the furnace.

If a particular metal will not react with APDC, other extraction systems can be

used.

GBC Graphite Furnace Methods Manual 21

4. Sample Preparation

4.2.2 Oxine

Oxine can be used for Sr, Mg, Al, Ca, La and Zr using xylene as the solvent.

Table 3. pH factors for trace metal extraction with oxine-xylene

OXINE - XYLENE pH Extraction Range

Element pH range Element pH range

Ag 8 - 9.5 Mn 7 - 10

Al 5 - 11 Mo 1-5

Bi 3 - 11 Ni 4 - 10

Ca 11 Pb 6 - 10

Cd 6 - 10 Pd 6 - 10

Co 5 - 10 Th 4 - 10

Cu 4 - 12 Ti 3-9

Fe 5 - 10 U 5-9

Ga 4 - 10 V 3-6

Hf 5 - 11 Y 7 - 10

Ho 5-7 Yb 9 - 11

In 4 - 10 Zn 4-5

La 7 - 10 Zr 2-4

Transfer 10-100 mL of sample to a 250 mL beaker and adjust the volume to 100

mL with distilled water. Prepare a blank solution and sufficient standards in the

same manner. Adjust the pH of the samples and standards to the pH range listed

above, with either 2.5% HCl or 10% NaOH and a pH meter. Extract the

complex with xylene using the procedure outlined in the APDC section above.

4.2.3 NaDDC (Sodium dimethyldithiocarbamate)

NaDDC can be used for Ag, Hg and Ti using MIBK as the solvent.

Table 4. pH factors for trace metal extraction using NaDDC-MIBK

Element pH Element pH

Ag 4 - 11 Ni 5 - 11

As 5-6 Pb 4 - 11

Bi 4 - 11 Pd 4 - 11

Cd 4 - 11 Sb 4-9

Co 4 - 11 Se 4-6

Cu 4 - 11 Sn 5-6

Fe 4 - 11 Te 4-8

Hg 4 - 11 Tl 5 - 13

In 4 - 10 Ti 4 - 11

Mn 6-9 Zn 4 - 11

Transfer a volume of sample (100 mL max.) into a 250 mL beaker and adjust the

volume to 100 mL with distilled water. Prepare a blank and sufficient standards

in the same manner and adjust the volume of each to 100 mL with distilled

water. Adjust the pH of the samples and standards to the pH range listed above

with 0.3N HC1 solution or 2.5N NaOH solution, using a pH meter. Transfer

22 GBC Graphite Furnace Methods Manual

4. Sample Preparation

each sample and standard to a 200 mL volumetric flask and add 2 mL of fresh

NaDDC solution and mix. Add 10 mL of MIBK and shake for two minutes.

4.2.4 Ion Exchange

An alternative method to solvent extraction involves the use of an ion exchange

column, and an appropriate adsorbing resin. The element is separated from the

matrix by selective adsorption onto the resin at a particular acid concentration.

Careful selection of acid, resin, and acid concentration will enable the analyst to

separate most metals from their corresponding matrix.

Investigations by Strelow (Ref. 105, 107-110), have provided a comprehensive

overview of conditions for particular elements and their relative affinities for

various resins.

The affinity is determined by the distribution co-efficient (Kd) of the element in

question.

amount of element in resin grams of dry resin

Kd = x

amount of element in solution mLs of solution

The higher the “Kd” value, the greater the affinity for the resin. A low

concentration acid will typically have a high “Kd” value and will be used to

remove the analyte element from the solution. The element can then be isolated

by eluting with a higher concentration of the acid.

Typical resins used for anion and cation exchange include Dowex resins, Biorad

series and Chelex 100. (For further information see Ref. 105, 107-110).

GBC Graphite Furnace Methods Manual 23

4. Sample Preparation

4.3 Contamination

Glassware used in furnace analysis should be meticulously cleaned to prevent

contamination from the surface of the glass. Washing with detergent followed

by several rinses with distilled water is necessary. Volumetric flasks and

pipettes should also be soaked for 24 hours in 10-20% HNO3. Volumetric flasks

can be stored containing this solution, then rinsed with distilled water before

use. Elements such as sodium, magnesium and zinc are commonly found at high

levels on glassware surfaces.

Pre-cleaned glassware open to the environment can collect airborne particulates

which can cause contamination problems. Airborne dust can contain high levels

of iron, copper, potassium and calcium. One dust particle falling onto a furnace

tube during a run can dramatically change results. This is often the cause of

erroneous results in a poorly designed laboratory.

Ideally, for studying ultra-trace levels, a clean room with filtered air and an

adequate extraction system should be used. Benches and surfaces should be

cleaned regularly to prevent build-up of particulates.

4.3.1. Storage Materials

Materials used for sample storage vary considerably in their properties.

Borosilicate glass is often used, but is not highly recommended. Potassium,

sodium, boron, silicon and aluminium can be leached from the surface of the

glass on contact with hydrofluoric acid and various alkaline solutions. In these

cases, plastic containers can be used. These include polypropylene (PP),

polyvinyl chloride (PVC), teflon (PTFE), and polyethylene.

The order of preference of materials for storage vessels is:

1. Polyethylene

2. Teflon (expensive)

3. Polypropylene (high levels of Cd and Zn; can adsorb Ag readily)

4. Borosilicate glass (some elements)

4.3.2. Washing Procedures

After purchasing plastic containers, careful washing procedures should be

applied to remove all contaminants retained during manufacture. These can

come from air particles or often when the plastic comes in contact with

chemicals or machinery involved in the manufacturing process. The most

common problems associated with plastics involve permeability to solvents.

However, this will only occur over long storage times, and will be humidity

dependent. Typically, the loss of solvent might be 1% per year.

A recommended washing procedure for new plastics and glassware is as

follows:

1. Fill with 30 % V/V HC1 and leave to soak for 2 days.

2. Rinse with distilled water, fill with 30% V/V HNO3 and leave to soak for

two days.

3. Rinse with distilled water (container can be left filled with this solution).

4. Air dry/oven dry (low temp for plastics approx. 60 ⊃C).

24 GBC Graphite Furnace Methods Manual

4. Sample Preparation

4.3.3. Purity of Solutions

Flame atomic absorption, typically aimed at the part per million range, requires

high levels of contamination before any significant change can be noticed in the

sample readings. However, graphite furnace work is aimed at the part per billion

range and is highly susceptible to contamination from a wide range of sources.

Water should be prepared via one or more purification methods, depending on

the purity required. Equipment and methods available include distillation units,

deionizing units, reverse osmosis, ion exchange columns, filtering and

electrodialysis. For trace work, water should have a minimum resistivity of 18

megohms/cm at 25 ⊃C, be filtered through a 0.2 µm membrane filter and passed

through an ion exchange column. Standards are commonly prepared from high

purity reagents such as BDH “Aristar range” acids and 1000 ppm stock

solutions. Standards may be prepared by a series of dilutions using glass pipettes

or by a single step using micro pipettes, although these are not recommended for

highly accurate dilutions.

+

Note:

1. All standards, blanks and samples should be acidified, typically 1.0 %

HNO3 is sufficient.

2. Blanks should be prepared using the same method as applied to

sample and standards. i.e., any contamination will be in blanks as

well as standards.

3. Before running samples, check that good sensitivity can be achieved

with standard solutions. Compare results with the quoted

characteristic mass, thus checking the efficiency of the method.

For further reading, Ref. 104.

GBC Graphite Furnace Methods Manual 25

5. Developing A Method

Method development for Graphite Furnace AAS can be fraught with problems if

a systematic approach is not used. The increasing use of graphite furnace

analysis, primarily due to its enhanced sensitivity, has produced a lot of

literature describing incurable interferences and non-reproducible results,

branding graphite furnace a difficult technique.

Contamination can be introduced in several places during the analysis. The

acids, solvents, or other reagents used during sample preparation, the containers,

glassware, and even the laboratory environment can be a source of

contamination. The key to minimizing contamination is to simplify the method

as much as possible. Minimize the number of sampling steps and additives that

may be deemed essential by the latest paper.

5.1 Sample Preparation

The sample should be in liquid form with a low viscosity to enable easy and

reproducible pipetting into the graphite furnace. If the sample is in a solid form,

establish whether the sample has to be totally decomposed to obtain the analyte,

or whether an acid extraction process will be adequate. Does the sample require

filtration? Remember that any particles that may be injected will almost

certainly degrade the precision of the analysis.

The acid of choice is an OXY-ACID such as nitric or sulphuric acid.

Hydrochloric acid should be avoided because of volatile chloride formation.

Check the instrumental parameters required such as wavelength, slit, lamp

+

current and whether background correction is required.

Note:

For all wavelengths below 425 nm, background correction can be performed but

will not be essential for all analyses and elements.

Check the sensitivity (concentration of element to produce an absorbance of 0.3

for a 20 mL injection) from the sensitivity section of this manual and calculate

whether the sample will require dilution or concentration.

5.2 Instrument Set-up

The instrument should be turned on and optimized approximately 10 minutes

prior to commencement of analysis. (The deuterium lamp should also be turned

on).

The workhead should be aligned in the optical beam, the G.F. slit mask selected

to reduce the slit height and reduce the emission from the furnace walls entering

the photomultiplier tube.

5.3 Furnace Optimization

Check the analytical data in this manual for the element of interest. Either make

a standard, or preferably dilute a sample that will produce approx. 0.3

absorbance, when using the maximum ash and typical atomize temperature

given. Construct an ash/atomize plot for the element.

26 GBC Graphite Furnace Methods Manual

5. Developing A Method

5.4 Ash/Atomize Plots

Ash/Atomize plots are performed to establish the maximum ash temperature that

can be used for the particular matrix, and the minimum atomize temperature that

can be used. A minimum atomize temperature prolongs the life of the graphite

tube and using a higher ash temperature will yield a minimum of matrix residue

prior to atomization, hence minimizing any interference.

To produce an ash/atomize plot, select the recommended atomize temperature

and vary the ashing temperature in 100 ⊃C steps. Commence from

approximately 50% of the maximum ash recommended until an ash temperature

is reached where the atomization signal (PEAK HEIGHT or PEAK AREA)

starts to decrease, indicating a loss of analyte in the ash stage.

+ Note: Ensure that a constant atomization ramp rate is maintained when the ash

temperatures are changed.

Once the ash temperature has been optimized, the atomize temperature is varied

from a low temperature (usually 600-1000 ⊃C above the ash temperature) until

the measured signal reaches a well defined plateau, or the maximum temperature

of 3000 ⊃C is attained. The atomize temperature selected will be on the plateau

for the majority of cases, except where the presence of very high background

signals or interference effects may require the ash or atomize temperatures to be

de-optimized to reduce the sensitivity of both signals.

Fig. 7. Ash/atomize plot

GBC Graphite Furnace Methods Manual 27

5. Developing A Method

5.5 Furnace Program Testing

Once a furnace program has been selected, a more detailed investigation is

required.

1. A blank should be run and checked for contamination. Blank levels should

be as close as possible to zero. However, this is not always possible. The

levels should be kept below 0.1 abs. Higher levels should be examined

further and the contamination corrected.

2. A standard should be run several times (between 5-10 times), and the

reproducibility checked. With auto-samplers, most elements should produce

an RSD of better than 5%. Areas to check if RSD’s are high include:

• The dry stage should produce an even drying without spitting or

bubbling.

• The injection capillary is clear, and the sample is deposited in the tube

and does not “Run-Up” the outside of the capillary. (If this occurs, wipe

the capillary with a tissue soaked in acetone).

• There are no air bubbles in the injected volume and it is reproducible.

• The rinse bottle is full, and there is a stream of rinse solution through the

capillary during the second rinse time at the beginning of a run.

+ Note: on first powering up the system, the rinse will be initiated for 60

seconds.

3. Run the calibration standards to confirm the top standard is in the optimum

working range (normally less than 0.8 abs., however, for most elements this

can be extended to 1.0 abs. or more).

4. Using a sample, check:

• That the concentration is within the range of the calibration standards

prepared.

• That the background absorbance is not excessive.

+ Note: Background absorbance plus atomic absorbance should be less

than 2 absorbance units for a System 2000, and less than 2.5 absorbance

units for a System 3000.

5.6 Background Correction

To check the amount of background in your samples, use the following modes:

Instrument mode

To measure absorbance of: System 2000 System 3000

Background ABS + B/ONLY Abs. Background Only

Analyte ABS + B/CORR Abs. B.C. On

Total Absorbance ABS Abs. B.C. Off

If the background is found to be excessive, there are several alternatives

available:

28 GBC Graphite Furnace Methods Manual

5. Developing A Method

• Sample dilution is the simplest method to reduce background, however,

this will only be possible where there is adequate sensitivity.

• Use an alternative higher wavelength where background is not as severe.

An example is the analysis of LEAD, where the 217.0 nm line is most

sensitive, but the 283.3 nm line has less background absorption, and is

the preferred line.

+

Note: there will be a sensitivity loss in doing so.

• Adjust the atomize ramp rate to a slower rate, thus separating the analyte

and background peaks. This will enable a reading to be made of the

analyte peak only.

• Use a chemical modifier to either remove the species causing the

interference, or shift the analyte peak away from the background.

• Use chemical modification in conjunction with a L’vov platform.

5.7 Interferences

To check for the presence of interferences in your analysis, it is necessary to run

your standards using the temperature program developed above, and construct a

calibration curve. A standard additions run should be performed using a sample

with a low absorbance (in PEAK HEIGHT and PEAK AREA modes).

The slopes of the calibration and standard addition curves should be compared

and if the slopes differ by less than 10 %, the analysis is deemed interference

free and the calibration standards prepared can be used. If the slopes differ by

more than 10%, an interference is confirmed and a further investigation is

necessary to try and eliminate or minimize the interference.

Methods that can be looked at are:

1. Dilution

2. Chemical modification

3. Chemical modification and platform atomization

4. Separation of the interferent from the analyte by chemical means

If chemical modification and/or platforms are used, the ash/atomize

temperatures have to be re-optimized. After all of the attempts at reducing the

interference have been unsuccessful, a standard additions method should be used

for each sample, or a set of closely matched matrix standards prepared.

GBC Graphite Furnace Methods Manual 29

5. Developing A Method

Perform furnace optimization and run

a calibration curve and standard additions

experiments on the furnace/sampler program Dilute

finalised using peak height and peak area

to determine if interference is a problem.

YES

The determination is

deemed interference Do the slopes of

free and a calibration NO calibration curve YES Is the sensitivity

curve with simple and standard sufficient to allow

standards using a additions differ dilution?

platform and chemical by more than 10%?

modifier can be used.

YES NO

Use a recommended chemical modifier to

either remove the interfering matrix or

enable higher ash temperatures to be

used. Recheck the ash/optimize curves

and optimize the furnace program.

Repeat the calibration curve/standard

addition runs.

The determination is Do the slopes of

deemed interference NO calibration curve

free and a calibration and standard

curve with simple additions differ

standards and modifier by more than 10%?

can be used.

YES

Use a platform and/or chemical modifier.

The furnace program will have to be

modified. Compare a calibration curve

using modifier and a standard additions

run with a sample using peak heights

and peak area.

The determination is

deemed interference Do the slopes of

free and a calibration NO calibration curve

curve with simple and standard

standards using a additions differ

platform and chemical by more than 10%?

modifier can be used.

YES

Can you use a chemical or other

separation technique to remove

the analyte or interferent?

YES NO

Use a standard additions

Start again method for all samples

at the or produce a set of

beginning. closely matrix-matched

standards.

Fig.8. Checking for the presence of interference

30 GBC Graphite Furnace Methods Manual

6. Analytical Methodology

6.1 Agricultural

The success of an agricultural system is highly dependent on the owner’s

understanding of the nutrient requirements of his product, and the naturally

occuring nutrient cycle within his immediate environment. If further input is

required to maximize the yield of his produce, some type of soil and plant

analysis is necessary to establish the exact proportions. Graphite Furnace can be

applied to this type of analysis quite easily. Plant material will usually require

some form of digestion prior to analysis, and soils will require a separation

technique because of the complexity and variability of the matrix.

A typical acid mixture for plant analysis might be:

1 mL sulphuric Acid, 1 mL perchloric Acid (60%), 5 mL nitric acid mixed with

0.1 g of plant material. This should cause complete dissolution of the organic

matrix. For soils, an aqua regia digest followed by an MIBK-chloroform

extraction is common.

Table 5. Reference materials for soil and plant analysis

ELEMENT MATRIX KEY WORDS REF

Various Soil extracts Dithiazone extracts 95

Various Pepperbush powder Reference material 96

Pb Environmental HC104, HN03, HF 97

samples

Mo Plant tissue HC104/HN03 98

Ni Plant material MIBK 99

Mo Plant samples HN03/H202 100

GBC Graphite Furnace Methods Manual 31

6. Analytical Methodology

6.2 Air Particulates

Atmospheric pollution has become a major topic of concern in recent years.

Graphite furnace has been successfully applied to trace metal analysis in this

area, mainly because of its excellent sensitivity. The preferred sampling method

involves using some type of air filtration unit, followed by analysis of the filter

itself. Various methods include total dissolution of the filter paper by wet or dry

ashing, acid leaching the filter paper or addition of a known amount of the paper

directly into the furnace. Filtering allows the volume of air sampled to be

regulated to fit the analytical range of the technique, or to simulate the human

uptake rate. Chronic poisoning in an industrial environment can be caused by

long term accumulation of some elements. This situation can be duplicated by

sedimentation, where collecting vessels are placed at various locations around

the factory and sampled over certain time intervals. This provides only an

approximation because of the many variables present. Acute poisoning can be

tested by taking samples over a short time interval.

For quantitative results, it is important that a known volume of air is sampled.

Table 6. Reference materials for air particulate analysis.

ELEMENT MATRIX KEY WORDS REF

Pb Airborne particulates Phosphoric acid 76

Pb Urban air Cellulose filter 77

Sb Air Scrubber system 78

Various Aerosols Sample prep only 79

Various Particulate matter in air Sampling filter 80

Ni, V Airborne particulates Nitric acid 81

Various Atmosphere Review 82

Pb Airborne to water NaDDC/EDTA 83

32 GBC Graphite Furnace Methods Manual

6. Analytical Methodology

6.3 Biological

Graphite furnace AA has fast become the preferred technique for trace element

analysis in human tissue and fluids. Small sample volumes and good sensitivity

are two reasons for its success.

The two main categories investigated are essential trace elements and toxic trace

elements. Levels of essential elements must be maintained above a certain limit,

because a deficiency in one can quite often relate to a certain disease. On the

other hand an excess of a toxic element can be just as detrimental to a person’s

health.

Arsenic, barium, cadmium, lead, mercury and tin are typical toxic elements.

The following is a table of normal levels of essential elements found in serum

and urine: (REF. 19 and REF. 4).

Table 7. Normal levels of essential elements found in serum and urine.

ELEMENT SERUM mg/100 ml URINE mg/100 ml

Iron 120 180

Copper 120 60

Zinc 100 900

Selenium 1 30

Manganese 0.2 300

Chromium 0.4 10

Cobalt 0.02 100

Vanadium 1 16

Nickel 0.5 85

Contamination associated with biological analysis has become a major area of

research in recent years. Early work using inadequate instrumentation provided

many misconceptions concerning levels of trace elements in biological fluids.

Verification of results by comparison with other instrumentation, reference

material or alternative sample preparation should be standard procedure until the

method is established.

Possible analytical errors include improper sampling, absorption loss or

contamination from container walls and procedural errors. Stainless steel

syringes used for sampling can quite often lead to serious errors because of

elements such as manganese, nickel and chromium in the steel. In these cases

plastic sampling devices should be used. Often the analyst himself is a major

source of error, carrying particles on his clothing, hands and hair. Wearing

plastic gloves can also cause problems with static charge, which attracts airborne

particulates from the laboratory environment onto the gloves.

GBC Graphite Furnace Methods Manual 33

6. Analytical Methodology

Table 8. Reference material for analysis of biological samples

ELEMENT MATRIX KEY WORDS REF

Se Urine Wet oxidation 20

Pb Fish tissue Matrix modification, L’vov 21

platform

Pb Blood Triton X 22

Pb Blood Platform, 02 ash 23

Various Biological samples Review 24

Cd Blood (NH4)2 HP04 25

Cr Urine Background correction 26

Cd Urine Matrix modifier 27

Au, Co, Li Blood plasma Bovine plasma 28

Al Neuronal tissue Triton X 29

Al Blood, serum, dialysis fluid and Acid washing 30

waters

Various Blood serum (SIMAAC) 31

Cd Urine Comparison samples 32

Bi Serum and urine EDTA 33

Ga Biological material EDTA 34

Various Biological fluids Method evaluation 35

Cd, Co, Zn Parotid saliva Gel filtration 36

34 GBC Graphite Furnace Methods Manual

6. Analytical Methodology

6.4 Food products

Analysis of foodstuffs and beverages for trace elements is becoming a necessary

part of the food industry as emphasis is placed on dietary intake. Essential

element levels in cereals and fruit juices are of major interest, as are toxic

elements in canned food and fish tissue. Sample preparation varies greatly,

depending on the matrix present. Wet ashing is common, and extraction

methods are often used.

The following is a simple method for the analysis of celery, spinach, lettuce and

tomato crops:

2 g of the dried (80 ⊃C) vegetable powder is placed in a 75 mL digestion tube

and 20 mL of Aristar nitric acid and 15 mL of Aristar sulphuric acid is added.

This solution has to stand for 2 hours to prevent excessive foaming. The tube is

then gently heated in a dry block heater, with the temperature being raised to

400 ⊃C over 3 hours. The solution will normally char, but then begin to clarify.

The heating is stopped and when the tube has reached approximately 150 ⊃C,

Aristar hydrogen peroxide is added, dropwise into the tube until the solution in

the tube is completely clear. The solution should be free from precipitates and

other solids. The clear solution is made up to 75 mL with 1% w/v phosphoric

acid. This addition forms a stable Pb (IV) phosphate complex which prevents

normal lead precipitation. The metals Fe, Cu and Zn can be directly analysed by

aspiration into an air/acetylene flame.

Standardization is done by calibration curves using known standards, or the

standard additions technique is used to assess metal recovery. Low levels of Ni,

Cr, Cd and Pb are detected using the graphite furnace. A 20 mL volume of the

digested sample solution is injected into the graphite tube for analysis.

Table 9. Reference materials for analysis of food products

ELEMENT MATRIX KEY WORDS REF

Cd Dried foods Slurry technique 89

Pb, Cd Foods Dry ash 90

Various Fruit juice HN03 91

Pb Beer (sample prep only) DDDC complex 92

Various Oil and fats 02 stream 93

Various Fresh water Solid sample 94

GBC Graphite Furnace Methods Manual 35

6. Analytical Methodology

6.5 Geochemical

Geochemical analysis requires a homogeneous mixture of the sample, usually

obtained by fine grinding. The sample can then be leached by boiling dry in

aqua regia, followd by a dissolution of salts in dilute nitric acid. Alternatively, a

wide range of extraction techniques is available.

Geological samples typically require background correction because of the high

levels of alkali metals present. Standard additions is also recommended, as

matching of standards is difficult when each sample matrix is different.

Table 10. Reference materials for the analysis of geochemical samples

ELEMENT MATRIX KEY WORDS REF

Various Organic extract Organic aminohalide

extracts 66

Various Geological materials 10 % aliquot 336 in MIBK 67

(sample prep only)

Au Geological materials DIBK, MIBK 68

(sample prep only)

Silicate rock Problems associated 69

with acid dissolution

Bi Rocks HF-HC104 70

Sn Ore samples HF/HN03 dissolution 71

(sample prep only)

Li Silicate rocks HF/HN03/HC104 72

(sample prep only) dissolution

Te Geological materials MIBK 73

Various Coal fly ash HF, H3B04 74

Au Gold plant barren solutions Automated flame 75

(sample prep only)

36 GBC Graphite Furnace Methods Manual

6. Analytical Methodology

6.6 Metallurgical

Most cities today are characterised by tall buildings, bridges and many other

constructions, all relying on the strength of the building materials used. It is

common knowledge today that low levels of certain metals can adversely affect

the physical properties of these materials, especially alloys and steels.

Dissolution of the metal sample is typically carried out by acid addition and

gentle heating. Mixtures of (1:1) nitric acid/deionized water and (1:1:1) nitric

acid/hydrofluoric acid/deionized water are commonly used but special cases will

require other acids. Hydrochloric acid should be avoided due to problems

associated with volatile compound formation in the furnace.

In most cases, the analyte element is in the presence of high concentrations of

other elements. Occasionally these other elements can interfere with the

analysis, so it is always wise to run reference standards with the samples. These

standards are available for the more common combinations of alloys and steel.

Recoveries of these standards determine the efficiency of the methodology.

Table 11. Reference materials for the analysis of metallurgical samples

ELEMENT MATRIX KEY WORDS REF

Al Low alloy and stainless steel HCl, HN03 59

Various Iron and Steel 40 % HN03 60

Various High purity nickel Nitric acid 61

As, Sb, Se, Te High purity copper Nitric acid 62

Pb, Bi, Se, Te, Sn Complex alloys Solid sample 63

In Metallic zinc and lead Ion exchange 64

Cr, Fe, Ni Lithium metal La(OH)3 65

Co-precipitation

GBC Graphite Furnace Methods Manual 37

6. Analytical Methodology

6.7 Petrochemical

Levels of trace metals in petroleum products are of major importance in the

petrochemical industry. Several areas of application are:

1. Fe and Ni will poison catalysts if they reach certain levels in crude

oil.

2. Vanadium can form refractory compounds in furnaces and cause

corrosion of engines when present in fuel oils.

3. Engine failure can be prevented by monitoring the presence of wear

metals in lubricating oil. A sudden increase in Ag, Si, Cr, Sn, Fe or

Pb can indicate breakdown of a certain component in the engine.

4. Sources of oil spillage can be identified by determining the levels of

trace elements in the oil.

5. Trace elements are used as additives to oils and fuels to improve

performance.

Several methods of sample preparation are available. The method used depends

on the volatility of the element and the complexity of the matrix. Viscous

samples can be diluted with a range of organic solvents and injected directly into

the furnace (hot injection is recommended). Very light oils require no dilution.

The samples can also be dry ashed and dissolved in acid (non volatile elements

only), or an acid digest can be used.

Note: Evaporation can be a problem with organic solvents if the sample is left in

+

an open container for long periods. This increases the concentration of the

analyte. A maximum sample volume of 20 µL is recommended for organic

solutions unless the hot injection technique is used.

Table 12. Reference materials for the analysis of petrochemical samples

ELEMENT MATRIX KEY WORDS REF

Fe, Ni Crude oils 84

P Oils MIBK extracts 85

Various Petroleum Modified furnace products 86

As Shale oil THF 87

P Gasoline La(NO3)3 88

38 GBC Graphite Furnace Methods Manual

6. Analytical Methodology

6.8 Waters

Over the past several decades there has been extensive research into

understanding the immediate and long term effects of industrial waste disposal

on ecosystems. The distribution of this waste through the river systems, drinking

water supplies and eventually into the oceans, has been systematically studied

and recorded by bodies worldwide. Graphite furnace has become one of the

most recognized techniques in this field. Pure waters typically require little if

any modification before analysis other than filtering and acidification. They are

low in salinity and total dissolved solids, and neutral in pH.

Sea and estuarine water often require chemical modification to eliminate

chemical interferences caused by the chloride present. Ammonium nitrate can be

used to modify the sample in the furnace or some form of ion exchange can be

used to separate the element from the matrix prior to the furnace measurement.

These samples are high in salinity and high in total dissolved solids. Method

development for industrial waste samples can be quite complex if the analyte

element is tightly bound to its matrix. In a river, the waste from several

industries can combine to form a matrix which is difficult to digest, and signal

depression during the analysis is possible.

Table 13. Reference materials for the analysis of water samples

ELEMENT MATRIX KEY WORDS REF

Various Sea water NH4NO3 37

Si Deionized process water Aqueous 38

Hg Sea water APDC-chloroform 39

Pb, Cd Waters La addition, platform 40

Se, Sb Sea water APDC, C18-bonded 41

silica gel

As, Sb, Se, Te Environmental water samples Acid enhancement 42

Various Sea water Electrode position 43

Various Effluent and natural water APDC, 2-4 dimethyl-4 44

-heptanone

Zn Sea water Organic matric modification 45

Various Sea water Back extraction Hg (II) 46

Bi Sea water NaHBO4 reduction 47

Pb Sea water Time expansion 48

Sb Natural waters G.F. with hydride 49

Al Natural waters Phosphoric acid 50

Ionic alkyl lead Water NaDDC/EDTA 51

Various Sea water CHELEX 100 52

GBC Graphite Furnace Methods Manual 39

6. Analytical Methodology

Table 13. cont’d.

ELEMENT MATRIX KEY WORDS REF

Various Sewage sludge Various pretreatment 53

methods only

Co, Cd, Zn, Ni Sea water Dithiocarbamate 54

Various Water Ascorbic acid 55

As Sea water Ion exchange 56

Various Natural waters Mg(NO3)2 modifier 57

Se Sediments, waters G.F. + hydride 58

Se, As Environmental samples Nickel modifier 111

40 GBC Graphite Furnace Methods Manual

6. Analytical Methodology

6.9 Characteristic Concentration (sensitivity)

Sensitivity is denoted by the characteristic mass or characteristic concentration.

These are the mass or concentration of an element giving a peak absorbance of

0.0044 abs. (1% absorption). With furnace methods, the sample volume can

vary with viscosity, sample availability and tube loading capacity. Because of

this, characteristic mass is usually quoted rather than characteristic

concentration. Picogram (10-12 g) is the unit used for quantifying characteristic

mass.

Mass in pg = Volume in mL x Concentration in ng/mL

e.g., 20 mL of 100 ng/mL aluminium

20 mL of 100 ng/mL = 20 mL of 100 pg/µL

= 2000 pg Absolute

Characteristic mass = mass of sample x 0.0044

absorbance of sample

e.g., If 2000 pg gives a response of 0.8 absorbance units

X pg gives a response of 0.0044 absorbance units

X = 11 pg characteristic mass

The lower limit of the normal working range is typically 10 times the

characteristic mass.

The following units are all equivalent:

pg/µL = ng/mL = µg/L

pg/µg = ng/mg = µg/kg

In Table 14 below, characteristic concentration (in ng/mL) is quoted for each

element on a 20 µL sample size for ARGON and NITROGEN, as well as an

absolute pg value for ARGON gas.

GBC Graphite Furnace Methods Manual 41

6. Analytical Methodology

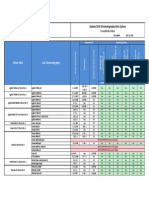

Table 14. Characteristic concentrations using argon and nitogen gas for 20 µL injection.

Element Characteristic Concentration Characteristic Mass

(ng/mL) (pg)

Argon Nitrogen Argon

______________________________________________________________

Ag 0.04 0.04 0.9

Al 0.25 0.45 5.0

As * 0.3 0.3 6

Au 0.2 0.3 4

B 50 - 1000

Ba 0.6 2.0 12

Be 0.035 0.045 0.7

Bi 0.35 0.35 7.0

Ca 0.03 0.07 0.6

Cd 0.013 0.013 0.25

Co 0.2 0.2 4.0

Cr 0.08 0.09 1.5

Cs 0.3 0.4 6.0

Cu 0.13 0.14 2.5

Dy 1.8 1.8 35

Er 3.8 4.3 75

Eu 0.8 1.0 15

Fe 0.08 0.08 1.5

Ga 1.0 1.5 20

Hg 18 19 350

In 1.3 2.3 25

K 0.025 0.035 0.5

Li 0.13 0.18 2.5

Mg 0.01 0.013 0.2

Mn 0.035 0.05 0.7

Mo 0.4 0.8 8.0

Na 0.01 0.01 0.2

Ni 0.25 0.25 5

P* 100 - 2000

Pb 217 0.13 0.13 2.5

Pb 283.3 0.28 0.28 5.5

Pd 0.6 0.6 12

Pt 4.5 5.5 90

Rb 0.06 0.10 1

Ru 1.3 1.3 25

Sb 0.45 0.50 9

Se * 1 1.1 20

Si 1.3 1.4 25

Sn 1.1 1.2 22

Sr 0.15 0.3 3

Tb 0.18 - 3.5

Te 0.9 0.9 18

Ti 2.3 3 45

Tl 1.0 1.2 20

V 1.0 1.1 20

Zn 0.01 0.01 0.25

* Chemical modifier used

42 GBC Graphite Furnace Methods Manual

7. Analytical Data For GF2000/3000

Table 15, commencing on p 46, is a quick guide to the optimum ash and

atomization temperatures for each element.

The atomization temperatures will vary with the matrix and as such should be

taken as a guide only, although these temperatures will be fairly close.

Atomization stage ramp rates are not included as these vary widely with the

element and matrix. However, in general, the maximum ramp rate of

2000 ⊃C/sec will yield the highest absorbance. The ramp rates will naturally

require optimization to suit the individual analysis, especially where a large

background absorbance is found to be present. The ramp rate can be reduced to

enable resolution of the atomic and background signals.

The conditions shown in Table 15 were determined using aqueous standards

made up in 0.5% HNO3, using the same drying conditions, 20 µL injected

volume and gas stop conditions for atomization.

Characteristic Concentration:

This is the concentration of the element which will yield an absorbance of

0.0044 in peak height mode with a new pyrolytic coated furnace. The

characteristic concentration is determined on a 20 microlitre sample size for

argon and nitrogen. An absolute value (characteristic mass) is also given for

argon.

Typical Response:

The concentration of element that produces approximately 0.3 abs is given for a

20 microlitre sample using argon. This is obtained for simple standards and a

figure within 25% of this value can be expected. This figure is given so that the

optimum working range can be determined. (The optimum absorbance range is

0.1 to 0.8 abs).

Ash Stage:

The maximum ash temperature for a nitric acid medium is given. This will vary

with the matrix and should be determined for your particular samples by starting

at a level about 60% of the quoted maximum and performing a single sample

run. Record the absorbance and increase the ash temperature approximately 100

⊃C and re-run the sample. The point at which the absorbance is reducing is

where analyte is lost during the ash stage, so reduce the ash temperature to a

+

level where analyte is not lost.

Note: Maintain the same atomize ramp rate when varying the ash temperature.

GBC Graphite Furnace Methods Manual 43

7. Analytical Data For GF2000/3000

Dry Stage and Injection Volume:

Injection volume used to generate the data was 20 µL. The dry stage was a two

step COLD injection program:

STEP FINAL RAMP HOLD INERT AUX READ

NUMBER TEMP TIME TIME GAS GAS ON

(⊃C) (sec) (sec)

1 90 10 5 YES NO NO

2 120 30 10 YES NO NO

For volumes of 20 µL or less this program will be satisfactory. For volumes up

to 60 microlitre the ramp stage of step 2 should be increased so that the sample

dries without splattering and bubbling prior to the end of the second stage.

For volumes greater than 60 µL a HOT injection was found to give the best

performance. The HOT injection again comprised a two stage program, with the

sample injected at the beginning of step 2:

STEP FINAL RAMP HOLD INERT AUX READ

NUMBER TEMP TIME TIME GAS GAS ON

(⊃C) (sec) (sec)

1 120 1 1 YES NO NO

2 140 10 1 YES NO NO

The second step is added to ensure the sample is dry. Otherwise a higher

temperature would have to be selected for Step 1. With this program, 100

microlitre volumes have been successfully dried. The Step 1 final temperature

will have to be determined for each sample matrix and furnace. This is typically

15 - 20 ⊃C above the point at which a sample dries when using the COLD

injection program shown above.

Inert/Auxiliary Gases:

The System 2000 and System 3000 have selection for two gases, INERT and

AUXILIARY. For most applications the INERT gas is nitrogen and the