Beruflich Dokumente

Kultur Dokumente

Zen Toolworks CNC Carving Machine DIY Kit User Installation Manual

Hochgeladen von

Martin SilisqueOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Zen Toolworks CNC Carving Machine DIY Kit User Installation Manual

Hochgeladen von

Martin SilisqueCopyright:

Verfügbare Formate

Zen Toolworks CNC Carving Machine DIY Kit User Manual

Zen Toolworks CNC Carving Machine DIY Kit

User Installation Manual

Visit Us At:

http://www.zentoolworks.com

or

http://www.zentoolworks.com/zenwiki/mediawiki

Contact Us At:

zentoolworks@gmail.com

1 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

P-01, Nema 17 Stepper Motor, 3 P-02, Motor Shaft Flex Coupling, 3 P-03, End Support Ball Bearing, 6

P-04, Anti Backlash Big Falan, 3 P-05, Anti Backlash Small Falan, 3 P-06, Anti Backlash Spring, 3

P-07, Lead screw End Holding Nut, 3 P-08, X, Y Axis Guide Rod, 4 P-09, X, Y Axis Lead Screw, 2

P-10, Z Axis Guide Rod, 2 P-11, Z Axis Lead Screw, 1 P-12, M3 x 20 Screw

2 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

P-13, M3 Washer P-14, M3 Machine Screw, 12 P-15, M4 Machine Screw, 18

P-16, M4 Washer P-17, M4 Lock Washer

P-18, M4 Nut

P-19, M6 x 15 Machine Screw, 8 P-20, M6 Washer P-21, M6 x 20 Machine Screw, 4

P-22, M6 x 25 Machine Screw,4 P-23, M6 Nut,4 P-24, Linear Ball Bearing, 12

3 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

#01 - Clamping Blocks #02 - Stepper Motor Base #03 - End Bearing Block

#04 - Z Axis Upper support #05 - Z Axis Lower Support #06 - Gantry Right Support

#07 - Gantry Left Support #08 - Z Bottom Frame #09 - Z Top Frame

#10 – Y Axis Higher Support #11 - Y Axis Lower Support #12 - Motor Support Block

4 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

#13 - Y Axis Lower Frame #14 - Y Alex Top Frame #15 - Y Alex Side Frame

#16 - Tool Base #17 - Gantry Left Outer #18 - Gantry Left Inner Frame

Frame

#19 - Gantry Right Outer #20 - Gantry Right Inner #21 - Z Axis Base Frame

Frame Frame

#22 - Gantry Back Enforce #23 - Working Table

Frame

5 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

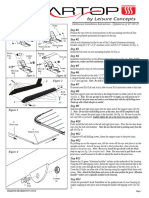

Assemble Instruction:

STEP Y-01

Here is the layout of the main components for

assembling Y Axis.

STEP Y-02

First, we need to put the bearing into #3. If you have

a bench vise, it will make this job much easier. If

not, you can find any equivalent tool that you have

the access. Just make sure that when you apply the

pressure, it should be even and slow. The bearing

should be pushed straight into the block. When it is

done, the bearing edge should be flush with the

bearing block.

Parts:

P-03

Frame #3

STEP Y-03

Before push the bearings, make sure the hole is

clean from manufacture debris. If not, use a needle

file and small tool to clean it.

STEP Y-04

Push the bearing slowly into the bearing block hole.

6 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-05

Here is how it looks like when it is done.

STEP Y-06

We need to push the linear ball bearings into the

support frames. Be aware of the orientation during

the install.

Parts:

Frame #10, #11

P-24(4)

STEP Y-07

Again, we are using bench vise for the job.

STEP Y-08

Push it slowly and make sure it is straight.

7 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-09

Push it till the end.

STEP Y-10

Then do the other side. Please take a look at the

orientation of two bearings in the picture.

STEP Y-11

Here is how they will look like when it is done.

STEP Y-12

Other side. The bearing's ends flush with the board

surface.

8 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-13

Now we need to attach the bearing block (with

bearing already installed) onto part #13.

Parts:

Frame #13, #3

P-15(2)

P-16(4)

P-18(2)

STEP Y-14

Using M4 machine screw, and put flat washers on

both sides.

STEP Y-15

Now it is done.

STEP Y-16

On the other side, we need to put another bearing

block onto part #14. The stepper motor will be

attached to this frame.

Parts:

Frame#14, #3

P-15(2)

P-16(4)

P-18(2)

9 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-17

Using M4, washers and nuts.

STEP Y-18

It is done now.

STEP Y-19

Here is the Y Axis lead screw, and anti backlash

nuts assembly. We will need to put them on

following the steps as illustrated in the next few

picture.

Parts:

P-09(1)

P-04(1)

P-05(1)

P-06(1)

STEP Y-20

First, put the small falan on. Just make a few turns

onto the lead screw.

10 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-21

Now put the spring onto it.

STEP Y-22

Finally, put the falan on. Apply some pressure to

squeeze both falans together, and then turn the

screw into the big falan. You may need to give it a

couple of tries. Make sure the anti backlash nuts and

lead screw are aligned properly.

STEP Y-23

Turn the anti backlash into the lead screw.

STEP Y-24

Here is the anti backlash nuts installed on the lead

screw.

11 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-25

The #10 will be attached to the anti backlash nuts

using M4 machine screw, with flat washer, lock

washer and nuts.

Parts:

Frame#10

P-15(2)

P-16(4)

P-17(2)

P-18(2)

STEP Y-26

Put the screws on.

STEP Y-27

And then tight them up.

STEP Y-28

Now, we need to put another support frame and

guide rods on.

Parts:

Frame #11

P-08(2)

12 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-29

Before we put the guide rod on, please use WD-40

clean the rod thoroughly.

STEP Y-30

Using a paper towel is fine.

STEP Y-31

The rods and #11 are installed.

STEP Y-32

On the other side, we need to first install the motor

support blocks on before moving forward. This will

make it much easier to access the screws.

Parts:

Frame#14, #12(2)

P-12(4)

P-13(4)

13 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-33

Using M3 screws to attach the motor support blocks.

STEP Y-34

Using an electrical screwdriver is a good idea.

STEP Y-35

Now the motor support blocks are installed onto the

frame #14

STEP Y-36

We are ready to put the rest of the frames of Y Axis

together.

Parts:

Frame#14, #13, #15(2)

14 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-37

Push the lead screw shaft through the end ball

bearings.

STEP Y-38

The other side, same.

STEP Y-39

It should look like this

STEP Y-40

Using M6x15 for attaching the guide rods to end

frames.

Parts:

P-19(2)

P-20(2)

15 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-41

Using a hex key to fasten the screws.

STEP Y-42

It is done on one side.

STEP Y-43

Same to the other side of the Y Axis.

Parts:

P-19 (2)

P-20 (2)

STEP Y-44

It is done.

16 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-45

Now we are ready to put the side frame on.

STEP Y-46

Using M3 screws provided, M3 flat washers should

also be used.

Parts:

P-12 (6)

P-13 (6)

STEP Y-47

Screw them on. Check the squareness often.

STEP Y-48

On the other side, same.

Parts:

P-12 (6)

P-13 (6)

17 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-49

Now we finished the M3 screws for the side frames.

STEP Y-50

Finally, we need to fasten the M6 screws on guide

rods.

STEP Y-51

It is done.

STEP Y-52

Check whether you can turn the lead screw easily. It

should, other wise, you should check where can be

the problem. It is always a good idea to identify the

issue earlier in the install. Otherwise, you will have

to back out many steps to get it fixed.

18 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-53

We use a lead screw end holding nut to hold the lead

screw to the ball bearing and frame.

Parts:

P-07(1)

STEP Y-54

To install the nut, you should hold the lead screw

and the nut as shown in the picture. Make sure the

nut, lead screw and ball bearing; there is no gap in

between. Then fasten the setscrews on the nut.

STEP Y-55

Using a hex key to fasten the setscrews on the lead

screw end holding nut. After this, check that there

should no play between lead screw, bearing and

frame.

STEP Y-56

Now we are ready to put the motor on.

Parts:

P-01(1)

Frame #2(1)

P-14(4)

P-13(4)

19 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-57

Use M3 Machine screws provided to attach the

stepper motor to the part #2.

STEP Y-58

Now, put the flex coupling onto the lead screw

shaft.

Parts:

P-02 (1)

STEP Y-59

Then put the motor onto the motor support blocks.

Parts:

P-12 (4)

P-13 (4)

STEP Y-60

Here you go.

20 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-61

Move the coupling to the middle position.

STEP Y-62

Fasten the setscrews on the flex coupling. Now the

motor and lead screw is connected.

STEP Y-63

Be aware of the motor lead orientation; make sure it

is easy for your wiring later. For Y Axis, you can

either let the wire outlet face up or on the side.

STEP Y-64

Now we are putting the working table onto the

support frames for Y Axis.

Parts:

Frame #23

P-12 (10)

21 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Y-65

Now, the Y Axis assembly is done. The picture

shows tools we have used, except the bench vise.

STEP Y-66

Tools we have used so far.

STEP X-01

Now let's start Gantry install.

STEP X-02

First thing, we need to prepare the ball bearings and

linear bearings. Clean the holes if necessary.

Parts:

Frame#19,#17

22 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-03

Again, we are going to use bench vise.

Parts:

Frame #19,#17

P-03(2)

STEP X-04

Push it slowly and make sure it is straight. If it is not

aligned properly and force the bearing in, it can

break the board, so be very careful here.

STEP X-05

Now ball bearings have been pushed into the side

frames.

STEP X-06

Now let's install linear bearings to the support

frames.

Parts:

P-24 (4)

Frame #7

Frame #8

23 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-07

Make sure it is straight, it is important.

STEP X-08

Linear bearings have been installed to Gantry

support frames.

STEP X-09

The end of the bearings is flush with the frame

surface.

STEP X-10

Again, install the anti backlash nuts to the Gantry

lead screw; refer to the install procedure for Y Axis.

Parts:

P-09

P-04

P-05

P-06

24 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-11

The anti backlash nuts are on the lead screw.

STEP X-12

Here is the layout of the main parts for Gantry.

Parts:

P-08 (2)

STEP X-13

Again, clean the rod using WD-40.

STEP X-14

Attach the anti backlash to the support frame using

M4, with lock washers.

Parts:

P-15(2)

P-16(4)

P-17(2)

P-18(2)

25 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-15

Fasten them using a hex key.

STEP X-16

Ready for guide rods.

STEP X-17

Slide the rods on.

STEP X-18

Now, let's prepare the side frames. This two are on

the motor side (right).

Parts:

Frame #19, #20

P-15(2)

P-16(4)

P-18(2)

26 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-19

Close them up as shown.

STEP X-20

Using 2 M4 machine screws.

STEP X-21

Ready to fasten the screws.

STEP X-22

Put the washers and nuts on.

27 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-23

It is done on one side.

STEP X-24

Ready for the other side.

Parts:

Frame #17, #18

P-15(2)

P-16(4)

P-18(2)

STEP X-25

Be aware of the orientation.

STEP X-26

Close them up.

28 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-27

Fasten using M4 screws with washers and nuts.

STEP X-28

Now, we need to put the motor support blocks on.

The M3 screws are much easier to access then after

put everything together.

Parts:

Frame #19,#20

P-12(4)

P-13(4)

STEP X-29

2 Motor support blocks for Gantry will be inserted

into those square holes.

STEP X-30

As shown.

29 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-31

Use M3 screws and washers.

STEP X-32

It is done.

STEP X-33

Now we put all Gantry parts together.

STEP X-34

Using M6x20 to connect the gantry side frames and

guide rods.

Parts:

P-21(2)

P-20(2)

30 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-35

Done on one side.

STEP X-56

Similar to the other side.

Parts:

P-19(2)

P-20(2)

STEP X-37

Using a hex key to fasten the screws.

STEP X-38

Same, install lead screw holding nut.

Parts:

P-07

31 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-39

Squeeze them together; make sure there is no gap

between lead screw and ball bearing and holding

nut.

STEP X-40

Then fasten the setscrews on the holding nut.

STEP X-41

Put the flex coupling on before the stepper motor.

Parts:

P-02(1)

STEP X-42

Put the motor onto motor base #2.

Parts:

P-01

P-14(4)

P-13(4)

Frame #2

32 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-43

Using M3 machine screws provided.

STEP X-44

For gantry motor, you probably want to face the

motor leads backward.

STEP X-45

Use screwdriver to fasten the screws.

STEP X-46

Now we need to put the Z Axis base onto the gantry

support frames.

Parts:

Frame #21

P-12(8)

P-13(8)

33 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-47

Using M3 screws and washers.

STEP X-48

It is done.

STEP X-49

Make sure you can turn the lead screw by hand

easily. Check it often and it will save you later.

STEP X-50

Now let's put the gantry back support on.

Parts:

Frame #22

P-12(16)

P-13(16)

34 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-51

Use M3 screws with washers.

STEP X-52

No hurry, do it slowly. There are a lot of screws.

STEP X-53

Yes, it is done.

STEP X-54

Here is the finished gantry assembly.

35 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-55

Now, let't try to put the gantry and Y Axis base

together.

STEP X-56

Using M6 x 25 machines screws.

Parts:

P-22 (2)

P-20(4)

P-23(2)

STEP X-57

Finished one side.

STEP X-58

Tight them up.

36 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP X-59

Here is the other side.

Parts:

P-22 (2)

P-20 (4)

P-23 (2)

STEP X-60

Before you tighten the screws on the other side, use

a ruler, check that it is even on both side. You can

fine-tune it later, but now, let's just make sure that

there is no big error just because ignorance.

STEP X-61

Tight them up.

STEP X-62

Now we have gantry and Y-axis installed. We are

ready for putting Z Axis together.

37 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-01

Here is a layout of main components of assembling

the Z Axis.

STEP Z-02

For Z Axis, we also need to push the ball bearings

into bearing blocks. # 3.

Parts:

P-03 (2)

Frame #3 (2)

38 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-03

Also, linear bearings will be pushed into support

frames.

Parts:

Frame #3 (2)

Frame #4 (2)

P-24 (4)

STEP Z-04

Linear bearings have been installed onto Z Axis

support frames.

STEP Z-05

Screw the Anti back lash nuts onto the Z Axis lead

screw, as demonstrated earlier.

Parts:

P-11(1)

P-4(1)

P-5(1)

P-6(1)

STEP Z-06

Screw the Anti back lash nuts onto the Z Axis lead

screw, as demonstrated earlier.

Connect the support frame and anti backlash nuts

using M4 machine screw with lock washer, flat

washer and nut.

Parts:

P-15(2)

P-16(4)

P-17(2)

P-18(2)

39 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-07

Close up detail.

STEP Z-08

Use a hex key to and a small wrench to fasten M4

screws and nuts.

STEP Z-09

Put the bearing support onto #8 using M4 screws

and washers.

Parts:

Frame#3,#8

P-15(2)

P-16(4)

P-18(2)

STEP Z-10

On the motor side, we need to put bearing block

onto #9 using M4 screws and washers.

Parts:

Frame#3,#9

P-15(2)

P-16(4)

P-18(2)

40 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-11

Before we put the motor support blocks on, we need

to pre insert the M6 x 15 machine screws onto #9.

Otherwise, you will not be able to put those screws

in.

Parts:

Frame #9

Frame #12(2)

P-19(2)

P-20(2)

STEP Z-12

Push M6 screws into the #9 frame ...

STEP Z-13

The M6 screws are pre inserted ...

STEP Z-14

Then put the motor support blocks on.

Parts:

P-13(4)

P-12(4)

41 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-15

Using M3 screw between #9 and motor support

blocks.

STEP Z-16

Now we can put the motor side frame onto the guide

rods.

STEP Z-17

Here you can use a hex key to fasten the M6

machine screw.

STEP Z-18

Install another side with M6 x 15 machine screw.

Parts:

P-19(2)

P-20(2)

42 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-19

Looks good?

STEP Z-20

Check whether you can easily turn the lead screw by

hand. If not, there is an alignment problem, and it is

better fix it right now.

STEP Z-21

Put the lead screw holding nut on, squeeze lead

screw and holding nut towards the ball bearing.

Parts:

P-07(1)

STEP Z-22

The lead screw holding nut is installed.

43 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-23

Put the flex coupling on before install the motor.

Parts:

P-02(1)

STEP Z-24

The motor and motor base(#2)

Parts:

Frame#2

P-01(1)

P-14(4)

P-13(4)

STEP Z-25

Using M3 machine screws with washers to connect

motor and motor base (#2)

STEP Z-26

Put the motor onto the motor support blocks.

Parts:

P-12(4)

P-13(4)

44 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-27

Motor is installed for the Z Axis.

STEP Z-28

Fasten the setscrews on the flex coupling.

STEP Z-29

Z Axis assembly is ready to be put on the machine.

STEP Z-30

Use M3 screws and washers to connect the Z Axis

to the Z Axis baseboard on the gantry.

Parts:

P-12(8)

P-13(8)

45 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-31

Fasten them up with a screwdriver.

STEP Z-32

Don't forget the screws at the bottom.

STEP Z-33

Use a screwdriver to fasten all screws.

STEP Z-34

The Z Axis assembly is installed on the machine

now.

46 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit User Manual

STEP Z-35

Now, let's put the tool base #16 to the Z Axis

support frames. You can do this step later, if you

haven't decided what kind of tool will be used. It is

easier to install tool when the base is off.

Parts:

P-12(8)

P-13(8)

STEP Z-36

The tool base has been installed on Z Axis. There

are 4 pre-drilled holes on the tool base, which is for

your tool holders. Zen Toolworks carries optional

spindle motors with tool holders, which can be

easily screwed onto this tool base.

STEP Z-37

We have completed the machine assembly. Hope it

didn't take you too long and you have enjoyed the

process so far. Now it is time to learn stepper motor

controller software and design software for the

project want to do.

47 Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Das könnte Ihnen auch gefallen

- Zen Toolworks CNC Carving Machine DIY Kit User Installation ManualDokument47 SeitenZen Toolworks CNC Carving Machine DIY Kit User Installation Manualchompink6900Noch keine Bewertungen

- Singer Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetVon EverandSinger Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetNoch keine Bewertungen

- CNC Machine DIY InstructionDokument65 SeitenCNC Machine DIY Instructioncxin168100% (3)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualVon EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Lead CNC Assembly Instructions v1.0 01 2019Dokument27 SeitenLead CNC Assembly Instructions v1.0 01 2019Bonnelly Peralta AlmanzarNoch keine Bewertungen

- Bee Ball Optimum InstructionsDokument8 SeitenBee Ball Optimum InstructionszoltanpdcNoch keine Bewertungen

- Modulus Arms Heavy-Duty AR-15 Jig Instructions V1Dokument21 SeitenModulus Arms Heavy-Duty AR-15 Jig Instructions V1Justin HeadNoch keine Bewertungen

- Z-Axis - V1 Engineering Inc DocsDokument8 SeitenZ-Axis - V1 Engineering Inc DocsP StuartNoch keine Bewertungen

- Assembling The Printrbot Play Kit (Model 1505)Dokument29 SeitenAssembling The Printrbot Play Kit (Model 1505)Vishal PaiNoch keine Bewertungen

- 2.4.02 Assembly InstructionsDokument11 Seiten2.4.02 Assembly InstructionsStalin NunezNoch keine Bewertungen

- Cetac Z Drive AssemblyDokument13 SeitenCetac Z Drive AssemblyYanine Aranda MosqueraNoch keine Bewertungen

- Universal Cutter /grinder: Owner'S ManualDokument16 SeitenUniversal Cutter /grinder: Owner'S ManualMawan Bentz100% (1)

- A6-L 3D Printer Installation Instructions2019.6.28Dokument46 SeitenA6-L 3D Printer Installation Instructions2019.6.28Bruno LópezNoch keine Bewertungen

- 2010 - 2011 Subaru Outback - Outback Wheel Arch MoldingDokument7 Seiten2010 - 2011 Subaru Outback - Outback Wheel Arch MoldingSubie SecretNoch keine Bewertungen

- Kenwood KVT 719dvd KVT 729dvd KVT 729dvdy KTV 739dvdDokument114 SeitenKenwood KVT 719dvd KVT 729dvd KVT 729dvdy KTV 739dvdΓιωργος50% (2)

- TRONXY P802EA Installation Guide V.03 PDFDokument29 SeitenTRONXY P802EA Installation Guide V.03 PDFSalas Meneses JavierNoch keine Bewertungen

- Shimano Nexus Inter-7 - Coaster - BrakeDokument12 SeitenShimano Nexus Inter-7 - Coaster - BrakeGeorge OrfanidisNoch keine Bewertungen

- User Manual: CNC RouterDokument31 SeitenUser Manual: CNC RouterPIXIDOUNoch keine Bewertungen

- Manu N NT NL NLT v109 enDokument48 SeitenManu N NT NL NLT v109 enmooninjaNoch keine Bewertungen

- A4 Operation Manual: Safety InstructionDokument7 SeitenA4 Operation Manual: Safety InstructionIliana IvanovaNoch keine Bewertungen

- Build Manual v1.0Dokument123 SeitenBuild Manual v1.0Karoui FethiNoch keine Bewertungen

- A8 3D Printer Installation Instructions-170111Dokument44 SeitenA8 3D Printer Installation Instructions-170111José R. SilleroNoch keine Bewertungen

- Anet A8 Printer ManualDokument46 SeitenAnet A8 Printer ManualMelku AbebeNoch keine Bewertungen

- A8 3D Printer Installation Instructions-2016!6!30Dokument46 SeitenA8 3D Printer Installation Instructions-2016!6!30TheKauti0nNoch keine Bewertungen

- A8 3D Printer Installation GuideDokument46 SeitenA8 3D Printer Installation GuideDaniel MejiaNoch keine Bewertungen

- Anet A8 Installation Guide PDFDokument46 SeitenAnet A8 Installation Guide PDFEnrique FernándezNoch keine Bewertungen

- A8 3D Printer Installation GuideDokument46 SeitenA8 3D Printer Installation GuidepepeNoch keine Bewertungen

- A8 3D Printer Installation Instructions 2016 6 30 PDFDokument46 SeitenA8 3D Printer Installation Instructions 2016 6 30 PDFBendot CeblenkNoch keine Bewertungen

- A8 3D Printer Installation Instructions 2016 6 30 PDFDokument46 SeitenA8 3D Printer Installation Instructions 2016 6 30 PDFvoievodul1Noch keine Bewertungen

- A8 3D Printer Installation Instructions-2016!6!30Dokument46 SeitenA8 3D Printer Installation Instructions-2016!6!30hasanbasri_93Noch keine Bewertungen

- A8 3D Printer Installation Instructions-2016!6!30Dokument46 SeitenA8 3D Printer Installation Instructions-2016!6!30Peña EduardoNoch keine Bewertungen

- A8 3D Printer Installation GuideDokument46 SeitenA8 3D Printer Installation GuideMarcosFenollarNoch keine Bewertungen

- A8 3D Printer Installation GuideDokument46 SeitenA8 3D Printer Installation GuideMarcosFenollarNoch keine Bewertungen

- A8 3D Printer Installation Instructions 2016 6 30 PDFDokument46 SeitenA8 3D Printer Installation Instructions 2016 6 30 PDFAdelaide LoureiroNoch keine Bewertungen

- Ender-7: 3D Printer User ManualDokument36 SeitenEnder-7: 3D Printer User ManualNeindisciplinat RomanNoch keine Bewertungen

- Robotic Arm 4DOFDokument20 SeitenRobotic Arm 4DOFMahmood AhmadNoch keine Bewertungen

- Shimano Nexus3 178 ManualDokument12 SeitenShimano Nexus3 178 Manualgrazka20Noch keine Bewertungen

- Middle Assembly - V1 Engineering Inc DocsDokument15 SeitenMiddle Assembly - V1 Engineering Inc DocsP StuartNoch keine Bewertungen

- Before Removal: Special Tools Description Part No. QtyDokument6 SeitenBefore Removal: Special Tools Description Part No. QtyPhomma KhinphommavongNoch keine Bewertungen

- Mearm - Io: Assembly Manual For V1.0Dokument22 SeitenMearm - Io: Assembly Manual For V1.0gabrielapb19Noch keine Bewertungen

- ds10524 Lathe Tooling 1223aDokument13 Seitends10524 Lathe Tooling 1223a1drydensamuelNoch keine Bewertungen

- Metal Plus (Model 1412) : Written By: Brook DrummDokument30 SeitenMetal Plus (Model 1412) : Written By: Brook DrummEmmanuel LeggeriNoch keine Bewertungen

- Cutting Tools: Your Partner For Clever ToolingDokument9 SeitenCutting Tools: Your Partner For Clever ToolingPalade LucianNoch keine Bewertungen

- Humanscale Float Table Installation ManualDokument11 SeitenHumanscale Float Table Installation ManualFabiana RussoNoch keine Bewertungen

- Miss Hyperion HydroDokument5 SeitenMiss Hyperion HydroJoel LaguárdiaNoch keine Bewertungen

- Lathe Tooling Guide: A Reference Guide To Understanding How Cutting Tools Work and Which Inserts They Pair WithDokument11 SeitenLathe Tooling Guide: A Reference Guide To Understanding How Cutting Tools Work and Which Inserts They Pair WithmallardfirstNoch keine Bewertungen

- Smartop Upright Deckmount Installation Instructions 7-30-19Dokument4 SeitenSmartop Upright Deckmount Installation Instructions 7-30-19kimba worthNoch keine Bewertungen

- Vision SL Disc Brake Conversion Kit Instruction 6Dokument2 SeitenVision SL Disc Brake Conversion Kit Instruction 6robinNoch keine Bewertungen

- Alternator MountingDokument2 SeitenAlternator MountingNick Ildefonso Fuenmayor AntunezNoch keine Bewertungen

- Arduino 3D Printed CNC Pen PlotterDokument37 SeitenArduino 3D Printed CNC Pen Plotterseynif015Noch keine Bewertungen

- Bulldog 8x10 Camera DIY Instructions PDFDokument8 SeitenBulldog 8x10 Camera DIY Instructions PDFMalaNoch keine Bewertungen

- PatentesDokument6 SeitenPatentessergio romanNoch keine Bewertungen

- Manual Jack A4sDokument8 SeitenManual Jack A4sIliana IvanovaNoch keine Bewertungen

- Z Kit TutorialDokument9 SeitenZ Kit TutorialEduardo AlvesNoch keine Bewertungen

- XY-2 PRO Installation InstructionsDokument20 SeitenXY-2 PRO Installation InstructionsJohn VlahidisNoch keine Bewertungen

- Creality CR-10 ManualDokument18 SeitenCreality CR-10 ManualhijodeibnNoch keine Bewertungen

- White 1750 Sewing Machine Instruction ManualDokument31 SeitenWhite 1750 Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- NEPTUNE 2&2S English User Guide 20211203Dokument28 SeitenNEPTUNE 2&2S English User Guide 20211203marknerocavalloNoch keine Bewertungen

- Hypercube 3D Printer Using RatRig Frame KitDokument13 SeitenHypercube 3D Printer Using RatRig Frame KitceovcdkqgdheqgauwaNoch keine Bewertungen

- 25 Omni X Tube Bending GuideDokument15 Seiten25 Omni X Tube Bending GuideMartin SilisqueNoch keine Bewertungen

- Panaxismmcconst PDFDokument15 SeitenPanaxismmcconst PDFMartin SilisqueNoch keine Bewertungen

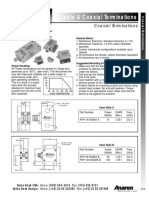

- Cable & Coaxial TerminationsDokument2 SeitenCable & Coaxial TerminationsMartin SilisqueNoch keine Bewertungen

- IIR FM Pre-Emphasis Filter Investigations and A Digital ImplementationDokument21 SeitenIIR FM Pre-Emphasis Filter Investigations and A Digital ImplementationMartin SilisqueNoch keine Bewertungen

- Model 6814: Circularly Polarized FM Broadcast AntennaDokument33 SeitenModel 6814: Circularly Polarized FM Broadcast AntennaMartin SilisqueNoch keine Bewertungen

- BCI88108LDokument3 SeitenBCI88108LMartin SilisqueNoch keine Bewertungen

- Arvind Check For Pedestal (Anchor Bolt) Concreting: Time:S124Dokument12 SeitenArvind Check For Pedestal (Anchor Bolt) Concreting: Time:S124Sudhanshu PalNoch keine Bewertungen

- Standard Housing PlanerDokument6 SeitenStandard Housing PlanerSathish RadhakrishnanNoch keine Bewertungen

- Optimization of Machining Parameters For Surface Roughness in Milling OperationDokument5 SeitenOptimization of Machining Parameters For Surface Roughness in Milling OperationArmando Rosas GonzalitosNoch keine Bewertungen

- RFI-3409Daily Welding Inspection ReportDokument12 SeitenRFI-3409Daily Welding Inspection ReportnguyennamxmNoch keine Bewertungen

- Fme6 Activity2 PDFDokument7 SeitenFme6 Activity2 PDFFred BorjaNoch keine Bewertungen

- Process Specification: Finishing of Metal Components (Deburring, Cleaning)Dokument6 SeitenProcess Specification: Finishing of Metal Components (Deburring, Cleaning)s0l1v3r18Noch keine Bewertungen

- Analysis of Grinding WheelDokument27 SeitenAnalysis of Grinding Wheelranarani2013100% (1)

- Wire RoadDokument16 SeitenWire Road02081987Noch keine Bewertungen

- Course Outline Development TemplateDokument7 SeitenCourse Outline Development TemplateMaribel Bonite PeneyraNoch keine Bewertungen

- Milling CutterDokument1 SeiteMilling Cutteradhikaritp9990Noch keine Bewertungen

- Milling MachineDokument11 SeitenMilling MachineAnil Deshpande100% (2)

- Bolt Depot - Pilot Hole Sizes For Wood ScrewsDokument2 SeitenBolt Depot - Pilot Hole Sizes For Wood ScrewsarqmemofirsNoch keine Bewertungen

- GB Standard PDFDokument2 SeitenGB Standard PDFsenthilkumarNoch keine Bewertungen

- KL Jack Fasteners-Technical Data and ChartsDokument32 SeitenKL Jack Fasteners-Technical Data and ChartsphuyangNoch keine Bewertungen

- 117BP - CNC Technologies PDFDokument8 Seiten117BP - CNC Technologies PDFvenkiscribd444Noch keine Bewertungen

- Firing Pin BushDokument3 SeitenFiring Pin BushIM_JohnnyVNoch keine Bewertungen

- High Efficiency Grinding Using CBN WheelDokument24 SeitenHigh Efficiency Grinding Using CBN WheelS.VigneshNoch keine Bewertungen

- YCM NT SeriesDokument6 SeitenYCM NT SeriesCNC SYSTEMSNoch keine Bewertungen

- Casting Procedures and Defects: Dr. Abhinav GuptaDokument53 SeitenCasting Procedures and Defects: Dr. Abhinav Guptaዘረአዳም ዘመንቆረርNoch keine Bewertungen

- Wel 13 HDokument8 SeitenWel 13 HWilly Uio100% (1)

- The Rev Olutionar Y Tooling Sy Stem: CatalogueDokument32 SeitenThe Rev Olutionar Y Tooling Sy Stem: CatalogueluzelarNoch keine Bewertungen

- A Seminar On NC MachineDokument25 SeitenA Seminar On NC MachineSai TejaNoch keine Bewertungen

- HQ126EN Balinit® LATUMADokument4 SeitenHQ126EN Balinit® LATUMAMari BraatzNoch keine Bewertungen

- Widia - Advances 2018 - Metric - LR PDFDokument84 SeitenWidia - Advances 2018 - Metric - LR PDFswami061009Noch keine Bewertungen

- Lathes Using Emery ClothDokument2 SeitenLathes Using Emery ClothvelmuruganNoch keine Bewertungen

- Formulae and Data SheetDokument3 SeitenFormulae and Data SheetHemantNoch keine Bewertungen

- (BSF) Whitworth Fine ThreadDokument1 Seite(BSF) Whitworth Fine ThreadmatjazNoch keine Bewertungen

- Grinder Checklist2Dokument3 SeitenGrinder Checklist2jovyNoch keine Bewertungen

- Presentasi Teknologi Mekanik Minggu 7Dokument35 SeitenPresentasi Teknologi Mekanik Minggu 7ibnuNoch keine Bewertungen