Beruflich Dokumente

Kultur Dokumente

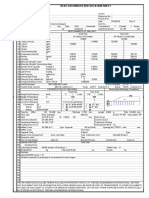

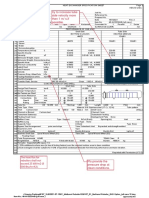

WTS Sample Printout

Hochgeladen von

saka dewaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WTS Sample Printout

Hochgeladen von

saka dewaCopyright:

Verfügbare Formate

WTS-2017

Table of contents

Thermal and hydraulic design of shell and tube heat exchangers ........................................................................................... 2

Tube sheet data ........................................................................................................................................................................ 4

Properties of Water and Steam ................................................................................................................................................ 6

Properties of Water and Steam ................................................................................................................................................ 7

Heat transfer in pipe flow ......................................................................................................................................................... 8

Heat transfer on the shell side in baffeled shell and tube heat exchangers .......................................................................... 10

Corrected logarithmic mean temperature difference (CLMTD) and temperature distribution according to cell method .... 13

Tube-side pressure drop in shell and tube heat exchangers .................................................................................................. 14

Tube bundle vibration analysis ............................................................................................................................................... 16

Pressure drop in the outer shell of heat exchangers .............................................................................................................. 17

CAD program for shell and tube heat exchangers .................................................................................................................. 19

CAD sketch from WCAD .......................................................................................................................................................... 20

MS Excel specification sheet ................................................................................................................................................... 21

Layout

Input values: 1.234 or 1.234

Calculated values: 1.234 or 1.234

Critical values: 1.234 or 1.234

Estimated values: 1.234 or 1.234

Lauterbach Verfahrenstechnik GmbH 1 20.11.2017

WTS-2017

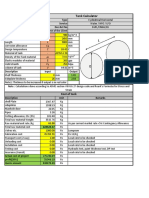

Thermal and hydraulic design of shell and tube heat exchangers

Tube-side Shell-side

Medium Water Water

Mass flow mi 20 kg/s ma 12.15 kg/s

Volume flow Vi 73.63 m³/h Va 44.01 m³/h

Inlet pressure (abs.) Pi 4 bar Pa 3 bar

Inlet temperature ϑei 80 °C ϑea 20 °C

Outlet temperature ϑai 60 °C ϑaa 53 °C

Mean temperature ϑmi 70 °C ϑma 36.5 °C

Actual

Inlet temperature ϑei 80 °C ϑea 20 °C

Outlet temperature ϑai 59.32 °C ϑaa 54.12 °C

Heat duty Qi -1675 kW Qa 1675 kW

Heat loss Qva 0 kW

Fouling resistance fi 0 m²·K/W fa 0 m²·K/W

Geometry

From tubesheet library

Installation position: Horizontal

Bare tubes Bare tubes

Straight tubes with fixed tubesheets Segmental baffles

Shell outside diameter Da 406.4 mm Shell wall thickness s 6.3 mm

Shell inside diameter Di 393.8 mm

Bundle-to-shell clearance 13.18 mm Min. bundle-to-shell clearance 12 mm

Tube outside diameter da 20 mm Tube wall thickness si 2 mm

Tube inside diameter di 16 mm

Tube pitch (transverse) s1 26 mm Tube pitch (longitudinal) s2 22.52 mm

Pitch angle Φ 60 °

Tube lane width (horizontal) bh 32 mm

Central baffle spacing 110 mm Number of baffles / pass 24

Inlet baffle spacing 235 mm Baffle diameter 390.8 mm

Baffle borehole diameter 20.8 mm Baffle cut in % of shell ID 22 %

Number of sealing strips pairs 0 Baffle thickness 4 mm

Tube material Stainless steel

Thermal conductivity of tube material λ 15 W/(m·K)

Number of tube-side passes 2

Number of shell-side passes 1

Number of serial heat exchangers 1

Evaluation

Required Final Overdesign

Heat transfer area A 26.57 m² Aa 28.27 m² 6.41 %

Tube length between the l 2819 mm la 3000 mm

tubesheets

Lauterbach Verfahrenstechnik GmbH 2 20.11.2017

WTS-2017

Results

Number of tubes N 150

Heat transfer coefficient (inside) αi 9209 W/(m²·K)

Heat transfer coefficient (outside) αa 5784 W/(m²·K)

Overall heat transfer coefficient k 2186 W/(m²·K)

Logarithmic mean temperature diff. LMTD ∆ϑ 33.08 K

FN Factor (Correction factor for LMTD) FN 0.8717

Log. mean temperature diff. (corrected) CLMTD ∆ϑc 28.83 K

Total fouling resistance f 0 m²·K/W

Tube-side Shell-side

Velocity (tube-side) 1.356 m/s Velocity (shell-side) 1.012 m/s

Velocity (window zone) 0.9001 m/s

Reynolds number Re 52574 Reynolds number Re 31881

Pressure drop ∆pi 16607 Pa Pressure drop ∆pa 25951 Pa

Mean tube wall temperature ϑwi 60.06 °C Mean tube wall ϑwa 49.16 °C

temperature

Inlet nozzle Inlet nozzle

Nominal width DN 125 Nominal width DN 125

Outside diameter 139.7 mm Outside diameter 139.7 mm

Inside diameter 131.7 mm Inside diameter 131.7 mm

Velocity 1.501 m/s Velocity 0.8975 m/s

ρ·v² 800.3 kg/(m·s²)

Outlet nozzle Outlet nozzle

Nominal width DN 125 Nominal width DN 125

Outside diameter 139.7 mm Outside diameter 139.7 mm

Inside diameter 131.7 mm Inside diameter 131.7 mm

Velocity 1.501 m/s Velocity 0.8975 m/s

Physical properties Tube-side Shell-side

Density ρi 977.9 kg/m³ Density ρa 993.6 kg/m³

Specific heat capacity cpi 4187 J/(kg·K) Specific heat capacity cpa 4178 J/(kg·K)

Thermal conductivity λi 0.6598 W/(m·K) Thermal conductivity λa 0.6242 W/(m·K)

Dynamic viscosity ηi 0.4036 mPa·s Dynamic viscosity ηa 0.6981 mPa·s

Equations

Heat balance

Overall heat transfer coefficient

Lauterbach Verfahrenstechnik GmbH 3 20.11.2017

WTS-2017

Tube sheet data

Description of type

Baffle-type Segmental baffles

Shell outside diameter Do 406.4 mm

Shell inside diameter Di 393.8 mm

Minimum bundle-to-shell clearance Dm 12 mm

Bundle-to-shell clearance D 13.18 mm

Bundle diameter at cross flow zone DB 362 mm

Bundle diameter (cross flow zone and window zone) DBE 367.4 mm

Tube outside diameter da 20 mm

Tube inside diameter di 16 mm

Tube pitch (transverse) s1 26 mm

Tube pitch (longitudinal) s2 22.52 mm

Pitch angle Φ 60 °

Baffle diameter Dl 390.8 mm

Height of baffle cut H 86.64 mm

Height of the window in % of shell inside diameter 22 %

Tube pattern staggered

Arrangement around central tube

No tubes in window? No

Number of tube-side passes 2

Number of shell-side passes 1

Tube lane width (horizontal) 32 mm

Tube lane width (vertical) 32 mm

Outside diameter of the head Da mm

Bolt-circle diameter Dt mm

Number of bolts on the bolt-circle

Rotation angle for bolt-hole pattern °

Number of tubes n 150

Number of dummy tubes nB 0

Number of tie rods nZ 0

Total number of tubes, dummy tubes and tie rods nG 150

Number of tubes, dummy tubes and tie rods in the upper and lower nF 40

window

Number of tubes, dummy tubes and tie rods in the cross flow zone nS 110

Number of tube rows in a window nR,F 2.5

Number of tube rows in the cross flow zone nW 9

Number of tube rows in the end zone nW,E 11.5

Sum of the shortest connecting paths in the center Le 109.8 mm

Shortest connecting path between tube and tube e 6 mm

Shortest connecting path between tube and shell e1 15.91 mm

Number of connections nV 13

Mean distance boundary tubes - bundle centre rh 155.4 mm

Number of boundary tubes required/actual RR / 70

Perimeter of the tube layout Cp 1066 mm

Total area enclosed by perimeter Ap 0.08339 m²

Lauterbach Verfahrenstechnik GmbH 4 20.11.2017

WTS-2017

Number of tubes, dummy tubes and tie rods per pass

Pass-No. 1 2 3 4 5 6 7 8

75 75 0 0 0 0 0 0

Final bundle length la 3000 mm

Total area Ages 28.27 m²

Number of baffles per shell-side path N 24

Central baffle spacing S1 110 mm

Distance between the tubesheet and the 1st baffle S2 235 mm

Baffle borehole diameter 20.8 mm

Number of pairs of sealing strips nD 0

Number of exchangers in series 1

Nozzles Tube-side Shell-side

Inside nozzle diameter (inlet) 131.7 mm 131.7 mm

Inside nozzle diameter (outlet) 131.7 mm 131.7 mm

Lauterbach Verfahrenstechnik GmbH 5 20.11.2017

WTS-2017

Properties of Water and Steam

State 1 State 2

Calculation for saturation? No No

Temperature ϑ1 36.5 °C ϑ2 49.15 °C

Pressure p1 3 bar p2 3 bar

Properties of liquid water or superheated steam

State 1 State 2

Liquid Liquid

Density ρ 993.6 kg/m³ ρ 988.5 kg/m³

Spec. isob. heat capacity cp 4178 J/(kg·K) cp 4179 J/(kg·K)

Thermal conductivity λ 0.6242 W/(m·K) λ 0.6397 W/(m·K)

Dynamic viscosity η 0.6981 mPa·s η 0.5544 mPa·s

Kinematic viscosity ν 7.026e-7 m²/s ν 5.608e-7 m²/s

Prandtl number Pr 4.673 Pr 3.622

Thermal diffusivity a 1.503e-7 m²/s a 1.548e-7 m²/s

Specific volume v 0.001006 m³/kg v 0.001012 m³/kg

Spec. isoc. heat capacity cv 4088 J/(kg·K) cv 4028 J/(kg·K)

Specific enthalpy h 153177 J/kg h 206052 J/kg

Spec. internal energy u 152875 J/kg u 205749 J/kg

Specific entropy s 525.4 J/(kg·K) s 692.7 J/(kg·K)

Compressibility factor Z 0.002113 Z 0.00204

Surface tension σ 70.16 mN/m σ 68.09 mN/m

Coefficient of thermal expansion β 3.576e-4 1/K β 4.516e-4 1/K

Isentropic exponent κ 7705 κ 7862

Speed of sound w 1525 m/s w 1545 m/s

Dielectric constant ε 74.39 ε 70.2

Characteristics

Validity

Molar mass M 18.02 g/mol 0.01°C ≤ ϑ ≤ 800°C

Gas constant R 461.5 J/(kg·K) 0.00612 bar ≤ p ≤ 1000 bar

Critical temperature Tc 373.9 °C 0.01°C ≤ ϑ ≤ 2000°C

Critical pressure pc 2.206e+7 Pa 0.00612 bar ≤ p ≤ 500 bar

Critical density ρc 322 kg/m³

Lauterbach Verfahrenstechnik GmbH 6 20.11.2017

WTS-2017

Properties of Water and Steam

State 1 State 2

Calculation for saturation? No No

Temperature ϑ1 70 °C ϑ2 60.06 °C

Pressure p1 4 bar p2 4 bar

Properties of liquid water or superheated steam

State 1 State 2

Liquid Liquid

Density ρ 977.9 kg/m³ ρ 983.3 kg/m³

Spec. isob. heat capacity cp 4187 J/(kg·K) cp 4182 J/(kg·K)

Thermal conductivity λ 0.6598 W/(m·K) λ 0.651 W/(m·K)

Dynamic viscosity η 0.4036 mPa·s η 0.4657 mPa·s

Kinematic viscosity ν 4.128e-7 m²/s ν 4.736e-7 m²/s

Prandtl number Pr 2.562 Pr 2.992

Thermal diffusivity a 1.611e-7 m²/s a 1.583e-7 m²/s

Specific volume v 0.001023 m³/kg v 0.001017 m³/kg

Spec. isoc. heat capacity cv 3922 J/(kg·K) cv 3973 J/(kg·K)

Specific enthalpy h 293320 J/kg h 251707 J/kg

Spec. internal energy u 292911 J/kg u 251300 J/kg

Specific entropy s 954.8 J/(kg·K) s 831.7 J/(kg·K)

Compressibility factor Z 0.002583 Z 0.002645

Surface tension σ 64.48 mN/m σ 66.23 mN/m

Coefficient of thermal expansion β 5.838e-4 1/K β 5.233e-4 1/K

Isentropic exponent κ 5935 κ 5940

Speed of sound w 1558 m/s w 1554 m/s

Dielectric constant ε 63.78 ε 66.77

Characteristics

Validity

Molar mass M 18.02 g/mol 0.01°C ≤ ϑ ≤ 800°C

Gas constant R 461.5 J/(kg·K) 0.00612 bar ≤ p ≤ 1000 bar

Critical temperature Tc 373.9 °C 0.01°C ≤ ϑ ≤ 2000°C

Critical pressure pc 2.206e+7 Pa 0.00612 bar ≤ p ≤ 500 bar

Critical density ρc 322 kg/m³

Lauterbach Verfahrenstechnik GmbH 7 20.11.2017

WTS-2017

Heat transfer in pipe flow

Constant wall temperature

Process data

Total mass flow mtot kg/h

Total volume flow Vtot m³/h

Number of tubes with parallel flow Z

Mass flow per tube m 960 kg/h

Inlet temperature ϑe 80 °C

Outlet temperature ϑa 60 °C

Mean temperature ϑm 70 °C

Pressure (abs.) p 4 bar

Physical properties

Fluid liquid / gaseous? liquid

Density ρ 977.9 kg/m³

Specific heat capacity cp 4187 J/(kg·K)

Thermal conductivity λ 0.6598 W/(m·K)

Dynamic viscosity η 0.4036 mPa·s

Kinematic viscosity ν 4.128e-7 m²/s

Prandtl number Pr 2.562

Prandtl number at wall temperature PrW 2.992

Wall temperature ϑW 60.06 °C

Geometry

Tube circular / non-circular? Circular tubes

Tube length l 3000 mm

Tube inside diameter di 16 mm

Cross sectional area of the tube f 2.011e-4 m²

Perimeter of the tube u 50.26 mm

Hydraulic diameter dh 16 mm

Heat transfer

Flow velocity w 1.356 m/s

Reynolds number Re 52574

Nusselt number Nu 223.3

Heat transfer coefficient α 9209 W/(m²·K)

Heat duty Q = mtot · cp · (ϑa - ϑe ) Q kW

Lauterbach Verfahrenstechnik GmbH 8 20.11.2017

WTS-2017

Equations Constant wall temperature

Turbulent flow (Re > 10000)

Correction factor K (Effect of temperature dependent property variations)

Liquids

Lauterbach Verfahrenstechnik GmbH 9 20.11.2017

WTS-2017

Heat transfer on the shell side in baffeled shell and tube heat exchangers

Geometrical data

Tube arrangement staggered

Shell inside diameter Di 393.8 mm

Bundle diameter at cross flow zone DB 362 mm

Tube outside diameter da 20 mm

Tube pitch (transverse) s1 26 mm

Tube pitch (longitudinal) s2 22.52 mm

Baffle diameter Dl 390.8 mm

Height of baffle cut H 86.64 mm

Diameter of the bore holes in the baffles dB 20.8 mm

Baffle spacing S 110 mm

Number of tubes including blanks and support tubes n 150

Number of tubes in the upper and lower windows nF 40

Number of main resistances in a cross-flow zone nW 9

Number of connections nV 13

Distance between boundary tubes and shell e1 15.91 mm

Shortest connecting path between tube and tube e 6 mm

Sum of the shortest connecting paths in the center LE 109.8 mm

Number of sealing strip pairs nS 0

Number of shell-side passes ND 1

Fluid

Mass flow m 43732 kg/h

Volume flow V 44.01 m³/h

Inlet temperature ϑe 20 °C

Outlet temperature ϑa 53 °C

Mean temperature ϑm 36.5 °C

Fluid liquid /gaseous? liquid

Density ρ 993.6 kg/m³

Specific heat capacity cp 4178 J/(kg·K)

Thermal conductivity λ 0.6242 W/(m·K)

Dynamic viscosity η 0.6981 mPa·s

Kinematic viscosity ν 7.026e-7 m²/s

Prandtl number Pr 4.673

Prandtl number at tube wall temperature PrW 3.622

Reynolds number Reψ,1 31881

Heat transfer coefficient α 6136 W/(m²·K)

Lauterbach Verfahrenstechnik GmbH 10 20.11.2017

WTS-2017

Results

Calculation of Nu0,Bundle

Calculation of fG

Lauterbach Verfahrenstechnik GmbH 11 20.11.2017

WTS-2017

Calculation of fL

Calculation of fB

for nS ≤ nW / 2

for e < (Di - DB)

Correction factor K (Effect of temperature dependent property variations)

Heating of liquids

Lauterbach Verfahrenstechnik GmbH 12 20.11.2017

WTS-2017

Corrected logarithmic mean temperature difference (CLMTD) and temperature

distribution according to cell method

Corrected logarithmic mean temperature difference (CLMTD) and distribution with cell method for shell

and tube heat exchangers

Tube-side inlet temperature ti1 80 °C

Shell-side inlet temperature ta1 20 °C

Tube-side mass flow mi 72000 kg/h

Shell-side mass flow ma 43732 kg/h

Specific heat capacity tube-side cp,i 4187 J/(kg·K)

Specific heat capacity shell-side cp,a 4178 J/(kg·K)

Heat capacity flow tube-side; W w,i = mi·cp,i W w,i 83749 W/K

Heat capacity flow shell-side; W w,a = ma·cp,a W w,a 50757 W/K

Number of baffles NU 20

Number of shell-side passes Ns 1

Number of tube-side passes Nt 2

Sheet plus shell type 1

Number of tube rows per cell 4

Actual overall heat transfer coefficient k 2186 W/(m²·K)

Actual heat transfer area A 28.27 m²

0 = unmixed; 0.5 = mixed 0

Tube flow: countercurrent = 1; cocurrent = 2 1

Flow pattern: countercurrent = 1; cocurrent = 2 101

Tube-side outlet temperature ti2 59.32 °C

Shell-side outlet temperature ta2 54.12 °C

LMTD countercurrent flow ∆TGeg 32.14 K

FN factor FN 0.8717

CLMTD corrected log. mean temperature difference ∆Tm 28.01 K

Number of cells 42

Product k·A 61817 W/K

Product k·A per cell 1472 W/K

Tube-side efficiency 0.3446

Shell-side efficiency 0.5686

Tube-side cell efficiency 0.01717

Shell-side cell efficiency 0.02834

Maximum tube-side temperature ti,max 80 °C

Maximum shell-side temperature ta,max 54.12 °C

Minimum tube-side temperature ti,min 59.32 °C

Minimum shell-side temperature ta,min 20 °C

Max. temperature inversion in one cell tinv 0 °C

Lauterbach Verfahrenstechnik GmbH 13 20.11.2017

WTS-2017

Tube-side pressure drop in shell and tube heat exchangers

Physical properties Mean temperature Wall temperature

Fluid: liquid / gaseous? liquid

Inlet temperature ϑe 80 °C

Outlet temperature ϑa 60 °C

Mean temperature ϑm = (ϑe +ϑa) / 2 ϑm 70 °C 60.06 °C

Inlet pressure (abs.) Pe 4 bar

Density ρ 977.9 kg/m³ 982.6 kg/m³

Specific heat capacity cp 4187 J/(kg·K)

Thermal conductivity λ 0.6598 W/(m·K)

Dynamic viscosity η 0.4036 mPa·s 0.4657 mPa·s

Geometrical data

Type: Straight tube / U-tube? Straight tube

Tube outside diameter da 20 mm

Tube wall thickness s 2 mm

Tube inside diameter di 16 mm

Number of tube-side passes nP 2

Number of tubes per pass nR 75

Length of one tube L 3000 mm

Inside nozzle diameter (inlet) dN,e 131.7 mm

Inside nozzle diameter (outlet) dN,a 131.7 mm

Acceleration due to gravity g 9.81 m/s²

Mass flow m 20 kg/s

Volume flow V 73.63 m³/h

Mean velocity in the tube w 1.356 m/s

Mean velocity in the inlet nozzle wN,e 1.501 m/s

Mean velocity in the outlet nozzle wN,a 1.501 m/s

Reynolds number Re 52564

Prandtl number Pr 2.562

Grashof number Gr 1136330

Friction factor (inlet, outlet and baffle) Ke 3.2

Fanning friction factor (tube, isothermal) ξis 0.006247

Correction factor for the viscosity Φ 1.022

Correction factor for the convection ψ 1

Friction factor (tube) (ξ = ξis · Φ · ψ) ξ 0.006386

Pressure drop (inlet nozzle) ∆PN,e 991.9 Pa

Pressure drop (outlet nozzle) ∆PN,a 991.9 Pa

Pressure drop (inlet, outlet and baffle) ∆Pe 2877 Pa

Pressure drop (friction) ∆Pt 8612 Pa

Fouling factor Ft 1.364

Total pressure drop (∆P = Ft · ∆Pt + ∆Pe + ∆PN,e +∆PN,a) ∆P 16607 Pa

Lauterbach Verfahrenstechnik GmbH 14 20.11.2017

WTS-2017

Equations

Straight tubes, multiple passes

Lauterbach Verfahrenstechnik GmbH 15 20.11.2017

WTS-2017

Tube bundle vibration analysis

General formulation

Tube outside diameter da 20 mm

Tube wall thickness s 2 mm

Tube inside diameter di 16 mm

Tube pitch (transverse) s1 26 mm

Tube pitch (longitudinal) s2 22.52 mm

Transverse pitch ratio s1/da 1.3

Longitudinal pitch ratio s2/da 1.126

Cross-sectional area of the tubes A 113 mm²

Second moment of area of the tubes J 4629 mm^4

Modulus of elasticity E 200000 N/mm²

Effective density ρ 7850 kg/m³

Support for the tubes jointed - fixed

Factor for the support C 3.93

Factor for additional forces Cf 1

Arrangement of the tubes Staggered bare tubes

Strouhal number of the bundle Sr 0.2292

Final span L 235 mm 345 mm

Velocity in the narrowest cross section we 0.8975 m/s 1.012 m/s

Natural frequency of the tubes fR 1438 1/s 667.1 1/s

Safety factor S 1.5

Allowable excitation frequency fz= fR/S fz 958.5 1/s 444.7 1/s

Excitation frequency of the flow ferr 10.29 1/s 11.6 1/s

Vibration probable, if ferr > fz

Equations

Lauterbach Verfahrenstechnik GmbH 16 20.11.2017

WTS-2017

Pressure drop in the outer shell of heat exchangers

Shell-side pressure drop in shell-and-tube heat exchangers with segmental baffles

Shell inside diameter Di 393.8 mm

Bundle diameter at cross flow zone DB 362 mm

Bundle diameter (cross flow zone and window zone) DBE 367.4 mm

Tube outside diameter da 20 mm

Tube pitch (transverse) s1 26 mm

Tube pitch (longitudinal) s2 22.52 mm

Pitch angle 60 °

Baffle diameter Dl 390.8 mm

Number of baffles nU 24

Height of baffle cut H 86.64 mm

Diameter of the bore holes in the baffles dB 20.8 mm

Central baffle spacing S 110 mm

Distance between the tubesheet and the 1st baffle SE 235 mm

Number of tubes including dummy tubes and tie rods n 150

Number of tubes in the upper and lower windows nF 40

Number of tube rows in a window nRF 2.5

Number of main resistances in the crossflow zone nW 9

Number of main resistances in the end zone nWE 11.5

Number of connection lines nV 13

Distance between boundary tubes and shell e1 15.91 mm

Number of sealing strip pairs nS 0

Number of shell-side passes ND 1

Inside nozzle diameter (inlet) dNi 131.7 mm

Inside nozzle diameter (outlet) dNo 131.7 mm

Fluid

Mass flow m 43732 kg/h

Volume flow V 44.01 m³/h

Inlet pressure PE 300000 Pa

Inlet temperature ϑE 20 °C

Outlet temperature ϑA 53 °C

Mean temperature ϑ 36.5 °C

Fluid liquid / gaseous? liquid

Density ρ 993.6 kg/m³

Specific heat capacity cp 4178 J/(kg·K)

Thermal conductivity λ 0.6242 W/(m·K)

Dynamic viscosity η 0.6981 mPa·s

Prandtl number Pr 4.673

Mean wall temperature ϑW 49.16 °C

Dynamic viscosity at mean wall temperature ηW 0.5544 mPa·s

Total pressure drop ∆ptotal 25951 Pa

Lauterbach Verfahrenstechnik GmbH 17 20.11.2017

WTS-2017

Shell-side pressure drop in shell-and-tube heat exchangers with segmental baffles

Cross-flow zone

(nU-1)· ND · ∆pQ = ( 24 - 1) · 1· 301.7 Pa = 6939 Pa

End zone

2 · ∆pQ,E = 2 · 265.9 Pa = 531.7 Pa

Window zone

nU · ND · ∆pF = 24 · 1· 715.5 Pa = 17173 Pa

Shell nozzles

∆pN,i + ∆pN,o = 746.8 Pa + 560.3 Pa = 1307 Pa

Total pressure drop

∆ptotal = 25951 Pa

Results

a 1.3 b 1.126 c 1.3 e 6 mm

Cross-flow zone

LE 109.8 mm AE 0.01208 m² we 1.012 m/s

fa,l,f 205.1 fa,t,f 0.6908 fa,l,v 205.1

fa,t,v 5.342 fz,l 0.9896 fz,t 0.9682

ξl 0.00712 ξt 0.41 ξ 0.404

ASRU 0.003333 m² ASMU 0.001272 m² ASG 0.004604 m²

RM 0.2762 RL 0.3811 r 0.6086

γ 112.4 ° Re 28808 β 3.7

RS 0 RB 0.2351 AB 0.002841 m²

fL 0.3892 fB 0.4189 ∆pQ,0 1850 Pa

∆pQ 301.7 Pa

End zone

ReE 13485 AE,E 0.02581 m² we,E 0.4737 m/s

fB,E 0.4189 ∆pQE,0 634.6 Pa ∆pQE 265.9 Pa

Window zone

AFG 0.02036 m² AFR 0.006283 m² AF 0.01407 m²

wp 0.8687 m/s wz 0.9376 m/s nWF 3.078

dh 34.27 mm UF 1643 mm

∆pF,l 884.5 Pa ∆pF,t 1680 Pa ∆pF 715.5 Pa

Shell nozzles

wN,i 0.8975 m/s wN,o 0.8975 m/s

ξN,i 1.866 ξN,o 1.4

∆pN,i 746.8 Pa ∆pN,o 560.3 Pa ∆pN 1307 Pa

Lauterbach Verfahrenstechnik GmbH 18 20.11.2017

WTS-2017

CAD program for shell and tube heat exchangers

TEMA type AEL

TEMA Front head A Shell E Rear head L

Tube-side Shell-side

Medium Water Water

Inlet pressure (abs.) pi 400000 Pa pa 300000 Pa

Pressure stage PN 5 PN 5

Inlet temperature ϑe,i 80 °C ϑe,a 20 °C

Outlet temperature ϑa,i 60 °C ϑa,a 53 °C

Mean temperature ϑm,i 70 °C ϑm,a 36.5 °C

Design temperature 100 °C 70 °C

Design pressure 500000 Pa 400000 Pa

Inlet nozzle Set-on Set-on

Type of flange Integral flange (welding-neck) with hub Integral flange (welding-neck) with hub

Flange connection nominal width DN 125 DN 125

Outside diameter 139.7 mm 139.7 mm

Nozzle wall thickness 4 mm 4 mm

Inside diameter 131.7 mm 131.7 mm

Outlet nozzle Set-on Set-on

Type of flange Integral flange (welding-neck) with hub Integral flange (welding-neck) with hub

Flange connection nominal width DN 125 DN 125

Outside diameter 139.7 mm 139.7 mm

Nozzle wall thickness 4 mm 4 mm

Inside diameter 131.7 mm 131.7 mm

CAD Data

Diameter of bore in tube sheet mm

CAD Tubesheet Configuration

Front head a - tubesheet integral with shell and channel

Rear head b - tubesheet extended as flange / integral with shell / gasketed with channel / narrow-face gasket

Geometry

Shell outside diameter Da 406.4 mm Shell wall thickness sa 6.3 mm

Shell inside diameter DI 393.8 mm

Bundle-shell distance 13.18 mm

Tube outside diameter da 20 mm Tube inside diameter dI 16 mm

Tube pitch (transverse) s1 26 mm Tube pitch (longitudinal) s2 22.52 mm

Pitch angle Φ 60 ° Pass lane width b 32 mm

Central baffle spacing 110 mm Number of baffles/pass 24

Inlet baffle spacing 235 mm Baffle diameter 390.8 mm

Baffle borehole diameter 20.8 mm Baffle cut 22 %

Sealing strips pairs 0

Number of tube-side passes nt 2

Number of shell-side passes ns 1

Final bundle length la 3000 mm

Final shell length la 3000 mm

Number of tubes R 150

Expansion joint diameter mm

Plate thickness (fixed plate) 30 mm

Outside diameter of tube sheet 370 mm

Plate thickness (free plate) 30 mm

Outside diameter of tube sheet (floating head) 370 mm

Lauterbach Verfahrenstechnik GmbH 19 20.11.2017

WTS-2017

CAD sketch from WCAD

Lauterbach Verfahrenstechnik GmbH 20 20.11.2017

WTS-2017

MS Excel specification sheet

Lauterbach Verfahrenstechnik GmbH 21 20.11.2017

Das könnte Ihnen auch gefallen

- Process Data Sheet - Rev.01Dokument1 SeiteProcess Data Sheet - Rev.01Giannis AnastasakisNoch keine Bewertungen

- Heat Exchanger Rating Calc SheetDokument14 SeitenHeat Exchanger Rating Calc SheetSatria 'igin' Girindra NugrahaNoch keine Bewertungen

- Heat Exchanger RatingDokument10 SeitenHeat Exchanger RatinggabrieltravassosNoch keine Bewertungen

- Steam HXDokument1 SeiteSteam HXrajachemNoch keine Bewertungen

- Heat Exchanger Specification Sheet SI-BARG UnitsDokument2 SeitenHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNoch keine Bewertungen

- VG 320 Oil CoolerDokument32 SeitenVG 320 Oil CoolergsdaundhNoch keine Bewertungen

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Dokument4 SeitenSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINoch keine Bewertungen

- Schimbator de Caldura 75 KWDokument4 SeitenSchimbator de Caldura 75 KWAlin Emil MuresanNoch keine Bewertungen

- CH-RA3 Page 2Dokument1 SeiteCH-RA3 Page 2Sonya LoveraNoch keine Bewertungen

- CH-RA3 Page 1Dokument1 SeiteCH-RA3 Page 1Sonya LoveraNoch keine Bewertungen

- 0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXDokument1 Seite0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXPhượng NguyễnNoch keine Bewertungen

- Heat Exchanger - Preliminary Data SheetDokument4 SeitenHeat Exchanger - Preliminary Data SheetgksakthiNoch keine Bewertungen

- Heat Transfer in Pipe Flow - VDI Heat Atlas, 11. Edition 2013, G1Dokument2 SeitenHeat Transfer in Pipe Flow - VDI Heat Atlas, 11. Edition 2013, G1Luis Fernando Castrillón MadrigalNoch keine Bewertungen

- 600RT LMTD 2 T20Dokument1 Seite600RT LMTD 2 T20syahmi yacobNoch keine Bewertungen

- Melegvíz TartályokDokument5 SeitenMelegvíz TartályokKovács TamásNoch keine Bewertungen

- Heat Exchanger Calculation Sheet - 1Dokument10 SeitenHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNoch keine Bewertungen

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDokument4 SeitenSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINoch keine Bewertungen

- Heat Exchanger Design ExampleDokument1 SeiteHeat Exchanger Design ExampleRufus D SNoch keine Bewertungen

- TD HE S&T v2020.00Dokument29 SeitenTD HE S&T v2020.00Claudia BonocoreNoch keine Bewertungen

- Crf271 6 CondenserDokument1 SeiteCrf271 6 Condenserkartikkhatri1188Noch keine Bewertungen

- Vessel Volume Calculation: Tag No. V-101 Chemical Engineering Calculations Description Receiver Date 20/09/14 by ChecalcDokument17 SeitenVessel Volume Calculation: Tag No. V-101 Chemical Engineering Calculations Description Receiver Date 20/09/14 by ChecalcDHAVALESH AM100% (1)

- Schimbator de CalduraDokument4 SeitenSchimbator de CalduraAlin Emil MuresanNoch keine Bewertungen

- Surface Condenser Thermal Analysis (100914)Dokument11 SeitenSurface Condenser Thermal Analysis (100914)amlanfacebookNoch keine Bewertungen

- Absorption Chiller Selection BriefDokument27 SeitenAbsorption Chiller Selection BriefUmar Majeed100% (1)

- Pressure DropDokument36 SeitenPressure DropdesignselvaNoch keine Bewertungen

- Anexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Dokument1 SeiteAnexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Antezana RodriguezNoch keine Bewertungen

- SizingDokument3 SeitenSizingheinfongNoch keine Bewertungen

- 30 TR IG Tube PDFDokument1 Seite30 TR IG Tube PDFshree awateNoch keine Bewertungen

- Huayi Compressor CMLT90LD N R404A 115 60Dokument2 SeitenHuayi Compressor CMLT90LD N R404A 115 60Naqqash SajidNoch keine Bewertungen

- Tube Side Velocity CalculationDokument20 SeitenTube Side Velocity CalculationNitin KurupNoch keine Bewertungen

- Kelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10Dokument2 SeitenKelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10JafarNoch keine Bewertungen

- Heat Exchanger Specification SheetDokument2 SeitenHeat Exchanger Specification SheetDycka Anugerah PuryantoroNoch keine Bewertungen

- CPP 540 Technical DairyDokument58 SeitenCPP 540 Technical DairySiddhant SatpathyNoch keine Bewertungen

- Mtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsDokument4 SeitenMtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsbaljeetjatNoch keine Bewertungen

- Electrode Steam Humidifier Data Sheet: GeneralDokument2 SeitenElectrode Steam Humidifier Data Sheet: GeneralHo KimNoch keine Bewertungen

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Dokument3 SeitenSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINoch keine Bewertungen

- 5TR CondenserDokument1 Seite5TR CondenserbevarsiNoch keine Bewertungen

- Pressurisation and Depressurization ResultsDokument8 SeitenPressurisation and Depressurization ResultsQayyum KhanNoch keine Bewertungen

- Che0405 Ped Lecture 1Dokument25 SeitenChe0405 Ped Lecture 1miraNoch keine Bewertungen

- E 105jewkbdjdDokument2 SeitenE 105jewkbdjdkeyNoch keine Bewertungen

- Heat Exchanger: E-107: Connections Tube Side Shell SideDokument2 SeitenHeat Exchanger: E-107: Connections Tube Side Shell SidekeyNoch keine Bewertungen

- CRF214 - 5 - 40 TR at 7°C - R134a - WATER COOLED SCREW WATER CHILLER - CONDENSERDokument1 SeiteCRF214 - 5 - 40 TR at 7°C - R134a - WATER COOLED SCREW WATER CHILLER - CONDENSERkartikkhatri1188Noch keine Bewertungen

- Resultado Do Cálculo e Seleção - TERREO-R5Dokument12 SeitenResultado Do Cálculo e Seleção - TERREO-R5RICELLES SILVEIRA MARTINSNoch keine Bewertungen

- 50KL Tank - API CalcDokument1 Seite50KL Tank - API CalcRathikaNoch keine Bewertungen

- Final SizingDokument14 SeitenFinal SizingAnand BhiseNoch keine Bewertungen

- Mtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsDokument4 SeitenMtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsbaljeetjatNoch keine Bewertungen

- PHE DesignDokument53 SeitenPHE Designchgourishankar2000100% (1)

- Exchanger Tube Min ThicknessDokument2 SeitenExchanger Tube Min ThicknessMohamed ElshehnyNoch keine Bewertungen

- GP04 2PHE 1M3H 98-40-10 FD Bermo TrocadorDokument5 SeitenGP04 2PHE 1M3H 98-40-10 FD Bermo TrocadorWanner MartinsNoch keine Bewertungen

- Chapter 1Dokument4 SeitenChapter 1Aiman HazimNoch keine Bewertungen

- CPE 664 Design Project 2 Design ProjectDokument120 SeitenCPE 664 Design Project 2 Design Projectsuhel ahmadNoch keine Bewertungen

- Climaveneta Air Handler Unit - SPDokument7 SeitenClimaveneta Air Handler Unit - SPJavier VespaNoch keine Bewertungen

- E-101, Precalentador de PropanoDokument1 SeiteE-101, Precalentador de PropanoIsaac RodriguezNoch keine Bewertungen

- PED (Design of Shell and Tube Heat Exchanger) 63Dokument5 SeitenPED (Design of Shell and Tube Heat Exchanger) 63DineshNoch keine Bewertungen

- Data SpesitxfikasiDokument4 SeitenData Spesitxfikasidede rizkiNoch keine Bewertungen

- Sea Water Cooled CondenserDokument4 SeitenSea Water Cooled CondenserTedy ChriswandaNoch keine Bewertungen

- Customer Date To The K. A. of Our Offer Your Reference DescriptionDokument1 SeiteCustomer Date To The K. A. of Our Offer Your Reference DescriptionMohammadNoch keine Bewertungen

- Mtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsDokument4 SeitenMtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsbaljeetjatNoch keine Bewertungen

- Transducer Handbook: User's Directory of Electrical TransducersVon EverandTransducer Handbook: User's Directory of Electrical TransducersNoch keine Bewertungen

- Handbook of Heating, Ventilating and Air ConditioningVon EverandHandbook of Heating, Ventilating and Air ConditioningBewertung: 4 von 5 Sternen4/5 (6)

- Packing ListDokument2 SeitenPacking Listsaka dewaNoch keine Bewertungen

- AVR BrochureDokument2 SeitenAVR Brochuresaka dewaNoch keine Bewertungen

- Supercast 155Dokument1 SeiteSupercast 155saka dewaNoch keine Bewertungen

- Supercast 155Dokument1 SeiteSupercast 155saka dewaNoch keine Bewertungen

- OrificeDokument6 SeitenOrificesaka dewaNoch keine Bewertungen

- AVI Brochure 2205Dokument2 SeitenAVI Brochure 2205saka dewaNoch keine Bewertungen

- EFX By-Pass Level Transmitter - NewDokument32 SeitenEFX By-Pass Level Transmitter - Newsaka dewaNoch keine Bewertungen

- 1Dokument2 Seiten1saka dewaNoch keine Bewertungen

- Silencer DimensioningDokument14 SeitenSilencer DimensioningAntonioVirardiNoch keine Bewertungen

- Industrial Boilers Product CatalogueDokument76 SeitenIndustrial Boilers Product CatalogueaqilahNoch keine Bewertungen

- 7Dokument34 Seiten7saka dewaNoch keine Bewertungen

- Complete Energy Analysis Draft Natural Gas Furnace PDFDokument1 SeiteComplete Energy Analysis Draft Natural Gas Furnace PDFsaka dewaNoch keine Bewertungen

- Draf System BoilerDokument1 SeiteDraf System Boilersaka dewaNoch keine Bewertungen

- Time To Drain TankDokument18 SeitenTime To Drain TankwaqashabibNoch keine Bewertungen

- Produksi Silika Amorf Dari Sekam Padi Untuk Filler Barang Jadi Karet Menggunakan Fluidized Bed CombustorDokument13 SeitenProduksi Silika Amorf Dari Sekam Padi Untuk Filler Barang Jadi Karet Menggunakan Fluidized Bed Combustorsaka dewaNoch keine Bewertungen

- Design of Welded Connections PDFDokument37 SeitenDesign of Welded Connections PDFMarat Khodzhaiev100% (1)

- Restriction Orifice Sizing PDFDokument5 SeitenRestriction Orifice Sizing PDFsaka dewaNoch keine Bewertungen

- Warning:: Start-Up and Operation Steam BoilersDokument16 SeitenWarning:: Start-Up and Operation Steam BoilersSubburajMechNoch keine Bewertungen

- NBTC - M3 - QC - Insul - 26.0: Doc. No. Rev. No. TitleDokument8 SeitenNBTC - M3 - QC - Insul - 26.0: Doc. No. Rev. No. Titlesaka dewaNoch keine Bewertungen

- Prosedur Start Up Boiler PDFDokument44 SeitenProsedur Start Up Boiler PDFarea_pratama1313100% (1)

- Acid Dew Point EstimationDokument4 SeitenAcid Dew Point EstimationJerry MateoNoch keine Bewertungen

- Complete Energy Analysis Draft Natural Gas FurnaceDokument1 SeiteComplete Energy Analysis Draft Natural Gas Furnacesaka dewaNoch keine Bewertungen

- CatalogDokument32 SeitenCatalogsaka dewa100% (1)

- Multistage Restriction Orifice DeltafluidDokument3 SeitenMultistage Restriction Orifice Deltafluidsaka dewaNoch keine Bewertungen

- Engine Output: 103 kW/141 HP/2.200 RPM Bucket Sizes: 2.0-2.4 M Operating Weight: 12.7 TonDokument4 SeitenEngine Output: 103 kW/141 HP/2.200 RPM Bucket Sizes: 2.0-2.4 M Operating Weight: 12.7 Tonsaka dewaNoch keine Bewertungen

- Extruder Screw Desing Basics PDFDokument54 SeitenExtruder Screw Desing Basics PDFAlvaro Fernando Reyes Castañeda100% (6)

- Statika Struktur Sesuai GBPP Pertemiuan KetigaDokument31 SeitenStatika Struktur Sesuai GBPP Pertemiuan KetigaAlvian HidayatullahNoch keine Bewertungen

- Film Temp FigureDokument1 SeiteFilm Temp Figuresaka dewaNoch keine Bewertungen

- Wall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingDokument12 SeitenWall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingAmir AbbaszadehNoch keine Bewertungen

- Fire Shield LFST - 42E: Premium Performance Industry Applications Product AvailabilityDokument1 SeiteFire Shield LFST - 42E: Premium Performance Industry Applications Product Availabilityray9699Noch keine Bewertungen

- Copper (II) Sulfate - Reagent - Anhydrous 98 - Acros OrganicsDokument5 SeitenCopper (II) Sulfate - Reagent - Anhydrous 98 - Acros OrganicsGaryoNoch keine Bewertungen

- Astm f2129Dokument9 SeitenAstm f2129edgmundarayNoch keine Bewertungen

- Comparing Microstructure and Mechanical Properties of AISI D2 Steel PDFDokument7 SeitenComparing Microstructure and Mechanical Properties of AISI D2 Steel PDFToramaru UtsunomiyaNoch keine Bewertungen

- Practical Physical Chemistry (II) Laboratory ManualDokument25 SeitenPractical Physical Chemistry (II) Laboratory Manualabdu30esNoch keine Bewertungen

- تقرير تأكل (Anodic Protection)Dokument10 Seitenتقرير تأكل (Anodic Protection)ياسر نوفل ورد100% (1)

- 8 Vol. 3 9 Sept. 2012IJPSR 636paper 8Dokument8 Seiten8 Vol. 3 9 Sept. 2012IJPSR 636paper 8Ingrid ContrerasNoch keine Bewertungen

- Practice Calculations 2012Dokument58 SeitenPractice Calculations 2012Lia Romain67% (6)

- EP 1108 Photoelectric EffectDokument12 SeitenEP 1108 Photoelectric EffectAryam SharmaNoch keine Bewertungen

- Beta OxidationDokument41 SeitenBeta Oxidationguna sundariNoch keine Bewertungen

- Electrolysis ProcessesDokument180 SeitenElectrolysis ProcessesEngineering Office Shahrak100% (1)

- CH # 7 Separator & Slug CatcherDokument15 SeitenCH # 7 Separator & Slug CatcherMuhammad Zeeshan Wasi100% (1)

- Enhancement in Biogas Production From Press MudDokument5 SeitenEnhancement in Biogas Production From Press MudHarsha Vardhan ReddyNoch keine Bewertungen

- BL-1400ashless Group 2 03Dokument2 SeitenBL-1400ashless Group 2 03M.ASNoch keine Bewertungen

- Science q1 WK 2Dokument3 SeitenScience q1 WK 2Junior FelipzNoch keine Bewertungen

- Basics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, CatalystsDokument5 SeitenBasics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, Catalystsonizuka-t2263Noch keine Bewertungen

- Opportunities and Limits of 2k Injection MouldingDokument22 SeitenOpportunities and Limits of 2k Injection Mouldingsa_arunkumarNoch keine Bewertungen

- 10 - Thermal Processing of FishDokument5 Seiten10 - Thermal Processing of FishRahul SainiNoch keine Bewertungen

- Chinook-Services-Wellsite GeologyDokument6 SeitenChinook-Services-Wellsite Geologyincharge geologistNoch keine Bewertungen

- Behavior DS MM247LC (Bae2001)Dokument6 SeitenBehavior DS MM247LC (Bae2001)Alex CostaNoch keine Bewertungen

- European Polymer Journal: SciencedirectDokument12 SeitenEuropean Polymer Journal: SciencedirectNgoc Hanh CaoNoch keine Bewertungen

- STP 491-1971Dokument90 SeitenSTP 491-1971Tim SchouwNoch keine Bewertungen

- LNG EconomicsDokument19 SeitenLNG EconomicsCal67% (3)

- Chem 315 - Lab 5 - Gas Chromatography - AcetatesDokument13 SeitenChem 315 - Lab 5 - Gas Chromatography - AcetateskNoch keine Bewertungen

- Reducing Eliminating ESD Hazards During PYRO OperationsDokument42 SeitenReducing Eliminating ESD Hazards During PYRO OperationsAnonymous TI2bUTNoch keine Bewertungen

- DSM-0295.0 Al2O3 NiAl CermetDokument3 SeitenDSM-0295.0 Al2O3 NiAl CermetApichitNoch keine Bewertungen

- Deaerator Post MCQ'sDokument50 SeitenDeaerator Post MCQ'sEhtisham ul haqNoch keine Bewertungen

- International Journal of Current Research in Biosciences and Plant BiologyDokument12 SeitenInternational Journal of Current Research in Biosciences and Plant BiologyFrancisco C. Gonçalves GonçalvesNoch keine Bewertungen

- Pasteurisation Process Objectives: CFB31103 Food Process Engineering Laboratory 4: Thermal ProcessingDokument3 SeitenPasteurisation Process Objectives: CFB31103 Food Process Engineering Laboratory 4: Thermal Processingnurul nabilah bt khairul anuarNoch keine Bewertungen

- Foaming Capacity of SoapsDokument7 SeitenFoaming Capacity of SoapsTitas SarkarNoch keine Bewertungen