Beruflich Dokumente

Kultur Dokumente

Metal Vessels and Tanks

Hochgeladen von

threedlabs0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

4 Ansichten10 Seitenffgreetrtrtrt

Originaltitel

13208 Metal Vessels and Tanks

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenffgreetrtrtrt

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

4 Ansichten10 SeitenMetal Vessels and Tanks

Hochgeladen von

threedlabsffgreetrtrtrt

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

TION 13208

METAL VESSELS AND TANKS.

1. SCOPE

a

b. Specific references to sections of this specification, where multiple choice exists,

and/or where modifications and deletions of certain paragraphs are desired shall be

noted on the Vessel Outline Drawing under "Spec. References". This drawing shall

also contain information peculiar to the individual piece of equipment and which

cannot conveniently be embodied in this specification. Use Design

Standard WDS-1201 with this specification.

c. All material as indicated on the Vessel Outline Drawing shall be furnished by the

vessel fabricator, unless specifically noted to the contrary. ‘The fabricator shall

submit shop fabrication drawings and calculations substantiating the design for

review.

d. __Itmay become necessary, for the sake of expediency, to indicate on the Vessel

Outline Drawing certain designs that are normally the fabricator’s responsibility.

This procedure shall, in no case, be so construed as to relieve the fabricator of his,

ultimate responsibility as described by the Vessel Specification and by the terms of

the Purchase Order. It shall be the fabricator’s responsibility to advise against any

designs that are, in his opinion, unsafe, and/or fail to meet minimum code

requirements and/or would otherwise make fabrication difficult and expensive.

Variations of a more stringent nature, when indicated in this specification or on the

Vessel Outline Drawing, will supersede any code requirements.

2. (Applicable paragraph -2.a.1.,2.a.2.,or 2.a.3.- is noted on the Vessel Outline

Drawing)

a. 1, Pressure Vessels (Over 15 PSIG and Vacuum)

Design, fabrication, inspection and testing of vessels subjected to internal

pressure in excess of 15 PSIG (not due to hydrostatic head) and/or external,

pressure shall be in accordance with all requirements of the "ANSV/ASME

Boiler and Pressure Vessel Code", latest edition. All vessels shall be

furnished with the appropriate stamp as required by that code.

Issued: 03/31/89

Revised: Page | of 13

SECTION 13208

2. Low Pressure Vessels (Except vertical, flat bottom tanks)

Design and fabrication of vessels subject to pressure of 15 PSIG or less

shall be in accordance with the latest editions of one of the following,

applicable codes:

ANSI/ASME Boiler and Pressure Vessel Code - Section VIII, ANSI/API

Standard 650 or ANSI/API Standard 620. The pertinent code will be

indicated on the Vessel Outline Drawing. Code Stamp requirements will be

indicated on Vessel Outline Drawing. For exception see Paragraph 2.4,

3. Vertical, Flat Bottom Tanks

Vertical, flat bottom tanks shall be designed and fabricated in accordance

with the latest editions of the following applicable codes: ANSI/API

Standard 650, ANSI/API Standard 620, or ANSIAWWA D100. The

pertinent code will be indicated on the Vessel Outline Drawing. The

maximum allowable stress values for tanks with tile or other rigid lining

shall be no greater than 9000 psi for simple tension. Code stamp

requirement will be indicated on Vessel Outline Drawing

b. All design conditions shall be as specified on the Vessel Outline Drawing.

©. Corrosion allowance for carbon steel vessels shall be 1/16" minimum or as

specified on the Vessel Outline Drawing or other documents.

Corrosion allowance shall be added to the minimum or calculated thickness of

shell, heads, and nozzles. Non-removable vessel internals (welded in place) shall

be designed for the full specified corrosion and removable vessel internals for half

of the specified corrosion, each case considering all surfaces exposed to vessel

contents. This corrosion allowance on internals shall be added to the minimum

thickness required for structural stability, taking into account both static and

dynamic loads.

4. The vessel fabricator shall be required to submit proof of his authority to affix the

official monogram of the applicable code to his fabricated vessels when code

stamping is called for on the Vessel Outline Drawing.

Issued: 03/31/89

Revised: Page 2 of 13

SECTION 13208

3. SHELL AND HEADS

a. The minimum thickness of shell and heads shall be 3/16 inch exclusive of corrosion

allowance, unless indicated otherwise on Vessel Outline Drawing,

b, Heads shall be of the following types:

1. Foradesign pressure of up to 100 PSIG and/or external pressure [Par.

2.a.1,] use "ASME Flanged and Dished" head. (The Radius of Dish to be

rno larger than the vessel diameter and the Inside Corner Radius to be not

less than 6% of Radius of Dish).

2. For adesign pressure of 100 PSIG or over (Paragraph 2.a.1.] and for the

bottom head of a vessel having a height to diameter ratio greater than 5 to 1

and which is supported by means of a cylindrical skirt use a "2:1 Elliptical

Head" (having a ratio of a major to minor diameter not greater than 2.0).

3. Fora vessel open to atmosphere [Par. 2.a.2.] use a "Standard Flanged and

Dished” head (The Radius of Dish is to be slightly larger than the vessel

diameter and the Inside Corner Radius is to be not less than three times the

head thickness).

4. Fora vessel open to atmosphere (Par. 2.a.3.] use self-supporting dished,

conical (2:12 slope) or flat heads. Internal column supports should be

avoided wherever possible.

c All shell and head seams shall be left unobstructed and are to be so placed as to

avoid interference with nozzles, reinforcing pads and other extemal attachments.

‘The fabricator shall advise the purchaser if this becomes unavoidable in isolated

cases, due to peculiarities in construction.

4, FLANGED CONNECTIONS

a. All flanged connections shall normally conform to ANSI Standard B16.5 for 24

inch nominal size and smaller unless otherwise noted on the Vessel Outline

Drawing. Larger flanges shall be designed in accordance with the applicable code

or other acceptable industrial standards. Pressure - temperature ratings shall be as

tabulated in ANSI Standard B16.5 or, as in the case of large size flanges, subject to

specific individual limitations. ‘The Vessel Outline Drawing will indicate the flange

Issued: 03/31/89 ¥

Revised: Page 3 of 13,

Das könnte Ihnen auch gefallen

- Calculation of Sheet Steel Diaphragms in The UK Calculation of Sheet Steel Diaphragms in The UKDokument44 SeitenCalculation of Sheet Steel Diaphragms in The UK Calculation of Sheet Steel Diaphragms in The UKthreedlabsNoch keine Bewertungen

- ANGLE ASSEMBLY 1-Static 1-2Dokument21 SeitenANGLE ASSEMBLY 1-Static 1-2threedlabsNoch keine Bewertungen

- ReadmeDokument1 SeiteReadmeAdekimi EmmanuelNoch keine Bewertungen

- FEA Report With BoltingDokument10 SeitenFEA Report With BoltingthreedlabsNoch keine Bewertungen

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Dokument17 SeitenMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)threedlabsNoch keine Bewertungen

- Calculation of PipeReinforcement ASMEB31 1Dokument4 SeitenCalculation of PipeReinforcement ASMEB31 1threedlabsNoch keine Bewertungen

- Anchors - Cross SectionDokument13 SeitenAnchors - Cross SectionthreedlabsNoch keine Bewertungen

- Curriculum Vitae: Personal InformationDokument2 SeitenCurriculum Vitae: Personal InformationthreedlabsNoch keine Bewertungen

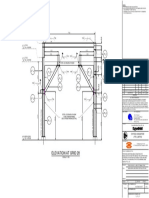

- Elevation at Grid 28: T.O.S. EL +12.050 M Typ. TypDokument1 SeiteElevation at Grid 28: T.O.S. EL +12.050 M Typ. TypthreedlabsNoch keine Bewertungen

- RSPL Fbs Sam FDN 101Dokument1 SeiteRSPL Fbs Sam FDN 101threedlabsNoch keine Bewertungen

- PV NRTDokument3 SeitenPV NRTthreedlabsNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)