Beruflich Dokumente

Kultur Dokumente

Icesp 09 A10

Hochgeladen von

Sushil KumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Icesp 09 A10

Hochgeladen von

Sushil KumarCopyright:

Verfügbare Formate

Acoustic Horn Made Electrostatic Precipitator Collecting

Plate and Hopper Clean in Zhangjiakou Power Plant

Wan Ronghui, Han Ke, Tan Ruitian

Liaoning zhongxin Automatic Instruments Co., Ltd.

Section 2, Nanhuan Street, Liaoyang 111005, Liaoning Province

China

Abstract

The two 4-fields, 230 m2 flow area, magnetic hammer top rapping precipitators of a 300MW unit

in Zhangjiakou Power Plant encountered dust accumulation and clogging difficulties, especially in

third and fourth fields. By mounting acoustic horns of SQ-75 type, produced by Liaoning zhongxin

Automatic Instruments Company, for one channel, four fields on the top, in the sidewalk between

electric fields and in the hopper, dust scale up and accumulation problems were eliminated.

Operation voltage and current were increased by 6% and 28% respectively. Working principle

and detailed description are given.

Brief Introduction

The application of acoustic horn for ESP electrodes cleaning in China was only beginning in

recent years. Due to general low sulfur of Chinese coal, high resistivity ash and higher than 15m

electrodes, troubles of

dust adhering on the collecting plates were often encountered in Chinese power plants. By

installation of domestic produced acoustic horn as additional rapping, this problem was solved in

many cases, such as in Zhangjiakou Power Plant.

Zhangjiakou Power Plant has two 4-fields, 230m2 flow area, electro-magnetic hammer top

rapping precipitators for its 300MW unit. The dusts sticking on the 15meter high collecting plates,

especially those of third and fourth fields could not be rapping down by pure hammer rapping.

Thickness of dust layer accumulated to about 8mm thickness (Fig.1). Besides, hoppers block up

was encountered also, often made ESP shutting down. By using acoustic horns, satisfying

cleaning for collecting plates and hoppers was achieved. ESP could work normally.

Fig. 1 Dust built up on ESP electrodes before acoustic horn rapping

2

Principle of Sonic Cleaning

Because reflected by the sidewall or top plate, the propaganda of longitudinal sonic wave in

precipitators can be treated as free sonic field, point source and semi-sphere type as shown in

Fig. 2.

Point Sonic Source Wave Line

Side Wall Point Sonic Source

Fig 2. Semi-sphere propaganda of sound wave

Sonic wavelength λ in air of 208C, atmosphere pressure is:

λ=C3T=C31/f

where: C---propagate velocity in air, equal to 344m/s

T and f---period and frequency, Sec and Hz

When using a 75 Hz frequency, λ=34431/75=4.59m

Sound pressure P is:

L P=20 lg P/Po

Pm = 20.53P

Where: LP---effective value of sound pressure grade, dB

P--- effective value of sound pressure, N/m2

Po---base value of sound pressure =2 3 10-5, N/m2,

Pm---amplitude sound pressure, N/m2

Amplitude acceleration a created by sound wave is:

a=20.53P3ϖ / ρ3C

Where: ϖ---angular velocity =2πf

ρ---air density,=1.204 kg/m3 (at 208C, 1 atmosphere pressure),

Considering 75 Hz frequency and gravitational acceleration g=9.81m/sec2, the parameters of a

SQ-75 type acoustic horn are calculated as Table 1.

Sonic wave propagate is really the process of sound pressure varies depressively and densely

from Po to Pm. From Table 1 we can see that for a SQ-75 acoustic horn, it can produce 40~623

atmosphere pressure and 6.4~102 g amplitude acceleration to the surfaces of 0~16m apart from

its exit. If the sonic wave is incline acting on the surface, the pressure and acceleration will be

reduced by a factor of sine function.

Because the wavelength of a 75 Hz frequency is 4.59m, generally greater than the dimension of

obstacles, so that sonic wave can make a detour motion without influencing its effect greatly.

ICESP IX : ACOUSTIC HORN MADE ELECTROSTATIC PRECIPITATOR COLLECTING PLATE

AND HOPPER CLEAN IN ZHANGJIKOU POWER PLANT

3

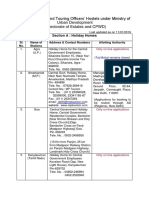

Table 1 Parameters calculated for SQ-75 acoustic horn

Distance from exit m Exit 2 4 6 8 12 16

Sound pressure grade dB 150 144 138 135 132 129 126

LP

10 3N/m

2 2

Sound pressure P 6.32 3.17 1.59 1.13 0.8 0.56 0.4

10 3N/m

2 2

Amplitude sound 8.94 4.48 2.25 1.59 1.13 0.8 0.56

pressure Pm

Amplitude acceleration a g 102 51 25.6 18.1 12.9 9.1 6.4

Installation of Acoustic Horn

Fig.3 shows the precipitator and the position of acoustic horns. Totally ten acoustic horns were

installed, among which seven were installed on the top (one for first field, two for second, third

and fourth fields each), three were installed at the lower sides opposed to the three passageways

between 1-2, 2-3 and 3-4 fields. Thus, both upper ends and lower ends of collecting plates could

be strongly vibrated by the sonic waves. Numbers were given to each acoustic horn as in Fig.3.

The installation methods of top and side acoustic horns are shown in Fig.4 respectively. Fig.5 are

their photographs.

Acoustic horn Acoustic horn

Fig. 3 Acoustic horns Install at the top and side wall of ESP

ICESP IX : ACOUSTIC HORN MADE ELECTROSTATIC PRECIPITATOR COLLECTING PLATE

AND HOPPER CLEAN IN ZHANGJIKOU POWER PLANT

4

Insulation

Fig. 4 Top and side mounting of acoustic horn

Fig. 5 Photographs of acoustic horn

Table 2 Two control variants

Position Rapping 1 field 1,2 field 2 field Top 2,3 field 3 Field Top 3,4 Field 4 Field Top

Variant Top Passage Passage Passage

No, of Horn # 1 2 3 4 5 6 7 8 9 10

Rapping time A 5 5 6 6 8 10 10 10 5~10 5~10

(Sec)

B 5 5 5 5 10 10 5~10 5~10

Time interval A 1 1 2 2 2 2 2 2 60~120

(Min)

B 2 2 5 3 5 3 60~120

Rapping perio A 15 60~120

(Min)

B 20.6 60~120

ICESP IX : ACOUSTIC HORN MADE ELECTROSTATIC PRECIPITATOR COLLECTING PLATE

AND HOPPER CLEAN IN ZHANGJIKOU POWER PLANT

5

Sonic Rapping Tests

Cleaning Effect in Precipitator Box

First, only using two SQ-75 type acoustic horns on the top of third field, we found the cleaning

effect was better than mechanical rapping. Secondary current was increased (See Table 3). No

fine dust reentrainment and noise exceeding standard were found.

Table 3 Comparison between using or not using acoustic horns

Date of Operating condition Secondary Secondary

testing voltage current

(KV) (mA)

Feb. 16, Without sonic horn 68 350

2003

April, 16, Using two top sonic 72 450

2003 horns

Then, a long time continuous operating test was going on. After 60 days operation, we entered

into the precipitator and carefully observed the dust accumulation on the collecting plates. We

found there were obviously marks of dust falling off on the collecting surface. Many marks

presented the forms of snowflake like spots or the original color of steel plate (Fig. 6).

Fig. 6 Dust particulates were falling down when sound rapping

Fig. 7 Cleaned collecting plates after sonic rapping

ICESP IX : ACOUSTIC HORN MADE ELECTROSTATIC PRECIPITATOR COLLECTING PLATE

AND HOPPER CLEAN IN ZHANGJIKOU POWER PLANT

6

While, at same time and working condition, in another part of the same precipitator, there were no

such marks of dusts falling down. The fingernail scratch depths of with and without sonic cleaning

were different obviously.

We also observed the effect of sonic cleaning outside of the precipitator. Opening the lower

manhole, we saw the dust layer crackling, falling from the plate surface. The small white

particulates of Fig. 6 represented the residual dust granules when sonic rapping was undertaking.

These proved the good cleaning effects of acoustic horn. Fig. 7 shows the cleaned collecting

plates after sound rapping.

Cleaning Effect in Precipitator Hoppers

In the hopper of fourth field of another precipitator, we installed a SQ-1000G type acoustic horn.

Before the horn working, the hopper was filled with dusts to an enough high level. At this

situation, in the past, bridging or clogging of dust in hopper often occurred.

Starting the air-lock rotating valve, we found no dusts falling down from hopper, which shown

bridging or clogging existed. Then, starting the acoustic horn 3 to 5 times by local hand control,

low frequency voice was heard. Soon afterwards, warm and dusts began falling out from hopper.

After this short test, normal continuous running of acoustic horn was going on by computer

remote control. There was no bridging or clogging in hopper again.

Summary

The use of acoustic horns in Zhangjiakou Power Plant was rather successful. Some other

applications in iron/steel industry are also satisfying. It proved that provide selection and

installation correct, dusts accumulation on the electrodes surfaces and clogging in the hoppers,

induced by insufficient mechanical rapping, can be cleaned or dredged by low frequency sonic

wave. Some times solely using acoustic horn instead of mechanical or electromagnetic rapper is

also possible. Simple, no obvious moving parts and flexible install make it to be another valuable

dust build up breaking device.

References

[1] Zhang Yufeng: Fundamental Theory of Acoustics, Text book for mechanical engineer, 1986

[2] Cheng Shoumo, Jiang Yuanshui: Physics, Reference book for university, 1979

[3] Chen Kangyuan: Techniques of ESP Electrodes Rapping, October 2000

ICESP IX : ACOUSTIC HORN MADE ELECTROSTATIC PRECIPITATOR COLLECTING PLATE

AND HOPPER CLEAN IN ZHANGJIKOU POWER PLANT

Das könnte Ihnen auch gefallen

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesVon EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNoch keine Bewertungen

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsVon EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsBewertung: 4 von 5 Sternen4/5 (1)

- Velocity of sound in air determined using resonance columnDokument8 SeitenVelocity of sound in air determined using resonance columnKaran TejwaniNoch keine Bewertungen

- ICA 2010 Proceedings explores vibro-acoustic behavior of micro-perforated platesDokument6 SeitenICA 2010 Proceedings explores vibro-acoustic behavior of micro-perforated platesAlonso RamírezNoch keine Bewertungen

- Room Acoustics: de Vera Institute of Technology Old Albay District, Legazpi City, AlbayDokument9 SeitenRoom Acoustics: de Vera Institute of Technology Old Albay District, Legazpi City, AlbayEren YeagerNoch keine Bewertungen

- Estimating guitar plucking point using time-domain autocorrelationDokument14 SeitenEstimating guitar plucking point using time-domain autocorrelationAmaury Jamir Meza PérezNoch keine Bewertungen

- Examination of Ae Wave Propagation Routes in A Small Model TankDokument6 SeitenExamination of Ae Wave Propagation Routes in A Small Model TankGonzalo TelleríaNoch keine Bewertungen

- Sound Quality Analysis of CymbalsDokument9 SeitenSound Quality Analysis of Cymbalsapi-643891443Noch keine Bewertungen

- J.C. G. C. F.: 3333 Coyote Hill RoadDokument8 SeitenJ.C. G. C. F.: 3333 Coyote Hill RoadGokhanSatilmisNoch keine Bewertungen

- Specialized Applications of Noise LoggingDokument9 SeitenSpecialized Applications of Noise LoggingVictor Javier PerniaNoch keine Bewertungen

- Acoustic Cleaning System Testing in 670MW CFB BoilerDokument9 SeitenAcoustic Cleaning System Testing in 670MW CFB BoilerExrtra TerrestrialNoch keine Bewertungen

- ET End Sem18Dokument3 SeitenET End Sem18venkatarao HanumanthuNoch keine Bewertungen

- A Novel Design For A Gel-Type DML Transducer Incorporating A Solid Panel Projecting Multiple Independent Sound SourcesDokument7 SeitenA Novel Design For A Gel-Type DML Transducer Incorporating A Solid Panel Projecting Multiple Independent Sound Sourcesanon_725930912Noch keine Bewertungen

- ApplicbuzzerDokument11 SeitenApplicbuzzerfaujohnNoch keine Bewertungen

- Acoustic Analaysis of The Gothenburg KonserthusDokument8 SeitenAcoustic Analaysis of The Gothenburg KonserthusmiffycanflyNoch keine Bewertungen

- Real-Time Sonic Logging Provides Valuable Drilling DataDokument14 SeitenReal-Time Sonic Logging Provides Valuable Drilling DataStephanMarquesNoch keine Bewertungen

- Ilovepdf Merged Other Half of TutDokument67 SeitenIlovepdf Merged Other Half of Tutmkwaloqhawe18Noch keine Bewertungen

- Ultra-Low-Noise Cavity-Stabilized Microwave Reference Oscillator Using An Air-Dielectric ResonatorDokument6 SeitenUltra-Low-Noise Cavity-Stabilized Microwave Reference Oscillator Using An Air-Dielectric ResonatorwaikyqinNoch keine Bewertungen

- Non-Contact Acoustic Manipulation in Air PDFDokument2 SeitenNon-Contact Acoustic Manipulation in Air PDFMikela LjermontovaNoch keine Bewertungen

- Influence of Reflecting Plane Having Finite Surface Density On Sound Power Level of Reference Sound Sources Calibrated in Hemi Free-FieldDokument9 SeitenInfluence of Reflecting Plane Having Finite Surface Density On Sound Power Level of Reference Sound Sources Calibrated in Hemi Free-FieldRamNoch keine Bewertungen

- Two Feed Back - JFS21 - 2005 PDFDokument12 SeitenTwo Feed Back - JFS21 - 2005 PDFHassoun09Noch keine Bewertungen

- A Coustic Attenuation Performance of Double Expansion Chamber Silencers With Inter Connecting TubeDokument4 SeitenA Coustic Attenuation Performance of Double Expansion Chamber Silencers With Inter Connecting Tube신동호Noch keine Bewertungen

- Jte10561j DL.1415051 1 PDFDokument8 SeitenJte10561j DL.1415051 1 PDFpaolaNoch keine Bewertungen

- Acoustic Logging Methods and Applications: Understanding Sonic Log Presentation and LimitationsDokument36 SeitenAcoustic Logging Methods and Applications: Understanding Sonic Log Presentation and LimitationsbijupiraNoch keine Bewertungen

- Damage Detection in Stiffened CompositeDokument9 SeitenDamage Detection in Stiffened CompositeAR HassanNoch keine Bewertungen

- Input-Output Impedance and Reverberation Decay TimeDokument6 SeitenInput-Output Impedance and Reverberation Decay Timerythmaccount100% (1)

- BBC Research Goodmans 'Maxim' Loudspeaker 1965-09Dokument10 SeitenBBC Research Goodmans 'Maxim' Loudspeaker 1965-09Грегори РобертNoch keine Bewertungen

- AkustikDokument5 SeitenAkustikNorazimah Mat ZainNoch keine Bewertungen

- Measurement and Estimation of LRG LS ArraysDokument17 SeitenMeasurement and Estimation of LRG LS Arraysjray1982Noch keine Bewertungen

- ENGINEERING REPORTS: The Use of Airborne Ultrasonics for Generating Audible Sound BeamsDokument6 SeitenENGINEERING REPORTS: The Use of Airborne Ultrasonics for Generating Audible Sound BeamsDaniel Cardona RojasNoch keine Bewertungen

- Chen Noise Characteristics and Simulation of Several Full Scale Turbojet Engines at Hush-HouseDokument7 SeitenChen Noise Characteristics and Simulation of Several Full Scale Turbojet Engines at Hush-HouseKen SuNoch keine Bewertungen

- Expedition LL Seismic Wave 955 - 2018-03-20 - 10-08-52 - IVC Group - Mohawk GroupDokument4 SeitenExpedition LL Seismic Wave 955 - 2018-03-20 - 10-08-52 - IVC Group - Mohawk GroupNovi ArianiNoch keine Bewertungen

- High-G-Factor S.A.W. Resonators at 780 MHzDokument3 SeitenHigh-G-Factor S.A.W. Resonators at 780 MHzShrey PathakNoch keine Bewertungen

- Introduction To Acoustics by B&K PDFDokument44 SeitenIntroduction To Acoustics by B&K PDFSuhas BharadwajNoch keine Bewertungen

- IJSRD - International Journal for Scientific Research & Development| Vol. 2, Issue 03, 2014 | ISSN (online): 2321-0613Dokument4 SeitenIJSRD - International Journal for Scientific Research & Development| Vol. 2, Issue 03, 2014 | ISSN (online): 2321-0613abhishek wajeNoch keine Bewertungen

- UT Level II Questions EGYPTAPR12 PDFDokument16 SeitenUT Level II Questions EGYPTAPR12 PDFrupamNoch keine Bewertungen

- Journal of Wind Engineering and Industrial AerodynamicsDokument10 SeitenJournal of Wind Engineering and Industrial Aerodynamicsmocker1987Noch keine Bewertungen

- AlexBergamini Paper IN2013Dokument8 SeitenAlexBergamini Paper IN2013hrcorsimapNoch keine Bewertungen

- Modulator processing improvements for parametric speaker systemsDokument24 SeitenModulator processing improvements for parametric speaker systemsComsa MariusNoch keine Bewertungen

- Sound reduction techniques for high frequency tonesDokument43 SeitenSound reduction techniques for high frequency tonesRavi HarperNoch keine Bewertungen

- Ac Panelerr3r23r43f2r34Dokument8 SeitenAc Panelerr3r23r43f2r34Juasadf IesafNoch keine Bewertungen

- Prediction of Noise Generated by Orifice Plates in Liquid Systems Using A Modified Form of IEC 534-8-4:1994Dokument12 SeitenPrediction of Noise Generated by Orifice Plates in Liquid Systems Using A Modified Form of IEC 534-8-4:1994Joshua HobsonNoch keine Bewertungen

- Source identification and noise reduction of a reciprocating compressorDokument9 SeitenSource identification and noise reduction of a reciprocating compressorShashank Sudhakar PathakNoch keine Bewertungen

- Resonance UnlockedDokument5 SeitenResonance UnlockedgjjgNoch keine Bewertungen

- Bismuth-Doped Fibre Amplifier For The Range 1300 - 1340 NMDokument4 SeitenBismuth-Doped Fibre Amplifier For The Range 1300 - 1340 NMkazitoufiqNoch keine Bewertungen

- Nature08967 s1 PDFDokument13 SeitenNature08967 s1 PDFohboy33Noch keine Bewertungen

- Vibro-acoustic behavior of Spanish bellsDokument6 SeitenVibro-acoustic behavior of Spanish bellsRamiel CalivaNoch keine Bewertungen

- Audio System Engineering Mid Sem17Dokument2 SeitenAudio System Engineering Mid Sem17Piyush DubeyNoch keine Bewertungen

- Introduction To Acoustics: Bruel & Kjaer Norcross, GeorgiaDokument35 SeitenIntroduction To Acoustics: Bruel & Kjaer Norcross, GeorgiaIrshad MahammadNoch keine Bewertungen

- A Technique For Estimating The Sound PowerDokument5 SeitenA Technique For Estimating The Sound Powercarito1223Noch keine Bewertungen

- (B.E. Sem-1 G.T.U.) Physics Paper With SolutionDokument19 Seiten(B.E. Sem-1 G.T.U.) Physics Paper With SolutionNimesh Nakhva83% (6)

- SM PDF Chapter14 PDFDokument37 SeitenSM PDF Chapter14 PDFsuryapmohantyNoch keine Bewertungen

- Heat Exchanger VibrationDokument3 SeitenHeat Exchanger VibrationTim KuNoch keine Bewertungen

- Passive Acoustic LoggingDokument27 SeitenPassive Acoustic LoggingSubh vermaNoch keine Bewertungen

- How To Solve Abnormal Combustion Noise Problems: Peter K. Baade, Consultant, Fayetteville, New YorkDokument6 SeitenHow To Solve Abnormal Combustion Noise Problems: Peter K. Baade, Consultant, Fayetteville, New Yorkyeneneh14Noch keine Bewertungen

- Ian Dayton P406 Project Report Sp12Dokument8 SeitenIan Dayton P406 Project Report Sp12Charles MichaelNoch keine Bewertungen

- Application of The Geometric Theory of DiffractionDokument9 SeitenApplication of The Geometric Theory of DiffractionSIA_2Noch keine Bewertungen

- Chapter 21Dokument4 SeitenChapter 21Paulo AzañeroNoch keine Bewertungen

- chap10Dokument14 Seitenchap10Sushil KumarNoch keine Bewertungen

- AdditivemanufacturiingDokument13 SeitenAdditivemanufacturiingSushil KumarNoch keine Bewertungen

- Applsci 06 00326Dokument11 SeitenApplsci 06 00326Sushil KumarNoch keine Bewertungen

- Plant EfficiencyDokument8 SeitenPlant EfficiencySushil KumarNoch keine Bewertungen

- Steam Turbine ControlDokument13 SeitenSteam Turbine Controlnirbhay111100% (4)

- Paper 5A1Dokument6 SeitenPaper 5A1Sushil KumarNoch keine Bewertungen

- 494Dokument3 Seiten494Sushil KumarNoch keine Bewertungen

- Introduction To Turbine Governing SystemsDokument33 SeitenIntroduction To Turbine Governing SystemsSam100% (1)

- Road Mode - Mine Wise Revised Price List With Effect From 01.11.2023 For Nfsa Customers (Notified Price List) RS/T (GST)Dokument6 SeitenRoad Mode - Mine Wise Revised Price List With Effect From 01.11.2023 For Nfsa Customers (Notified Price List) RS/T (GST)Sushil KumarNoch keine Bewertungen

- Assumption and Relinquishment Request For Promotion OrdersDokument6 SeitenAssumption and Relinquishment Request For Promotion OrdersSushil KumarNoch keine Bewertungen

- 6.01 Stress Corrosion Cracking: H. E. Haºnninen Helsinki University of Technology, FinlandDokument29 Seiten6.01 Stress Corrosion Cracking: H. E. Haºnninen Helsinki University of Technology, FinlandSushil KumarNoch keine Bewertungen

- Samall Oil Burner in Concepts in Low P (Ressure AutomationDokument10 SeitenSamall Oil Burner in Concepts in Low P (Ressure AutomationMOHAMMAD HASHIM KHANNoch keine Bewertungen

- Upthrust Problems On Multistage Vertical Turbine Pumps: by Donald R. Smith and Stephen PriceDokument12 SeitenUpthrust Problems On Multistage Vertical Turbine Pumps: by Donald R. Smith and Stephen PriceGerman ToledoNoch keine Bewertungen

- Resolution: 1. PreambleDokument14 SeitenResolution: 1. PreambleAkash SinghNoch keine Bewertungen

- Electrostatic Precipitator Performance Problems and Solutions in Indian Thermal Power StationsDokument13 SeitenElectrostatic Precipitator Performance Problems and Solutions in Indian Thermal Power Stationsavmurugan87Noch keine Bewertungen

- Vapour Preesure Vs Temperature Graph of AmmoniaDokument1 SeiteVapour Preesure Vs Temperature Graph of AmmoniaSushil KumarNoch keine Bewertungen

- Paper 5A1Dokument6 SeitenPaper 5A1Sushil KumarNoch keine Bewertungen

- Mechanical EngineeringDokument2 SeitenMechanical EngineeringmannamalairajaNoch keine Bewertungen

- ASER 2016 findings show enrollment and learning gains in rural IndiaDokument3 SeitenASER 2016 findings show enrollment and learning gains in rural Indiamy workNoch keine Bewertungen

- Loan Pmmy EngDokument4 SeitenLoan Pmmy EngAnimesh DikshitNoch keine Bewertungen

- IND - India Census 2013Dokument2 SeitenIND - India Census 2013m_kanwar8652Noch keine Bewertungen

- Record FDI-What About Jobs-18 To 24sepDokument13 SeitenRecord FDI-What About Jobs-18 To 24sepSushil KumarNoch keine Bewertungen

- Reserve Bank of India Services Board, Mumbai Advt. No. 6A/2017-18Dokument4 SeitenReserve Bank of India Services Board, Mumbai Advt. No. 6A/2017-18Sushil KumarNoch keine Bewertungen

- RBI Guidelines - Summary PDFDokument24 SeitenRBI Guidelines - Summary PDFSushil KumarNoch keine Bewertungen

- Holiday HomesDokument11 SeitenHoliday HomesatotNoch keine Bewertungen

- Failure Investigation of A Secondary Super Heat 2017 Case Studies in EngineeDokument4 SeitenFailure Investigation of A Secondary Super Heat 2017 Case Studies in EngineeSushil KumarNoch keine Bewertungen

- Government Schemes 2017 by AffairsCloudDokument24 SeitenGovernment Schemes 2017 by AffairsCloudRupesh PatraNoch keine Bewertungen

- TPS Review KwangDokument27 SeitenTPS Review Kwangedu15987Noch keine Bewertungen

- Case Studies in Engineering Failure Analysis: S.W. Liu, W.Z. Wang, C.J. LiuDokument5 SeitenCase Studies in Engineering Failure Analysis: S.W. Liu, W.Z. Wang, C.J. LiuSushil KumarNoch keine Bewertungen

- Nonlinear Optics Wave EquationDokument20 SeitenNonlinear Optics Wave EquationAmmarNoch keine Bewertungen

- Sa-Vs400h wvs500 ss-cn500 ms442 vf500Dokument3 SeitenSa-Vs400h wvs500 ss-cn500 ms442 vf500drishkNoch keine Bewertungen

- Radiographic and Ultrasonic Testing of WeldsDokument3 SeitenRadiographic and Ultrasonic Testing of WeldscinthyaNoch keine Bewertungen

- Phystcs B (Advancing Physics) U Nderstanding Processes: Friday AfternoonDokument21 SeitenPhystcs B (Advancing Physics) U Nderstanding Processes: Friday AfternoonKelen KawasakiNoch keine Bewertungen

- Interference & Frequency PlanningDokument64 SeitenInterference & Frequency PlanningFahrizal IlhamNoch keine Bewertungen

- Properties of Light Handout 1Dokument3 SeitenProperties of Light Handout 1hannah alexis agcolNoch keine Bewertungen

- Propagation of Seismic DisturbancesDokument22 SeitenPropagation of Seismic DisturbancesEriane Louise LorenzoNoch keine Bewertungen

- LHU RAD UMUM Toshiba RS Kurnia CilegonDokument20 SeitenLHU RAD UMUM Toshiba RS Kurnia CilegonDwi FatmawatiNoch keine Bewertungen

- Theory of Reflection Reflection and Transmission of Electromagnetic Particle and Acoustic WavesDokument539 SeitenTheory of Reflection Reflection and Transmission of Electromagnetic Particle and Acoustic Wavessouhail100% (1)

- Dental Laser Competition May 12Dokument16 SeitenDental Laser Competition May 12lucserpNoch keine Bewertungen

- Biconical Antenna Design and ApplicationsDokument7 SeitenBiconical Antenna Design and ApplicationsAmollohNoch keine Bewertungen

- Chapter 35Dokument7 SeitenChapter 35Abdulrahman AhmedNoch keine Bewertungen

- Understanding Frequencies Through Harmonics AssociationsDokument24 SeitenUnderstanding Frequencies Through Harmonics Associations1aquila1100% (2)

- 2023 IGCSE Chapter 14 Properties of WavesDokument19 Seiten2023 IGCSE Chapter 14 Properties of WavesHumalaNoch keine Bewertungen

- Microphones and Miking TechniquesDokument32 SeitenMicrophones and Miking TechniquesNameeta Parate100% (1)

- Chapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, ChemistryDokument9 SeitenChapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, Chemistrypumeananda100% (3)

- Intensity of Ultra Sound Generated The Rife Frequency InstrumentDokument7 SeitenIntensity of Ultra Sound Generated The Rife Frequency InstrumentHayley As Allegedly-Called YendellNoch keine Bewertungen

- B D-2Dokument23 SeitenB D-2Naidan DensmaaNoch keine Bewertungen

- EELE 3332 - Electromagnetic II: WaveguidesDokument36 SeitenEELE 3332 - Electromagnetic II: WaveguidesYohannes NakachewNoch keine Bewertungen

- Acoustic Manual WEBDokument96 SeitenAcoustic Manual WEBAlessandro SerafiniNoch keine Bewertungen

- CSEC PHYSICS Light WavesDokument19 SeitenCSEC PHYSICS Light WavesDejaunae LawsonNoch keine Bewertungen

- Chapter 8 - Physics 1st YearDokument6 SeitenChapter 8 - Physics 1st Yearshahid abbasNoch keine Bewertungen

- Optical Networks Lecture 1: Introduction Part 1 ReviewDokument59 SeitenOptical Networks Lecture 1: Introduction Part 1 Reviewjeddo2005Noch keine Bewertungen

- EMW Notes CLASS 12 CBSEDokument5 SeitenEMW Notes CLASS 12 CBSEShabnam ZakirNoch keine Bewertungen

- Survey and design guidelines for line of sight microwave linksDokument77 SeitenSurvey and design guidelines for line of sight microwave linksGagandeep Singh SodhiNoch keine Bewertungen

- Radio Wave Propagation: Space Environment Laboratory 325 Broadway, Boulder, CO 80303-3326 (303) - 497-5127Dokument4 SeitenRadio Wave Propagation: Space Environment Laboratory 325 Broadway, Boulder, CO 80303-3326 (303) - 497-5127Fernando MujicaNoch keine Bewertungen

- The Electromagnetic SpectrumDokument27 SeitenThe Electromagnetic SpectrumJacklyn Kate Caballero Garduque100% (2)

- Lesson 13 Distance Measurement Using EDM PDFDokument16 SeitenLesson 13 Distance Measurement Using EDM PDFASHISH MEENANoch keine Bewertungen

- Lecture 5 Fundamental of Remote SensingDokument50 SeitenLecture 5 Fundamental of Remote SensingAddo MawuloloNoch keine Bewertungen

- Stationary WavesDokument11 SeitenStationary WavesCarmella Mae QuidiligNoch keine Bewertungen